New type of crane motor

A new type of casing technology, applied in the direction of load suspension components, transportation and packaging, etc., can solve the problems of high manufacturing cost, poor braking reliability, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

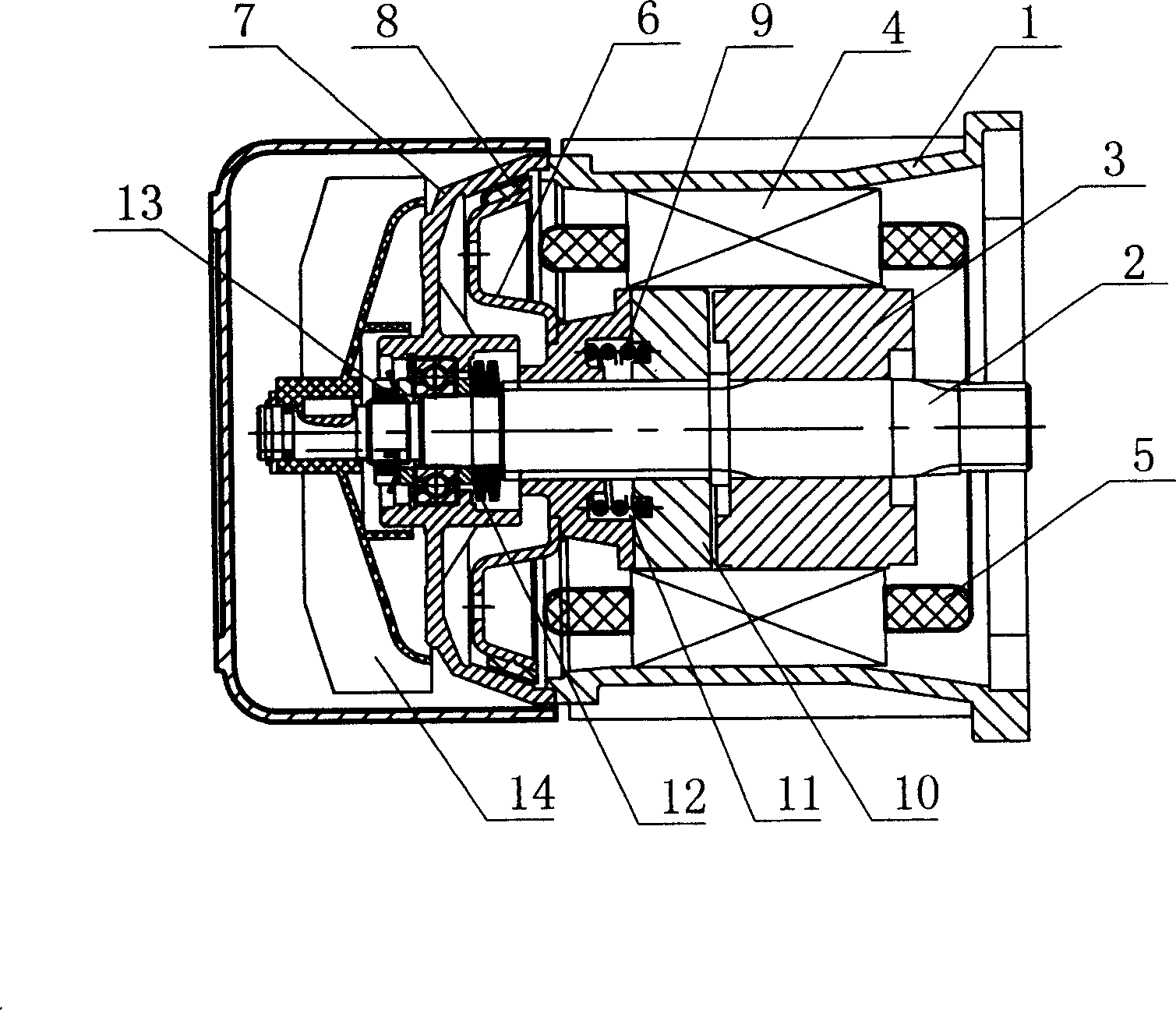

[0011] Such as figure 1 As shown, the present invention includes a casing 1, a rotor shaft 2 built in the casing 1, a rotor 3 fixed on the rotor shaft 2, and a stator core integrated with the casing 1 and fixedly connected with the casing 1. 4 and stator winding 5, the conical brake device includes a conical brake seat 6 and a conical brake disc 7, the conical brake seat 6 is fixedly connected to the casing 1, and the conical brake disc 7 is connected to the rotor shaft 2 For sliding connection, a friction plate 8 is provided between the conical brake seat 6 and the conical brake disc 7, and a compression spring 9 and a side magnetic device 10 are tightly arranged between the conical brake disc 7 and the rotor 3. The magnetic device 10 is fixed on the rotor shaft 2 in the stator core 4 , and the compression spring 9 is tightly fitted in the groove 11 between the conical brake disc 7 and the side magnetic device 10 . When the motor is powered off, the conical brake disc 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com