Short-shell axially compact high-speed flow distribution cycloid hydraulic motor

A cycloidal hydraulic motor, a compact technology, applied in the direction of rotary or swinging piston engines, rotary piston engines, machines/engines, etc., the ability to solve the large radial force of the motor is not well improved, and cannot be achieved In order to achieve the effects of compact axial size, cost saving and convenient assembly, in order to meet user requirements and structural restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

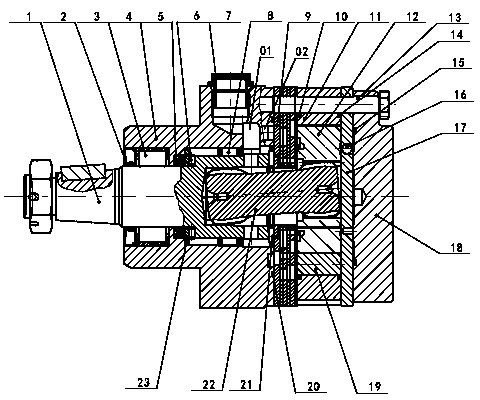

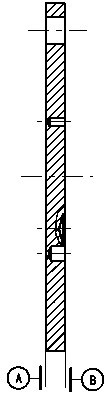

[0016] The basic structure of the short casing axially compact high-speed distribution cycloidal hydraulic motor of this embodiment is as follows: figure 1 As shown, it includes a casing 4 with liquid inlet and return ports 01 and 02, and one end of the casing 4 is equipped with a cycloidal pinwheel pair composed of a stator 11, a rotor 12 and pin teeth 19, and a flow distribution support plate The flow distribution mechanism composed of the compound hydraulic channel of 9 and the compound channel of the rotor 12, the output hole at the other end supports the output shaft 1 protruding from the housing 4; the rotor 12 of the cycloidal pin wheel pair passes through the The key meshes with the external gear at one end of the interlocking shaft 22, and the other end of the interlocking shaft 22 is connected to the output shaft 1; the other end of the rotor 12 with composite channels is in contact with the compensating plate 17, and the structure of the compensating plate 17 is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com