A double-acting multi-stage hydraulic cylinder with a solid piston rod

A hydraulic cylinder and piston rod technology, applied in the field of hydraulic cylinders, can solve the problems of collision interference and wear of the final piston rod, and achieve the effects of compact radial size, energy saving and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

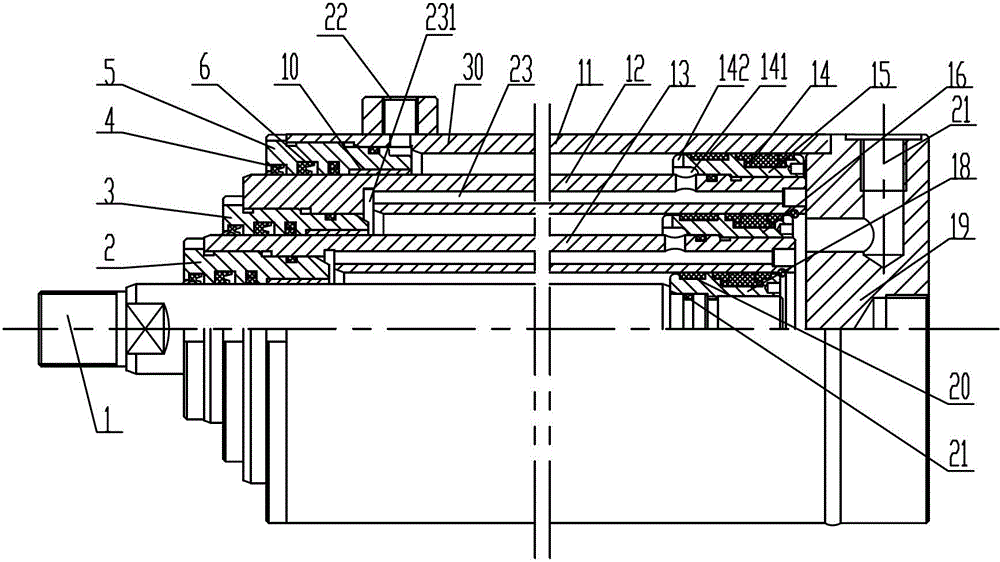

[0019] Embodiment: A double-acting multi-stage hydraulic cylinder with solid piston rod of the present invention, as attached figure 1 As shown, it includes a first-stage cylinder liner 30, a first-stage piston 15, a piston rod 1 and several inner cylinder liners including the final-stage cylinder liner 13, and the piston rod 1 is arranged in the final-stage cylinder liner 13; the piston rod 1 is Solid rod, the bottom end of the first-stage cylinder liner 30 is provided with an oil inlet hole 21, and the other end is provided with an oil outlet hole 22; The inner cylinder liner of the stage cylinder liner 30 is fixed with a first-stage piston 15 outside one end near the oil inlet hole 21, and the other inner cylinder liners of each stage are fixed with an intermediate stage piston 16 inside the end near the oil inlet hole 21; The inner cylinder liner is provided with an oil guide hole 23. The oil guide hole 23 is a through hole leading to the inside and outside of the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com