Patents

Literature

32results about How to "Radial dimensions are compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

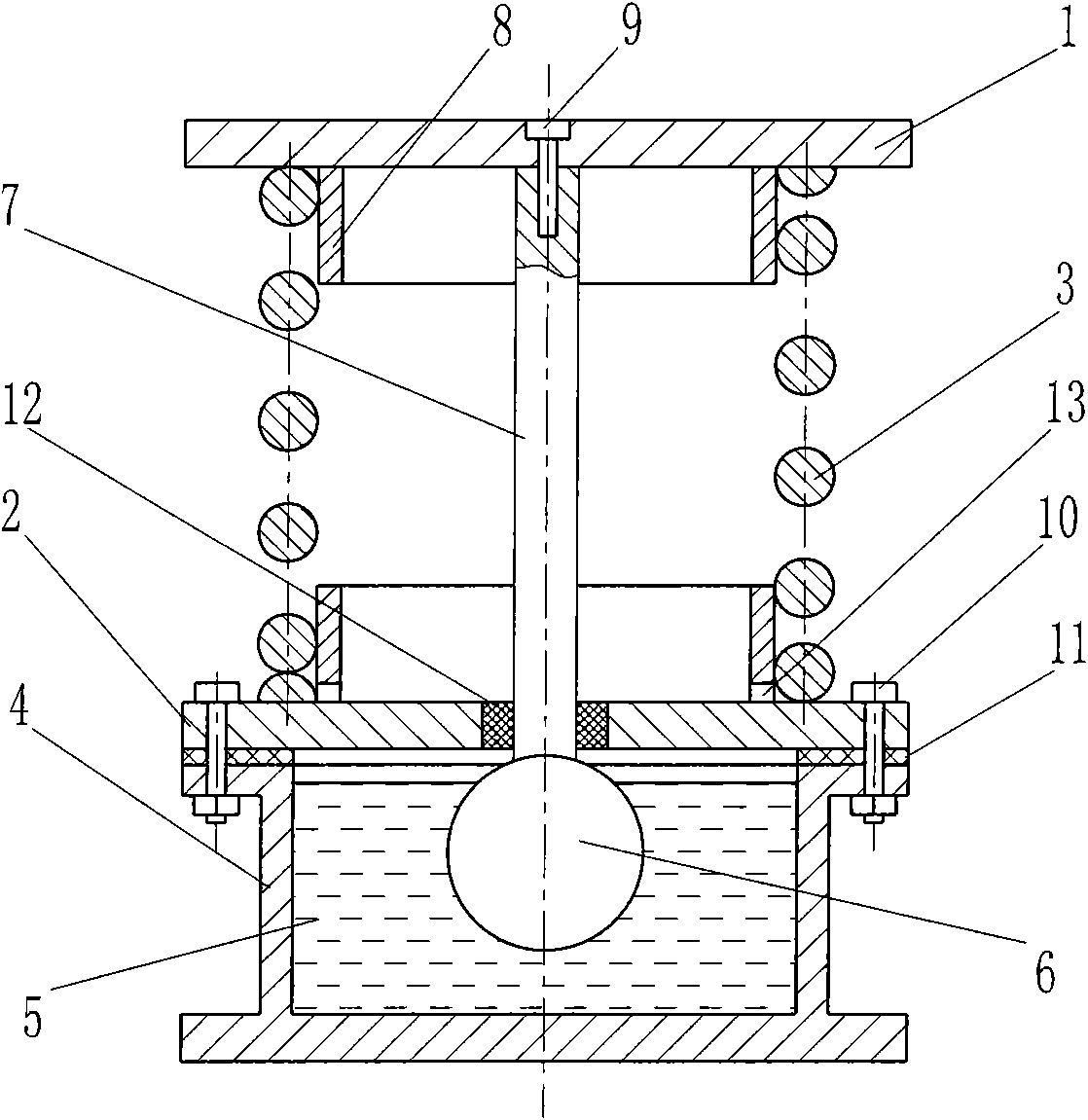

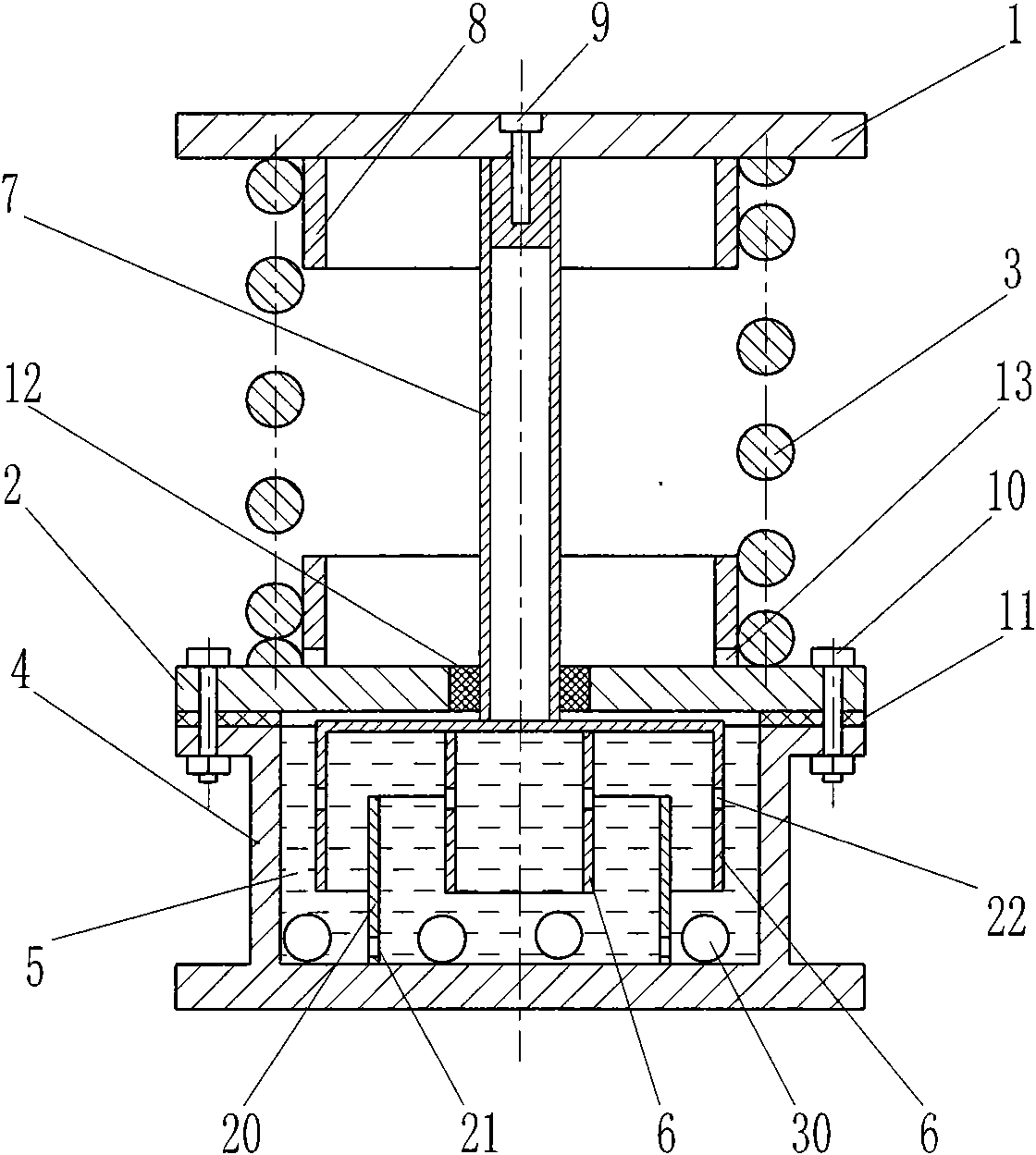

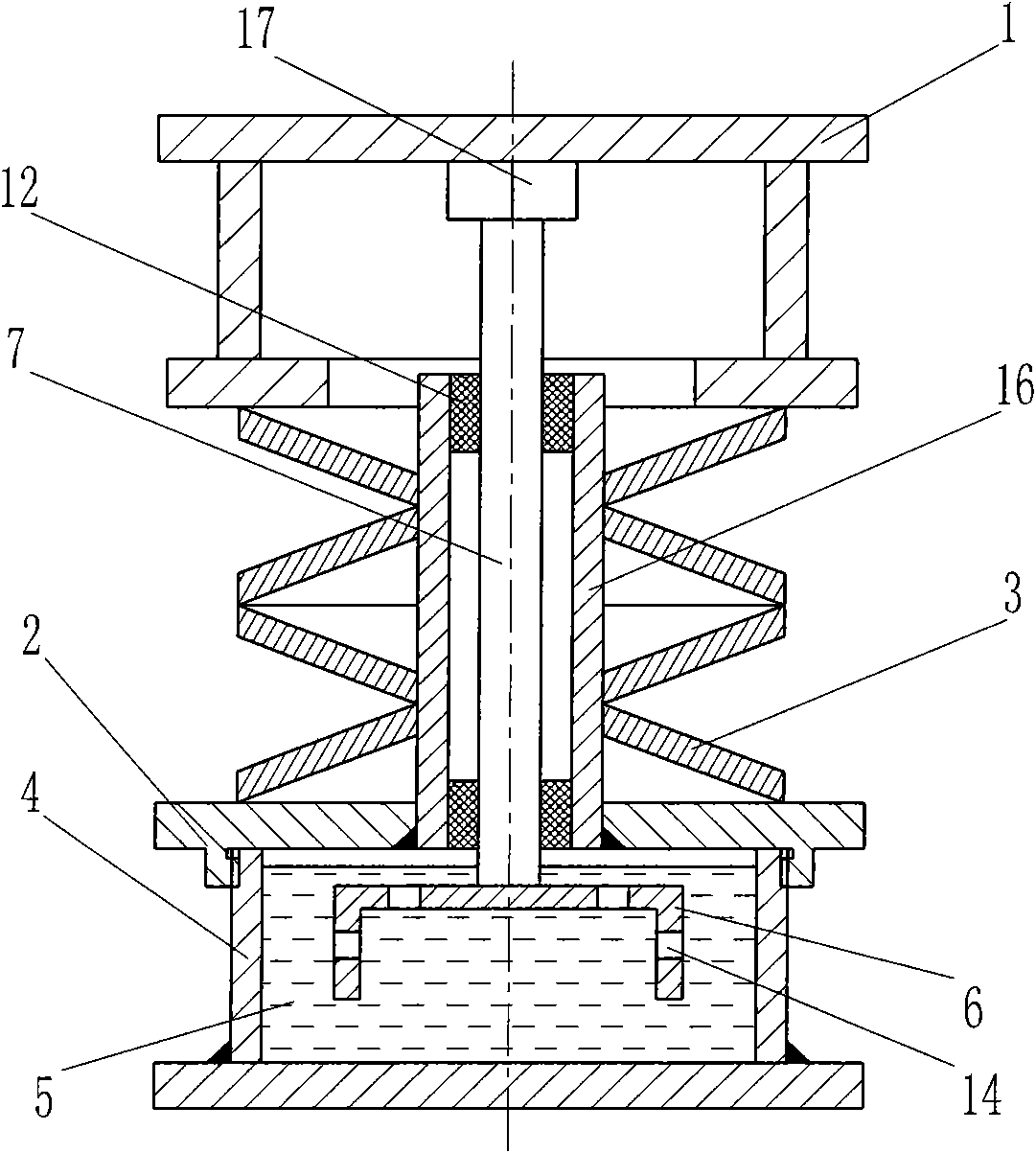

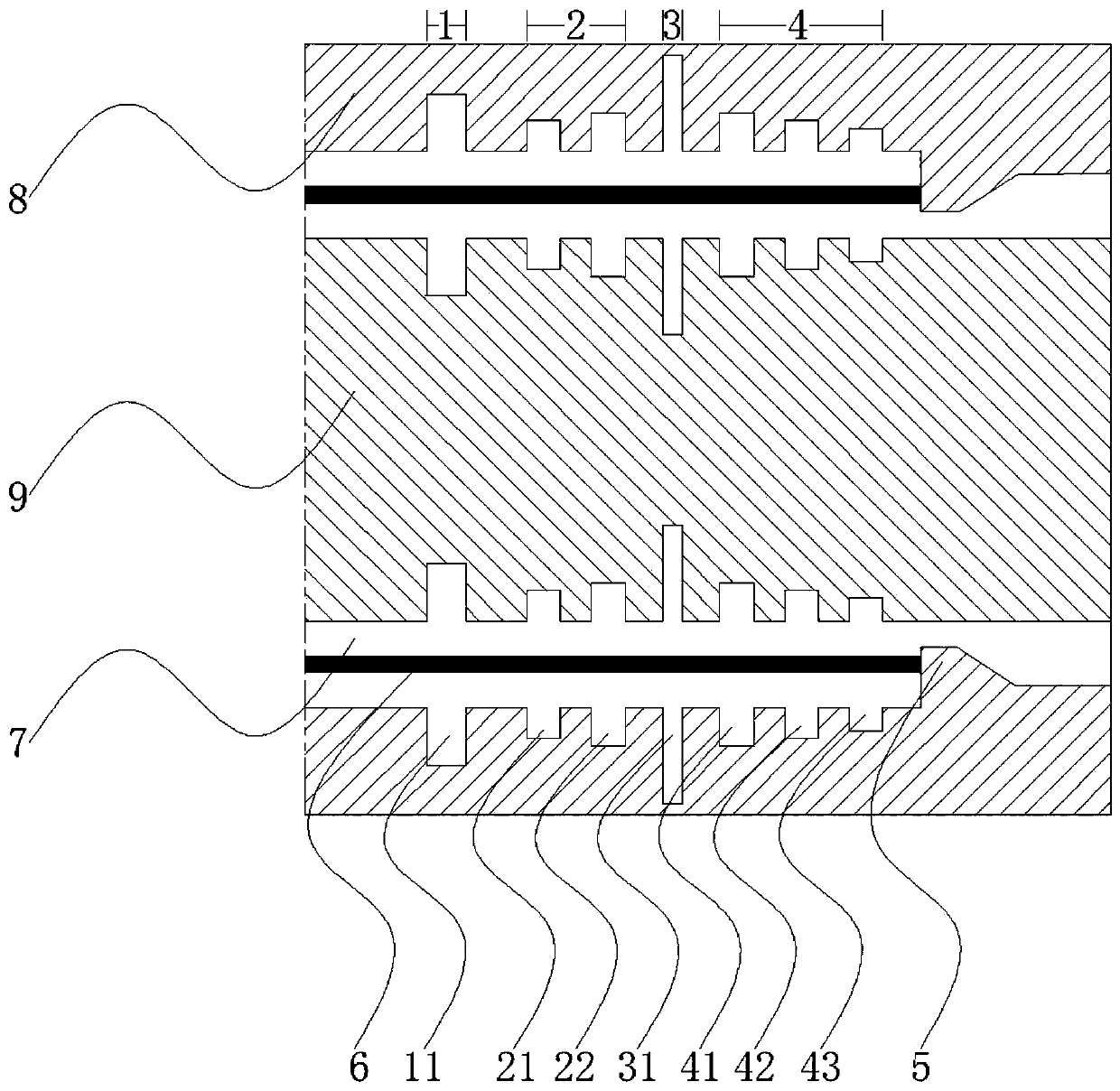

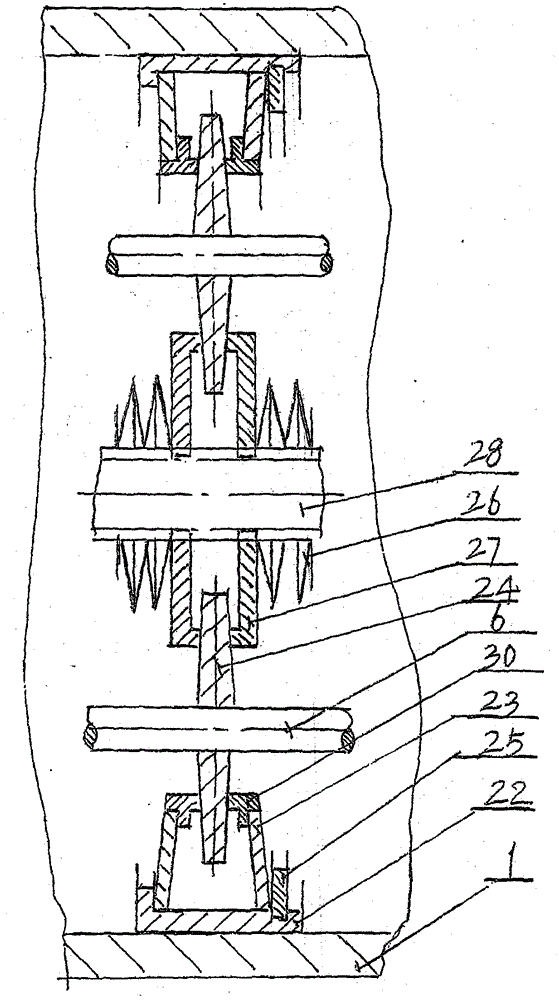

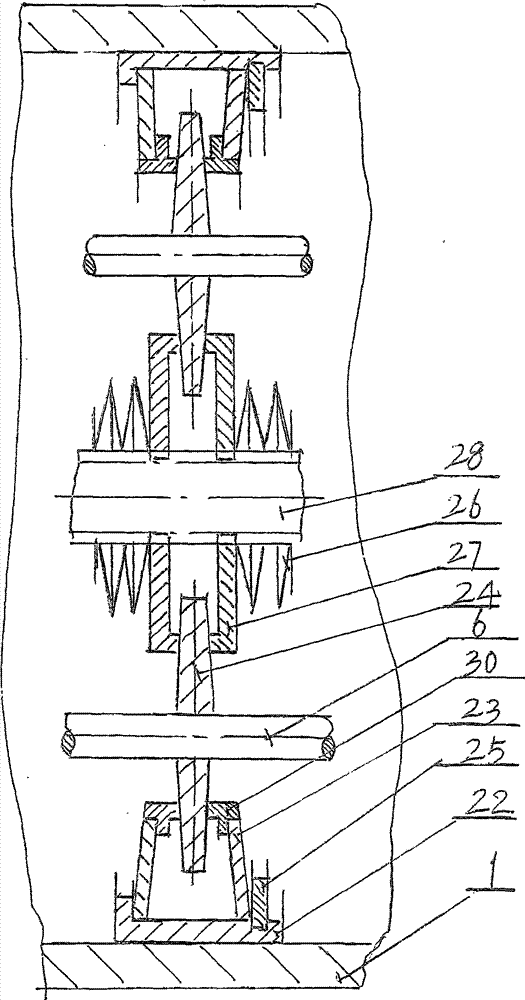

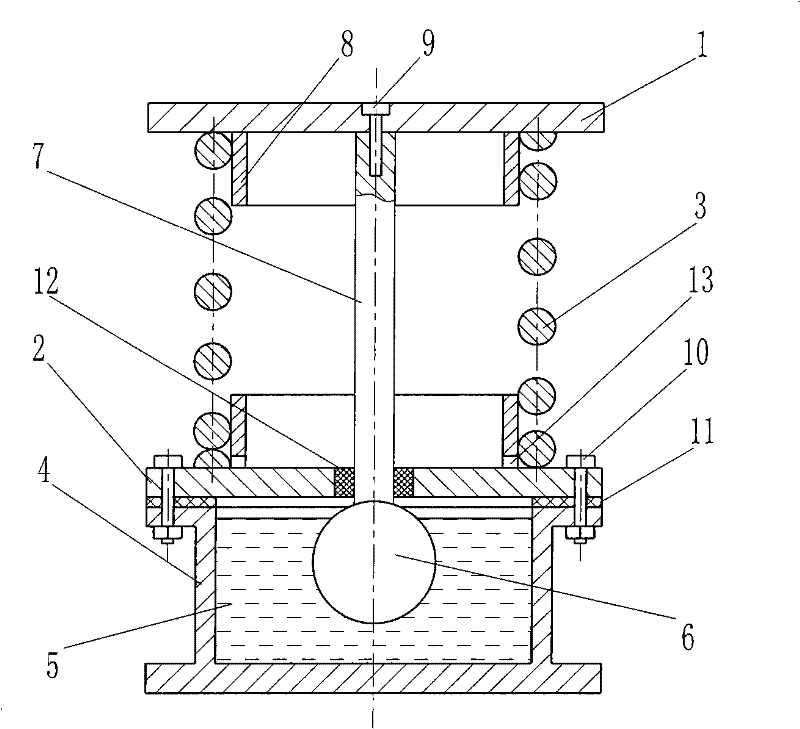

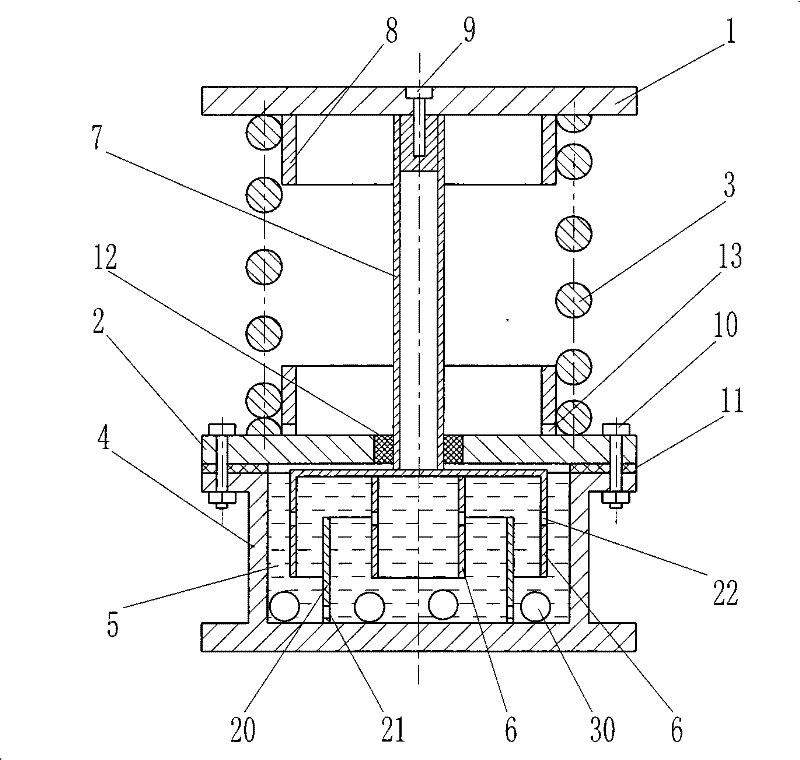

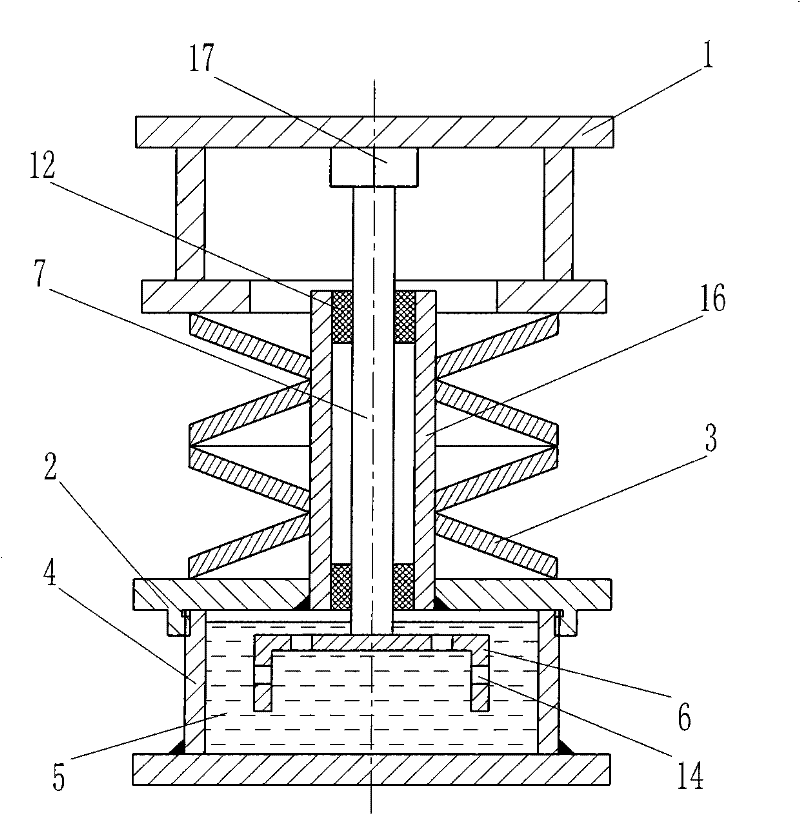

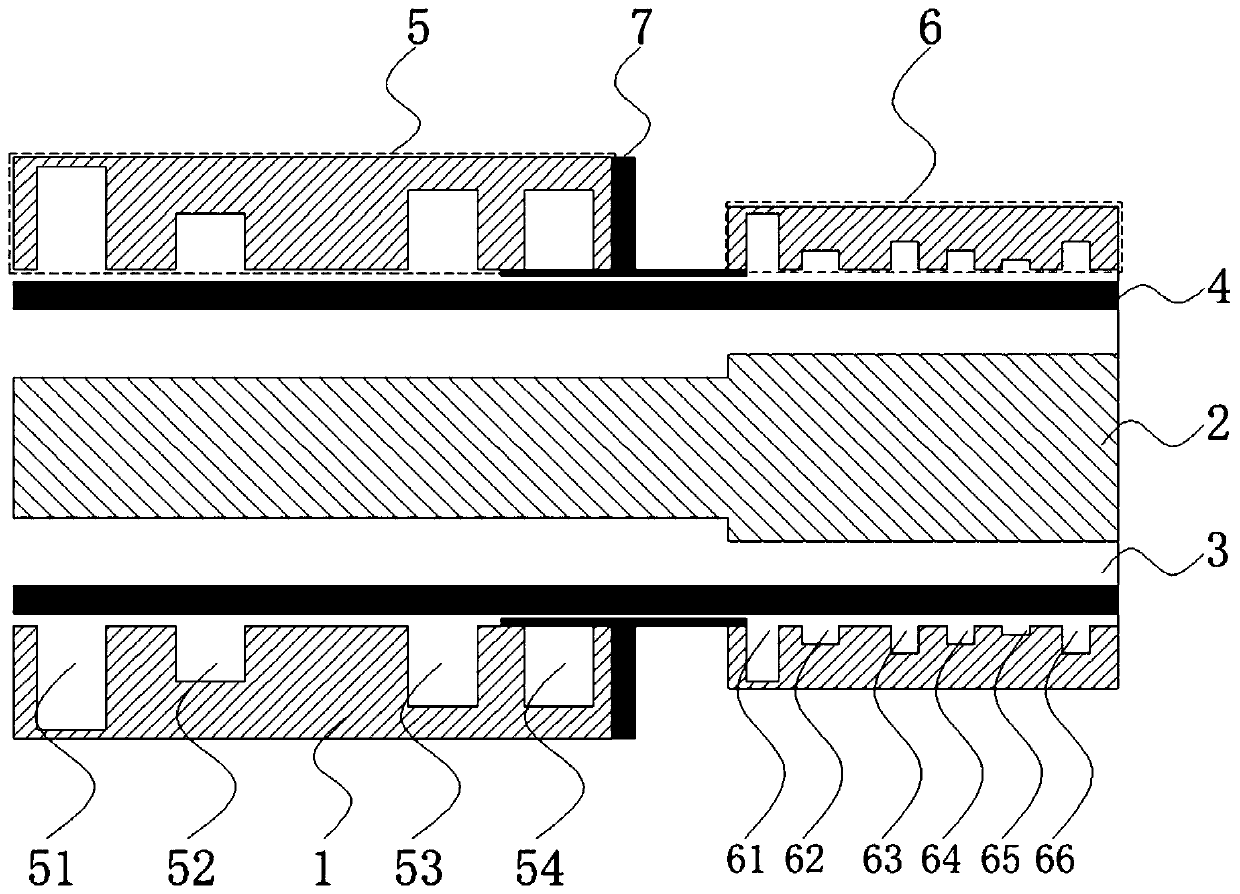

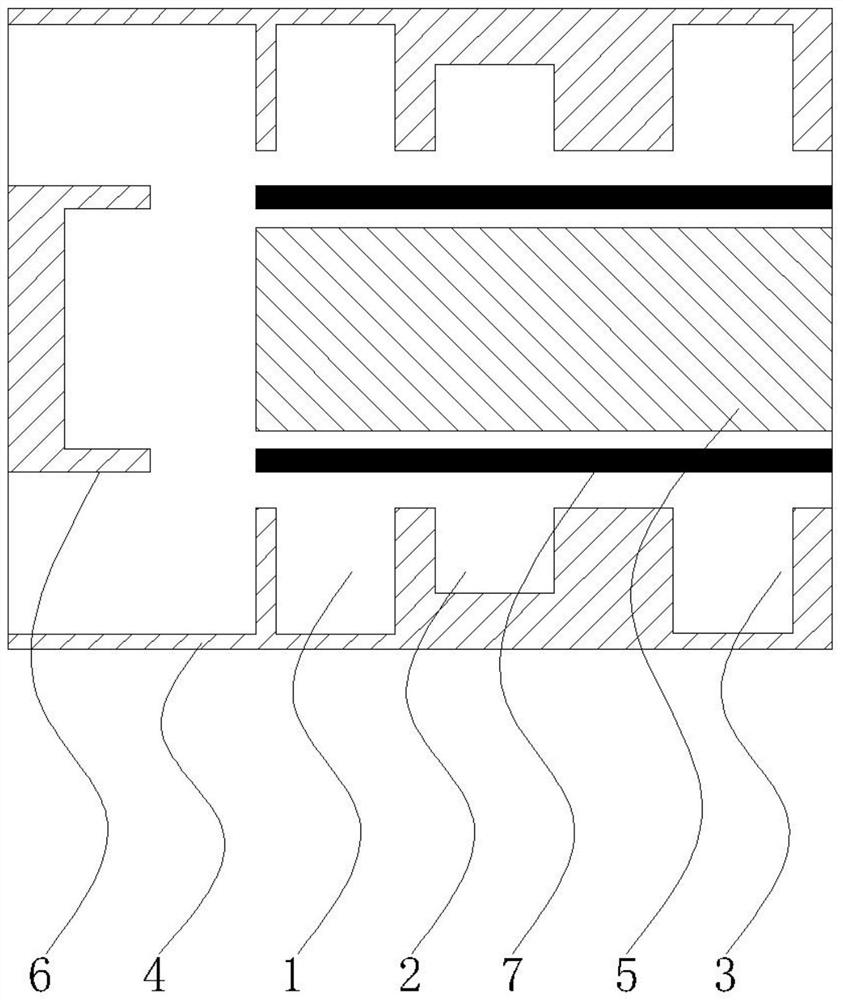

Spring damping vibration isolator

ActiveCN101825152AImprove waterproof performanceRadial dimensions are compactLiquid based dampersSocial benefitsVibration control

