Switchable automotive coolant pump

A car cooling and pump wheel technology, applied in the control of coolant flow, engine cooling, pumps, etc., can solve the problems of high production cost and complicated actuation arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

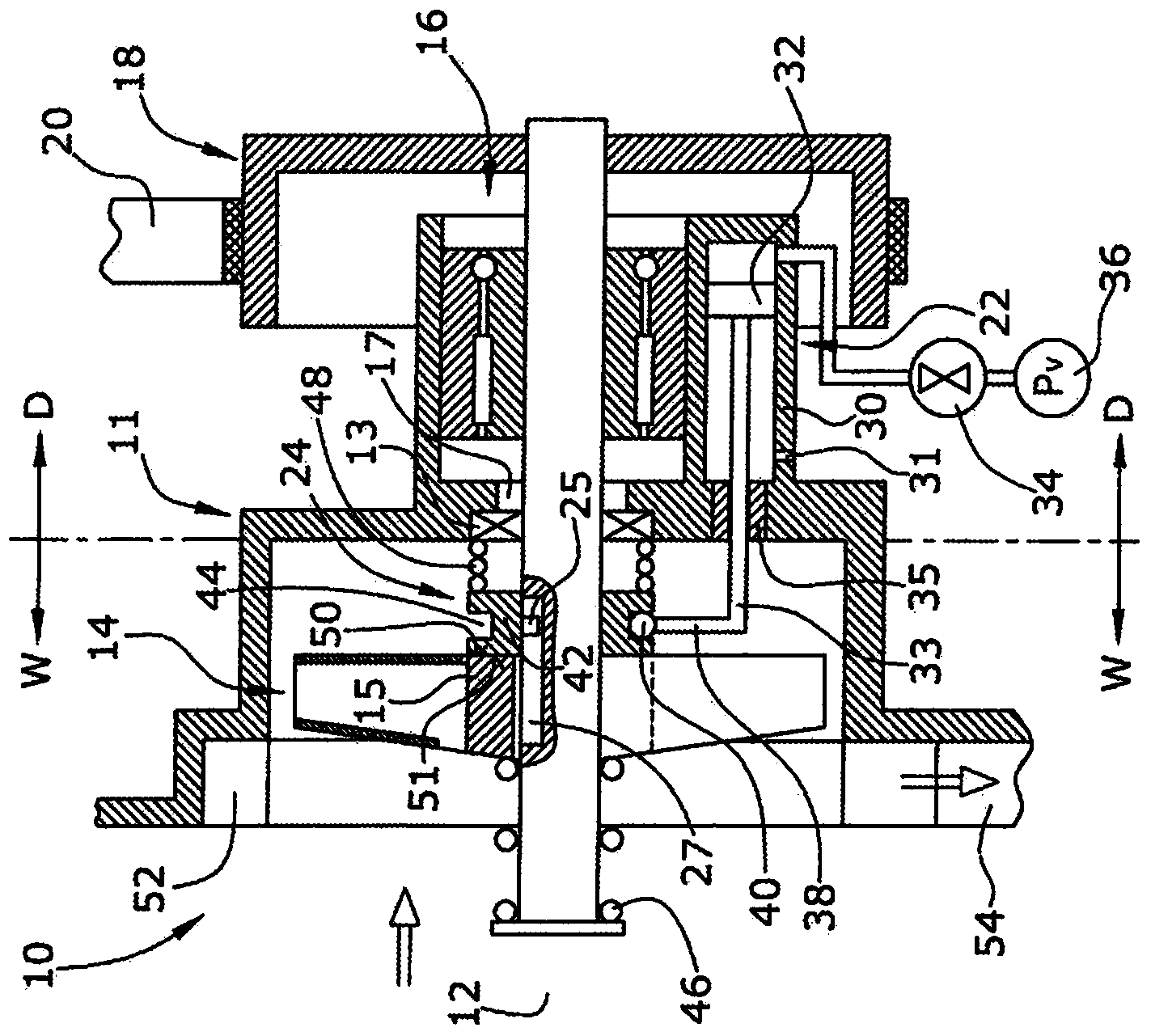

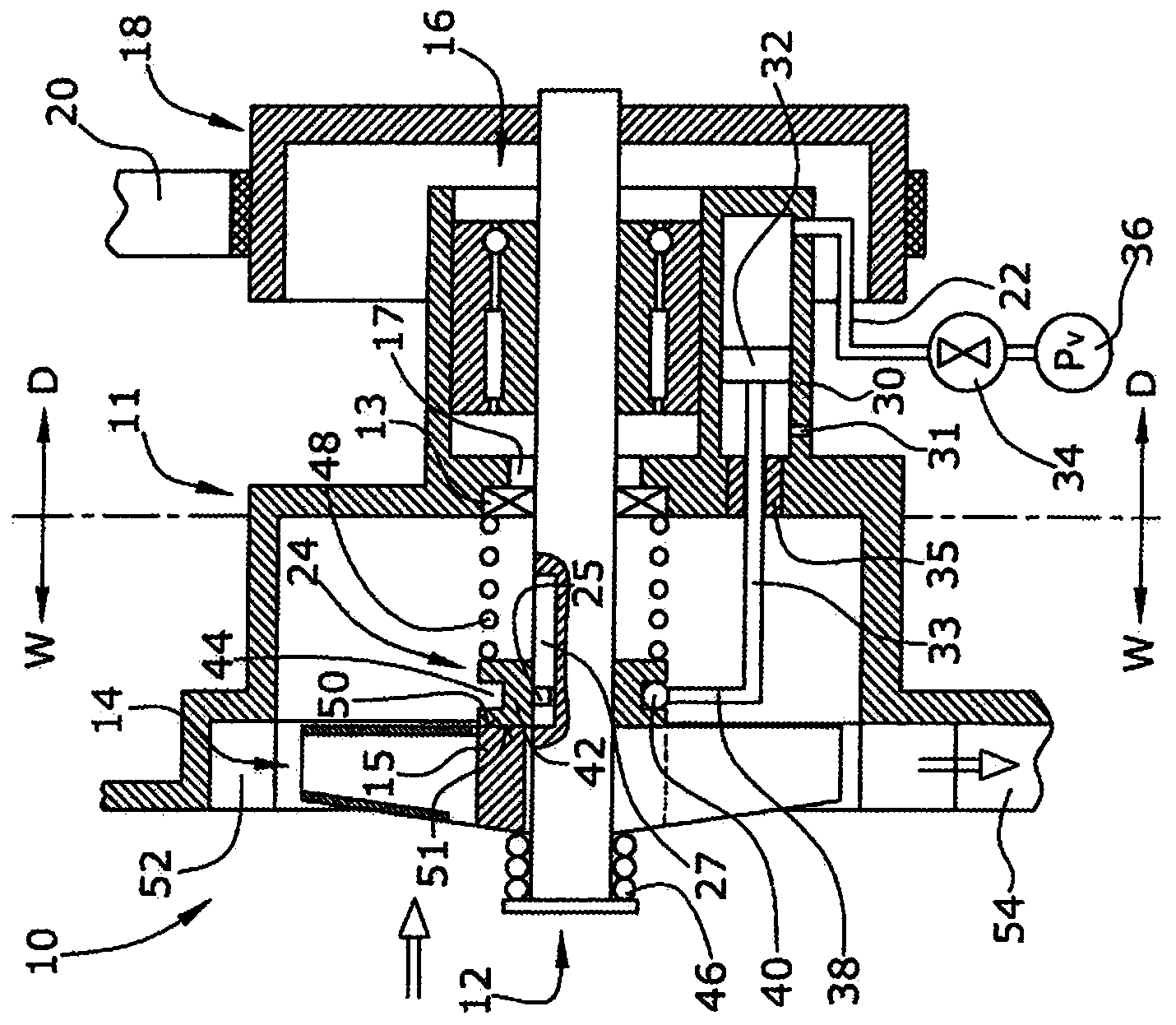

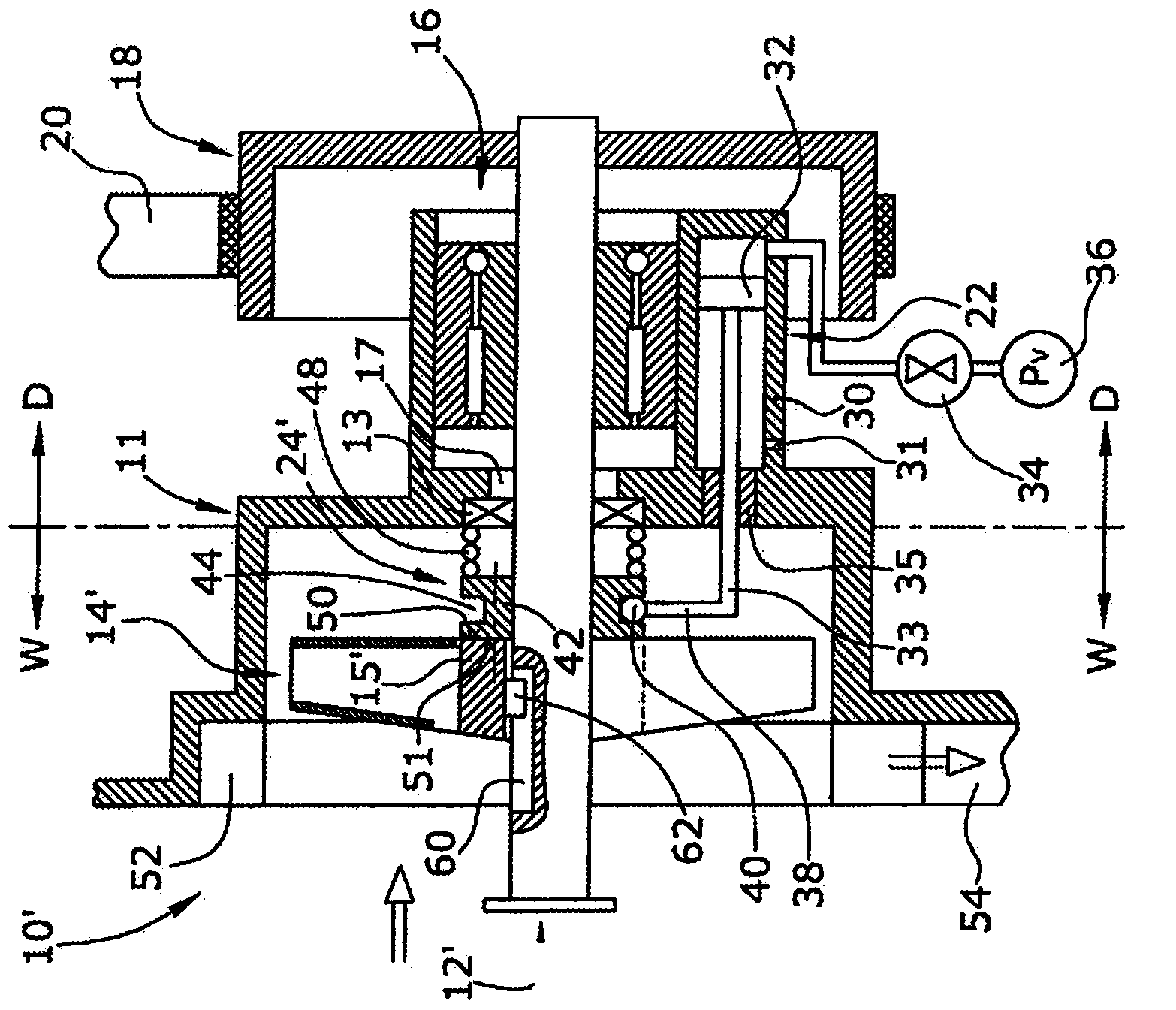

[0020] Figure 1 to 4 A switchable automobile coolant pump 10; 10' is shown, which is used to pump coolant, such as water, in a coolant circuit for cooling an internal combustion engine (not shown). The coolant pump 10; 10' is adapted to be mounted to the engine and is adapted to be driven by the engine via a transmission belt 20, which drives the pulley 18 of the coolant pump so that the pulley 18 of the coolant pump 10; 10' is always proportional to the engine speed The speed of rotation.

[0021] The coolant pump 10; 10' is provided with a housing 11 which separates the wet section W from the dry section D. The housing 11 supports the bearing 16 in the dry section D. The bearing 16 thus supports the rotatable rotor shaft 12; 12'. The pulley 18 is fixed to the rotor shaft 12 as a whole. The rotor shaft 12 protrudes through the opening 17 of the housing 11, in which an annular shaft seal 13 is provided to seal the annular gap between the opening edge of the opening 17 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com