Pump shaft bearing support

a technology for pump shafts and bearings, which is applied in the direction of piston pumps, positive displacement liquid engines, borehole/well accessories, etc., can solve the problems of irreparable damage to the pump, inability to adjust the lift capacity of the pump, and inability to run the pump dry, etc., to achieve the effect of low cost and modification of the pump lift capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

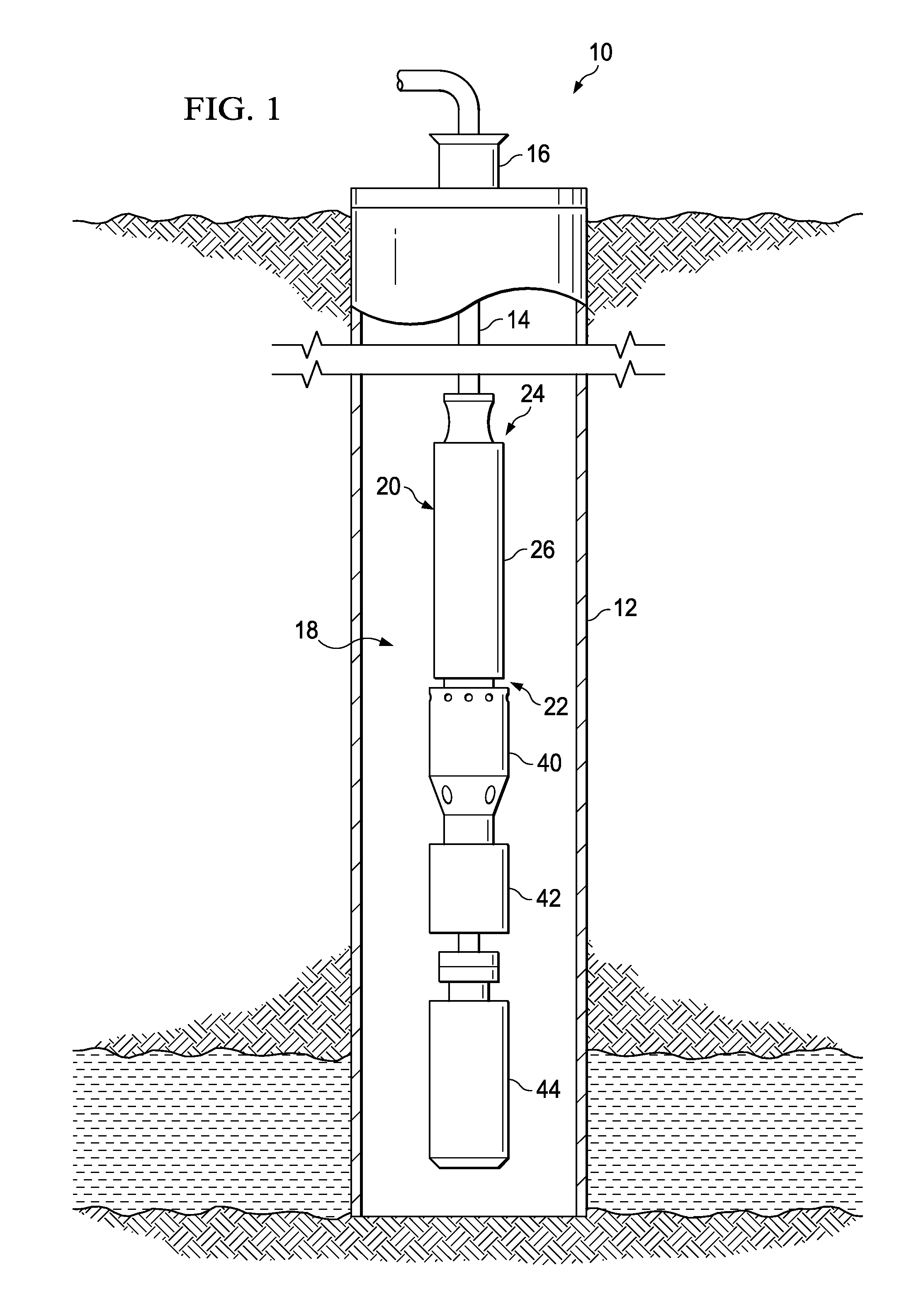