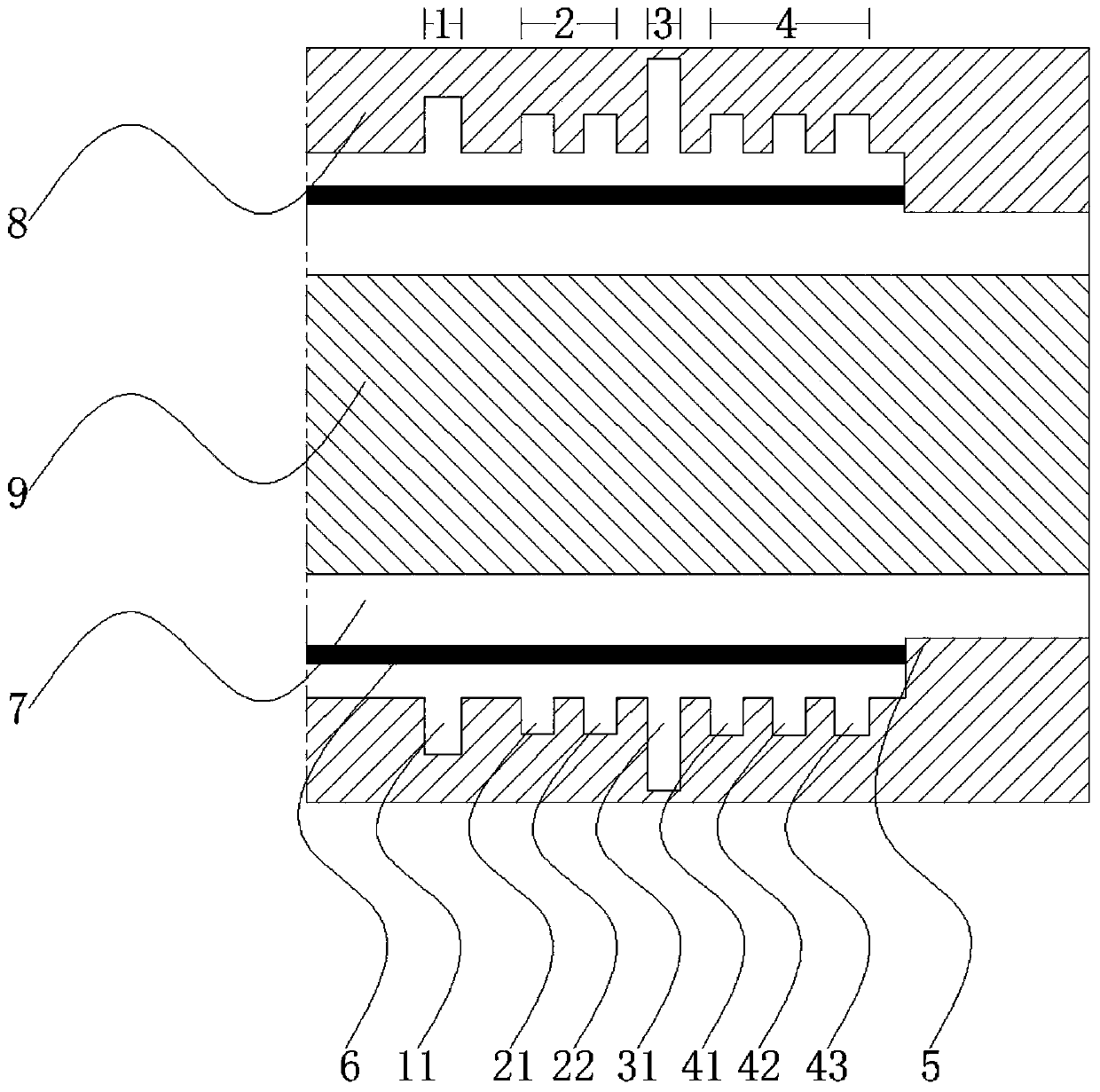

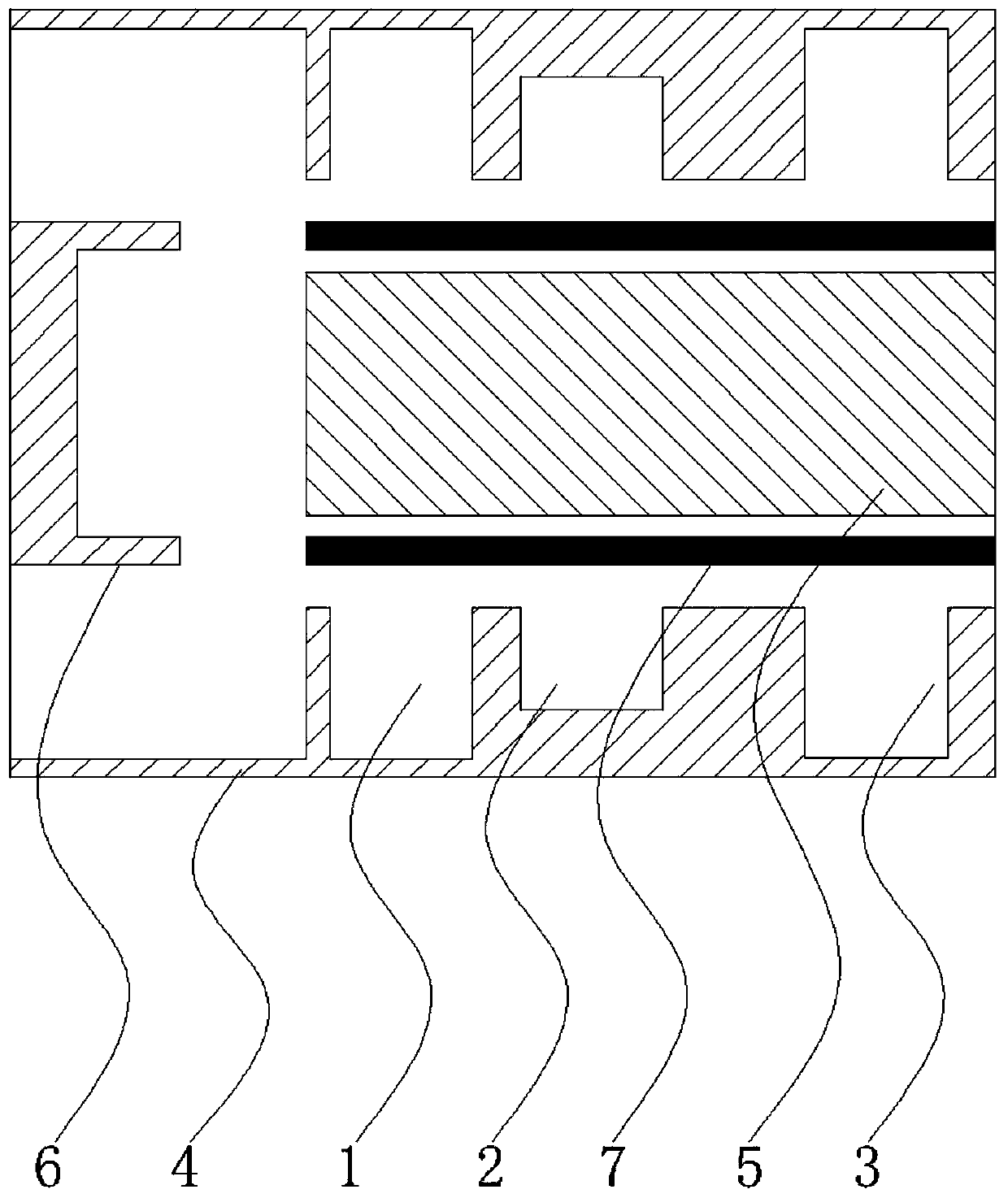

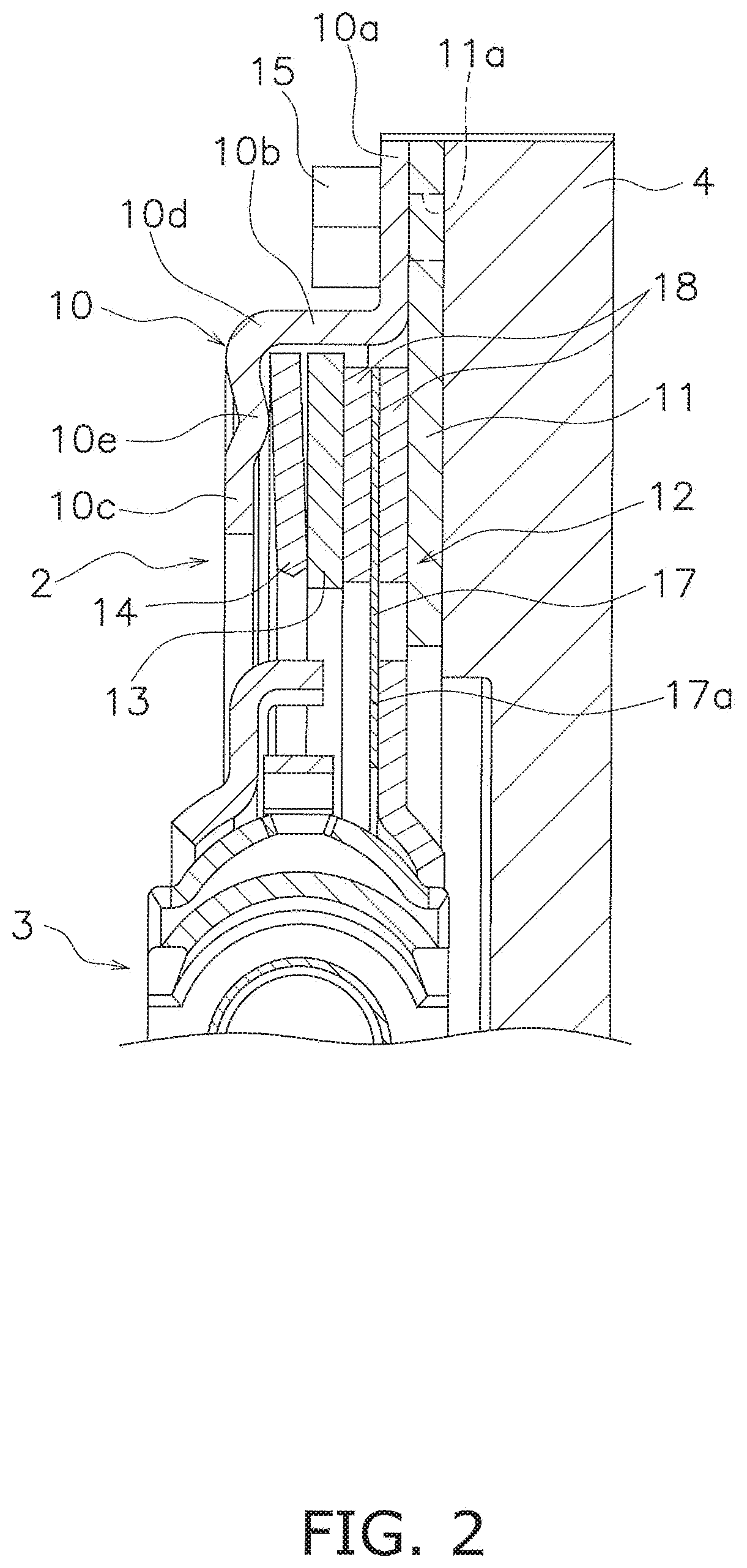

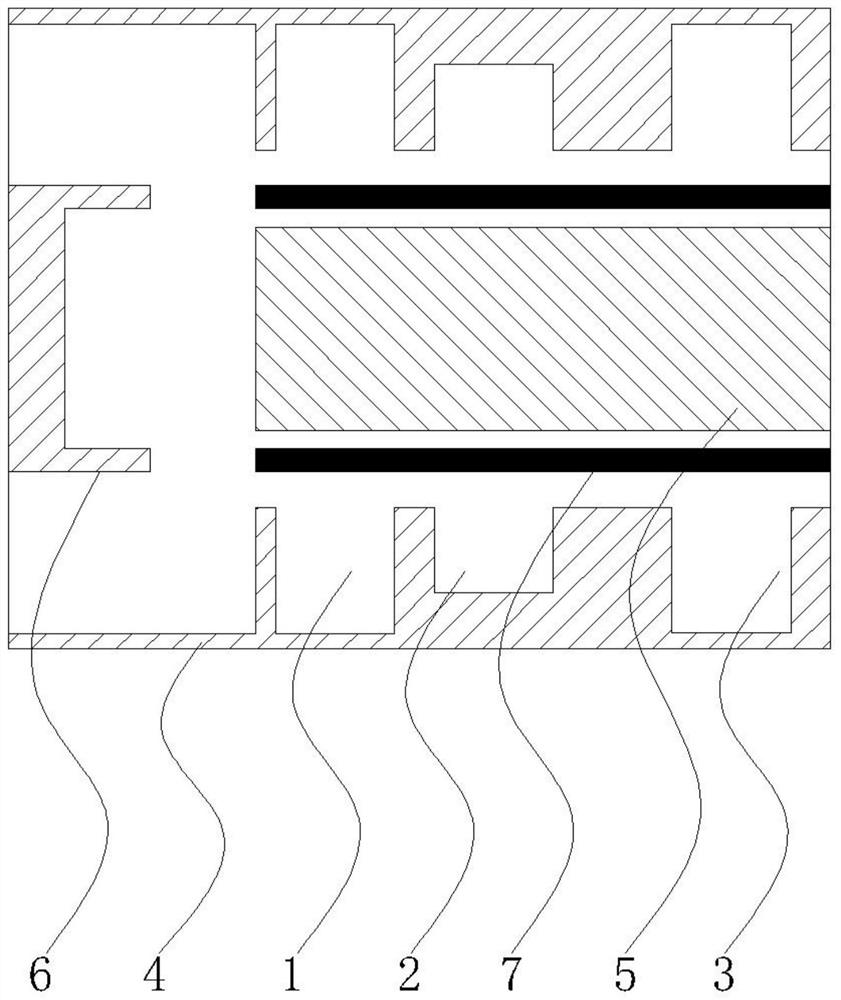

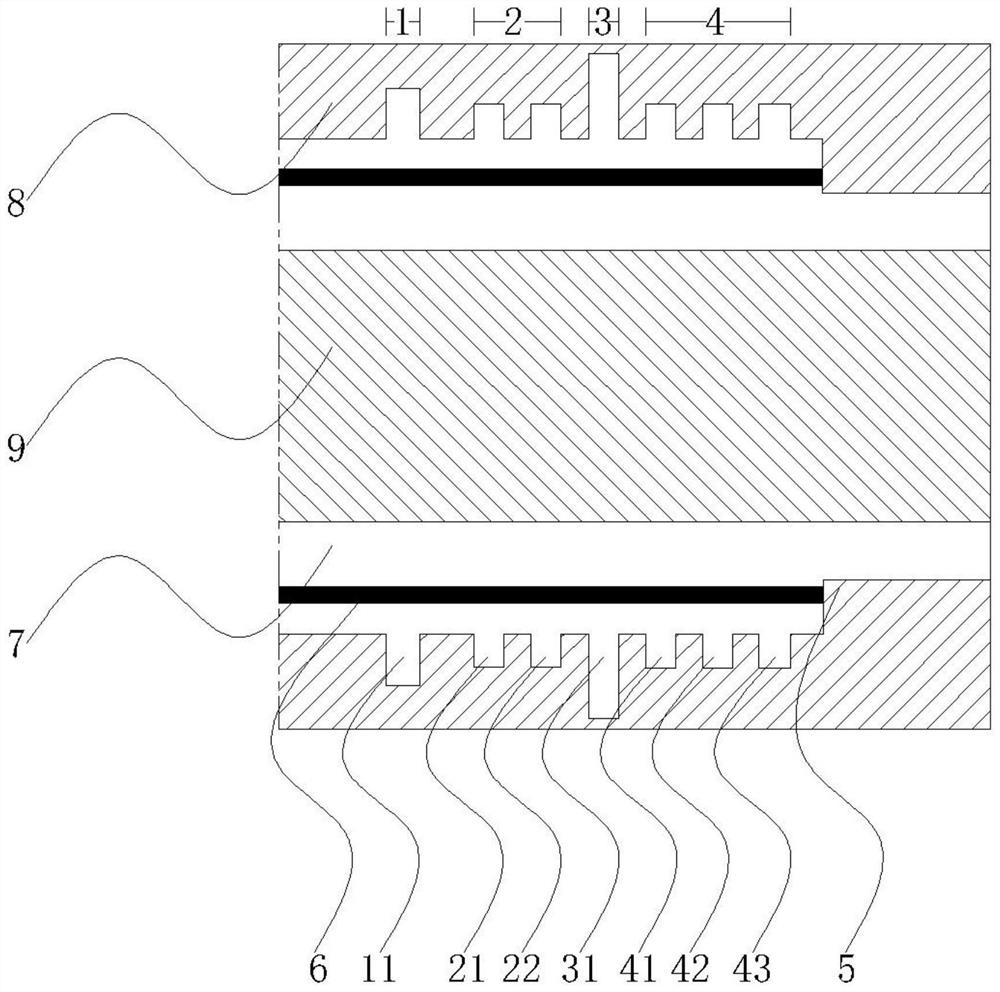

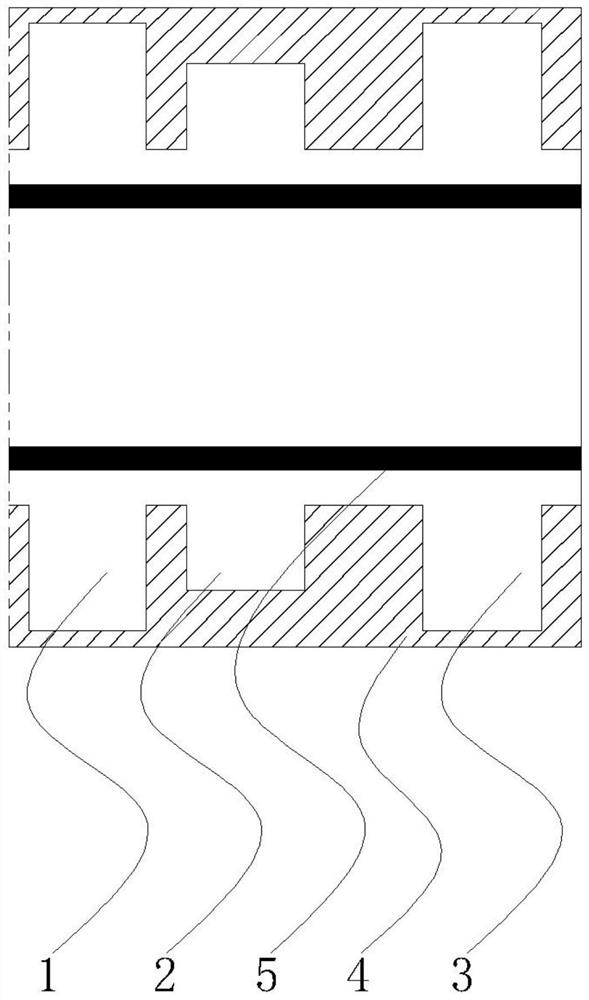

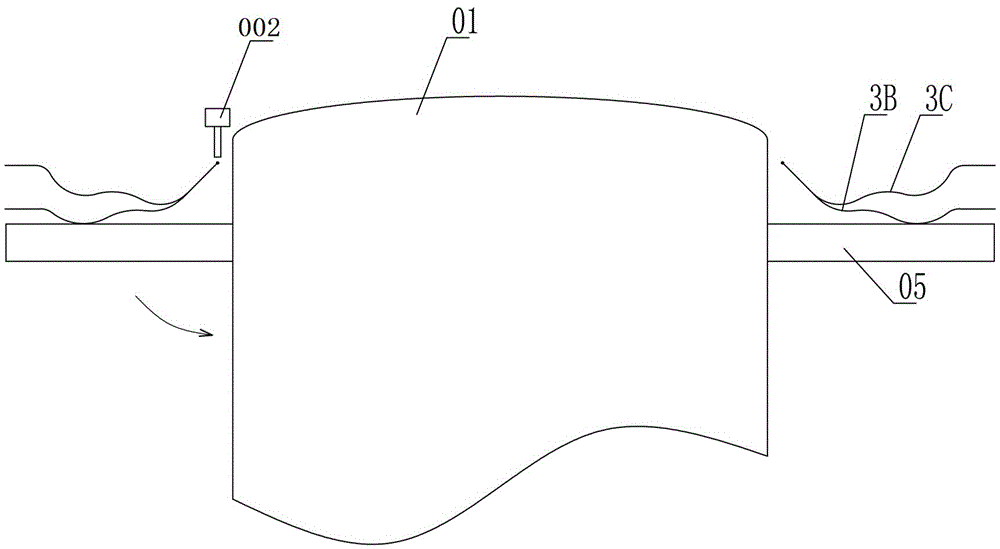

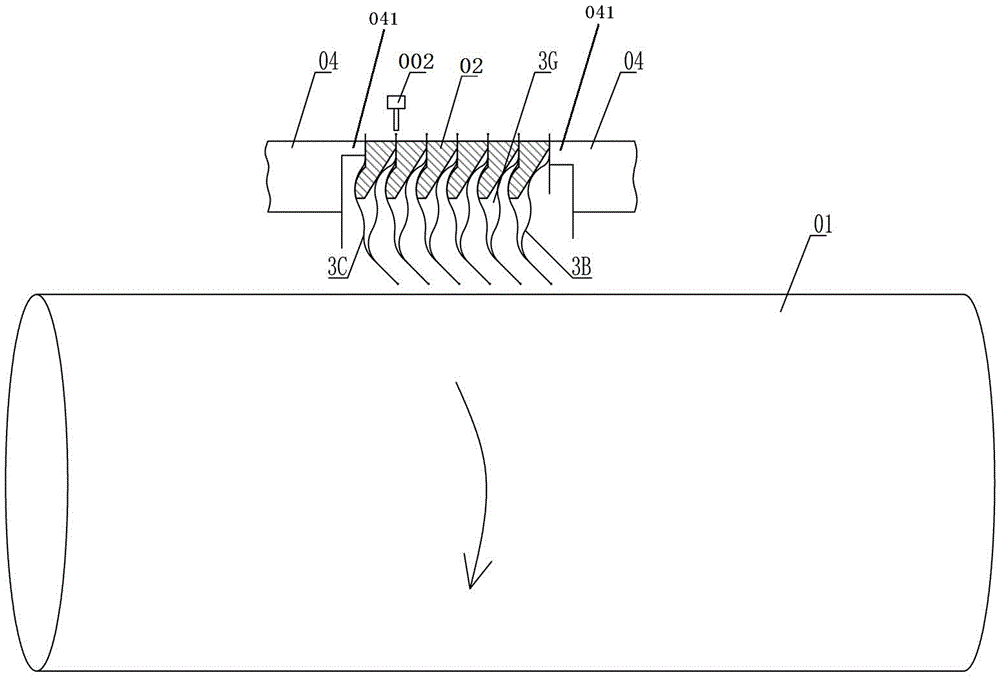

The invention belongs to the field of vibration control, and particularly relates to a spring damping vibration isolator for isolating vibrations. The spring damping vibration isolator comprises an upper support plate, an elastic element and a lower support plate, wherein the elastic element is positioned between the upper support plate and the lower support plate; a damping cylinder is arranged below the lower support plate; a liquid damping material is arranged in the damping cylinder; a movable body linked with the upper support plate or lower support plate is arranged in the damping cylinder; and at least part of the movable body is arranged in the liquid damping material. In the invention, the damping cylinder and the movable body are independently arranged under the elastic element, thereby greatly enhancing the system damping, and overcoming the defect of limited contact area of spring and damping material restricted by the space in the damping cylinder in the prior art; and the invention strengthens the sealing performance, thereby greatly enhancing the waterproof property of the vibration isolator. The invention has the advantages of simple structure, stable property and strong applicability, can be widely used for damping in the fields of machinery, rail transportation, bridges, architectural structures and the like, and has obvious economic and social benefits.

Owner:尹学军

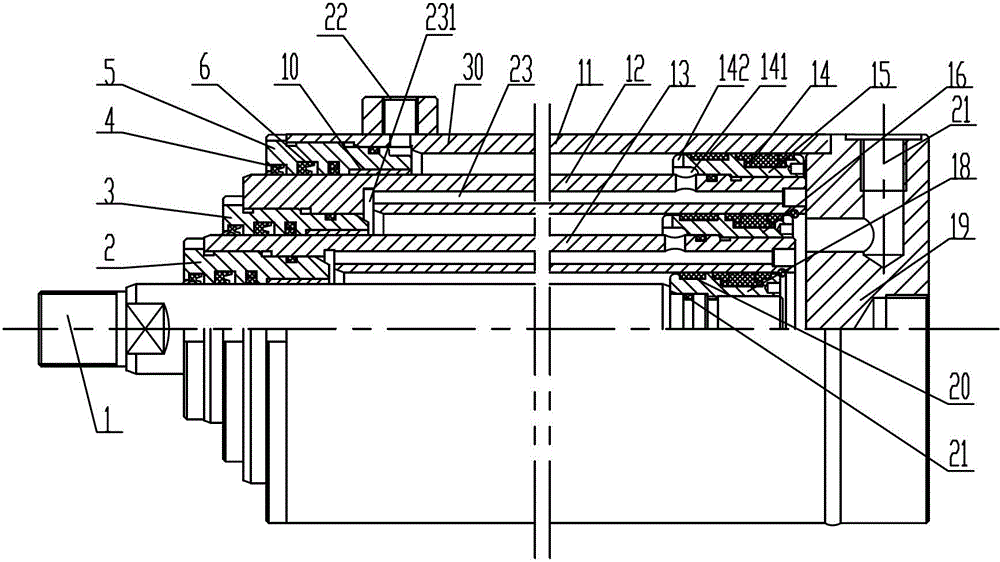

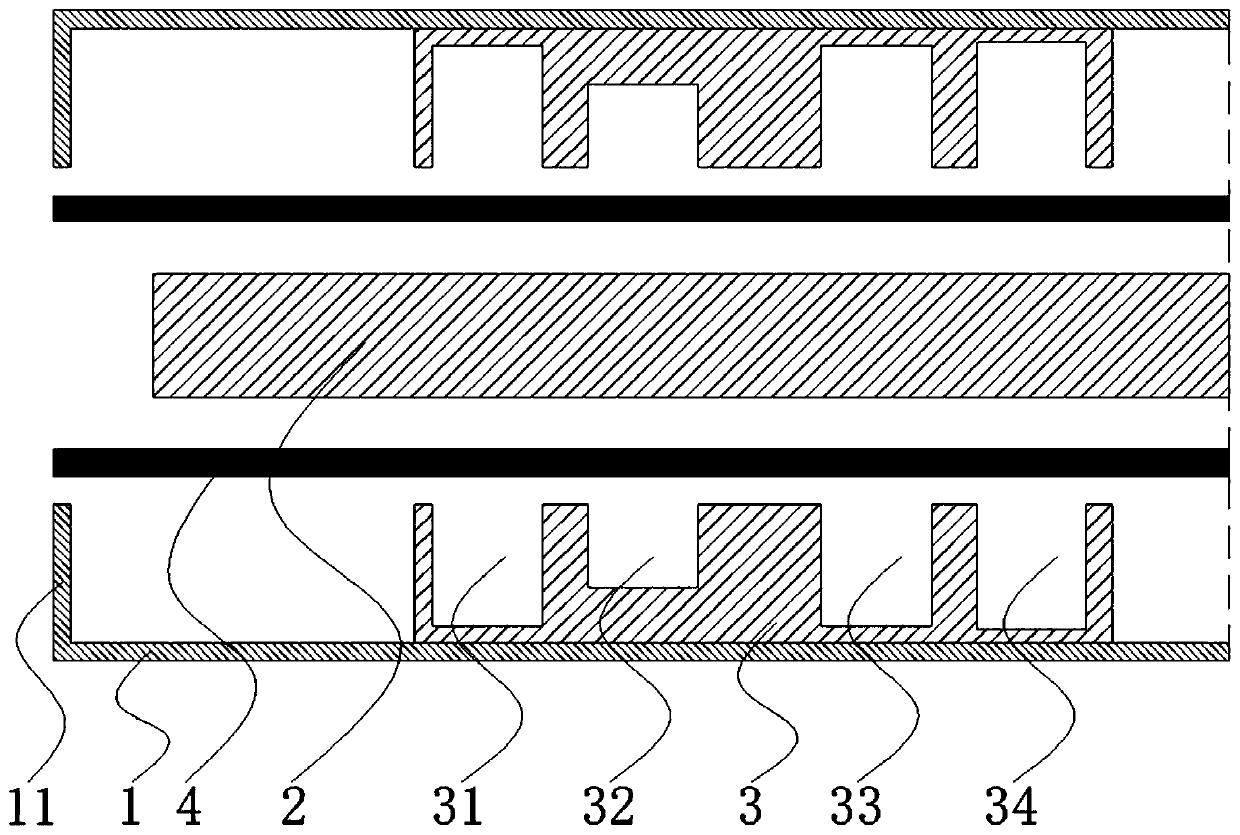

Double-action multistage hydraulic oil cylinder with solid piston rod

InactiveCN102852896AAvoid troubleAvoid resistanceFluid-pressure actuatorsReciprocating motionHydraulic ram

The invention relate to a double-action multistage hydraulic oil cylinder with a solid piston rod. The hydraulic oil cylinder comprises a first-stage cylinder sleeve, pistons, the piston rod and a plurality of stages of inner cylinder sleeves including a tail-stage cylinder sleeve. The piston rod is arranged in the tail-stage cylinder sleeve and is a solid rod. An oil feeding hole is arranged at the bottom end of the first-stage cylinder sleeve, and an oil discharging hole is arranged at the other end. A piston is fixed outside one end of each stage of inner cylinder sleeve close to the oil feeding hole, each stage of inner cylinder sleeve is provided with an oil guide hole which is a through hole communicating the inside and the outside of the inner cylinder sleeve, two outlets are located on the same side of the pistons and arranged , the outlet on the outer wall is close to the pistons, and the outlet arranged on the inner wall is arranged at the end far away from the piston. An oil pipe of the oil cylinder is not stretched, shortened or bended with reciprocating movement of the tail-stage piston rod, so that the oil cylinder prevents the oil pipe from being collided and interfered with the tail-stage piston rod in reciprocating movement and being abraded. The piston rod is of a solid structure, and is better in rigidity, low in processing cost and compact in radial size.

