High-frequency high-power microwave device

A high-power microwave and high-frequency technology, which is applied to the circuit components of transit-time electron tubes, coupling devices of transit-time electron tubes, etc., can solve the problems of reduced power capacity, reduced radial size, etc., and achieves light weight. , the effect of compact axial and radial dimensions and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

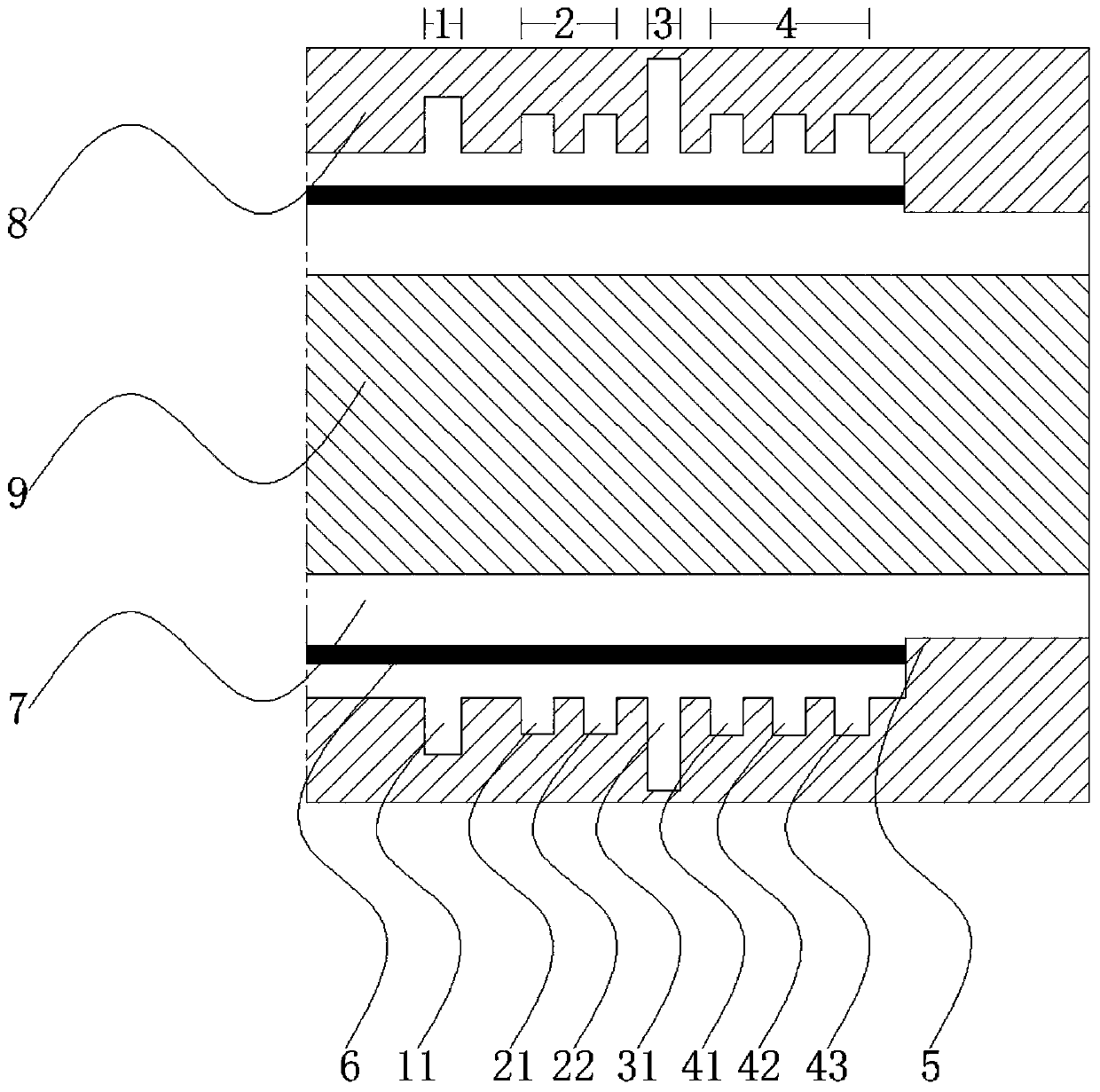

[0028] Such as figure 1 As shown, a high-frequency high-power microwave device in this embodiment includes a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. One end of the circular waveguide sleeve is provided with a cathode emitting an annular electron beam. The inner diameter of the circular waveguide sleeve is 14.6 mm, and the diameter of the inner conductor is 8 mm.

[0029] The coaxial reflection area, beam pre-modulation area, phase modulation area and beam conversion area are arranged in sequence along the electron beam transmission direction; the reflection area, beam pre-modulation area, phase modulation area and beam conversion area are respectively arranged in the An annular groove-shaped reflective cavity with a rectangular section, a beam pre-modulation cavity, a phase modulation cavity and a beam conversion cavity are arranged on the top.

[0030] The outer diameter of the reflective cavity in the reflective area is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com