Concrete for shear wall structure

A concrete and shear wall technology, which is applied in the field of concrete and building materials of shear wall structure, can solve the problems of large randomness and difficult control of concrete quality, achieve high performance advantages, great social environment and technical and economic benefits, and reduce The effect of heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention provides a kind of concrete for shear wall structure, the concrete for shear wall structure is prepared from cement, sand, gravel, water and fly ash which can partially replace cement according to the conventional concrete preparation process to make.

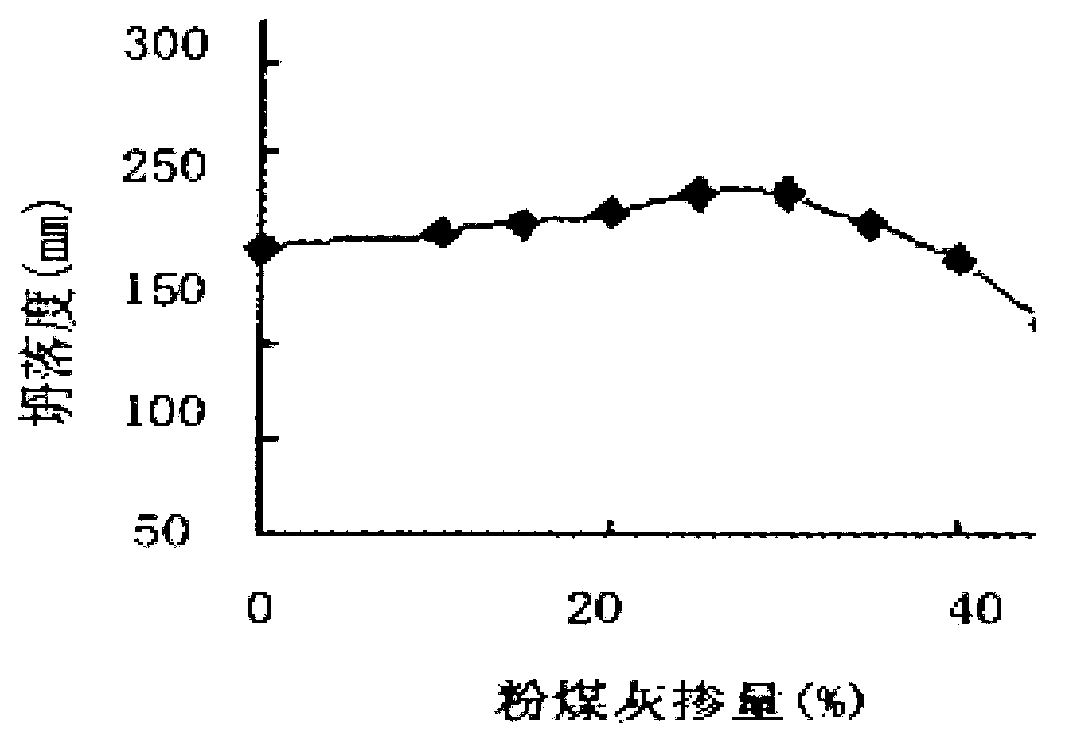

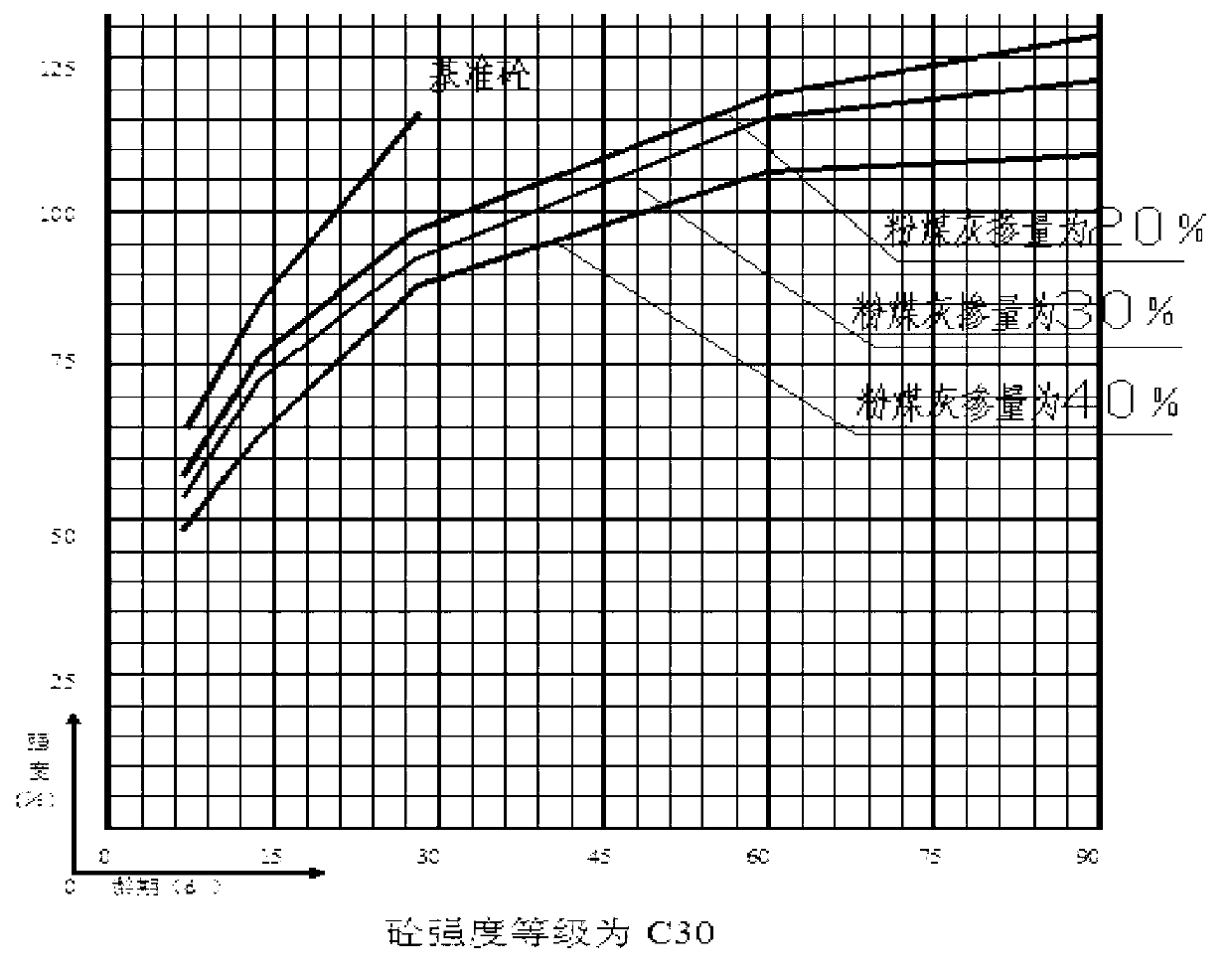

