Patents

Literature

37results about How to "There will be no false welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

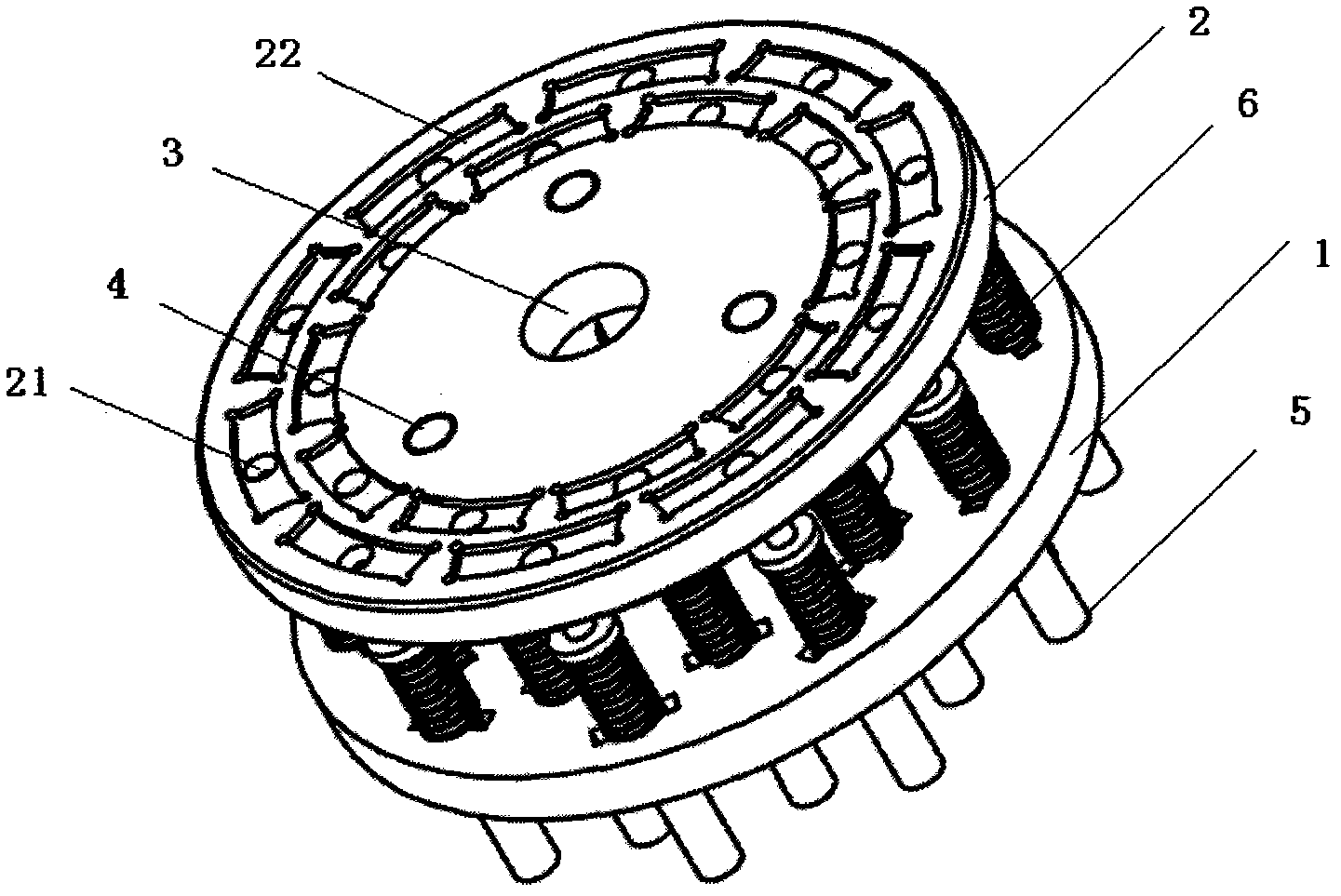

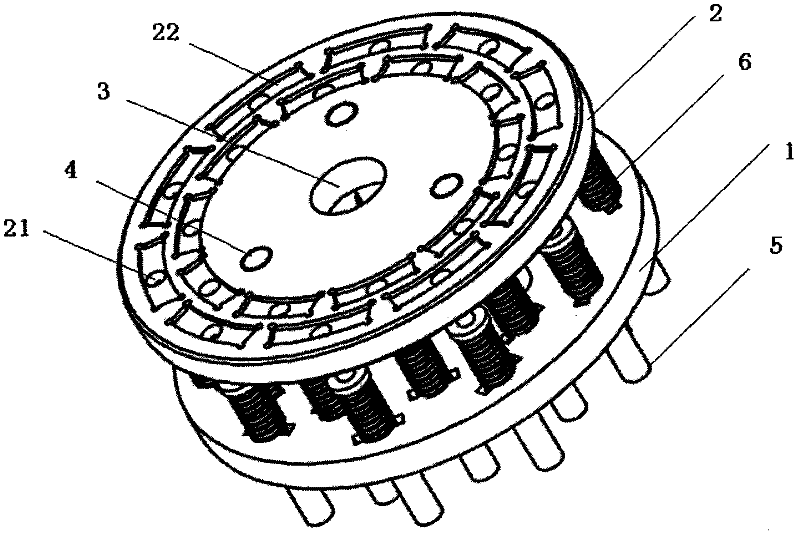

