Welding process and application device of corrugated pipe assembly

A corrugated pipe component and welding process technology, applied in the field of corrugated tube component welding process and its application device, can solve the problems of easy virtual welding, low welding strength, high welding precision requirements, etc., and achieve favorable adjustment, good heat dissipation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

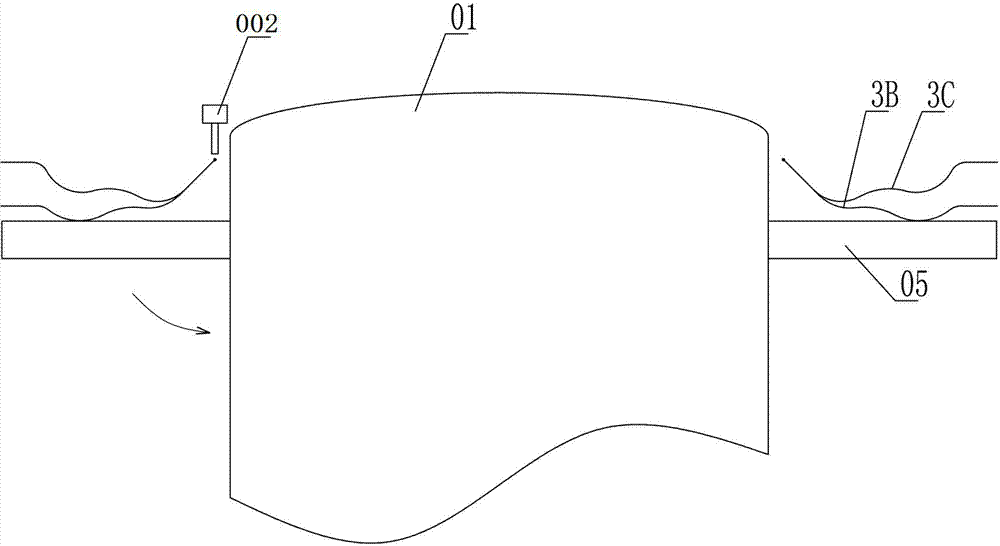

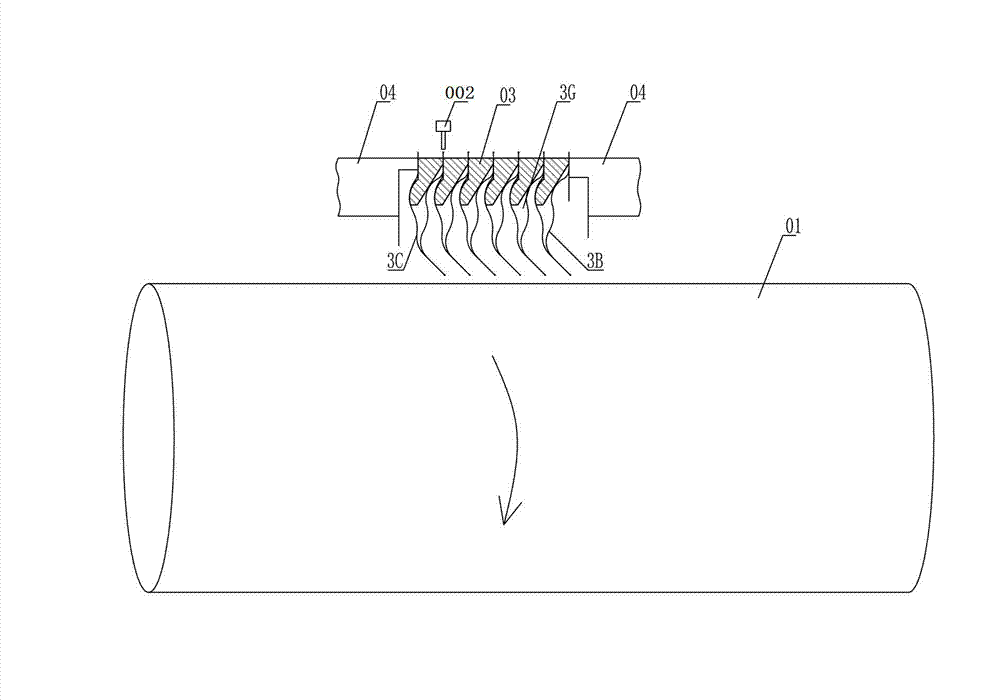

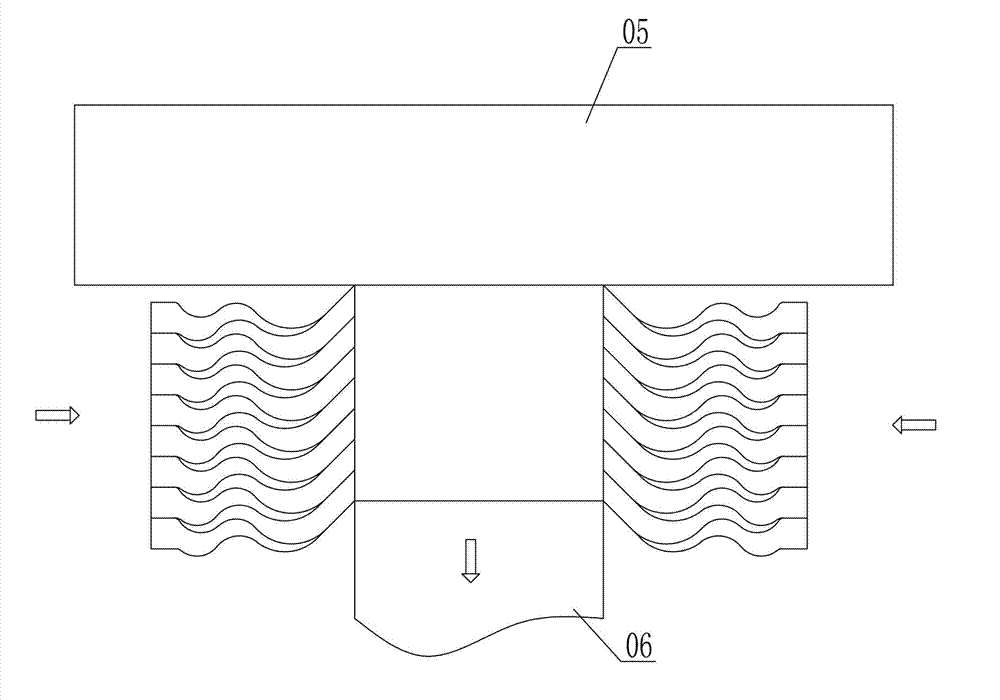

[0032] Such as Figure 1 to Figure 8As shown, the technical scheme adopted by the present invention is as follows, a welding process of a bellows assembly, the steps of which include: a. Welding to form a mother and daughter piece 3G: the wave plate convex plate 3B and the wave plate concave plate 3C are formed according to the wave plate concave plate 3C is inserted into the rotating shaft 01 in the order that the lower wave plate convex piece 3B is on the top, and the rotating shaft 01 is rotated so that the welding mechanism 002 welds the inner ring of the wave plate convex piece 3B and the wave plate concave piece 3C to form a master piece 3G; b. Welding Form the corrugated tube core 3A: insert the spacer ring 02 between the wave plate convex plate 3B and the wave plate concave plate 3C of the mother-child plate 3G, and insert at least two mother-child plates 3G inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com