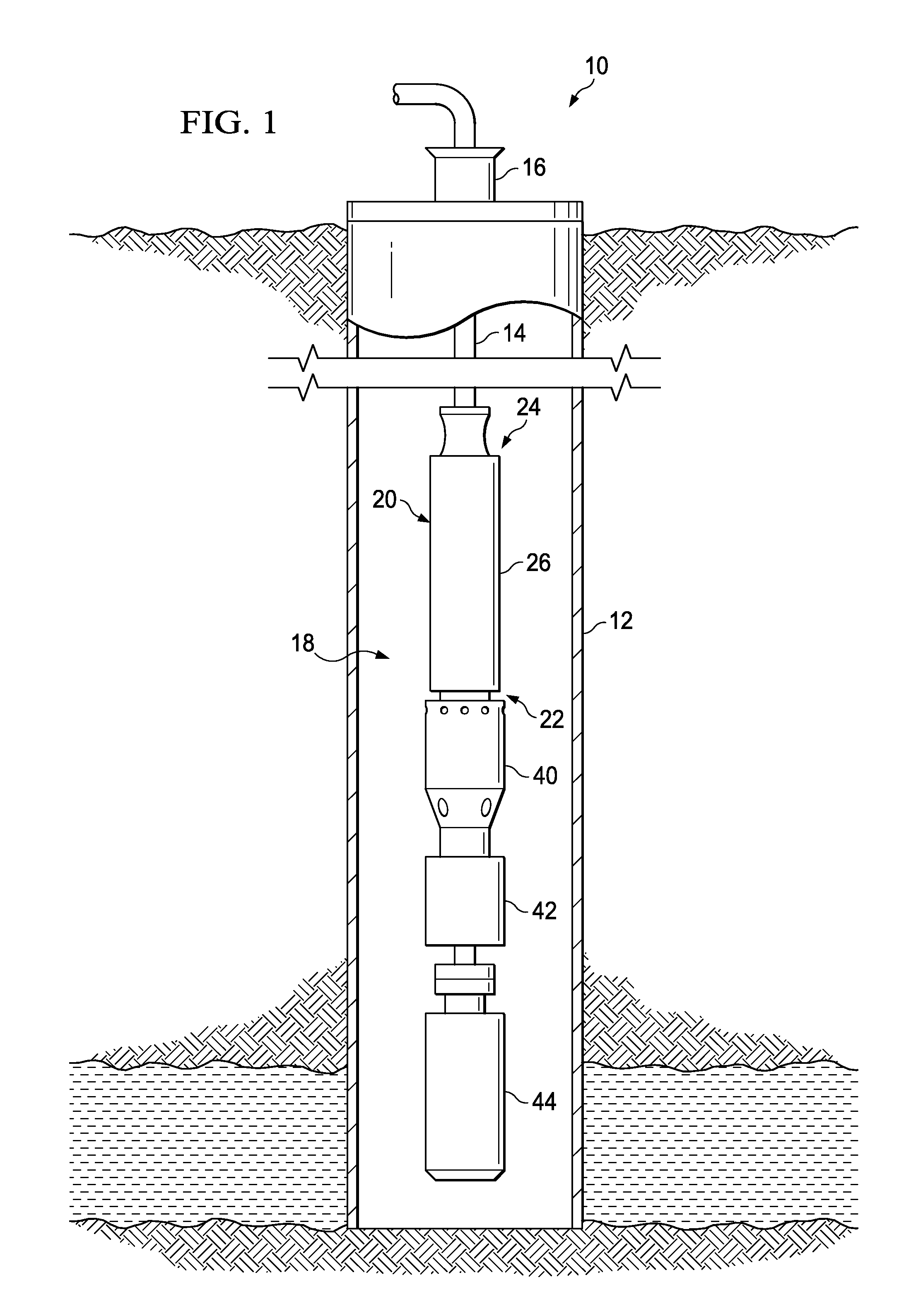

[0017]Referring now to FIG. 1, shown is a well designated generally 10. The well consists of casing 12. Tubing 14 extends downwardly into casing 12 from wellhead 16. An electrical submersible pump (ESP) unit, designated generally 18, is suspended from tubing 14. ESP unit 18 has a centrifugal pump unit 20. Pump unit 20 has an intake end 22 and an output end 24. Output end 24 is affixed to tubing 14 for delivering fluids to tubing 14.