Owner:沈姝君

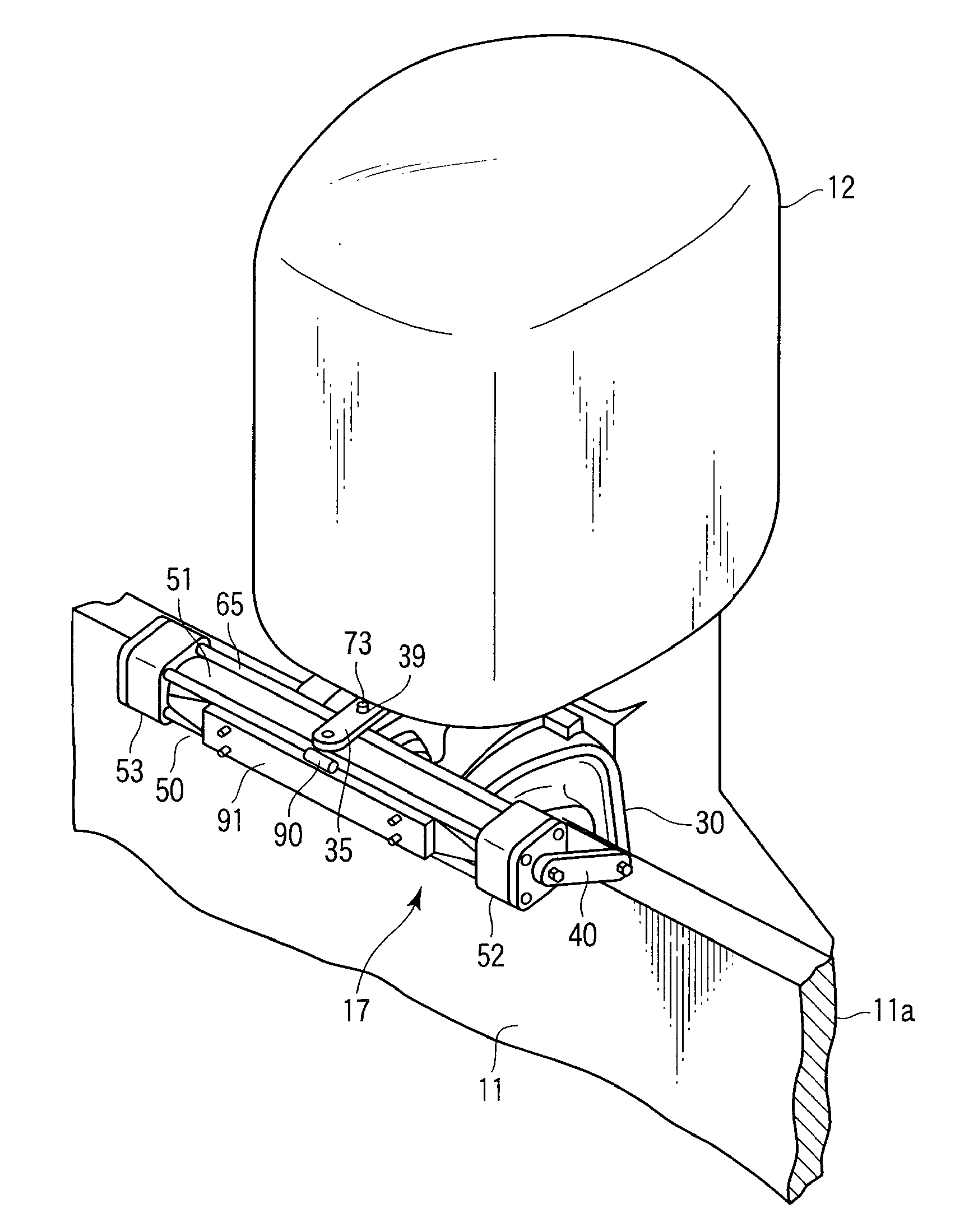

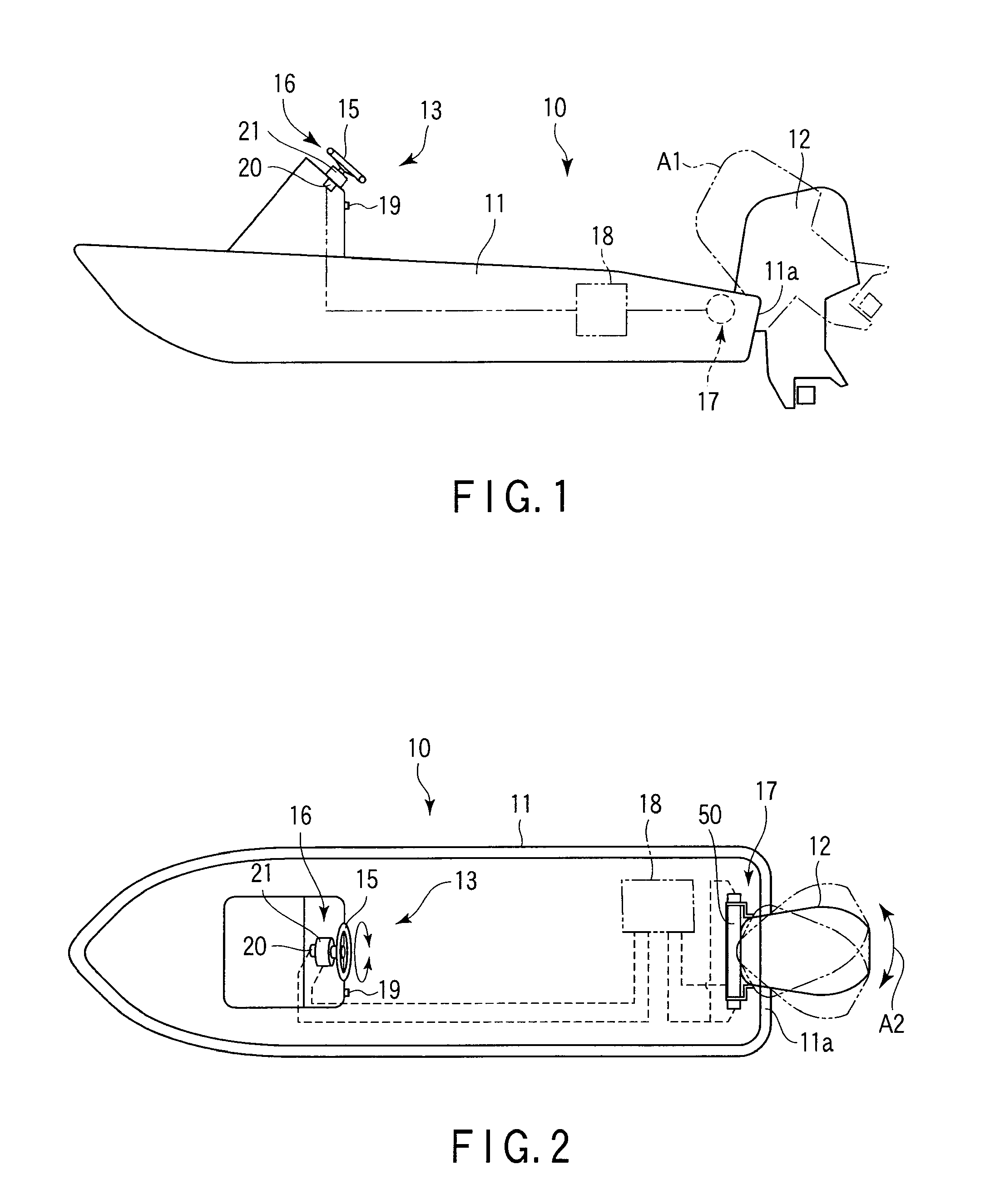

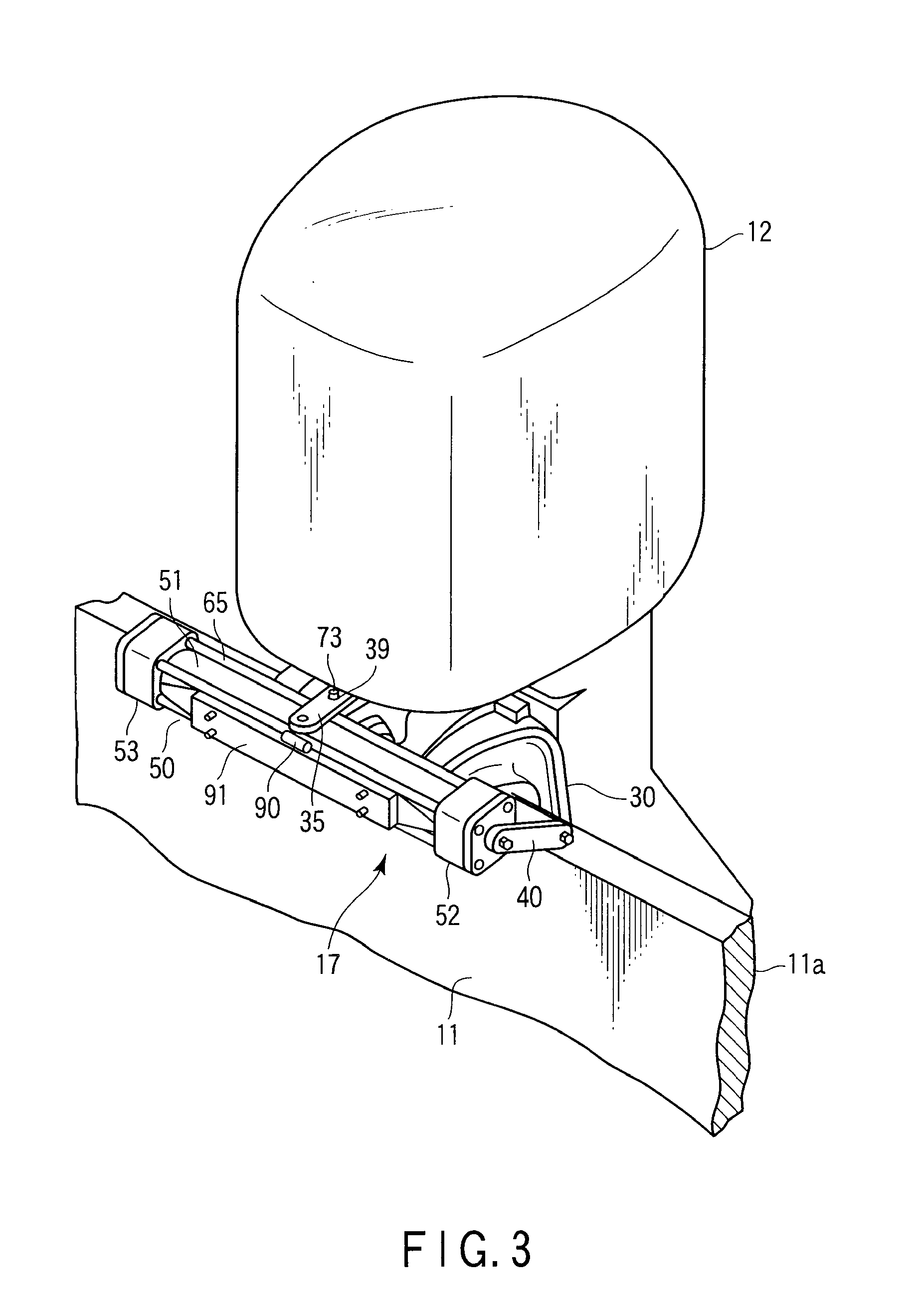

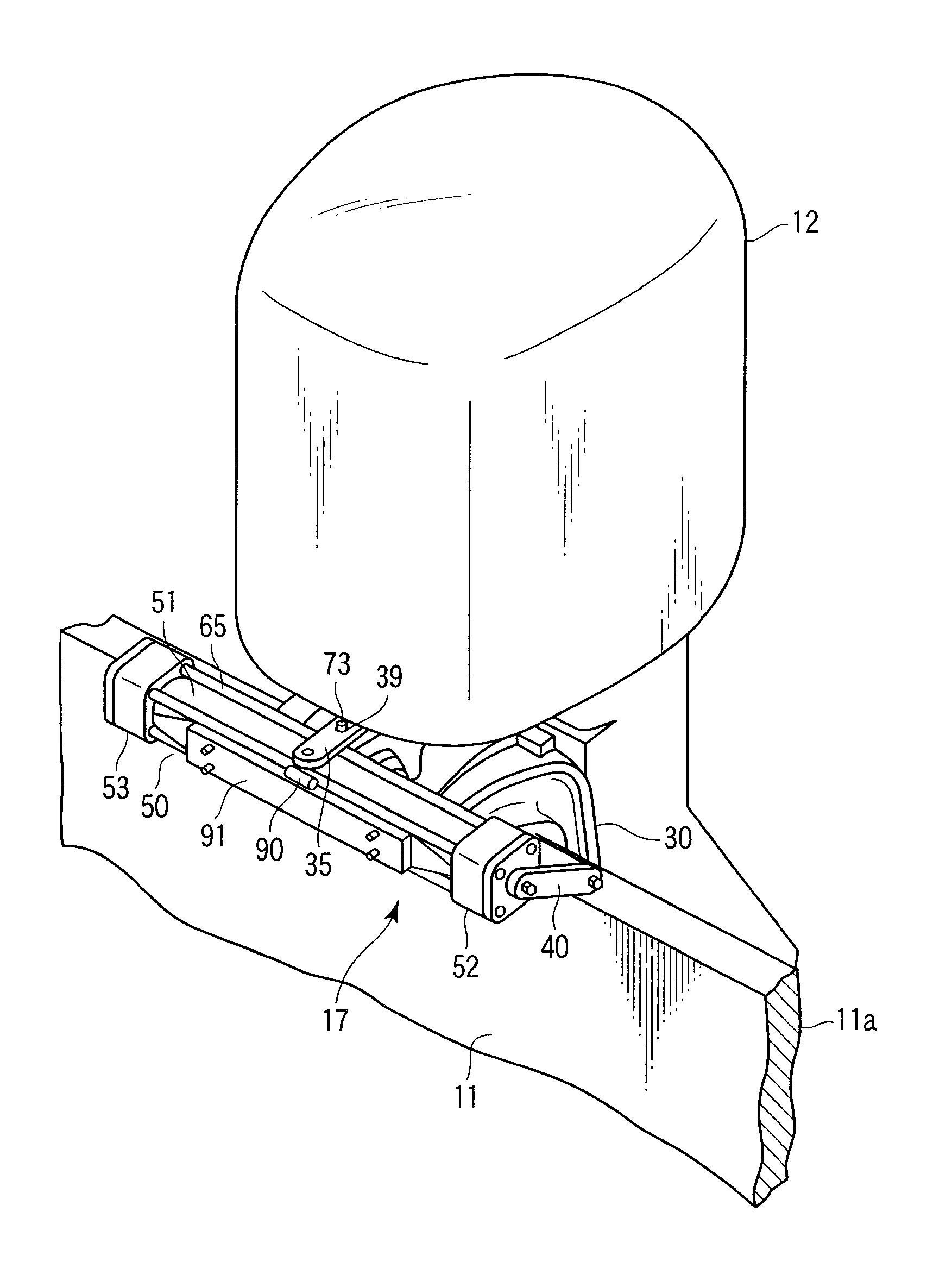

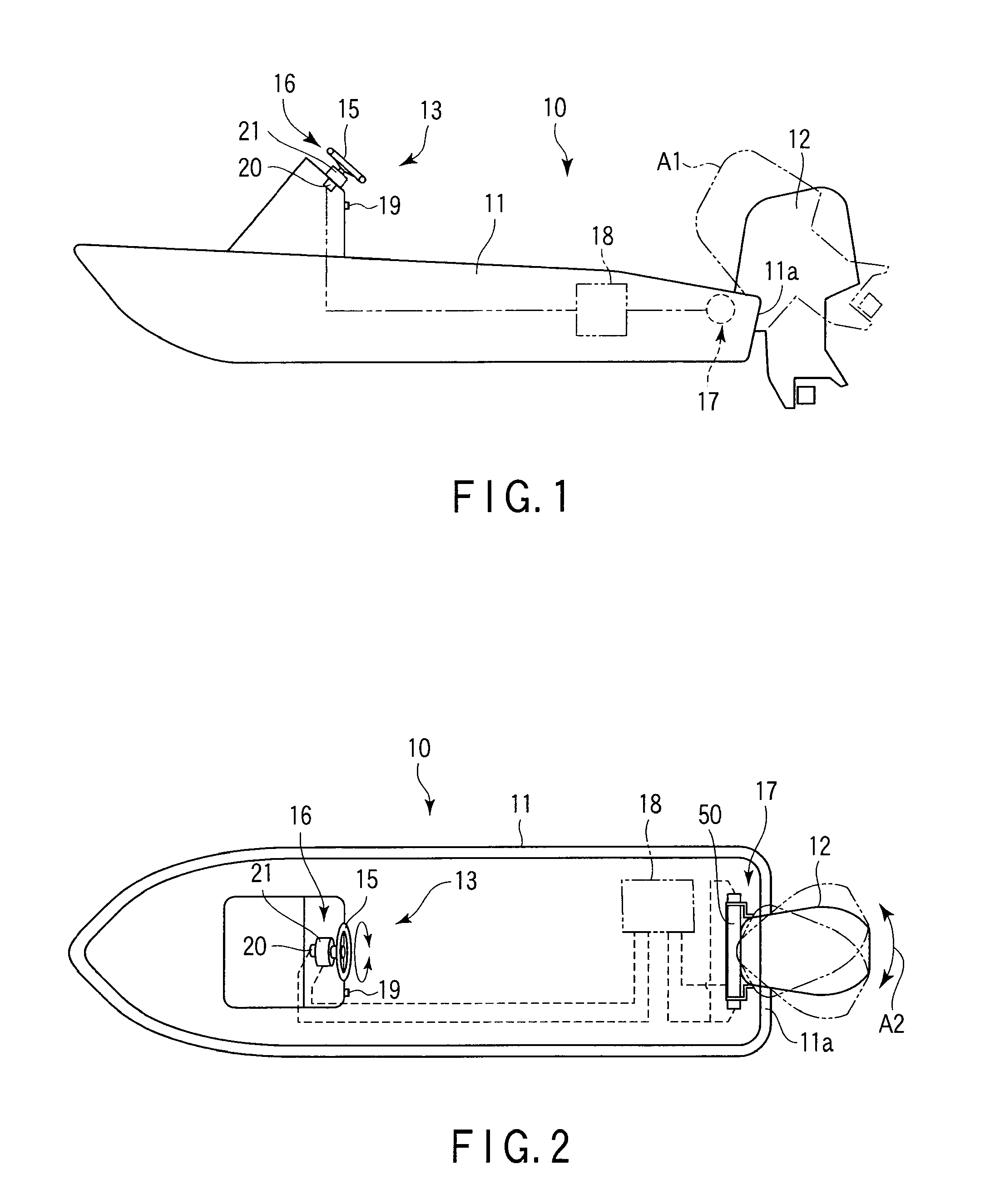

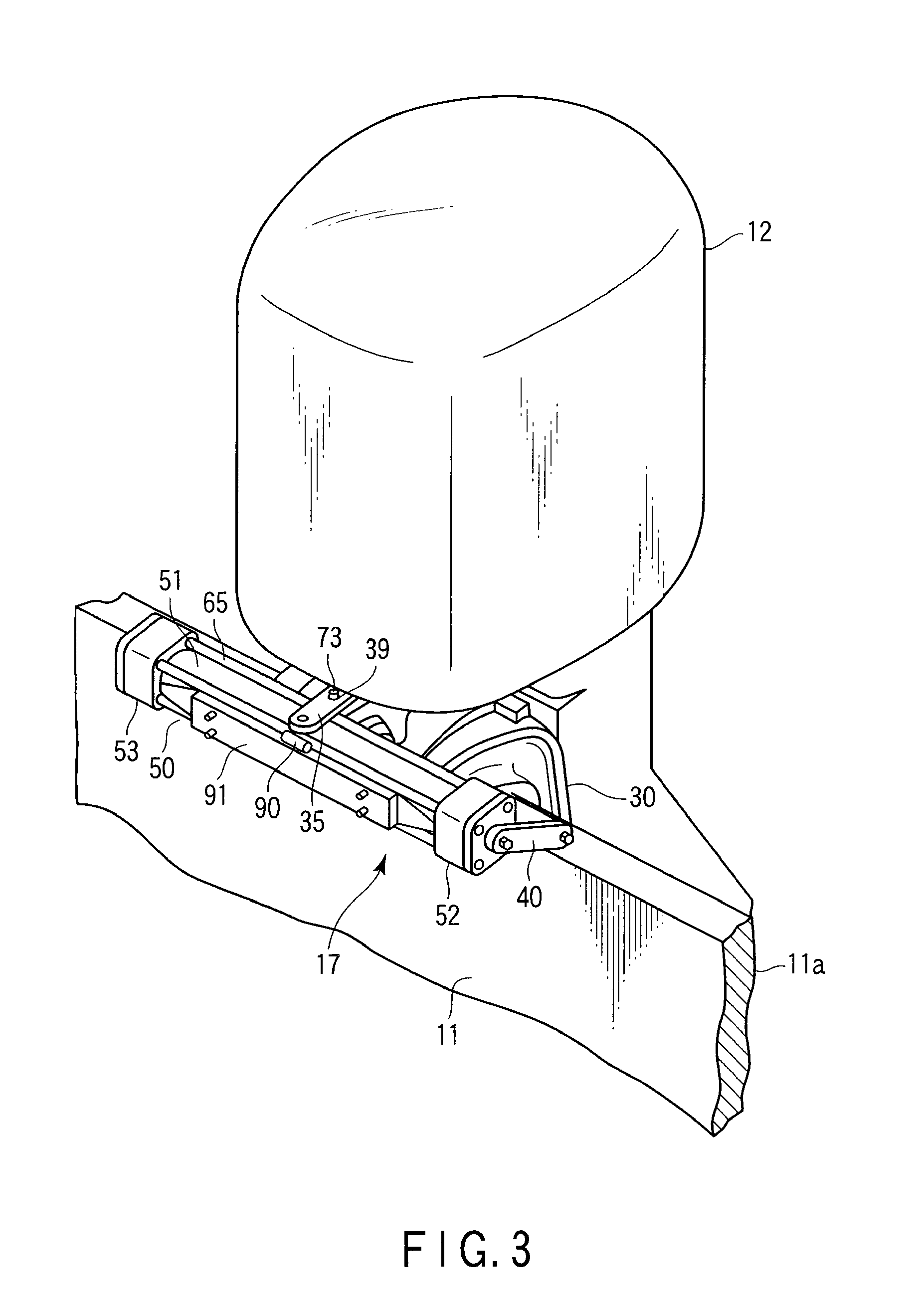

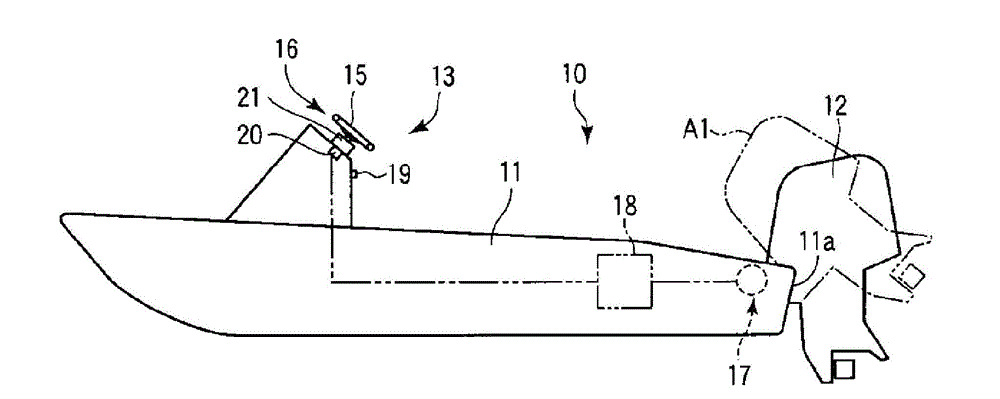

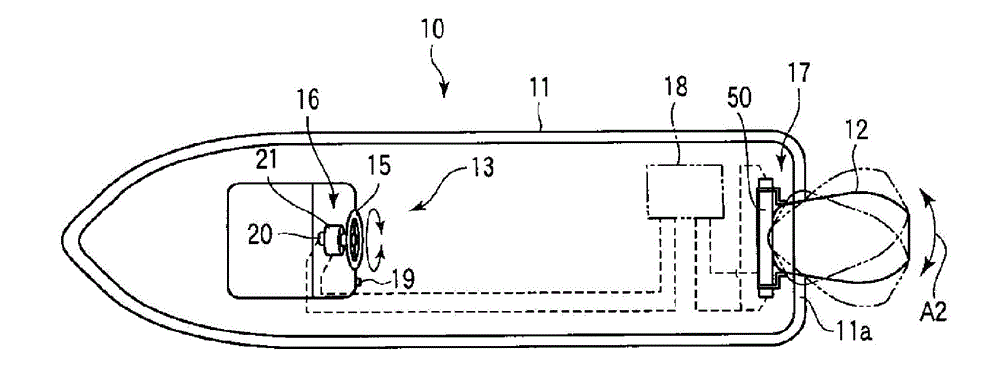

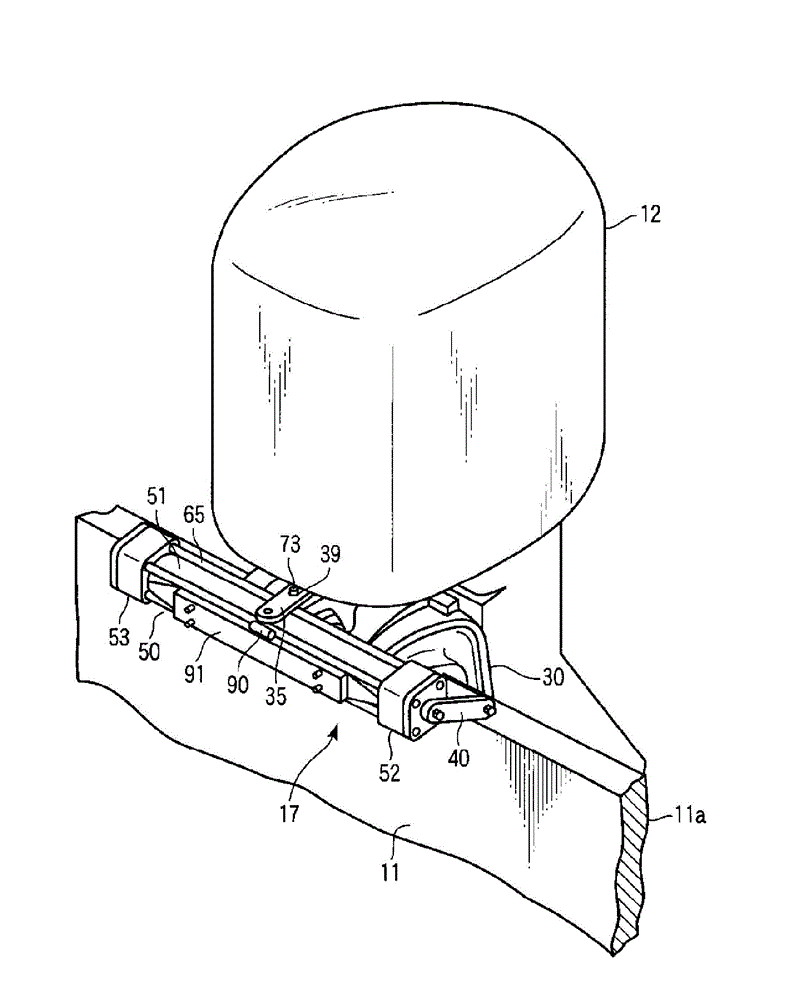

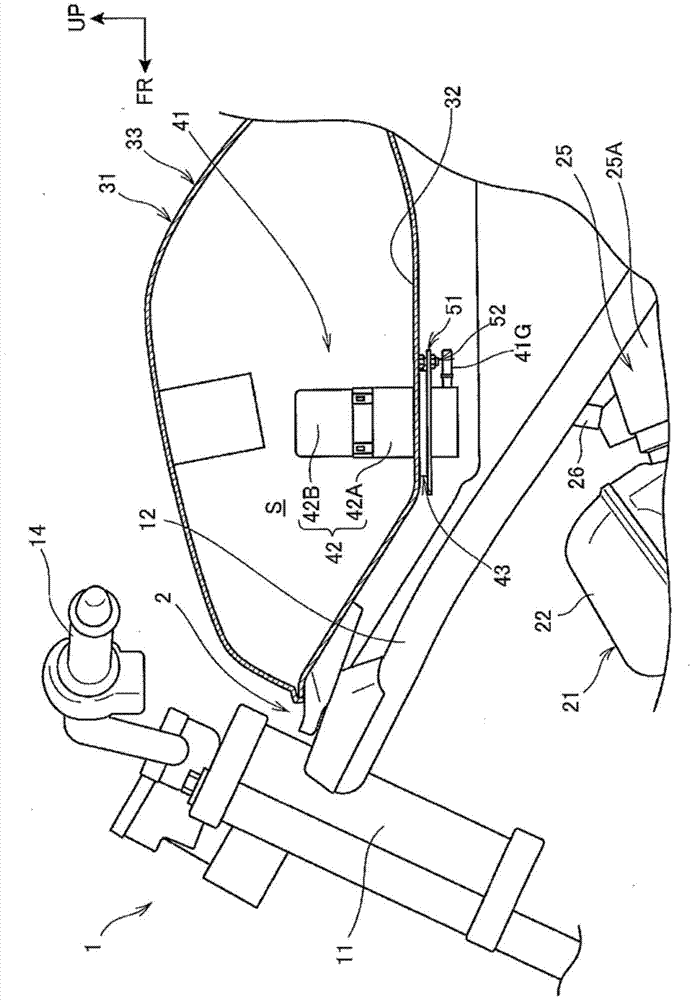

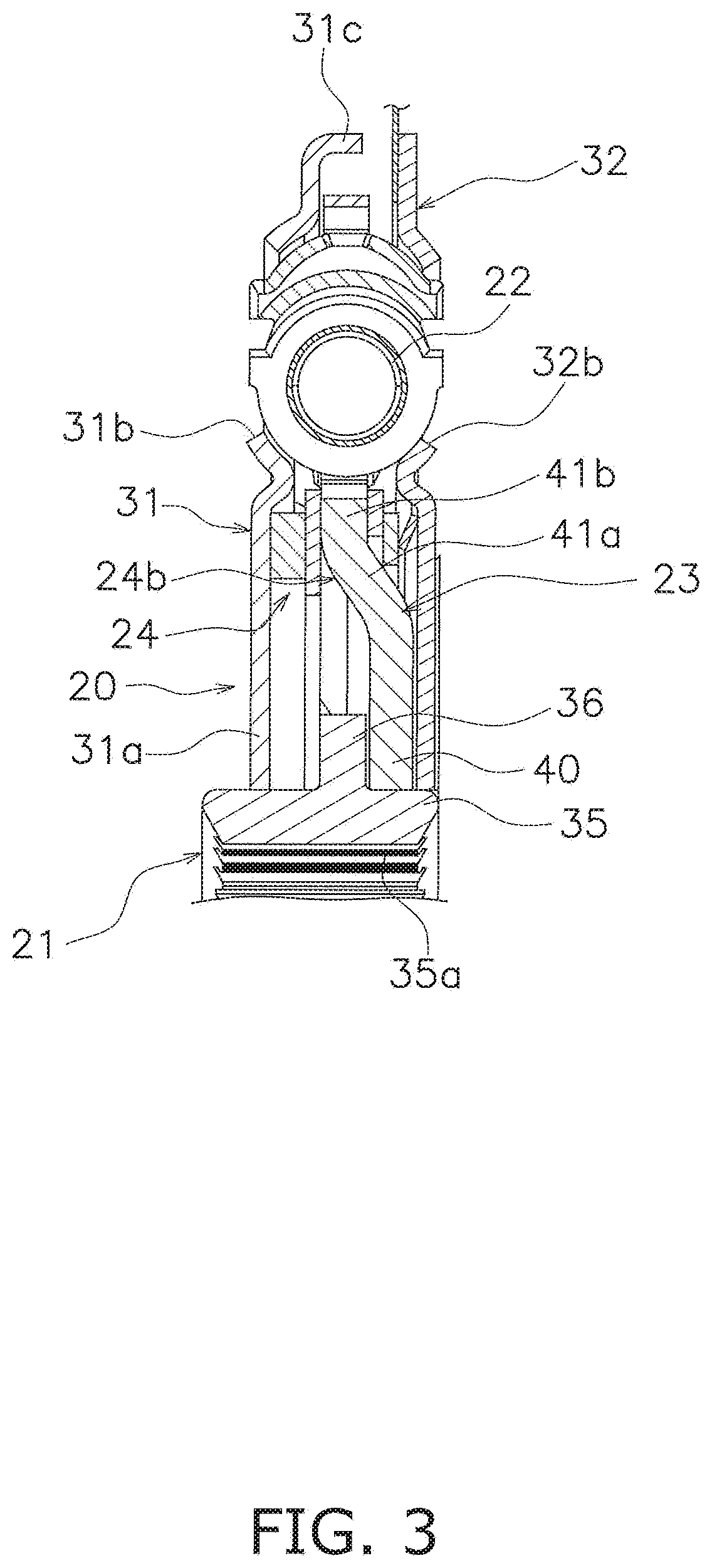

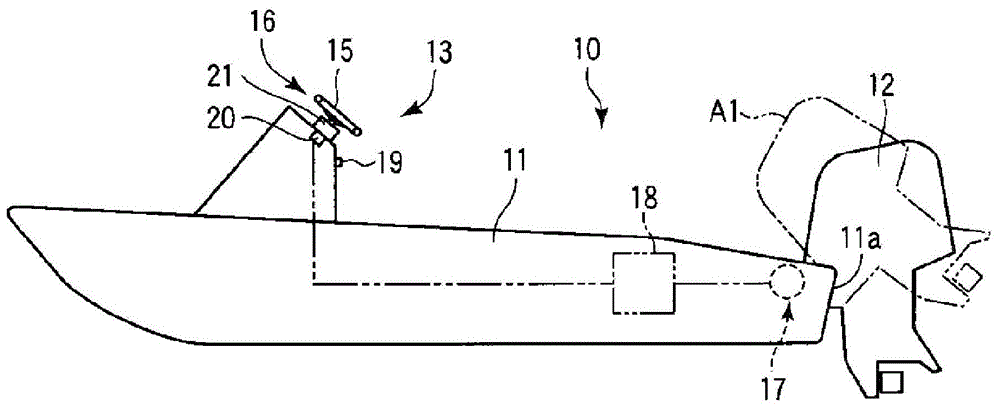

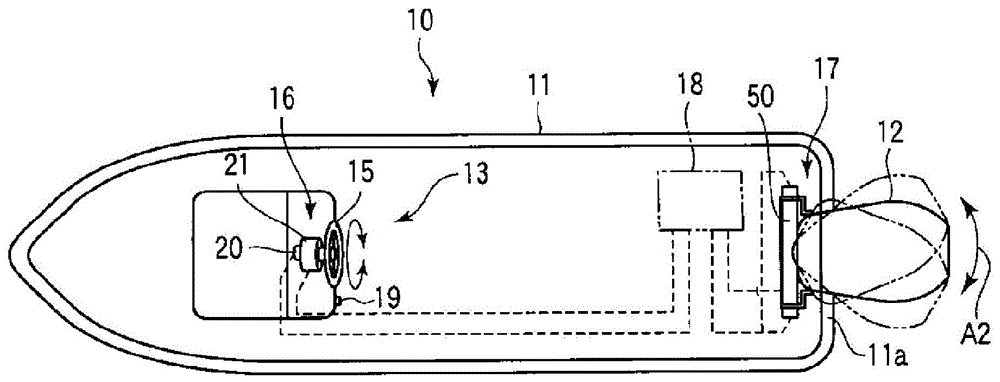

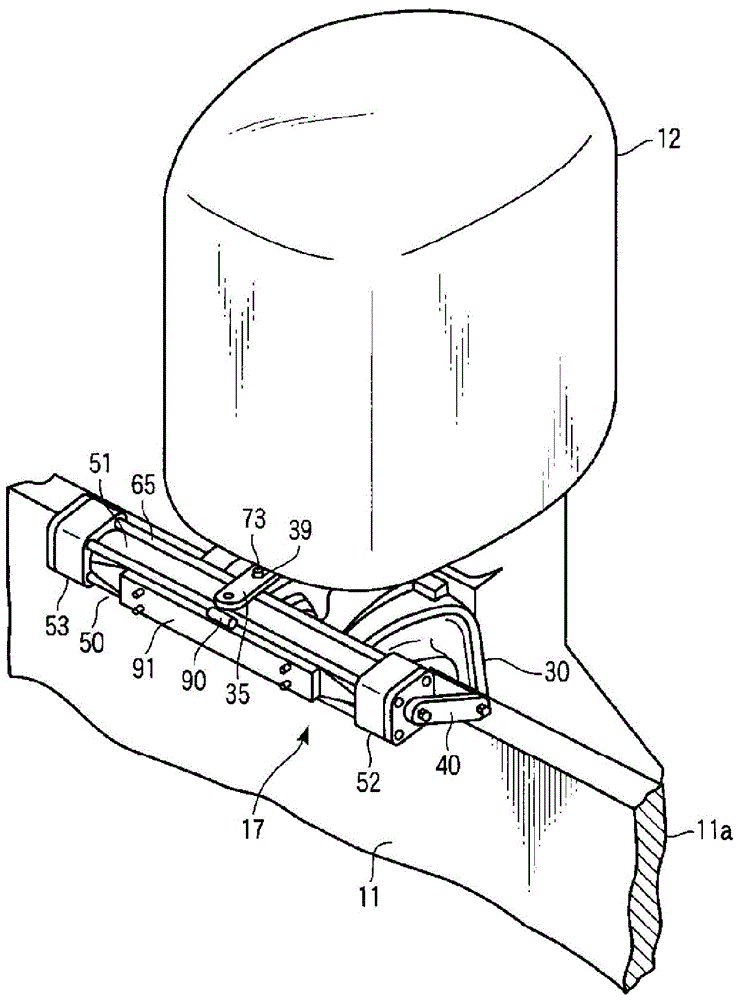

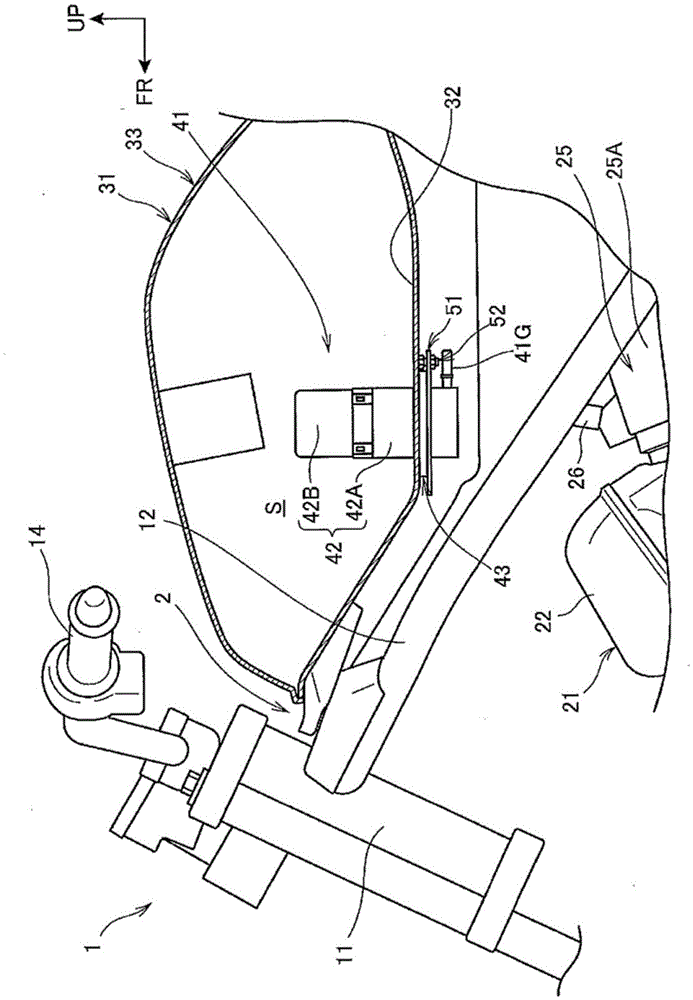

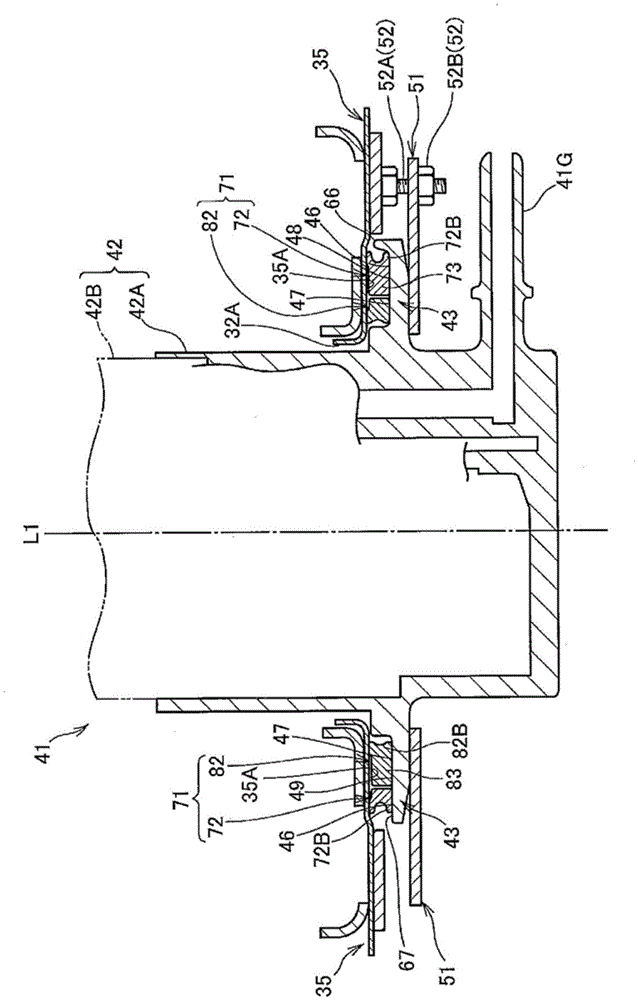

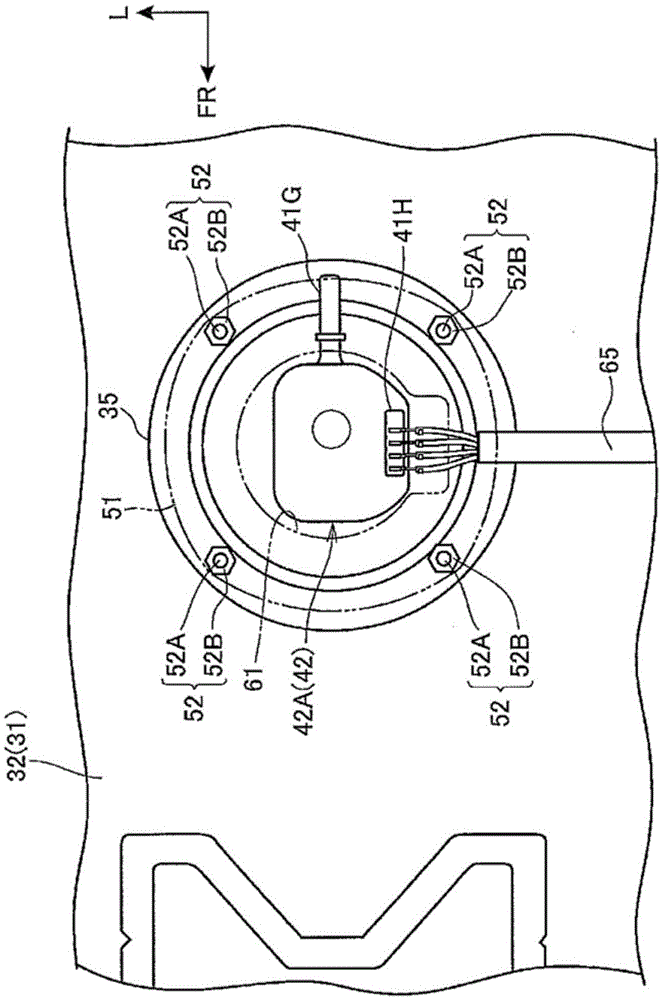

Steering apparatus for outboard motor

ActiveUS20120040572A1Prevent be damageAvoid damagePropulsion power plantsSteering initiationsArm movingSteering angle

Support arms are disposed on a tilting shaft on a bracket of an outboard motor. An electric actuator is mounted between the support arms. The electric actuator includes a cover member, first and second electric motors disposed individually on the opposite ends of the cover member, a feed screw configured to be rotated by the electric motors, a nut member configured to move along an axis as the feed screw rotates, a drive arm configured to move integrally with the nut member and transversely relative to the boat body, and protective boots. The drive arm is connected to a steering arm through an engaging member. If the drive arm moves in the direction of the axis along the cover member, the steering angle of the steering arm changes depending on the degree of movement of the drive arm.

Owner:NHK MEC CORP

Steering apparatus for outboard motor

ActiveUS8419488B2Avoid damageReduce overall outer diameterSteering ruddersSteering initiationsSteering angleControl engineering

Support arms are disposed on a tilting shaft on a bracket of an outboard motor. An electric actuator is mounted between the support arms. The electric actuator includes a cover member, first and second electric motors disposed individually on the opposite ends of the cover member, a feed screw configured to be rotated by the electric motors, a nut member configured to move along an axis as the feed screw rotates, a drive arm configured to move integrally with the nut member and transversely relative to the boat body, and protective boots. The drive arm is connected to a steering arm through an engaging member. If the drive arm moves in the direction of the axis along the cover member, the steering angle of the steering arm changes depending on the degree of movement of the drive arm.

Owner:NHK MEC CORP

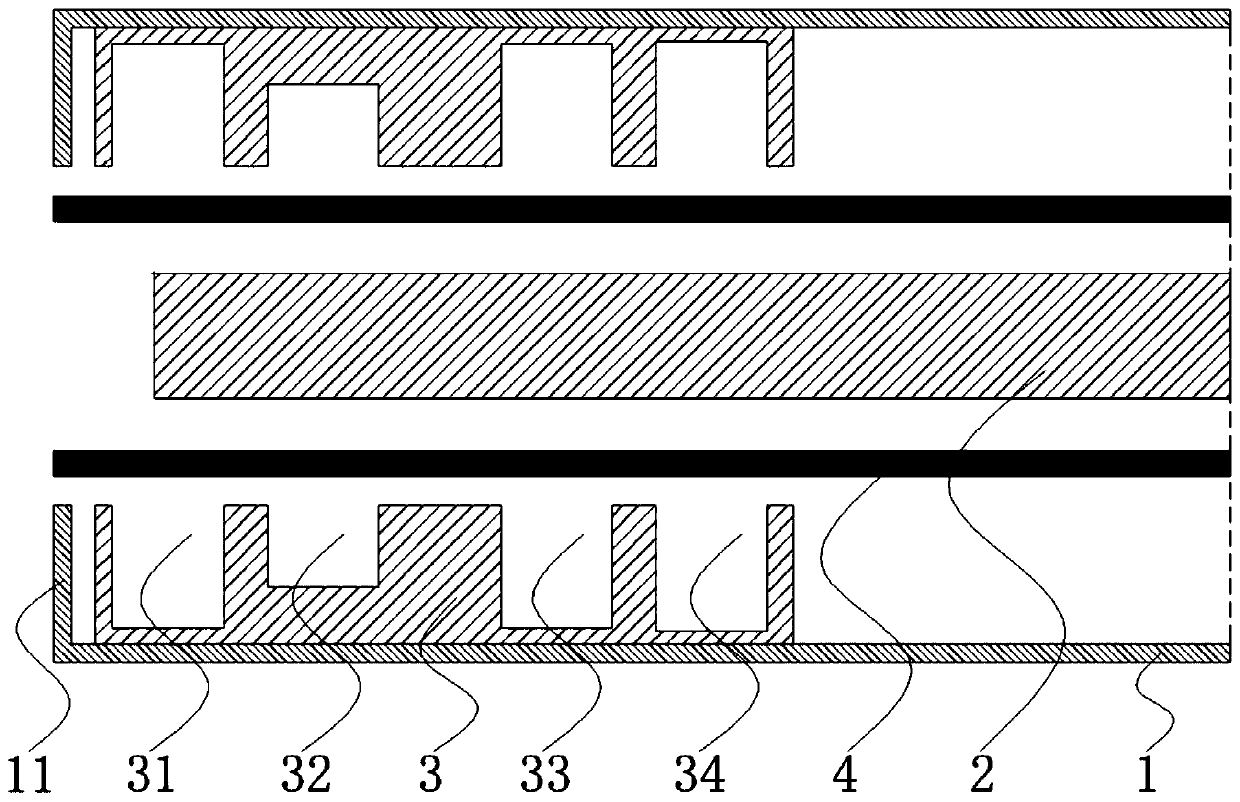

Steering system for outboard engine

ActiveCN103068673ASmall outer diameterAvoid damageSteering ruddersPropulsion power plantsSteering angleEngineering

A bracket (30) for an outboard engine holds a tilt shaft (32) which is supported by support arms (40, 41). Disposed between the support arms (40, 41) is an electric actuator (50). The electric actuator (50) includes: a cover member (51); first and second electric motors (52, 53) disposed at the respective ends of the cover member (51); a feed screw (54) which is rotated by the electric motors (52, 53); a nut member (70) to be moved in the axial direction (X1) by the feed screw (54) being rotated; an actuator arm (71) which is displaced in the direction of width of a hull (11) integrally with the nut member (70); and protective boots (80, 81). The actuator arm (71) is coupled to a steering arm (35) via an engaging member (73). When the actuator arm (71) moves along the cover member (51) in the axial direction (X1), the steering angle of the steering arm (35) varies depending on the amount of movement of the actuator arm (71).