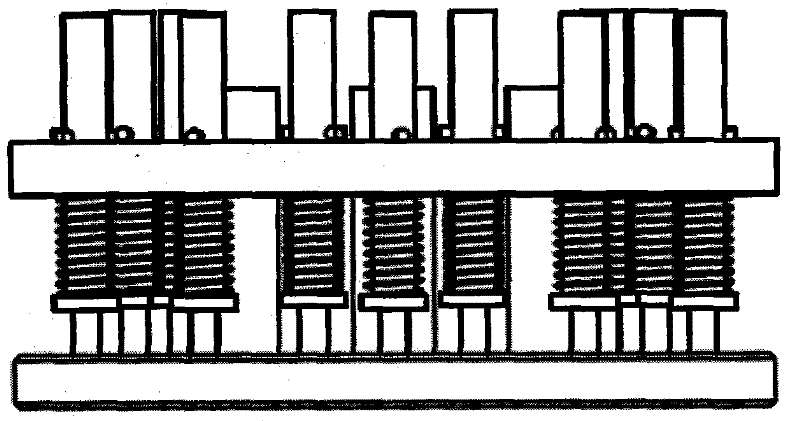

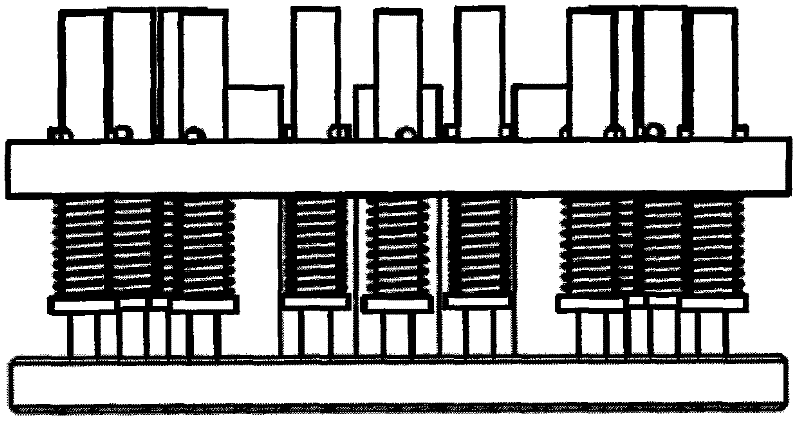

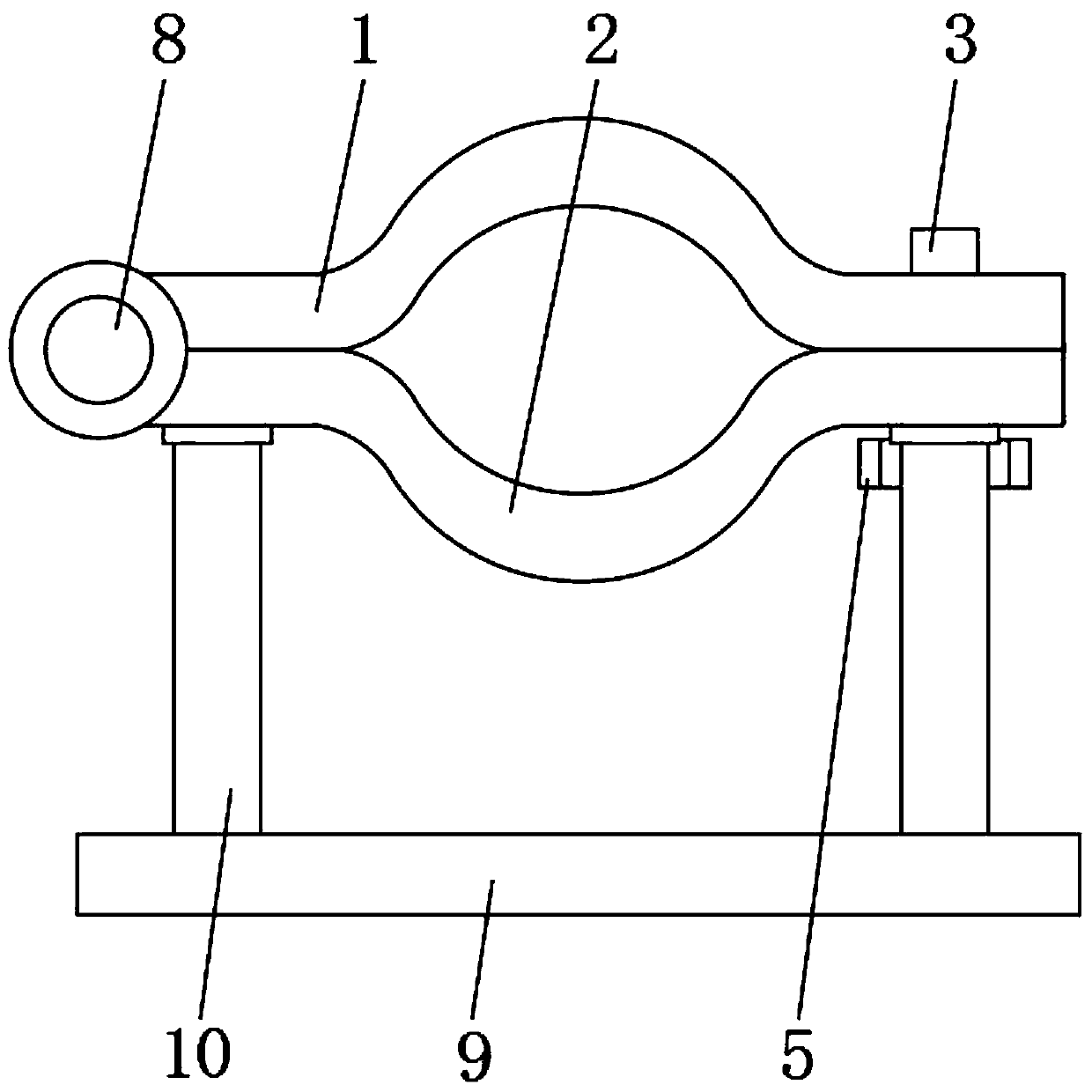

