A liquid processing mixer and method

A liquid handling and mixer technology, applied in the field of handling hygienic substances, which can solve problems such as loss of pumping capacity and reduced pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

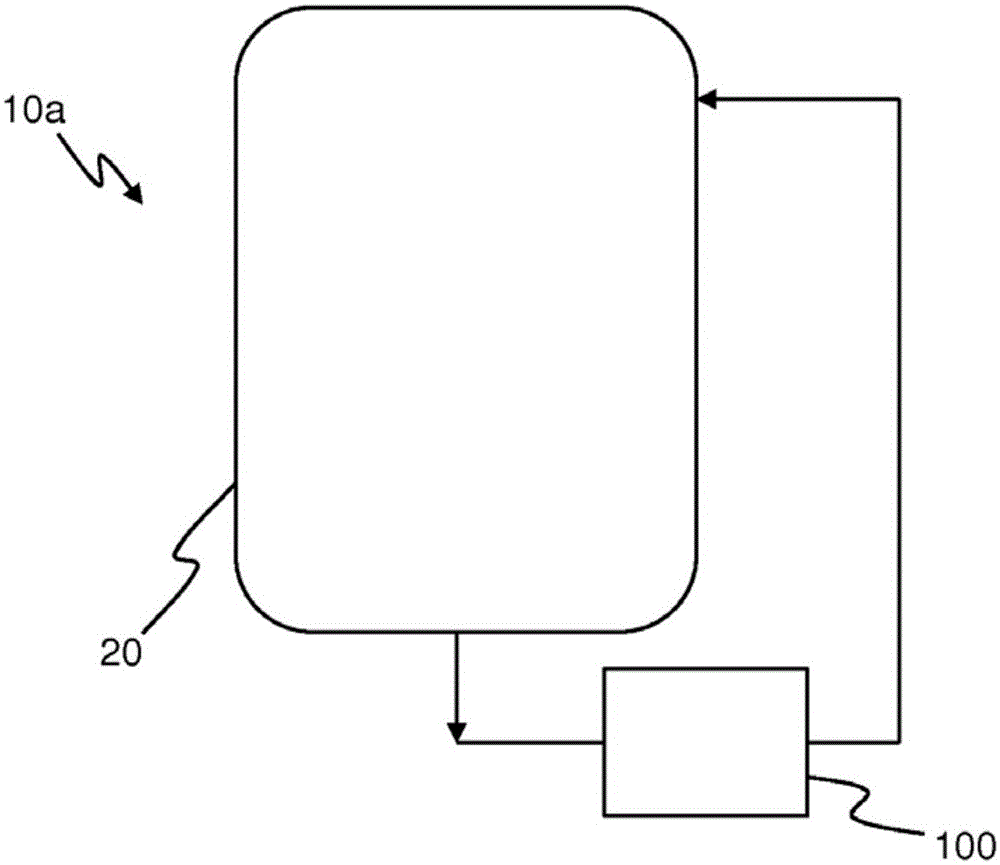

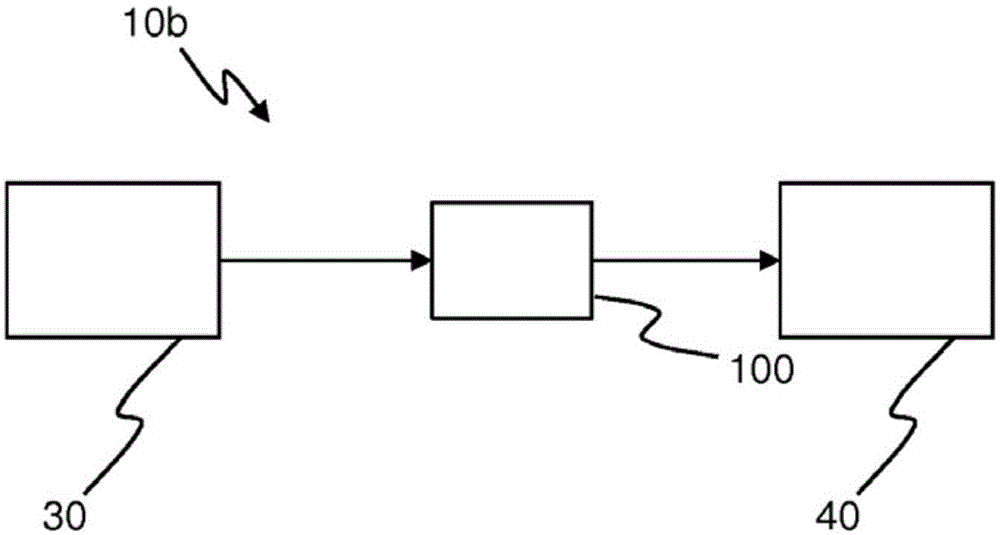

[0028] From Figure 1a Initially, a portion of a liquid handling system 10a is shown. The parts shown can be included in a much larger processing system including various liquid handling components such as heaters, homogenizers, separators, filters etc. to be able to completely Or partially handle hygienic liquid products. An example of a liquid handling system 10a for