Power system of four-wheel-drive electric vehicle and control method

A technology for power systems and electric vehicles, applied to motor vehicles, power plants, hybrid vehicles, etc., can solve problems such as low engine load rate, difficult cabin layout, complex system structure, etc., to improve engine load rate, axial The effect of compact size and simplified transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

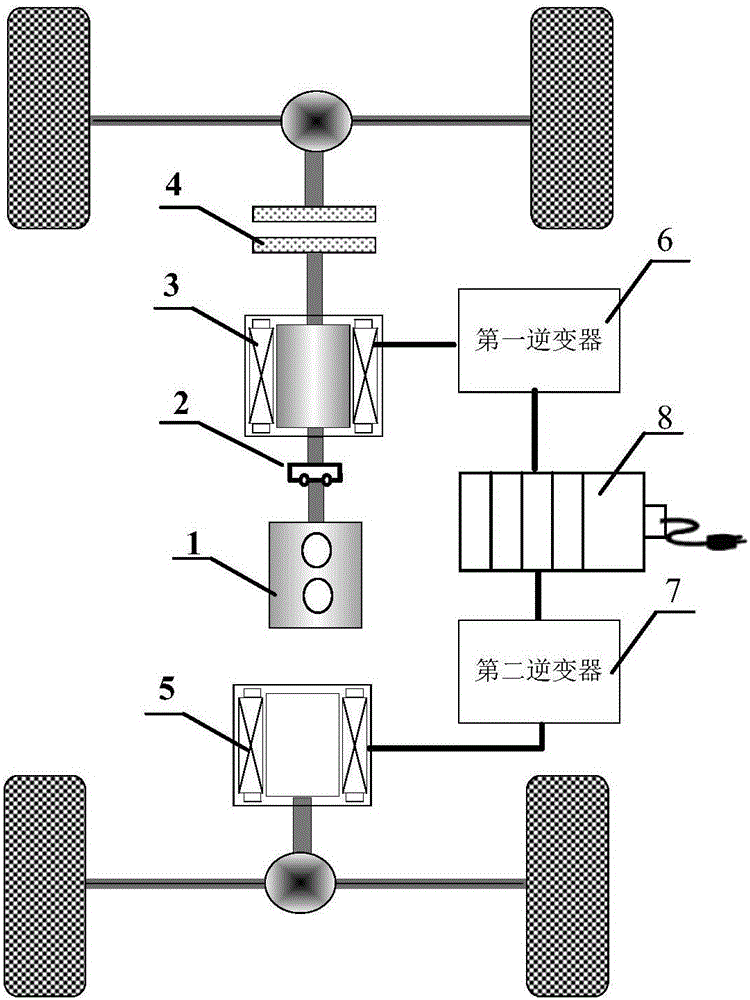

[0028] This embodiment provides a four-wheel drive electric vehicle power system, which includes an engine 1, a shock absorber 2, a first motor 3, a clutch 4, a second motor 5, a first inverter 6, and a second inverter 7 and power battery 8 .

[0029] The engine is connected to the shock absorber, the shock absorber is connected to the first electric motor, the first electric motor is connected to the clutch, and the clutch outputs power to the front wheels of the vehicle through the final reducer and the differential of the front axle of the vehicle. The electric motor outputs power to the rear wheels of the vehicle through the final reducer and the differential on the rear axle of the vehicle.

[0030] The maximum power of the engine is matched according to the maximum stable speed of the vehicle, not according to the acceleration of the vehicle, for example, its power can be 20-80KW. The engine can directly drive the wheels, the rated power of the first electric motor is m...

Embodiment 2

[0036] This embodiment provides a control method for the four-wheel drive electric vehicle power system described in Embodiment 1, which includes the following steps:

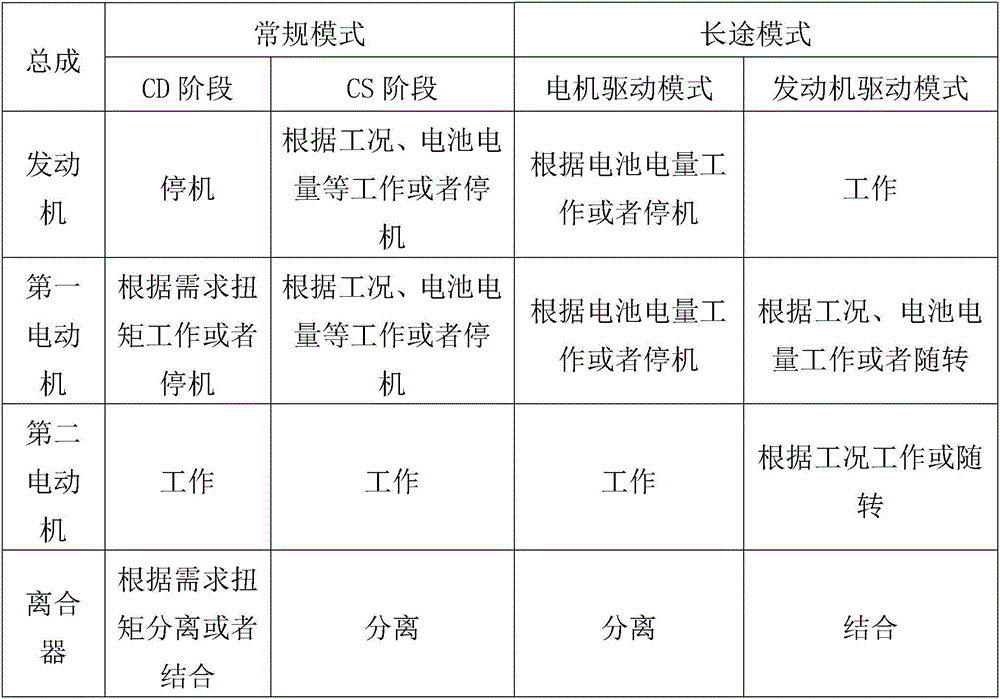

[0037] S10. Select a control mode, where the control mode includes: a regular mode and a long-distance mode;

[0038] Among them: in the normal mode, according to the battery power, the vehicle working mode is divided into the charge depleting (CD) stage and the charge sustaining (charge sustaining, CS) stage; when the battery power is greater than a certain threshold, the power system is in the CD stage , when the battery power is less than or equal to a certain threshold, the power system is in the CS stage; for example, when the power battery power is higher than 40%, the power system works in the CD stage; when the power battery power drops below 40% or 35%, the power system The system enters the CS phase.

[0039] Among them, in the CD stage, the vehicle works in pure electric mode, the engine is stopped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com