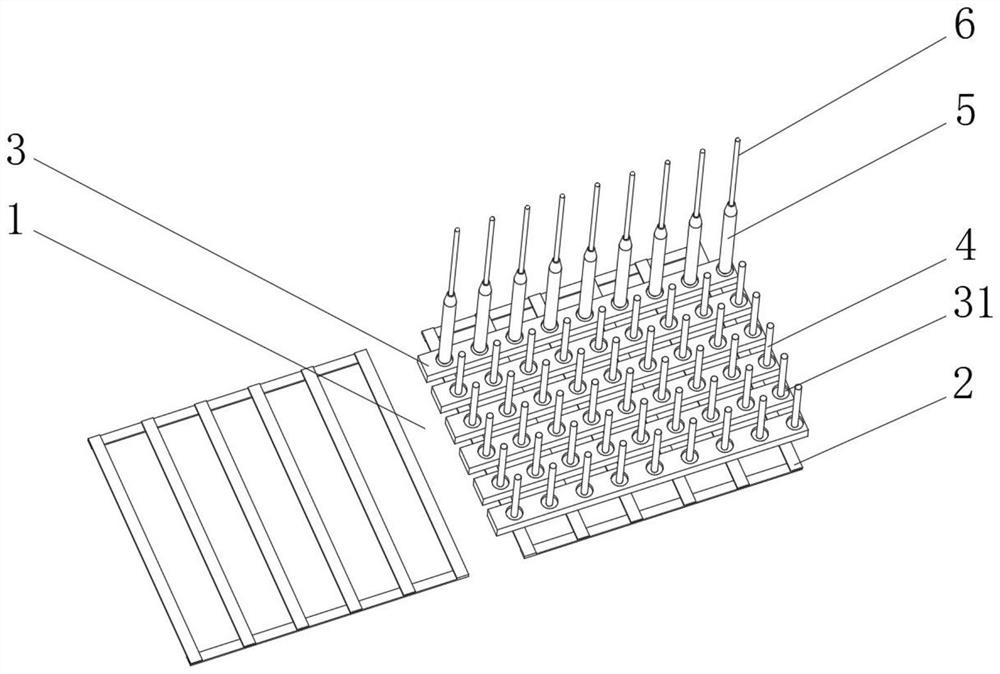

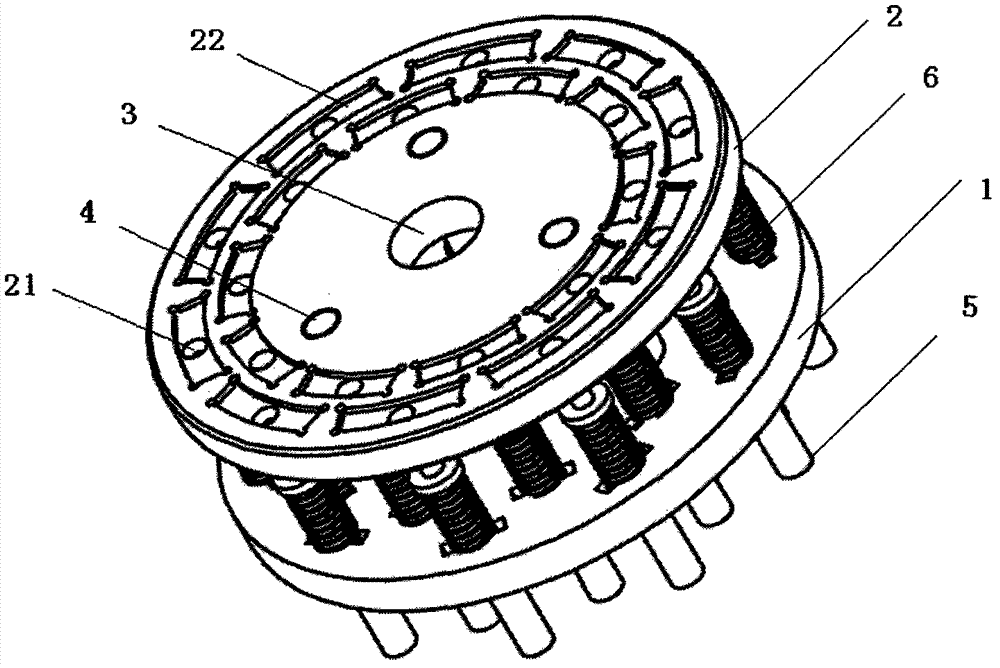