Owner:NHK MEC CORP

High-frequency high-power microwave device

ActiveCN110718426AAffect outputHigh energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. An electron beam transmission channel with an inner diameter of 8mm and an outer diameter of 14.6mm is formed between the inner conductor and the circular waveguide sleeve. A high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the inner diameter of 12mm, the outer diameter of 12.6mm, thevoltage of 400kV and the beam intensity of 7.3kA is transmitted in the high-frequency structure under the guidance of an axial magnetic field with the magnetic field intensity of 1.5T, and high-frequency high-power microwaves with the frequency of 67.4GHz are generated. The high-frequency high-power microwave device is simple in structural size, and has the advantages of being small, light and easy to assemble.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

L-band three-cavity high-power microwave device

ActiveCN110718431ASimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesResonant cavityElectrical conductor

The invention discloses an L-band three-cavity high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A cathode coaxial with the circular waveguide sleeve is arranged at one end in the circular waveguide sleeve. The opening of the cathode is annular, the inner diameter of the cathode is 60mm, and the outer diameter of the cathode is 69mm. The circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter in the electron beamtransmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are annular grooves formed in the circular waveguide sleeve. The axial length of the microwave device is 130mm, the maximum diameter of the microwave device is 150mm, and the diameter of the inner conductor is 40mm. The cathode emits an annular electron beam with the beam intensity of 7.0kA, the innerdiameter of 60mm and the outer diameter of 69mm under a 400KV voltage, the annular electron beam is transmitted in the microwave device under the guidance of a 0.4T axial magnetic field, and L-band high-power microwaves with the frequency of 1.92GHz are generated through radiation within one pulse time. The L-band three-cavity high-power microwave device has the advantages of being small in size,light and easy to adjust.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

S-band three-cavity high-power microwave device

ActiveCN110718430ASimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesResonant cavityMicrowave

The invention discloses an S-band three-cavity high-power microwave device, which comprises a circular waveguide sleeve. The circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter in the electron beam transmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are annular grooves formed in the circular waveguide sleeve. An annular electron beam with the voltage of 400kV and the beam intensity of 7.0kA is transmitted in the microwave device under the guidance of a 0.4T axial magnetic field, and S-band high-power microwaves with the frequency of 2.4GHz are generated through radiation within one pulse time. The S-waveband three-cavity high-power microwave device has the advantages of being small in size, light and easy to adjust.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

