Spring damping vibration isolator

A spring damping and vibration isolator technology, applied in the field of vibration isolation devices and spring damping vibration isolators, can solve problems such as affecting the normal use of vibration isolators, unable to meet waterproofing, affecting vibration isolation effects, etc., and achieve economic and social benefits. Significant, simple structure, the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

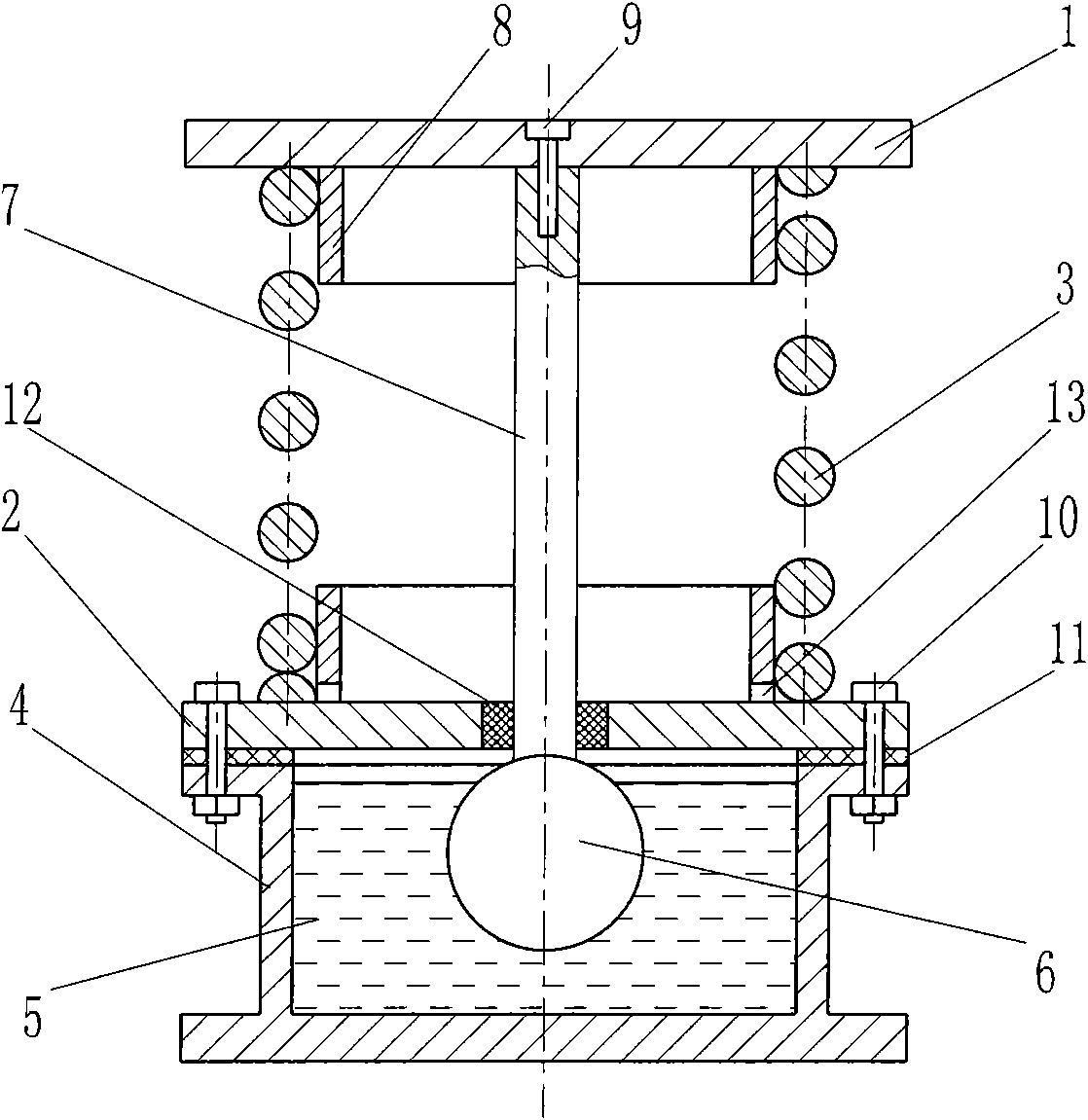

[0021] Such as figure 1 The shown spring damping vibration isolator of the present invention includes an upper support plate 1, an elastic element 3 and a lower support plate 2. Here, the elastic element 3 is a helical steel spring. In order to facilitate the positioning of the elastic element 3, the upper and lower Limiting sleeves 8 are respectively arranged on the lower supporting plate, and the damping cylinder 4 is arranged under the lower supporting plate 2, and a liquid damping material 5 is arranged in the damping cylinder 4, which is high-viscosity silicone oil. The damping cylinder 4 is also provided with a spherical moving body 6 linked with the upper supporting plate 1, the moving body 6 is partially immersed in the liquid damping material 5, and the moving body 6 is connected with the upper supporting plate 1 through the connecting rod 7 passing through the lower supporting plate 2 , and utilize fasteners 9 to be firmly connected together, wherein the moving body ...

