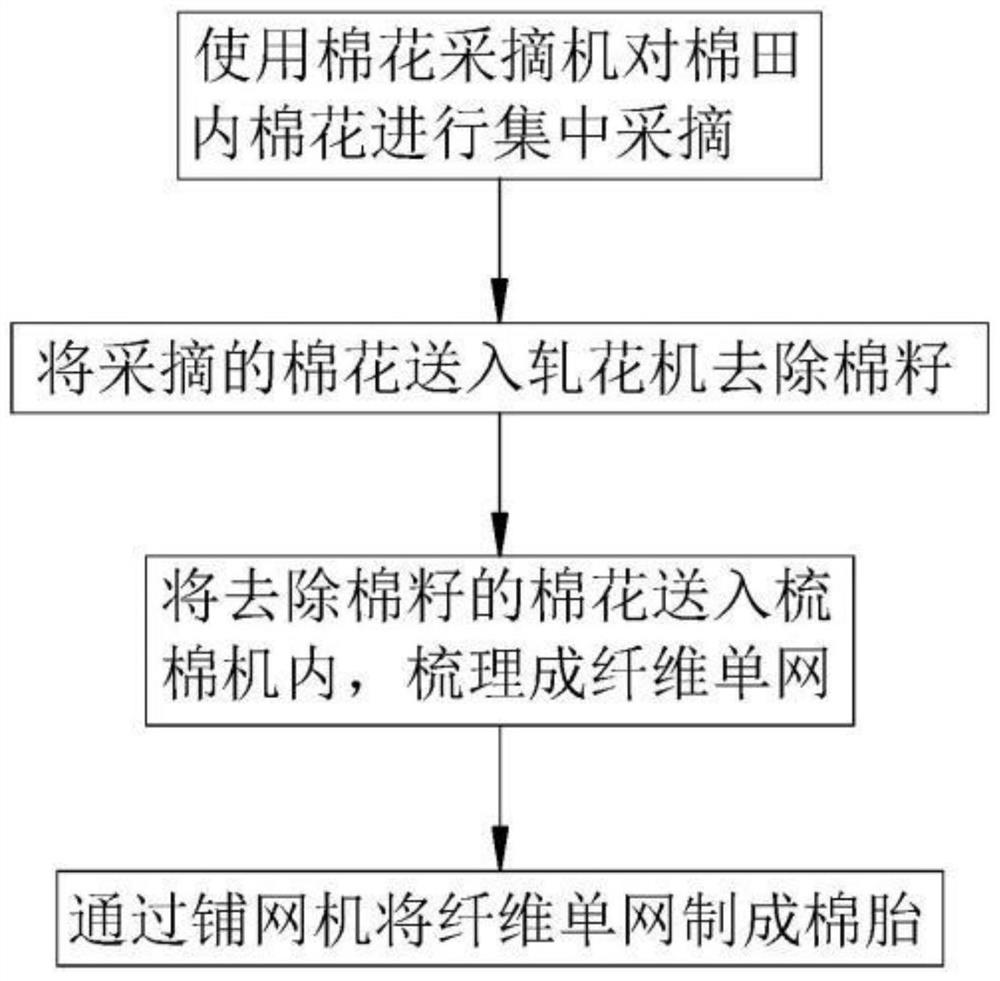

A kind of cotton batting production method

A production method and technology of cotton tires, applied in the field of textile production, can solve the problems of increased workload of equipment cleaning and maintenance, low efficiency of raw material collection, and reduced picking efficiency, so as to reduce the workload of cleaning and maintenance, improve stability, and avoid repetition winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

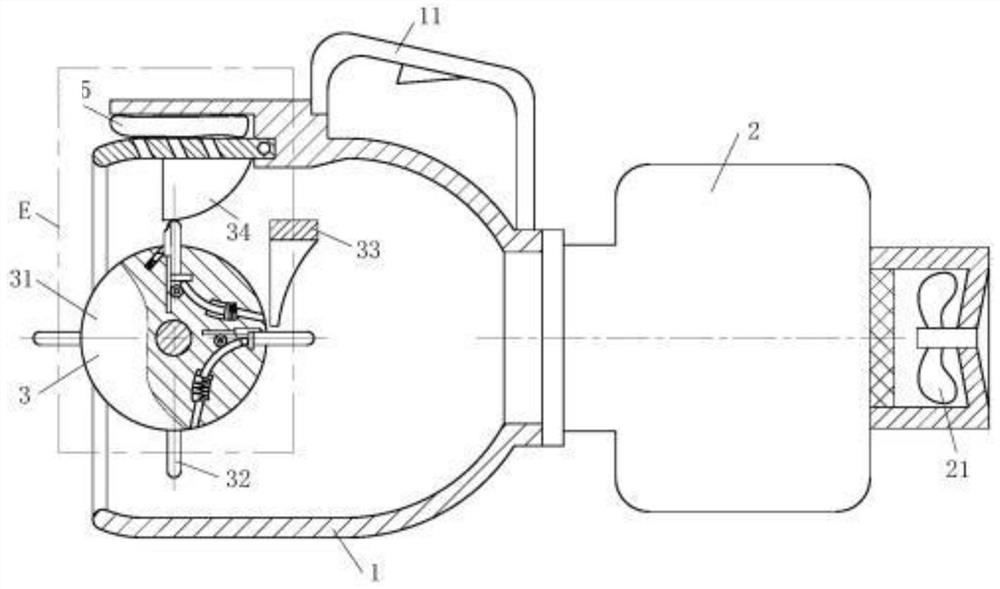

[0035] As an embodiment of the present invention, the arc-shaped block 34 is fixedly installed on the rotating plate 4; the rotating plate 4 is hinged on the inner wall of the housing 1, and a torsion spring is arranged in the rotating shaft, and the rotating plate 4 is only within a certain range. Turn inside. When in use, the steel needle 32 rotates quickly and collides with the arc block 34, generating a relatively large impact force. By installing the arc block 34 on the rotating plate 4, the collision damage of the steel needle 32 can be reduced, and the use of the equipment can be improved. life.

[0036] As an embodiment of the present invention, an air bag 5 is provided between the rotating plate 4 and the housing 1; an inclined air outlet 41 is provided on the rotating plate 4; the air outlet 41 is corresponding to the arc-shaped block 34 Set up vias. During use, by arranging the air bag 5, on the one hand, the impact force of the steel needle 32 colliding with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com