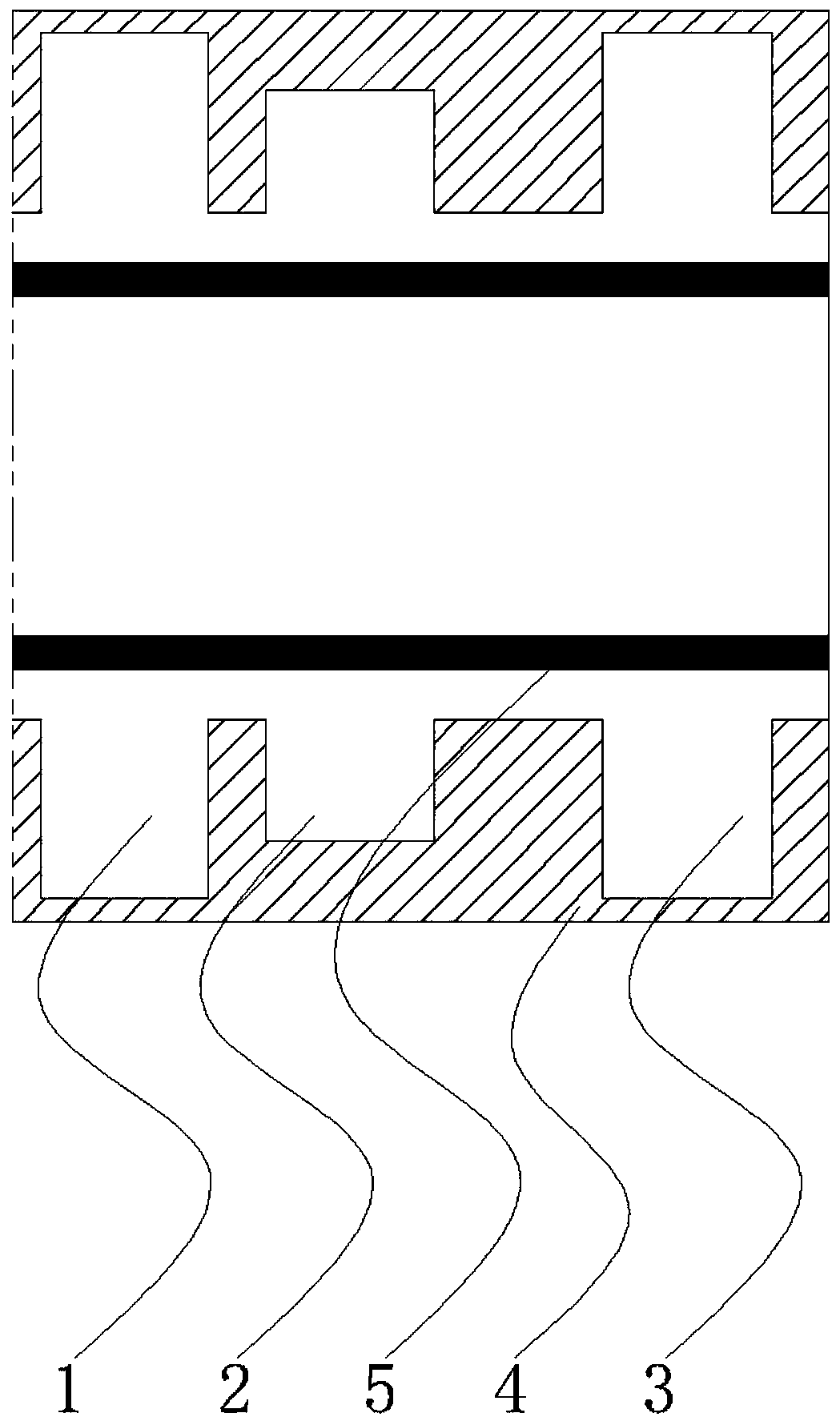

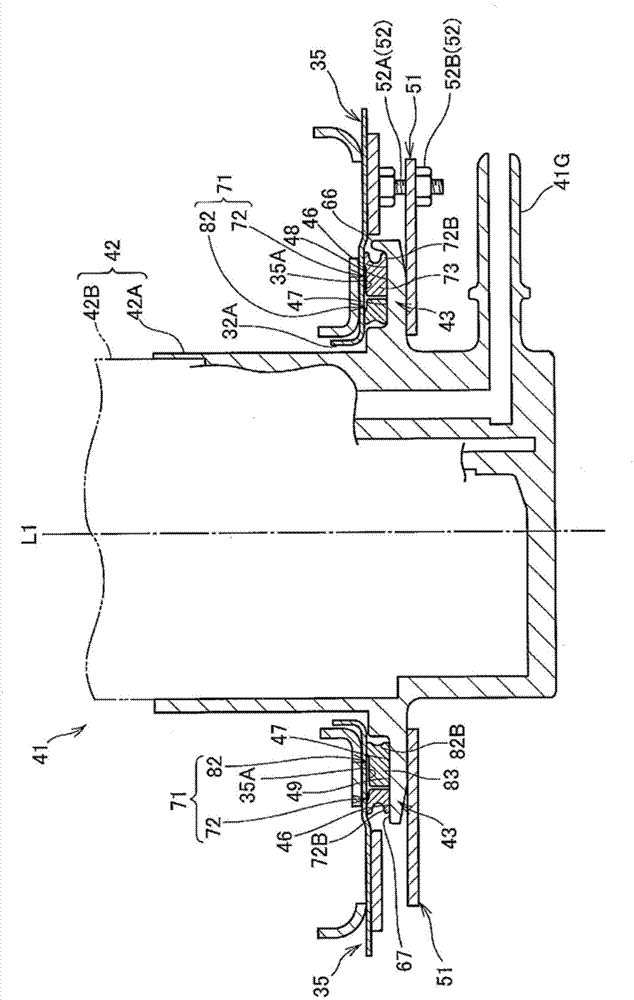

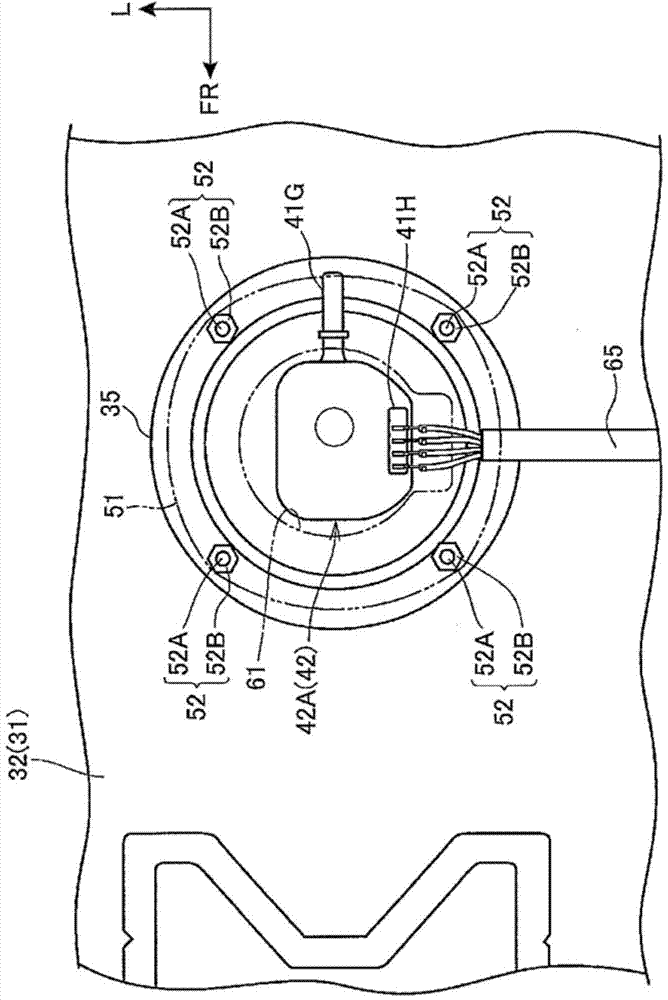

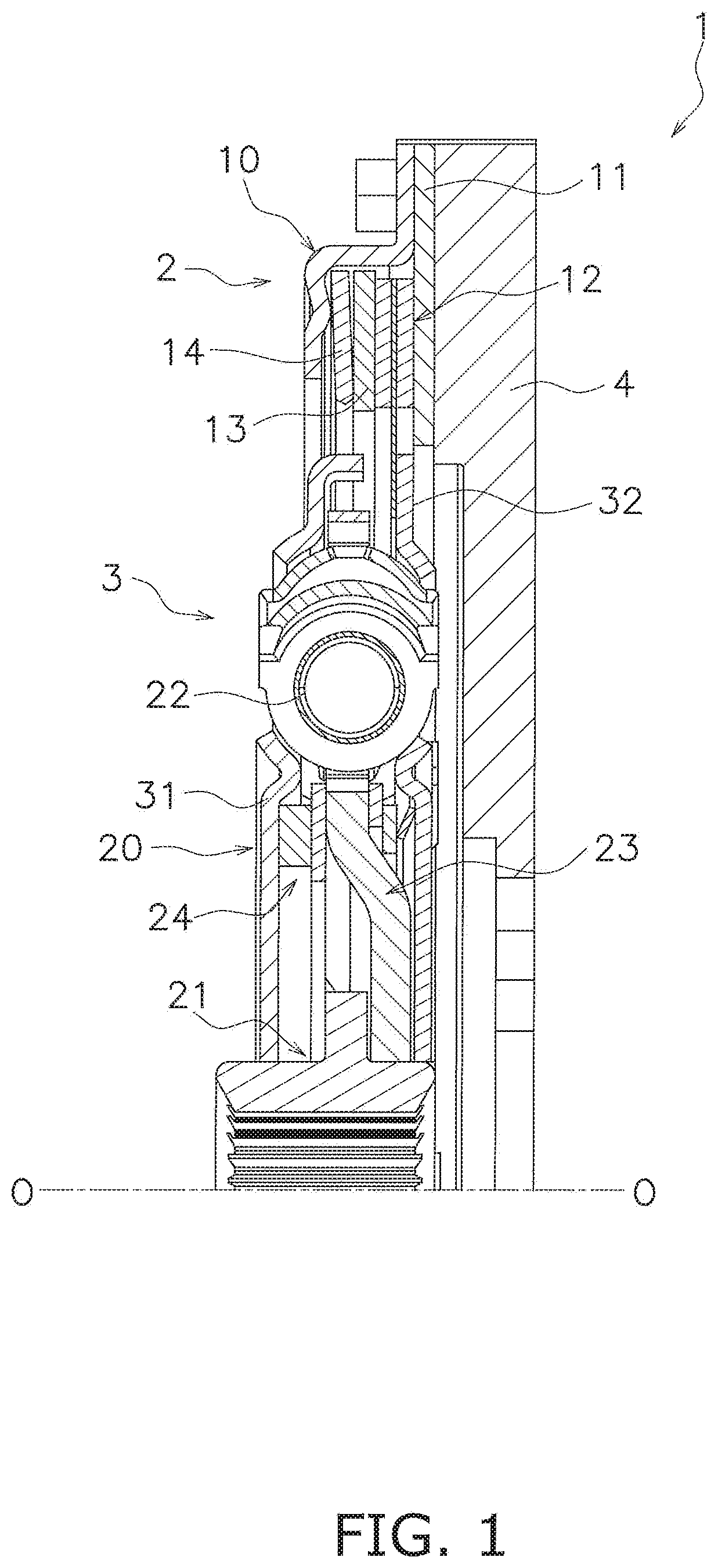

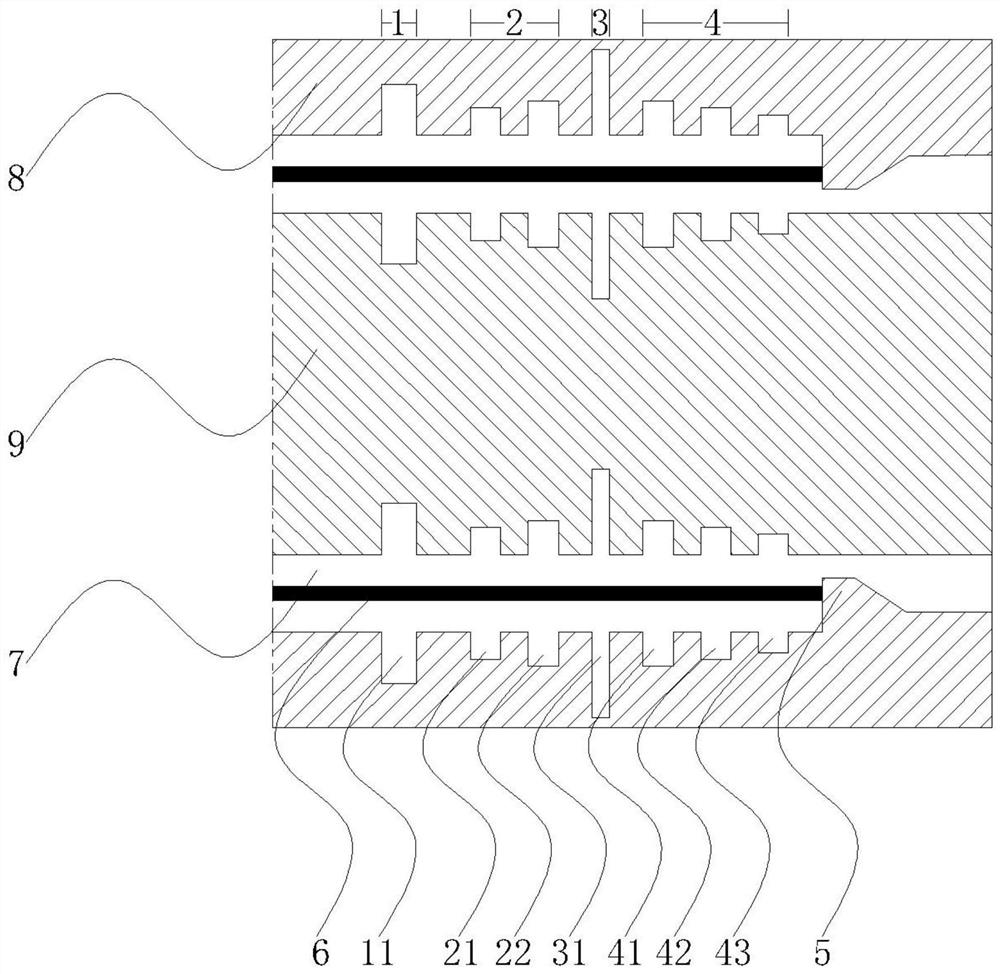

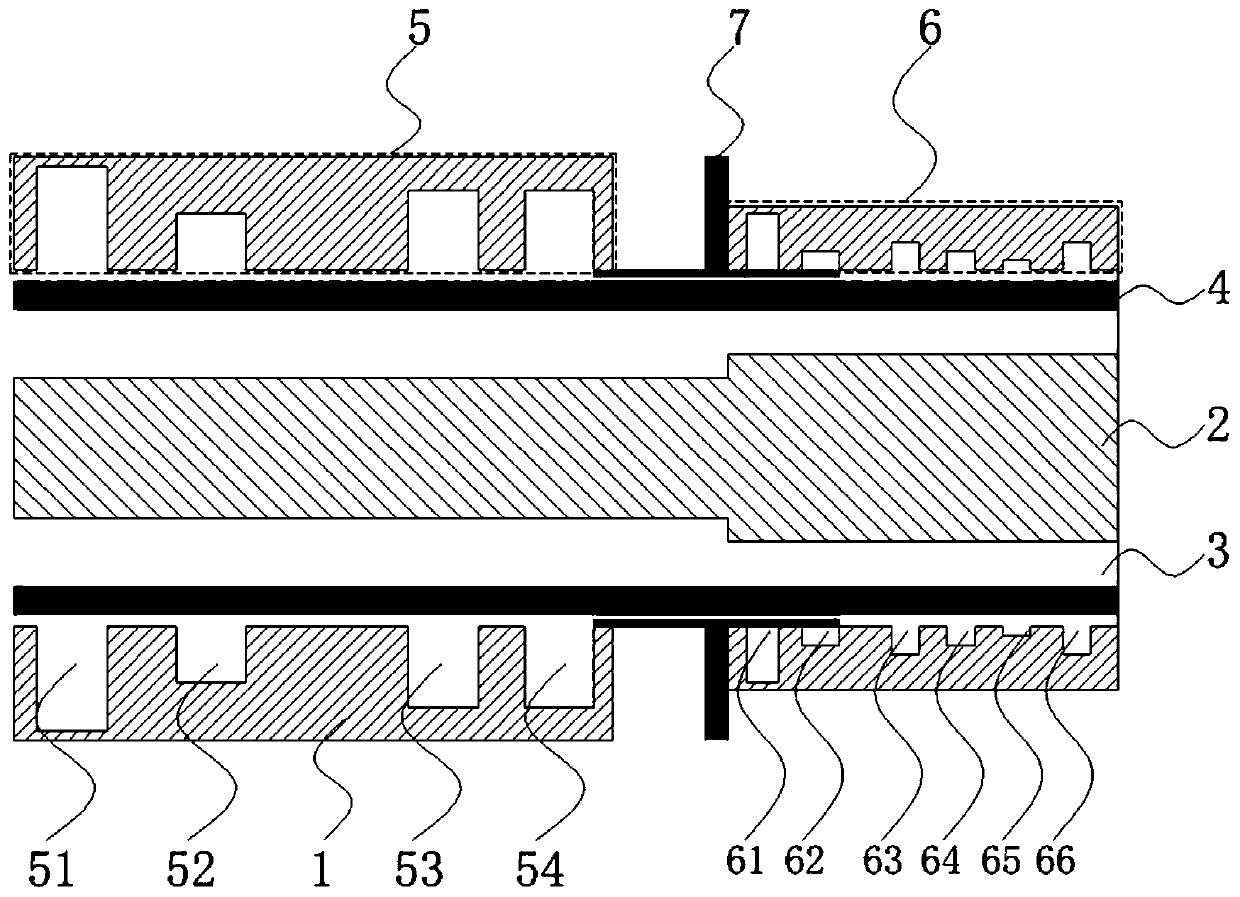

Seal structure for fuel pump

Provided is a seal structure for a fuel pump having a double-seal construction of a separately provided outer seal and inner seal, with which it is possible to improve the ease with which both seals can be assembled, and with which it is possible to employ a compact installation area for the double seal. This double seal (71) is provided between a fuel pump insertion hole and a flange (43) of the fuel pump, and has an outer seal (72) and a separate inner seal (82). Outer seal inward protrusions (73) which protrude radially inward are provided on the outer seal (72), and inner seal outward protrusions (83) which protrude radially outward are provided on the inner seal (82), and slits (48, 49) are provided as positioning parts into which the respective protrusions (73, 83) fit. The protrusions (73, 83) are arranged alternately in the circumferential direction of the seals (72, 82), and are positioned within the same region in the radial direction.

Owner:HONDA MOTOR CO LTD

Coaxial high-frequency high-power microwave device

ActiveCN110718425AAffect outputIncrease beam energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a coaxial high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A high-frequency structure is arranged in the circular waveguide sleeve. The high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. The reflection region, the beam pre-modulation region, the phase modulation region and the beam-wave conversion region are respectively provided with annular groove-shaped cavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor, and thecavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor form a reflection cavity, beam pre-modulation cavities a phase modulation cavity andbeam-wave conversion cavities. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the voltage of 400kV and the current of 9.0kA is transmitted in the microwave device under the guidance of an axial magnetic field with the magnetic field intensity of 1.2T, and 70GHz high-frequency high-power microwaves are generated. By adopting the coaxial high-frequency high-power microwave device, high-frequency high-power microwaves can be generated, and the microwave generation efficiency can be improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