Embodiment 2

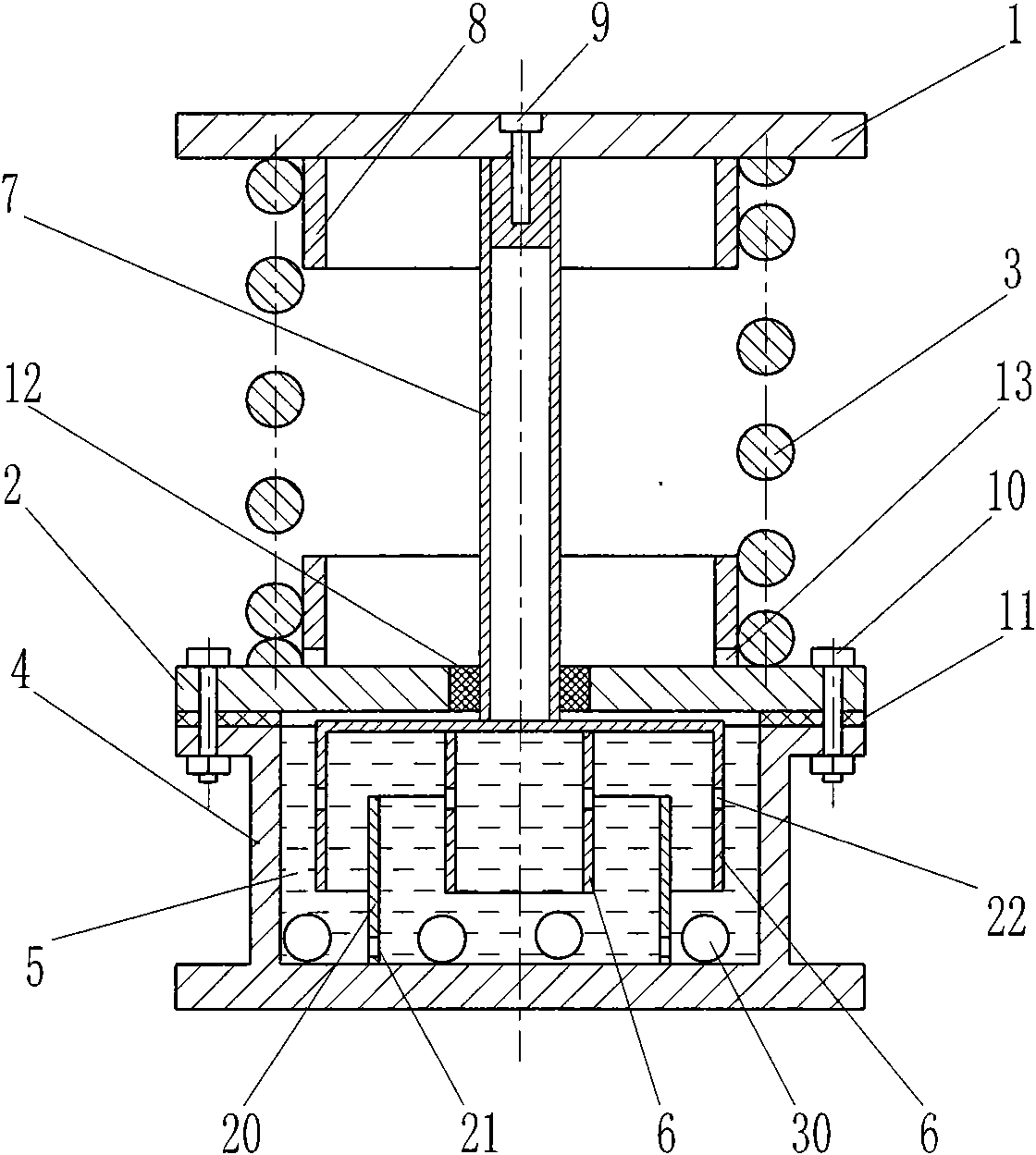

[0029] Such as figure 2 The difference between the spring damping vibration isolator of the present invention and the first embodiment is that the liquid damping material 5 is modified emulsified asphalt. In order to increase the system damping, two tubular moving bodies 6 are integrated in the spring damping vibration isolator. In addition, a tubular static body 20 is welded at the bottom of the damping cylinder 4 to cooperate with the moving body 6, which greatly increases the effective area for the relative movement of the moving body and the static body to shear the liquid damping material 5 when the spring damping vibration isolator works. Therefore, the system has greater damping, faster energy consumption, and better vibration isolation. In order to further increase the system damping and facilitate the smooth circulation of the liquid damping material 5 during high-speed vibration, the moving body 6 and the static body 20 are also provided with through holes 22 and 21...

