Compact type constraint number shifting planetary gear train transmission

A planetary gear train, compact technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the complex structure of AT transmission, increased production cost and maintenance cost, complicated control oil circuit system, etc. problem, to achieve the effect of favorable heat dissipation, easy installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

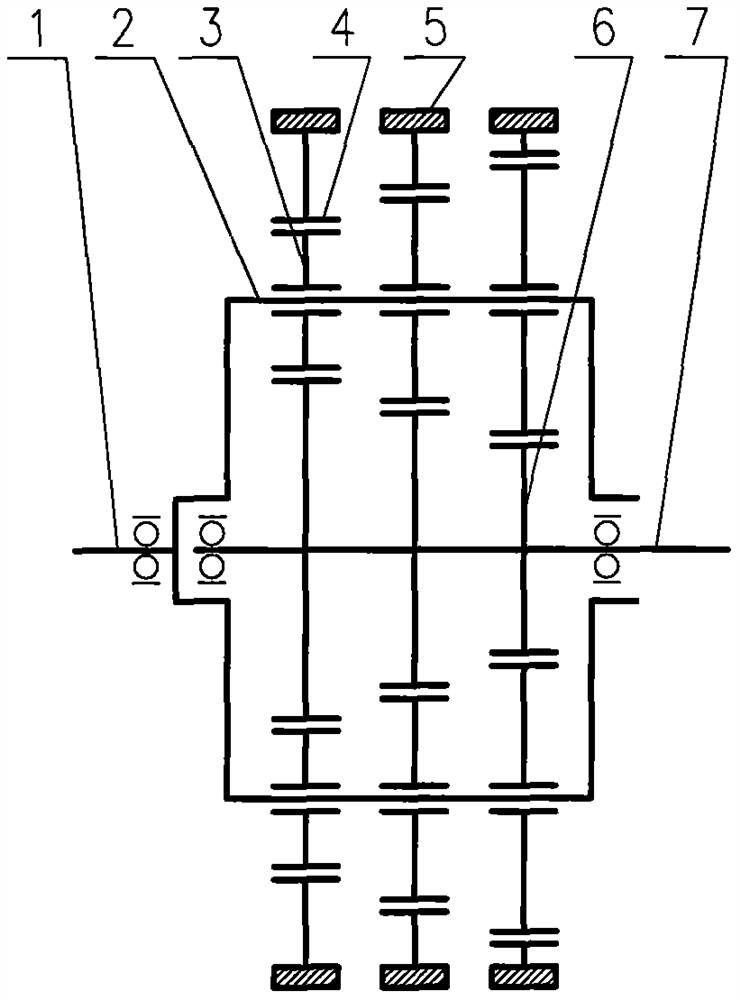

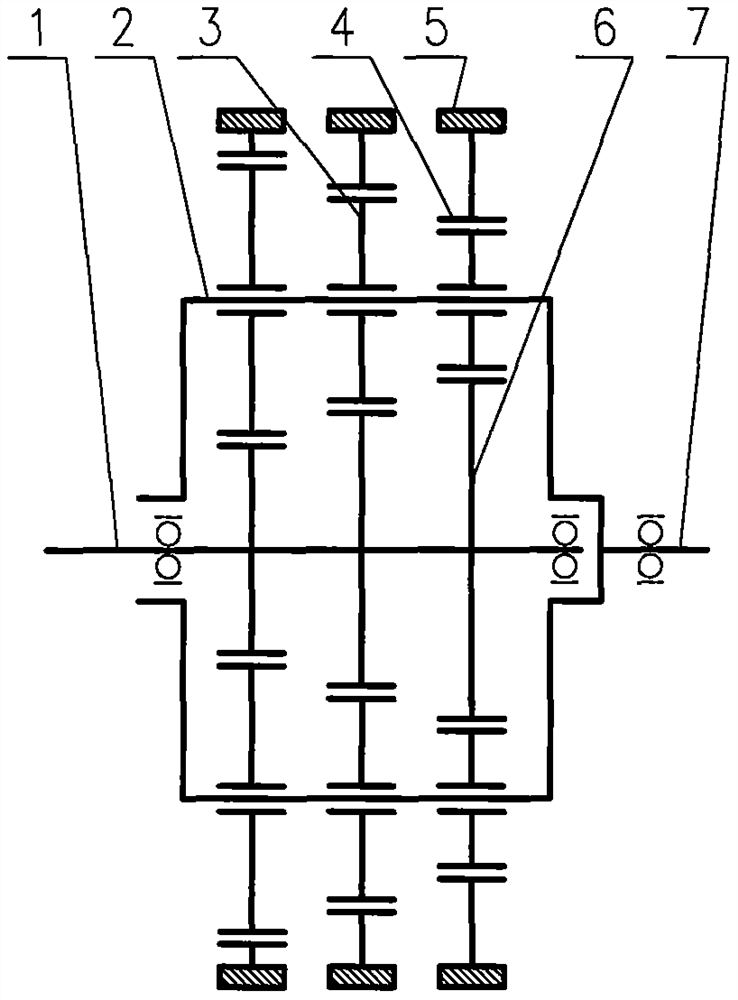

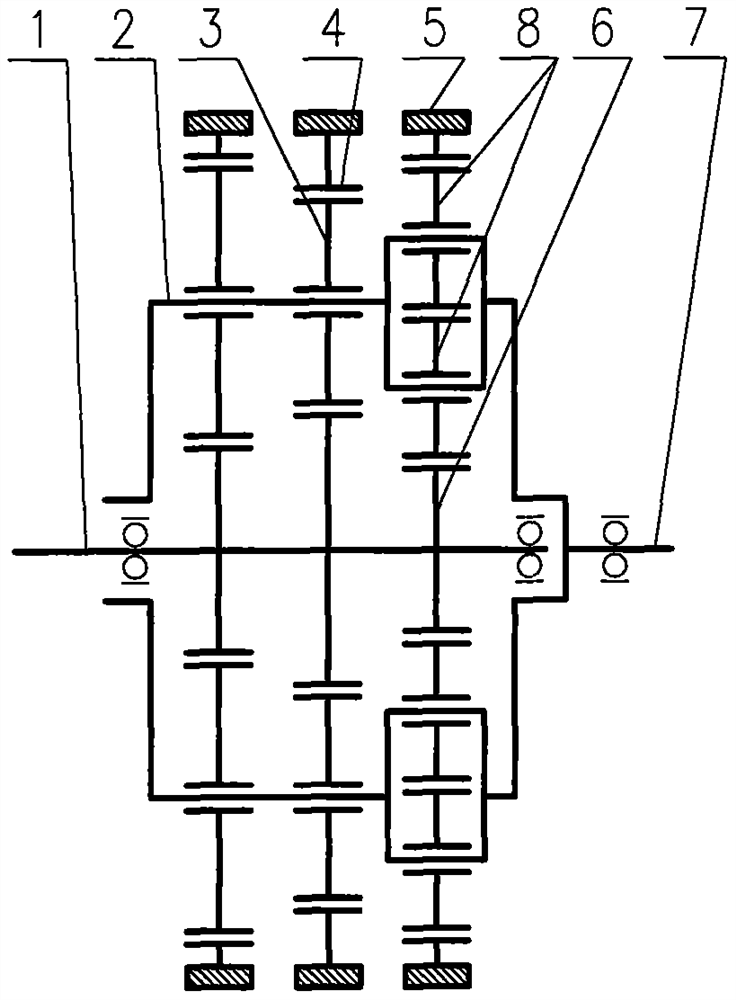

[0059] The schematic diagram of the basic type A mechanism of the compact constrained number shift planetary gear train transmission is as follows figure 1 As shown: the input shaft is connected to the planetary carrier, and the planetary carrier constrains several sets of planetary gears at the same time. , the ring gears corresponding to the engagement are fixedly connected with the respective brake drums, and each brake drum can brake the ring gear by controlling its brake. Its working principle of shifting is: relying on changing the constraint number of the planetary gear train to construct a state with a degree of freedom equal to or greater than 1, thereby obtaining a fixed transmission ratio output gear or obtaining a neutral gear. When the degree of freedom of this group of planetary gear trains is equal to 1, Output a fixed speed ratio to form the corresponding gear output. When the degree of freedom is greater than 1, the power cannot be output, which is equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com