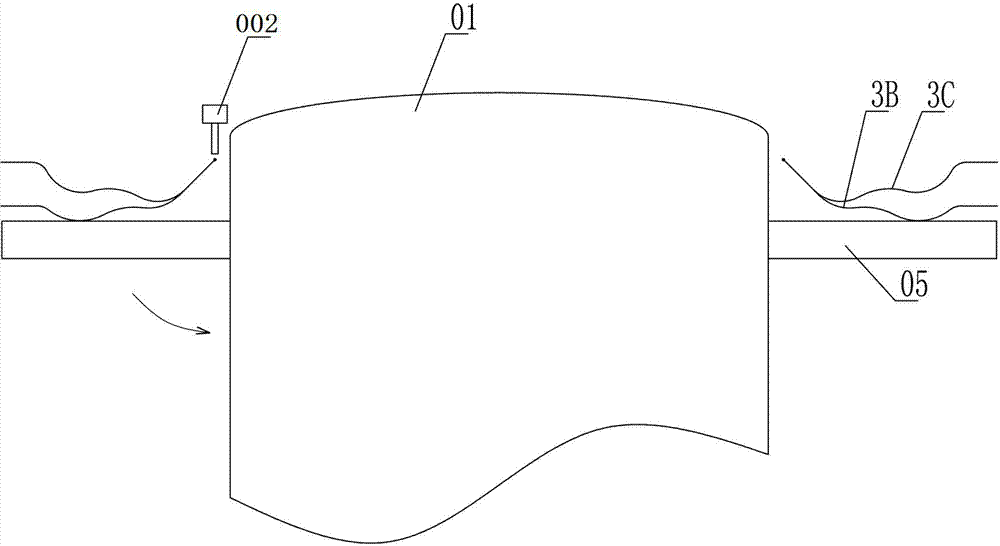

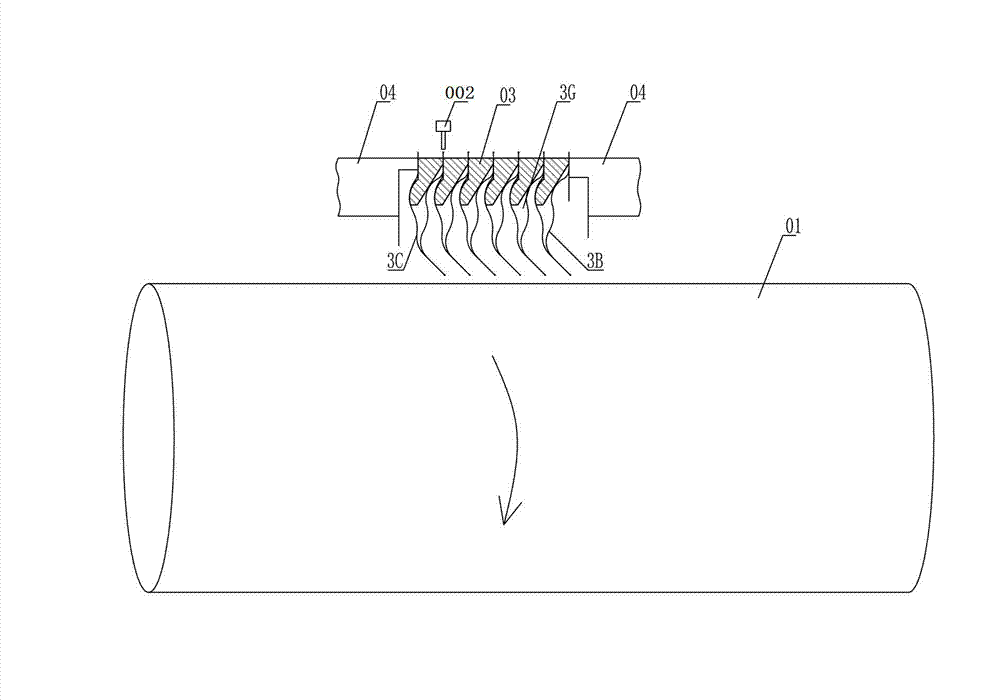

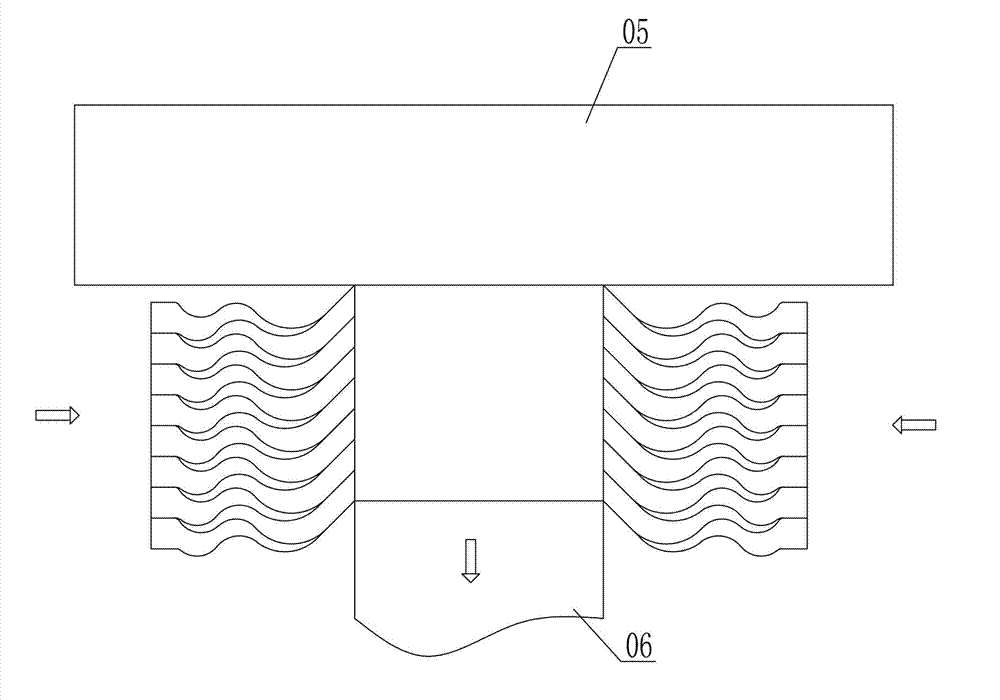

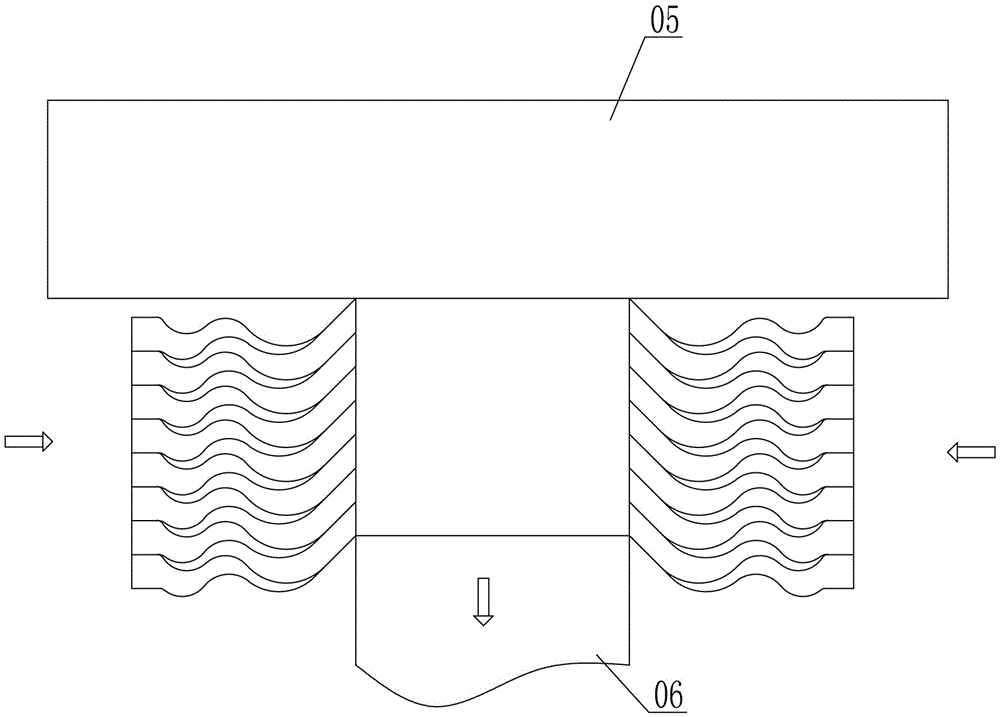

Welding process and application device of corrugated pipe assembly

ActiveCN103753038AHigh strengthImprove cooling effectPump componentsPumpsStructural engineeringMechanical engineering

The invention discloses a welding process and an application device of a corrugated pipe assembly. The welding process includes steps that a, primary and secondary pieces are formed by welding; b, a corrugated pipe core is formed by welding; c, a corrugated pipe is formed by welding; d, the corrugated pipe assembly is formed by welding; a sealing performance test is performed. A corrugated pipe sealing device is characterized by comprising the corrugated pipe assembly, a casing, a stationary ring and a moving ring, wherein the left end of the casing is embedded into a groove face, the stationary ring is arranged in a step surface, the moving ring is attached to the end face of the stationary ring, and a contact face forms a sealing end face. The welding process and the application device of the corrugated pipe assembly have the advantages that the welding efficiency is high, the accuracy is good, the elastic compensation is stable, and the service life is long.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

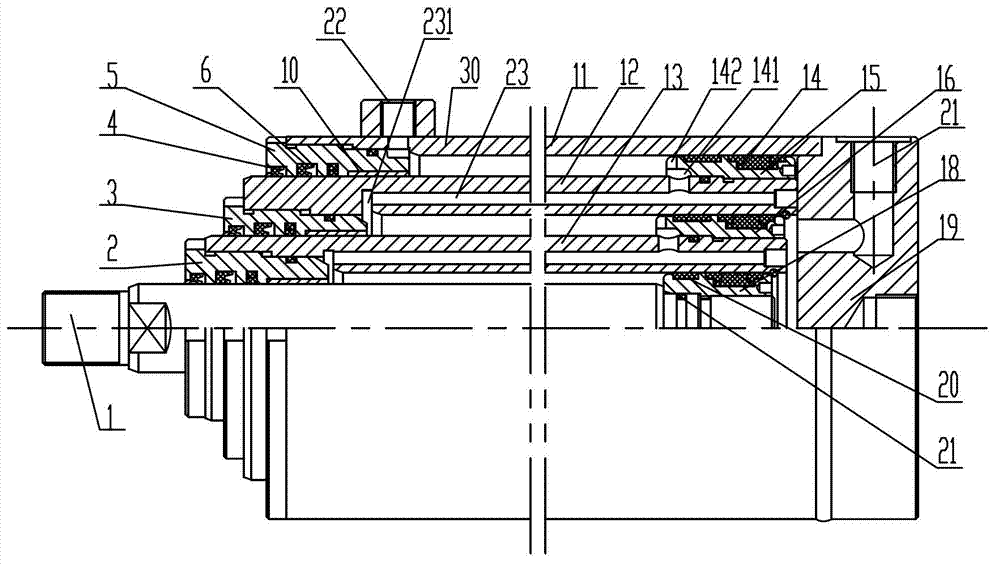

Torque limiter device

PendingUS20200292008A1CompactnessSize andSlip couplingPlural diverse prime-mover propulsion mountingPhysicsEngineering

A torque limiter device for limiting a torque transmitted between a power source-side member and an output-side member is disclosed. The torque limiter device includes a cover, a friction disc and an urging member. The cover includes a coupling portion, a tubular portion and a support portion. The coupling portion is coupled to the power source-side member. The tubular portion axially extends from the coupling portion. The support portion extends from the tubular portion to an inner peripheral side. The friction disc is accommodated in an inner peripheral space of the tubular portion of the cover, and is pressed toward the power source-side member. The urging member is supported by the support portion of the cover, and urges the friction disc toward the power source-side member.