Embodiment 3

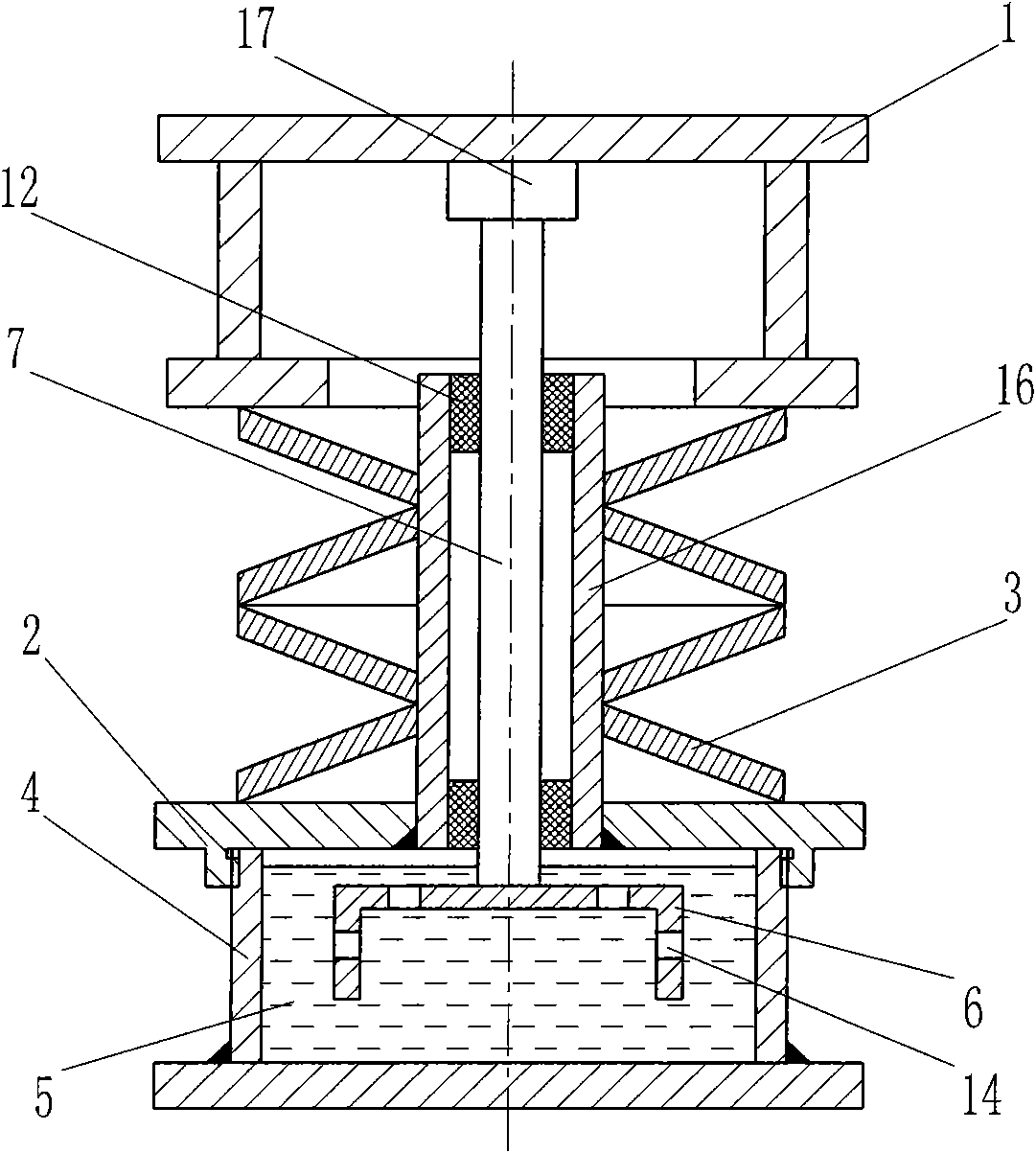

[0034] Such as image 3 The difference between the spring damping vibration isolator of the present invention shown in Embodiment 1 is that the liquid damping material 5 is high-viscosity grade A silicone oil, and the elastic element 3 adopts a metal disc spring. In order to simplify the connection between the lower support plate 2 and the damping cylinder 4 The connection between the two is provided with a threaded structure to connect with each other and achieve sealing. In order to enhance the guiding effect and sealing effect, a guide sleeve 16 is provided on the lower support plate 2 , and sliding seals 12 are respectively provided between the upper and lower ends of the guide sleeve 16 and the connecting rod 7 . The moving body 6 is arranged in a tubular shape. In order to increase the damping of the system and facilitate the smooth passage of the liquid damping material when the moving body 6 moves, some through holes 14 are arranged on the moving body 6 . In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com