use with the present invention is a liquid food processing system capable of handling various liquid food products such as milk, juice, still drinks, ice cream, yogurt, and the like. However, liquid handling systems for use with the present invention may also include systems for handling and processing chemical, pharmaceutical and / or cosmetic liquids.

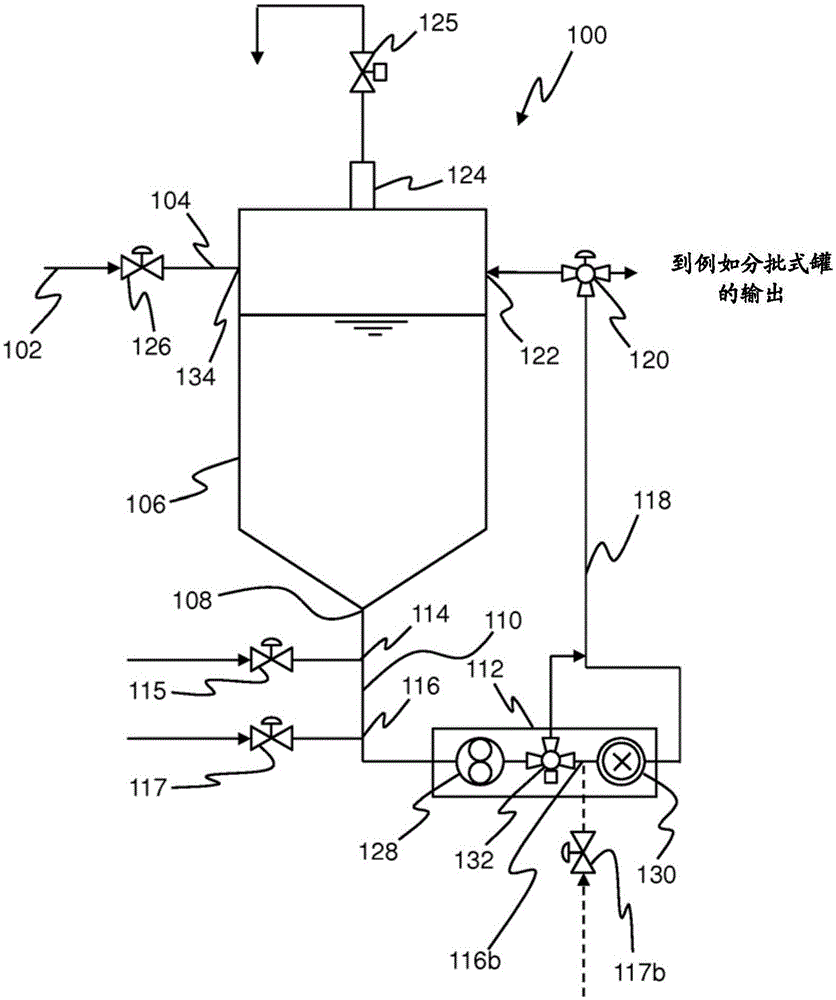

[0029] The portion shown includes a batch tank 20 and a mixer 100 fluidly connected to the batch tank. Accordingly, the liquid to be mixed is circulated through the mixer 100 disposed outside the batch tank 20 for supplying and storing a large volume of mixed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com