Owner:EXEDY

Steering gear for outboard motors

ActiveCN103068673BSmall outer diameterAvoid damageSteering ruddersPropulsion power plantsEngineeringActuator

Owner:NHK MEC CORP

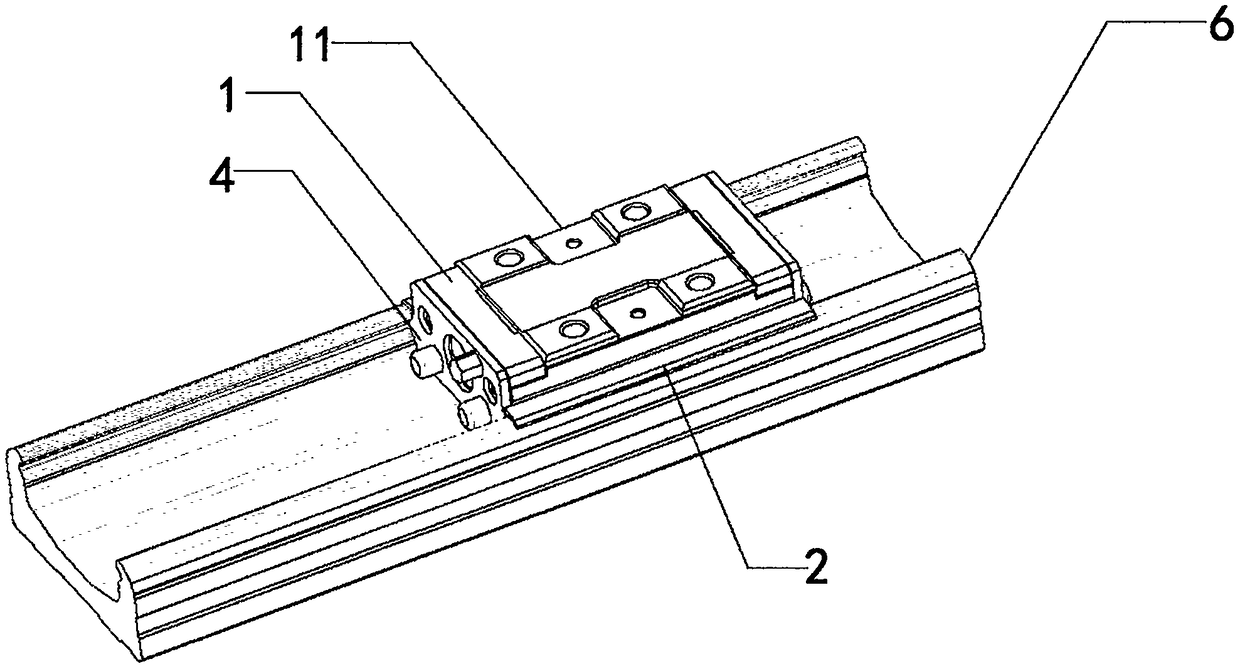

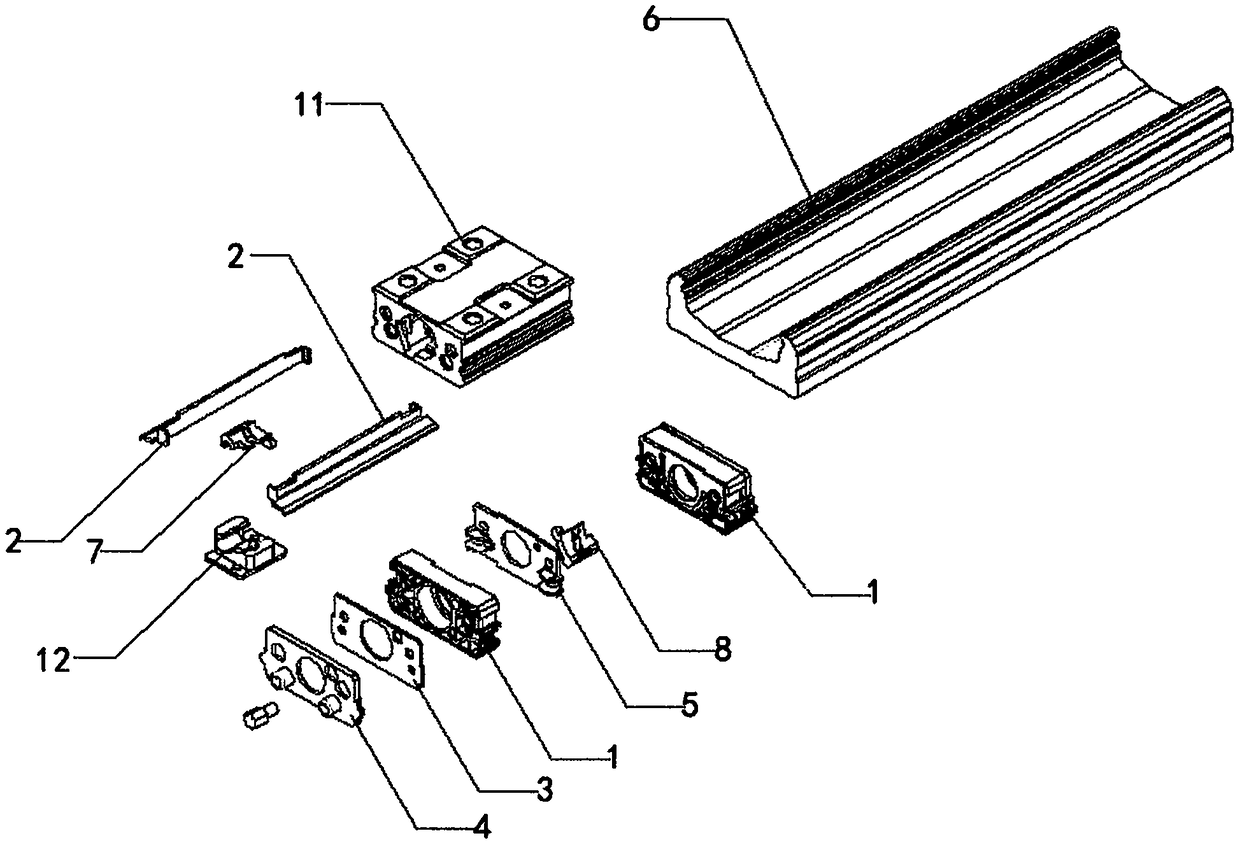

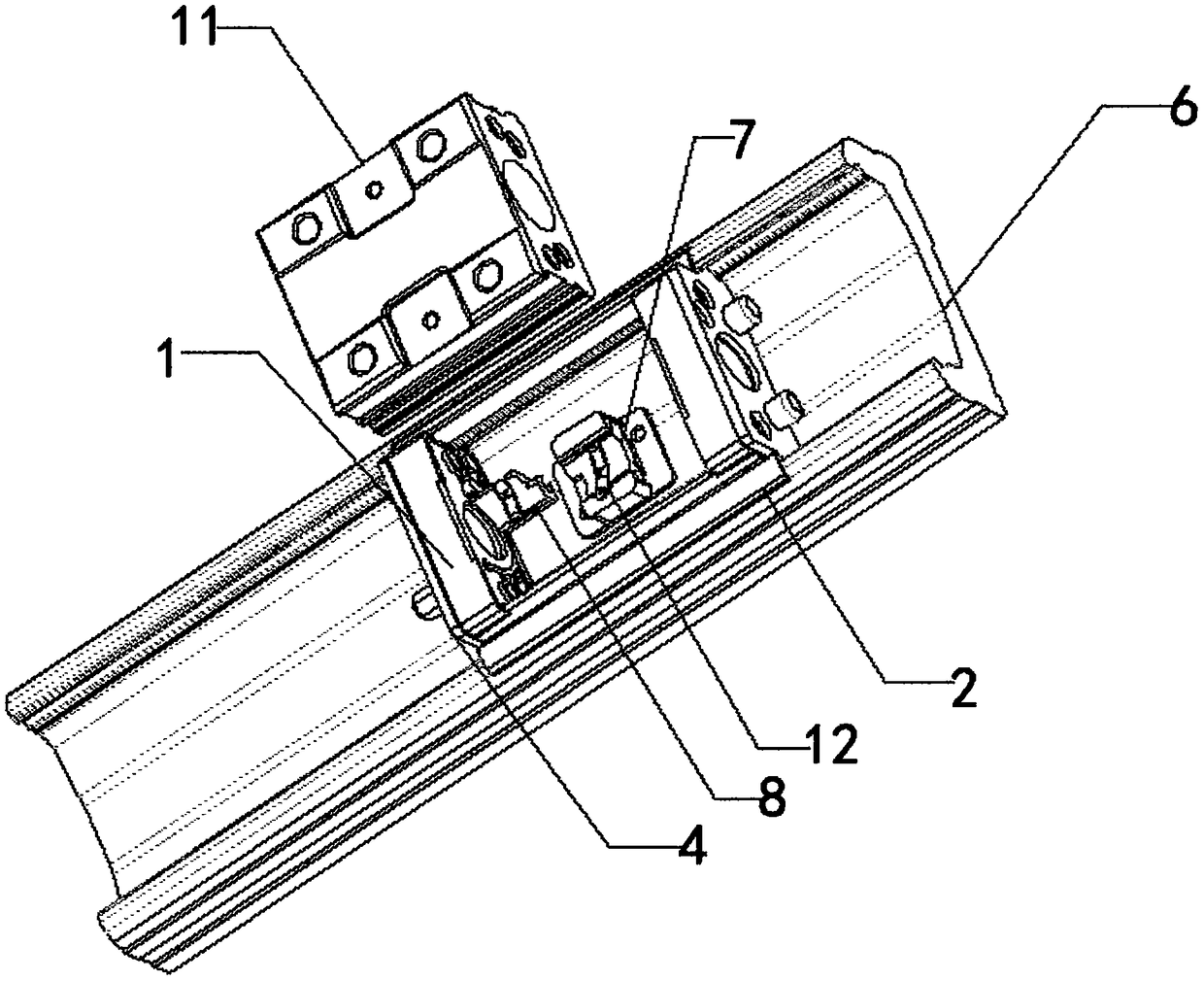

Single-shaft driver

The invention discloses a single-shaft driver. The single-shaft driver comprises a base. A sliding block is arranged on the base. Dust-proof strips are arranged between the two sides of the sliding block and the base. Sliding block outer circulators are arranged at the front end and the rear end of the sliding block. End dust-proof iron pieces and end dust-proof pieces are sequentially arranged onthe outer sides of the two sliding block outer circulators. Sliding block inner circulators are arranged on the inner sides of the sliding block outer circulators. A reverser stop piece is arranged in the bottom of the sliding block. A first lead screw reverser is arranged in the reverser stop piece. Second lead screw reversers are arranged on the inner sides of the sliding block inner circulators. The single-shaft driver is simple in structure, external circulation is replaced with internal circulation to achieve ball circulation through the reversers, the radial size is small, and the rigidity is good; and the return distance to a rollerway is short, so that the friction loss is small; the single-shaft driver is suitable for high-sensitivity and high-precision transmission, and processing the circulating path of the main sliding block is made easy; the reversers are modularized, so that the universality of modules is greatly improved, and the cost is reduced; meanwhile, the production efficiency of the modules is greatly improved; and noise is lowered.

Owner:宁波莱盟机器人有限公司

An L-band three-cavity high-power microwave device

ActiveCN110718431BSimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses an L-band three-cavity high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve; one end of the circular waveguide sleeve is provided with a cathode coaxial with the circular waveguide sleeve, and the cathode The opening of the cathode is ring-shaped, the inner diameter of the cathode is 60mm, and the outer diameter is 69mm; the circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter along the electron beam transmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are The annular groove is set on the circular waveguide sleeve; the axial length of the microwave device is 130mm, the maximum diameter is 150mm, and the diameter of the inner conductor is 40mm; the intensity of the cathode emission beam is 7.0kA under the voltage of 400KV, the inner diameter is 60mm, and the outer diameter is 69mm The circular electron beam is transmitted in the microwave device under the guidance of the axial magnetic field of 0.4T, and the L-band high-power microwave with a frequency of 1.92GHz is radiated within a pulse time. The L-band three-cavity high-power microwave device of the present invention has the advantages of miniaturization, light weight and easy adjustment.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

A high-frequency high-power microwave device

ActiveCN110718426BAffect outputHigh energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a high-frequency and high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. An electronic device with an inner diameter of 8mm and an outer diameter of 14.6mm is formed between the inner conductor and the circular waveguide sleeve. Beam transmission channel; the high-frequency structure is provided with a coaxial reflection area, a beam pre-modulation area, a phase modulation area and a beam conversion area in sequence along the electron beam transmission direction; after the beam conversion area, a radially inwardly protruding annular collector is set ;Reflective area, beam pre-modulation area, phase modulation area and beam conversion area, respectively set annular groove-shaped reflection cavity, beam pre-modulation cavity, phase modulation cavity and beam conversion cavity on the circular waveguide sleeve; inner diameter 12mm , an outer diameter of 12.6mm, a voltage of 400kV, and a beam intensity of 7.3kA are transmitted in a high-frequency structure under the guidance of an axial magnetic field with a magnetic field strength of 1.5T, generating high-frequency and high-power microwaves with a frequency of 67.4GHz. The high-frequency and high-power microwave device of the present invention has the advantages of simple structure size, miniaturization, light weight and easy assembly.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

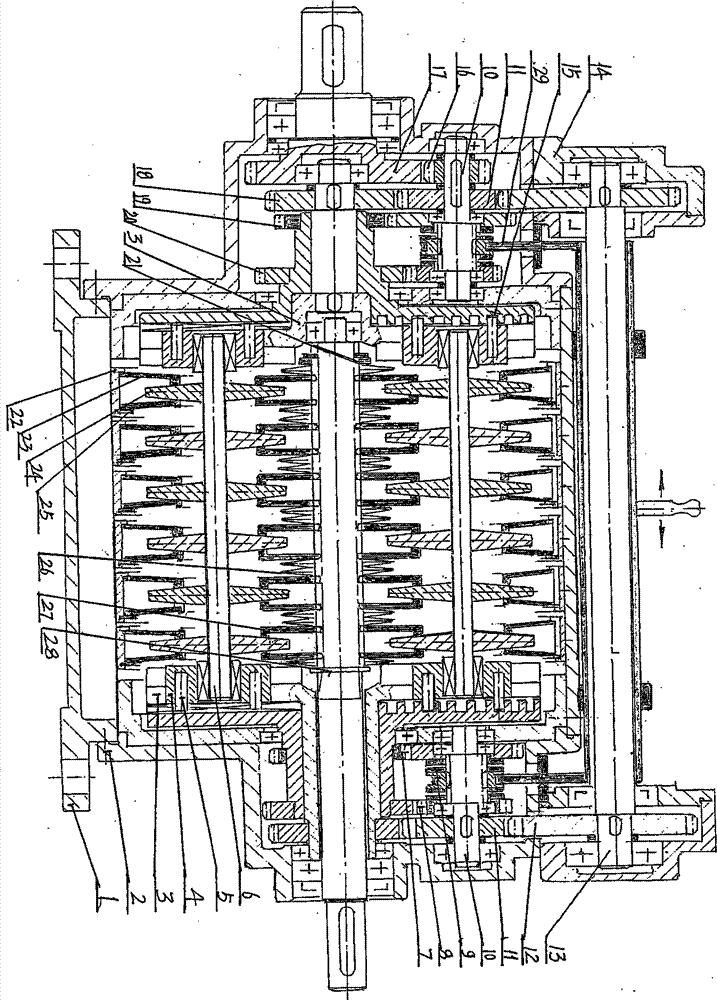

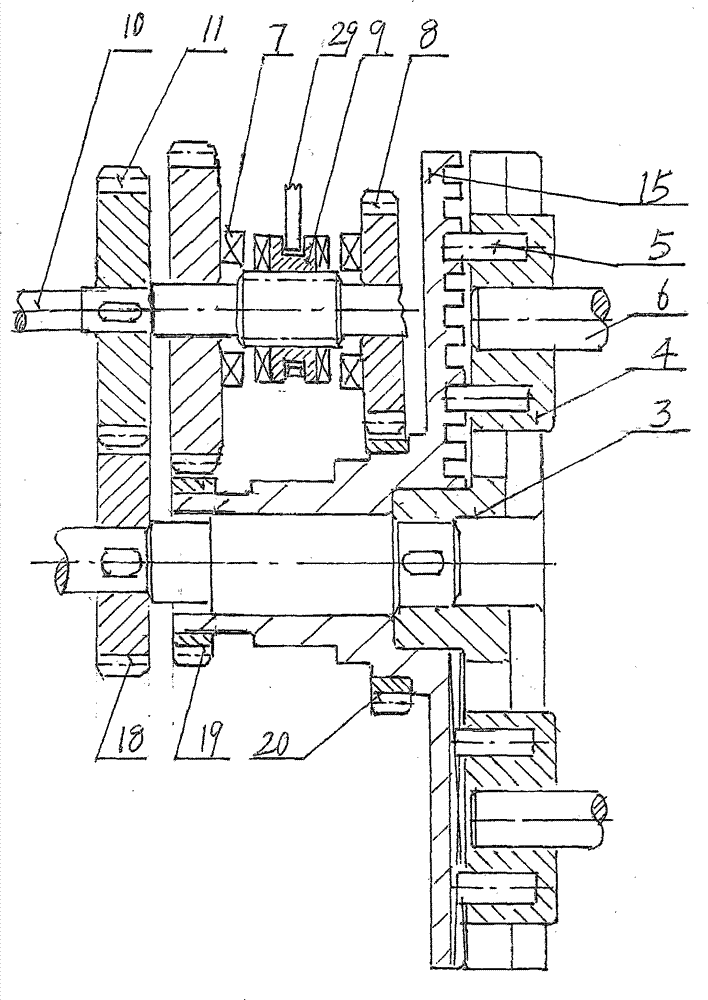

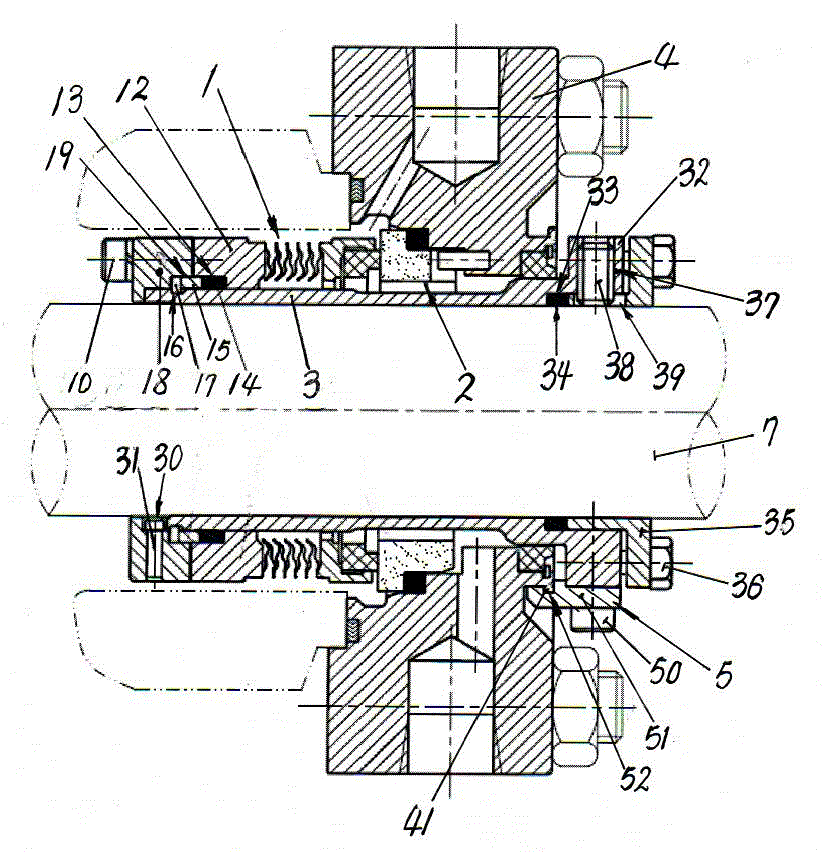

A variable speed transmission mechanism with radial roller screw

ActiveCN104214298BAchieve speed controlStable speedGearingTransmission elementsNumerical controlRoller screw

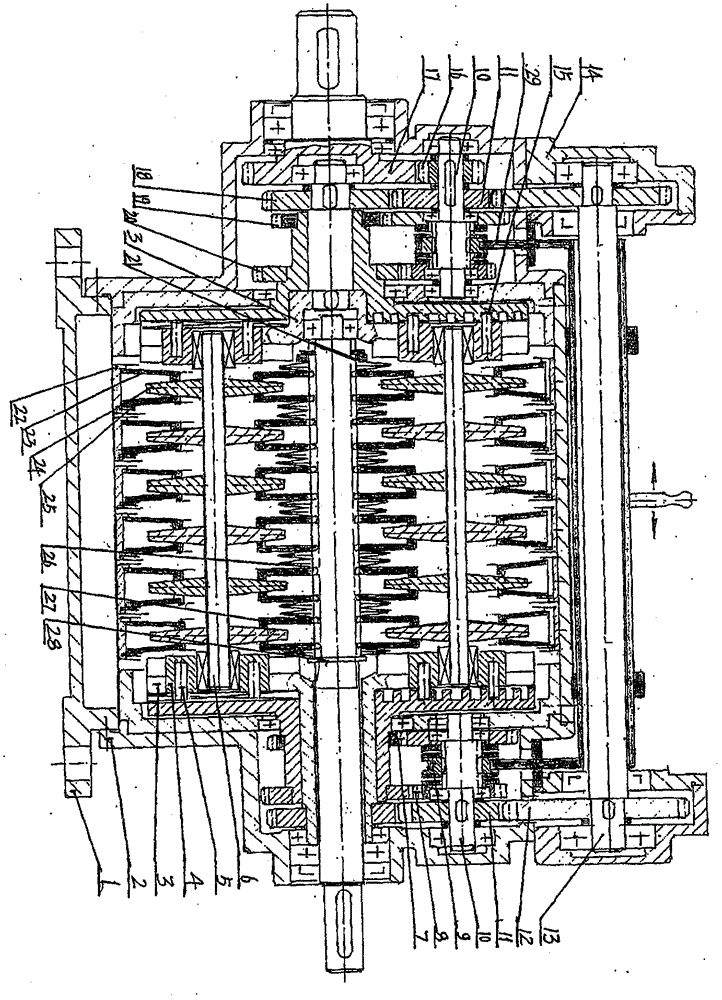

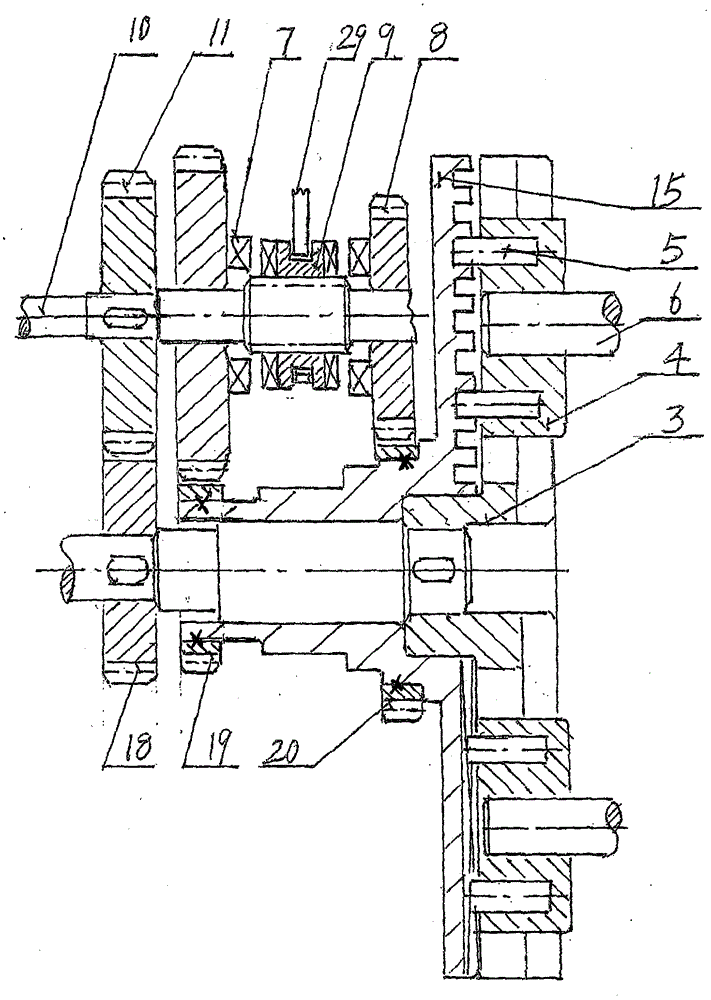

The invention relates to a radial roller screw and a variable-speed transmission thereof. A rotary disc (3), a toothed disc (15), a slide block (4) and a roller (5) are used for sheathing and rotation; when a differential gear is engaged by a clutch, the rotary disc (3) rotates relative to the toothed disc (15), the slide block (4) drives a small center shaft (6) and planetary wheels (24) to do radial displacement, the output rotation speed is gradually increased and decreased, and the stepless variable-speed transmission is realized; a spline shaft (28) is connected with a plurality of pairs of driving wheels (27) to respectively drive several planetary wheels (24); an outer press ring (30) and an outer disc spring (23) are fixedly connected and are arranged in a radial floating sleeve ring to form single-line transmission; the planetary wheels (24) are movably matched and parallelly connected with the small center shaft (6) to form a multi-line distribution beam type cage-shaped revolving body; the planetary wheels (24) are pressed by an inner disc spring and the outer disc spring, and the contact transmission force and torque are proportionally increased and decreased, and are consistently adjusted; the clutch (9) and a shift rod (29) synchronously move left and right at equal amount, and the small center shaft (6) parallelly displaces. Each line of planetary wheels (24) bears the load, so the contact stress is decreased, and the slip rate is reduced. The transmission effect of the high-power and high-efficiency stepless variable speed in automobiles and numerical control machining tools is obvious.

Owner:南通弘铭机械科技有限公司

Radial roller screw and variable-speed transmission thereof

ActiveCN104214298ASpeed adjustment is easy and labor-savingReliable operationGearingTransmission elementsClutchSlip rate

The invention relates to a radial roller screw and a variable-speed transmission thereof. A rotary disc (3), a toothed disc (15), a slide block (4) and a roller (5) are used for sheathing and rotation; when a differential gear is engaged by a clutch, the rotary disc (3) rotates relative to the toothed disc (15), the slide block (4) drives a small center shaft (6) and planetary wheels (24) to do radial displacement, the output rotation speed is gradually increased and decreased, and the stepless variable-speed transmission is realized; a spline shaft (28) is connected with a plurality of pairs of driving wheels (27) to respectively drive several planetary wheels (24); an outer press ring (30) and an outer disc spring (23) are fixedly connected and are arranged in a radial floating sleeve ring to form single-line transmission; the planetary wheels (24) are movably matched and parallelly connected with the small center shaft (6) to form a multi-line distribution beam type cage-shaped revolving body; the planetary wheels (24) are pressed by an inner disc spring and the outer disc spring, and the contact transmission force and torque are proportionally increased and decreased, and are consistently adjusted; the clutch (9) and a shift rod (29) synchronously move left and right at equal amount, and the small center shaft (6) parallelly displaces. Each line of planetary wheels (24) bears the load, so the contact stress is decreased, and the slip rate is reduced. The transmission effect of the high-power and high-efficiency stepless variable speed in automobiles and numerical control machining tools is obvious.