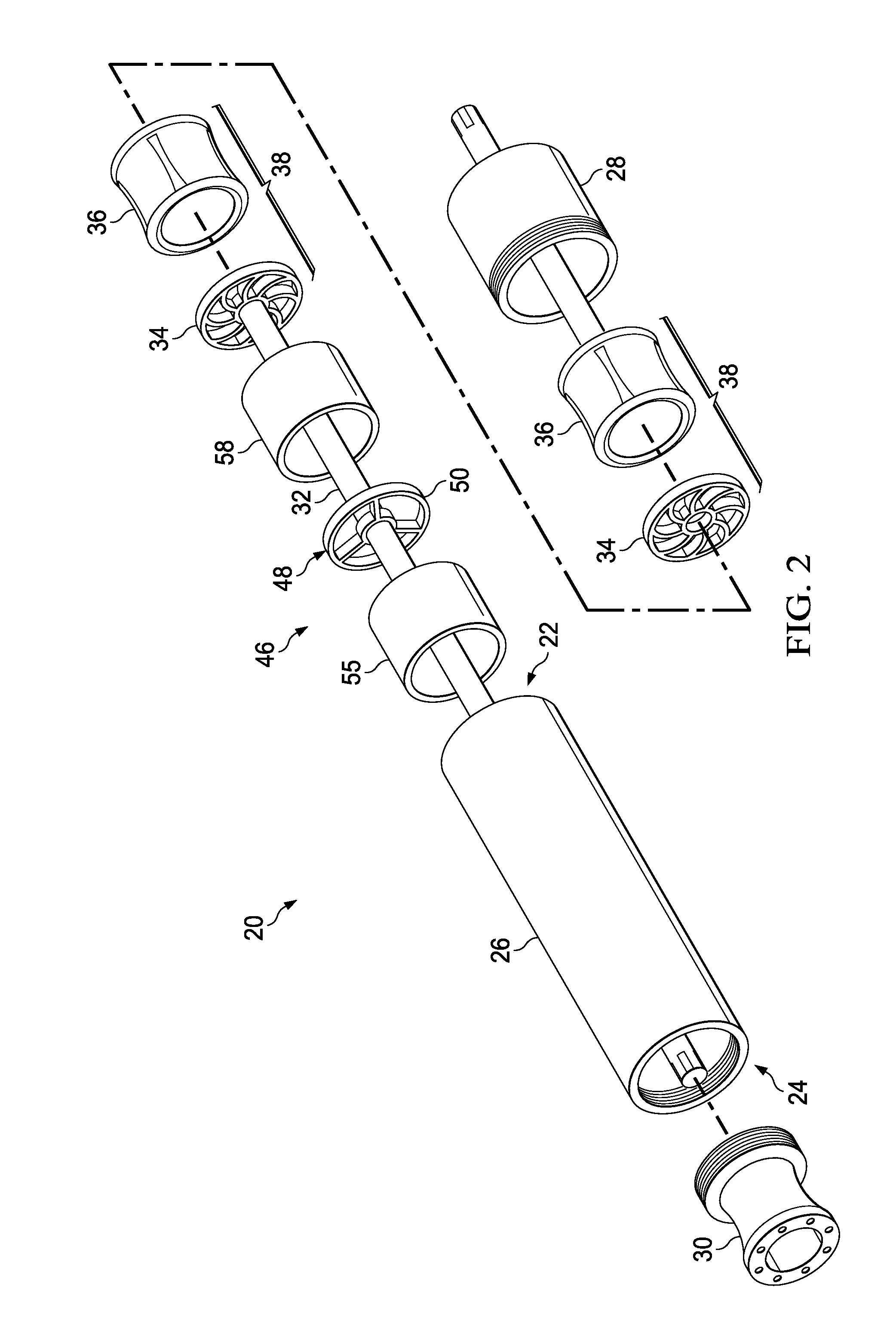

[0018]Pump unit 20 further includes a housing 26. A pump base 28 (FIG. 2) is affixed to intake end 22 of housing 26. Pump head 30 is affixed to output end 24 of housing 26. Pump shaft 32 extends through housing 26. A plurality of impellers 34 are affixed to pump shaft 32 for rotating with pump shaft 32. A plurality of diffusers 36 are located adjacent to each of impellers 34 for directing fluid flow toward a center of an adjacent impeller 34. As shown in FIG. 2, each of said impellers 34 and diffusers 36 comprise a stage 38.

[0019]ESP unit 18 additionally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com