[0018] The amount of fly ash to replace cement is 20% to 35% of the total mass of cement, preferably 30%.

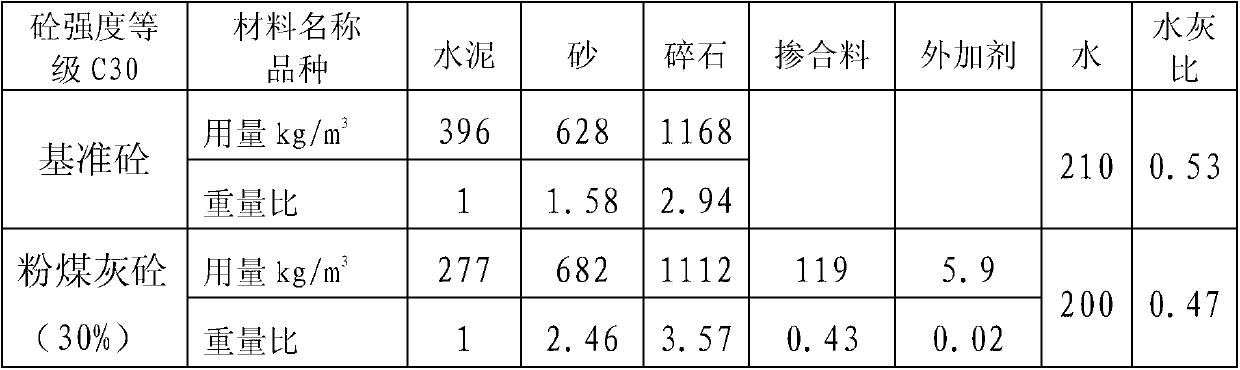

[0019] The concrete used for the shear wall structure is prepared from cement, sand, gravel, fly ash and water according to the mass ratio of 1:2.46:3.57:0.43:0.47 according to the conventional concrete preparation process.

[0020] The concrete used for the shear wall structure is also added with a pumping agent; the concrete used for the shear wall structure is composed of cement, sand, gravel, fly ash, pumping agent and water in a mass ratio of 1:2.46:3.57 : 0.43: 0.02: 0.47 Prepared according to the conventional concrete preparation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com