Owner:南通弘铭机械科技有限公司

Spring damping vibration isolator

ActiveCN101825152BImprove waterproof performanceRadial dimensions are compactLiquid based dampersSocial benefitsVibration control

The invention belongs to the field of vibration control, and particularly relates to a spring damping vibration isolator for isolating vibrations. The spring damping vibration isolator comprises an upper support plate, an elastic element and a lower support plate, wherein the elastic element is positioned between the upper support plate and the lower support plate; a damping cylinder is arranged below the lower support plate; a liquid damping material is arranged in the damping cylinder; a movable body linked with the upper support plate or lower support plate is arranged in the damping cylinder; and at least part of the movable body is arranged in the liquid damping material. In the invention, the damping cylinder and the movable body are independently arranged under the elastic element,thereby greatly enhancing the system damping, and overcoming the defect of limited contact area of spring and damping material restricted by the space in the damping cylinder in the prior art; and the invention strengthens the sealing performance, thereby greatly enhancing the waterproof property of the vibration isolator. The invention has the advantages of simple structure, stable property and strong applicability, can be widely used for damping in the fields of machinery, rail transportation, bridges, architectural structures and the like, and has obvious economic and social benefits.

Owner:尹学军

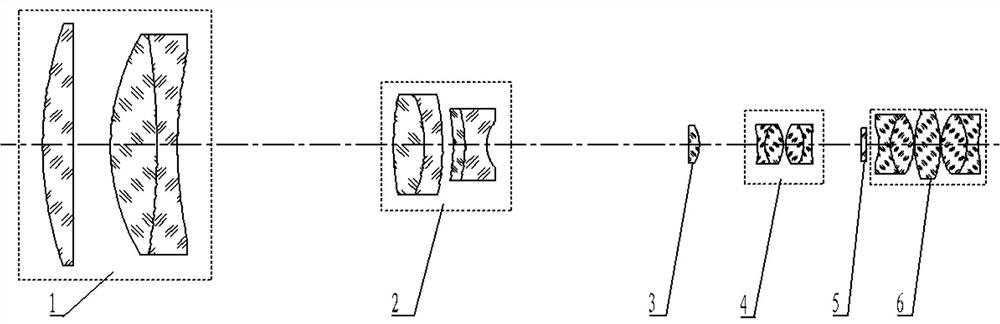

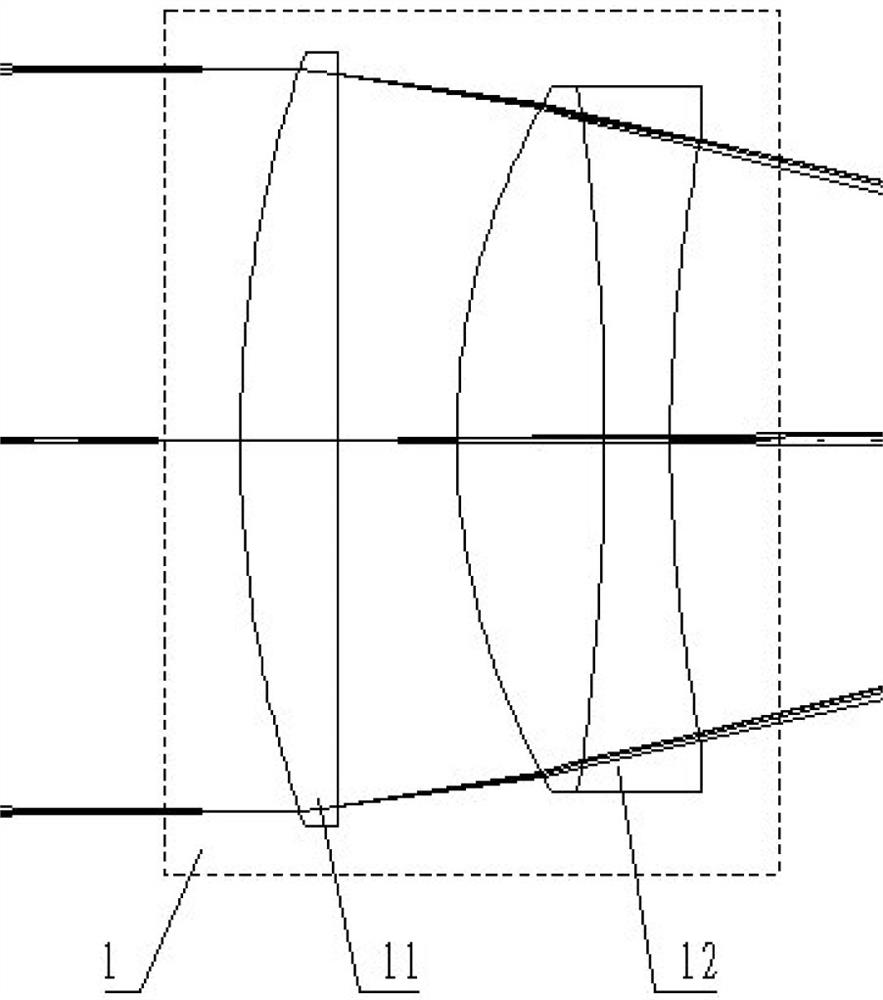

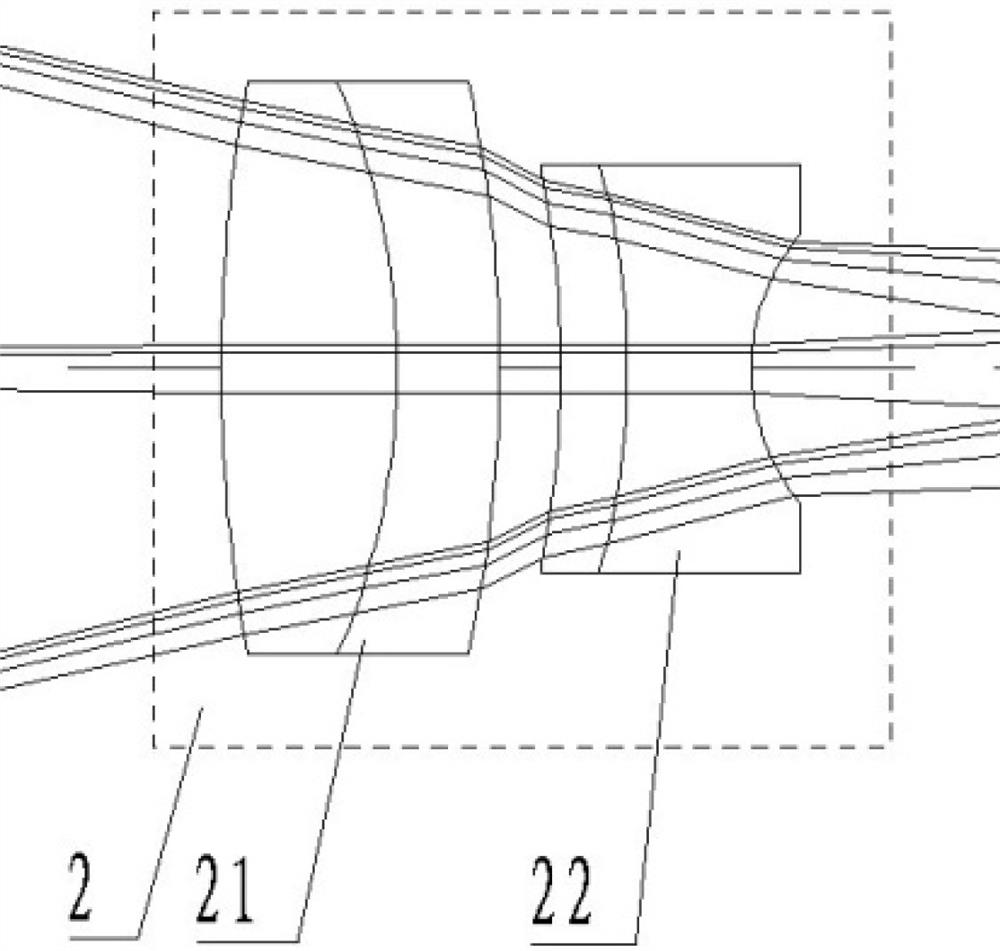

A high magnification compact telescopic sight optical system

ActiveCN109884777BAchieving High Precision AimingRadial dimensions are compactMagnifying glassesEyepieceOphthalmology

The invention discloses a high-magnification compact telescopic sight optical system, which comprises an objective lens group, a focusing lens group, a field lens, an image transfer lens group, a reticle and an eyepiece group on the same optical axis, and is parallel to infinity. The light passes through the chromatic aberration correction objective lens group from the object surface to form a converging light, which is converged into an inverted image point through the focusing lens group, forms a divergent light, and passes through a high-power field lens to greatly compress the beam height, and then forms a converging light again and passes through the image transfer lens group. Make the image of the reticle converged on the reticle to form a secondary positive image point, and finally the human eye observes the scene enlarged by the angle through the large field of view eyepiece group of the Elver eyepiece structure. The present invention adopts an internal focusing structure, which has very good sealing performance, and can be observed at a close distance without a deflection system. The consistency of the optical axis of the reticle is very high, and it can directly form a positive real image for the human eye and the ability to collect light energy. Strong, high magnification.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

A double-acting multi-stage hydraulic cylinder with a solid piston rod

InactiveCN102852896BEasy to processStraightness is easy to guaranteeFluid-pressure actuatorsHydraulic cylinderReciprocating motion

The invention relate to a double-action multistage hydraulic oil cylinder with a solid piston rod. The hydraulic oil cylinder comprises a first-stage cylinder sleeve, pistons, the piston rod and a plurality of stages of inner cylinder sleeves including a tail-stage cylinder sleeve. The piston rod is arranged in the tail-stage cylinder sleeve and is a solid rod. An oil feeding hole is arranged at the bottom end of the first-stage cylinder sleeve, and an oil discharging hole is arranged at the other end. A piston is fixed outside one end of each stage of inner cylinder sleeve close to the oil feeding hole, each stage of inner cylinder sleeve is provided with an oil guide hole which is a through hole communicating the inside and the outside of the inner cylinder sleeve, two outlets are located on the same side of the pistons and arranged , the outlet on the outer wall is close to the pistons, and the outlet arranged on the inner wall is arranged at the end far away from the piston. An oil pipe of the oil cylinder is not stretched, shortened or bended with reciprocating movement of the tail-stage piston rod, so that the oil cylinder prevents the oil pipe from being collided and interfered with the tail-stage piston rod in reciprocating movement and being abraded. The piston rod is of a solid structure, and is better in rigidity, low in processing cost and compact in radial size.

Owner:沈姝君

Fuel pump seal structure

The invention provides a sealing structure of a fuel pump. The sealing structure of the fuel pump is a double sealing structure in which an outer seal and an inner seal are separately arranged, which can make the assembly of the two seals good, and can make the installation area of the double seal compact. . A double seal (71) is provided between the fuel pump insertion port and the fuel pump flange (43). The double seal (71) includes an outer seal (72) and an inner seal (82) separate from the outer seal (72). ), the outer seal (72) is provided with an outer seal inner protrusion (73) protruding radially inward, and the inner seal (82) is provided with an inner seal outer protrusion (83) protruding radially outer ), are provided with cutouts (48, 49) that become positioning portions embedded with each protruding portion (73, 83), and each protruding portion (73, 83) is arranged alternately along the circumferential direction of the seal (72, 82), and in radially within the same width.

Owner:HONDA MOTOR CO LTD

A coaxial high-frequency high-power microwave device

ActiveCN110718425BAffect outputIncrease beam energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a coaxial high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A high-frequency structure is arranged inside the circular waveguide sleeve; The coaxial reflection area, beam pre-modulation area, phase modulation area and beam conversion area are set in sequence in the transmission direction; the reflection area, beam pre-modulation area, phase modulation area and beam conversion area are respectively located on the wall and inner An annular groove-shaped cavity is arranged at the corresponding position of the conductor, and the wall of the circular waveguide sleeve and the cavity at the corresponding position of the inner conductor constitute a reflection cavity, a beam pre-modulation cavity, a phase modulation cavity and a beam conversion cavity; after the beam conversion area Set radially inwardly protruding ring-shaped collectors; the ring-shaped electron beam with a voltage of 400kV and a current of 9.0kA is transmitted in the microwave device under the guidance of an axial magnetic field with a magnetic field strength of 1.2T, generating 70GHz high-frequency and high-power microwaves. The coaxial high-frequency high-power microwave device of the present invention can generate high-frequency high-power microwaves, and effectively improves the microwave generation efficiency.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

C-band and X-band double-frequency controllable compact high-power microwave device

ActiveCN111540658AAxial dimensions are compactRadial dimensions are compactTravelling-wave tubesTransit-tube cathodesWave structureElectrical conductor

The invention discloses a C-band and X-band double-frequency controllable compact high-power microwave device. The microwave device comprises aperiodic C-band and X-band slow-wave structures which aresequentially arranged and comprise coaxial inner conductors, a metal circular waveguide capable of moving axially is arranged between the C-band slow-wave structure and the X-band slow-wave structure, and part of the cavity of the C-band slow-wave structure or the X-band slow-wave structure can be directionally covered by controlling the axial position of the metal circular waveguide; the ratio of the total axial length of the C-band slow-wave structure to the C-band radiation wavelength is 1.6, the ratio of the total axial length of the X-band slow-wave structure to the X-band radiation wavelength is 1.97, and the inner diameter of the microwave device is 76 mm. Annular electron beams with the voltage of 380kV, the current of 6kA, the inner diameter of 60mm and the outer diameter of 70mmare transmitted in the microwave device under the guidance of a 0.63 T magnetic field, and 4GHz or 8GHz high-power microwaves are generated through controllable radiation. By adopting the C-band andX-band double-frequency controllable compact high-power microwave device provided by the invention, radiation can be controlled to generate 4GHz or 8GHz high-power microwaves.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

S-band and C-band double-frequency controllable high-power microwave device

ActiveCN111540656ALower energy requirementsAxial dimensions are compactTravelling-wave tubesTransit-tube cathodesWave structureMicrowave

The invention discloses an S-band and C-band double-frequency controllable high-power microwave device, an inner conductor and a four-cavity slow-wave structure which are coaxial are arranged in the microwave device, and the left end of the microwave device is provided with a circular ring closed structure with the same inner diameter as the four-cavity slow-wave structure; the relative position of the four-cavity slow-wave structure in the microwave device can be axially adjusted, the total axial length of the four-cavity slow-wave structure is 170mm, and the inner diameter of the four-cavityslow-wave structure is 76mm; when the axial distance between the rightmost end of the four-cavity slow wave structure and the leftmost end of the inner conductor is adjusted to be 240 mm, an annularelectron beam is transmitted and radiated in the microwave device to generate S-band high-power microwaves; when the axial distance between the rightmost end of the four-cavity slow-wave structure andthe leftmost end of the inner conductor is adjusted to be 162.5 mm, the annular electron beam is transmitted in the microwave device, and C-band high-power microwaves are generated through radiation.By adoption of the S-band and C-band double-frequency controllable high-power microwave device, S-band and C-band controllable high-power microwave output can be achieved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Integrated bellows mechanical seal for pumps

ActiveCN103233910BOvercoming deformationImprove structural performancePump componentsPumpsClassical mechanicsStructural engineering

Owner:DANDONG COLOSSUS GROUP

A s-band three-cavity high-power microwave device

ActiveCN110718430BSimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesResonant cavityMicrowave

The invention discloses an S-band three-cavity high-power microwave device, which includes a circular waveguide sleeve, and the circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter along the electron beam transmission direction. The cavity, resonant cavity and extraction cavity are annular grooves arranged on the circular waveguide sleeve; the annular electron beam with a voltage of 400kV and a beam intensity of 7.0kA is transmitted in the microwave device under the guidance of an axial magnetic field of 0.4T. One pulse time Internal radiation generates S-band high-power microwaves with a frequency of 2.4GHz. The S-band three-cavity high-power microwave device of the invention has the advantages of miniaturization, light weight and easy adjustment.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Welding process and application device of bellows assembly

ActiveCN103753038BHigh strengthImprove cooling effectPump componentsPumpsStructural engineeringWelding process

The invention discloses a welding process of a corrugated pipe assembly and an application device thereof. The welding process steps include: a. welding to form a master piece; b. welding to form a corrugated tube core; c. welding to form a corrugated tube; d. welding to form a corrugated tube Tube assembly; leak test. A bellows sealing device, characterized in that it includes a bellows assembly, a casing, a static ring and a moving ring, wherein: the left end of the casing is embedded in a groove surface, the static ring is arranged in a step surface, and the The moving ring is arranged close to the end face of the static ring, and the contact surface forms a sealing end face. High welding efficiency, good precision, stable elastic compensation and long service life.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

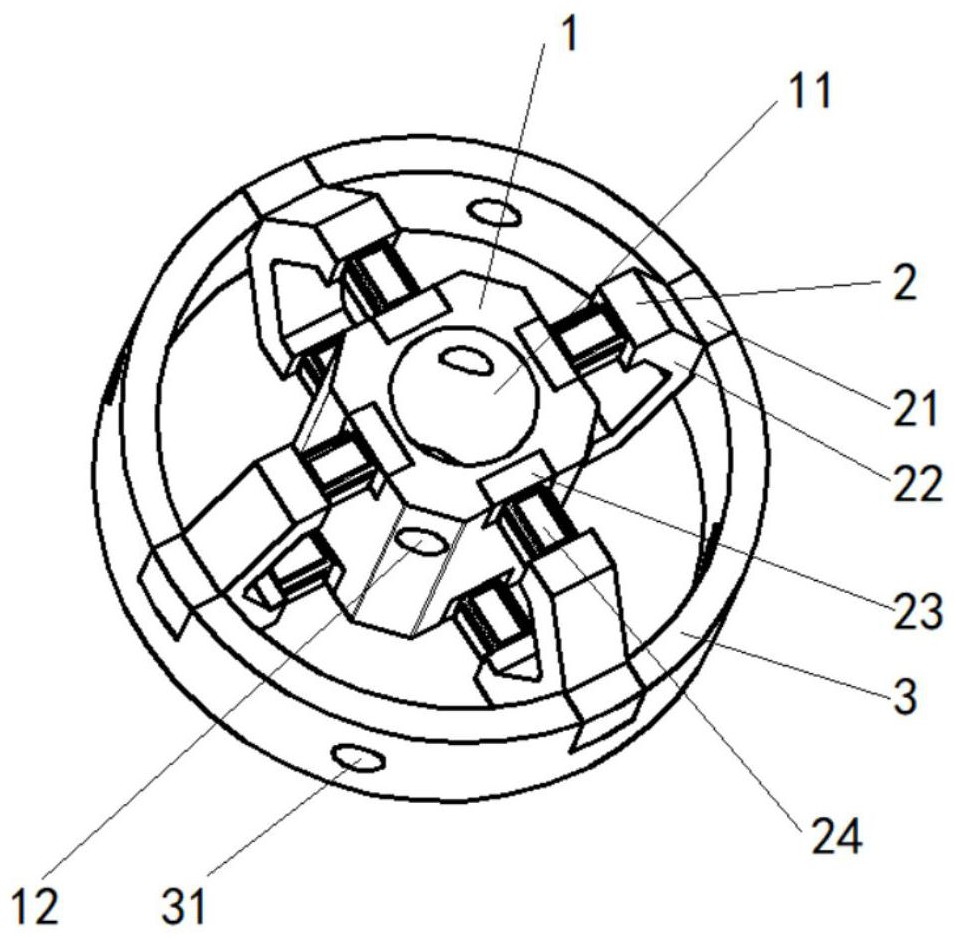

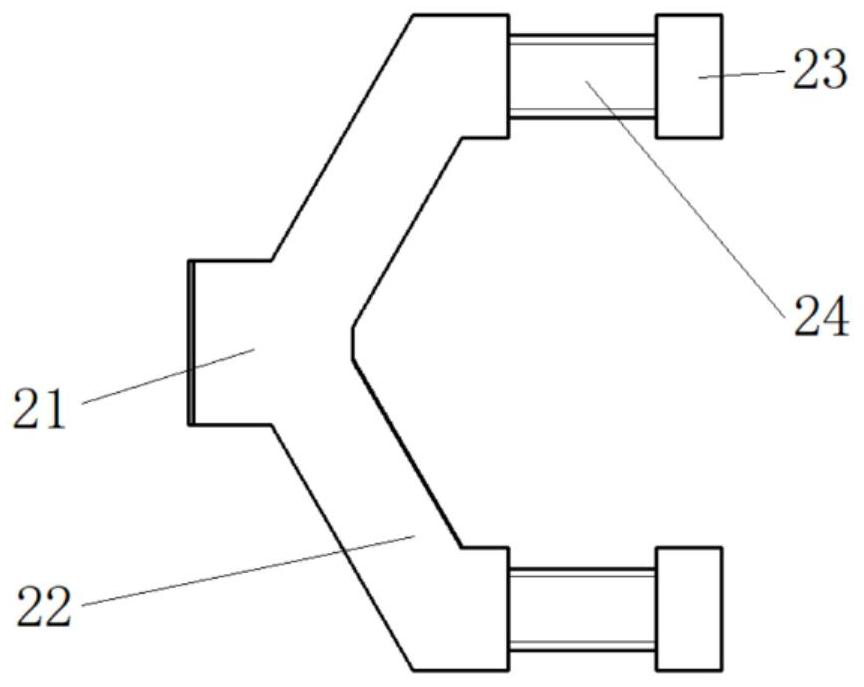

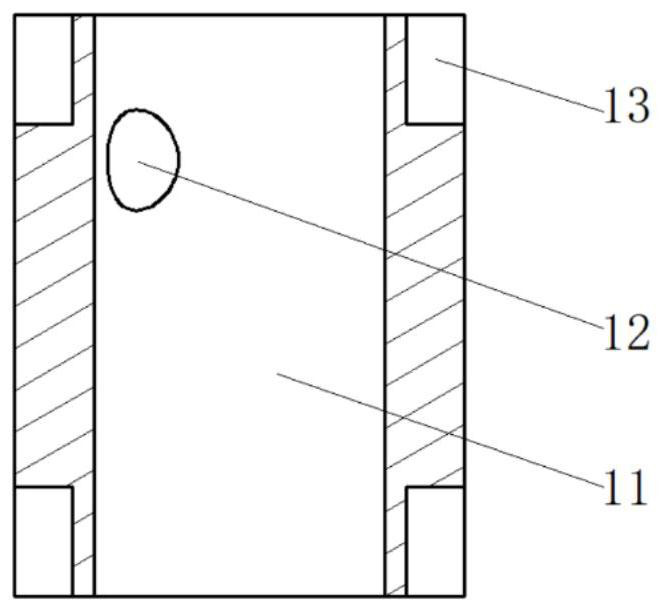

A three-component force sensor for measuring the load at the joint of automobile suspension bushing

InactiveCN110987271BRadial dimensions are compactEasy to installApparatus for force/torque/work measurementStrain gaugeForce sensor

The invention discloses a three-component force sensor for measuring the load at the joint of the automobile suspension bushing. It includes a tubular connector, an annular connector and four Y-shaped elastic elements. The four Y-shaped elastic elements are elastic elements with the same structure, and are arranged symmetrically at intervals of 90° along the circumferential direction. The Y-shaped elastic element includes an internal fixed end, a strain beam, a Y-shaped connecting beam, and an external fixed end. Strain gauges are fixed on the strain beam. The tubular connecting piece includes an internal connection hole, an internal groove, and top wire holes on both sides. The annular connecting piece includes an external groove connected with the Y-shaped elastic element and a threaded hole connected with the test piece. The invention has the advantages of improving the level of local measurement stress while ensuring the connection rigidity, and at the same time eliminating the collection error caused by the misalignment of the load.

Owner:SOUTH CHINA UNIV OF TECH +1

A dual-frequency three-cavity high-power microwave device

ActiveCN110718429BSimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesMicrowaveElectrical conductor

The invention discloses a dual-frequency three-cavity high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve; one end of the circular waveguide sleeve is provided with a cathode coaxial with the circular waveguide sleeve, and the cathode The opening of the cathode is ring-shaped, the inner diameter of the cathode is 60mm, and the outer diameter is 70mm; the circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter along the electron beam transmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are The annular groove set on the wall of the circular waveguide sleeve; the axial length of the microwave device is 130mm, the maximum diameter is 150mm, and the diameter of the inner conductor is 40mm; the cathode emits an annular electron beam with a beam intensity of 7.0kA at a voltage of 400KV. The beam is transmitted in the microwave device under the guidance of the axial magnetic field of 0.4T, and the dual-frequency high-power microwaves with frequencies of 1.92GHz and 2.2GHz can be radiated simultaneously within one pulse time. The dual-frequency three-cavity high-power microwave device of the present invention has the advantages of miniaturization, light weight and easy adjustment.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com