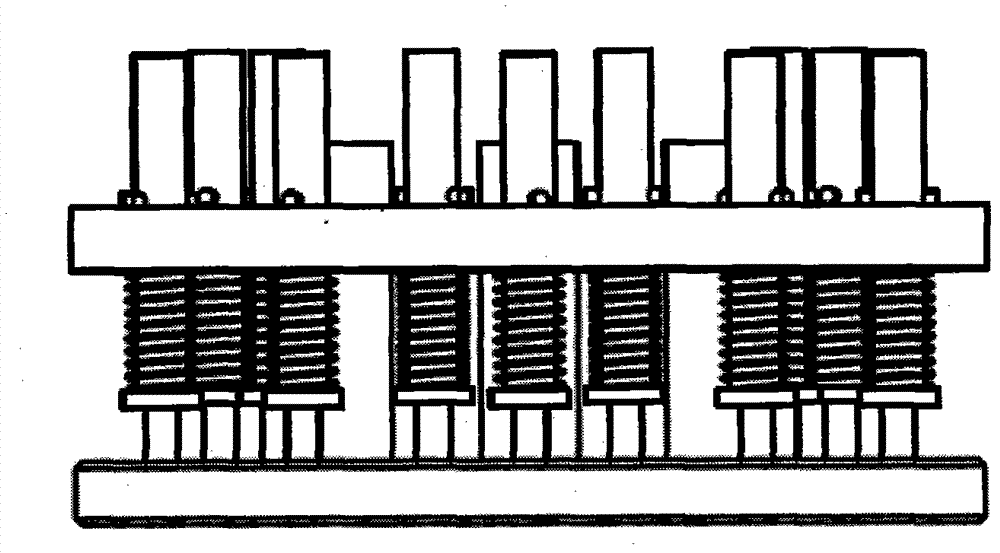

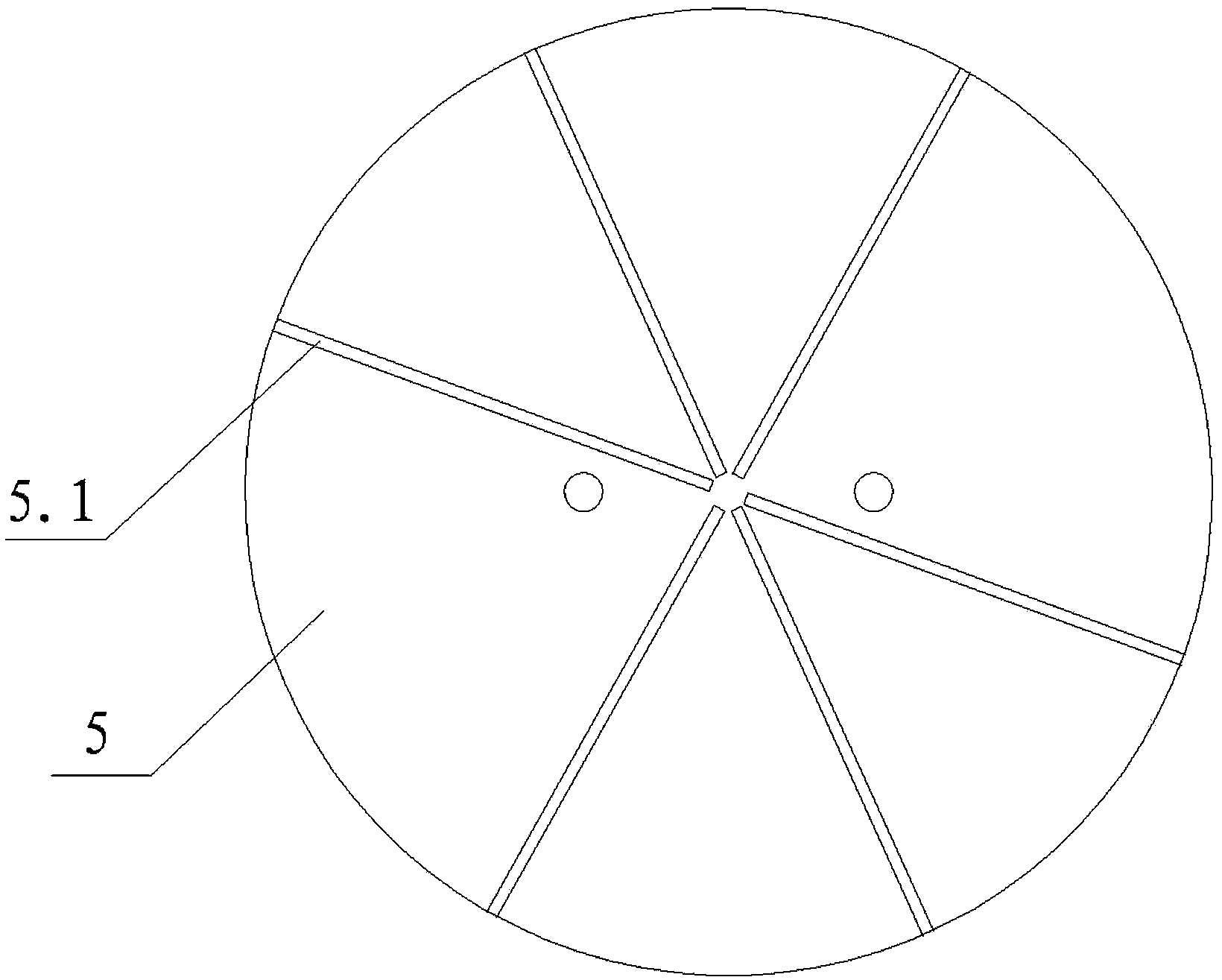

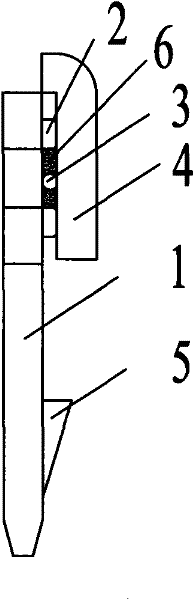

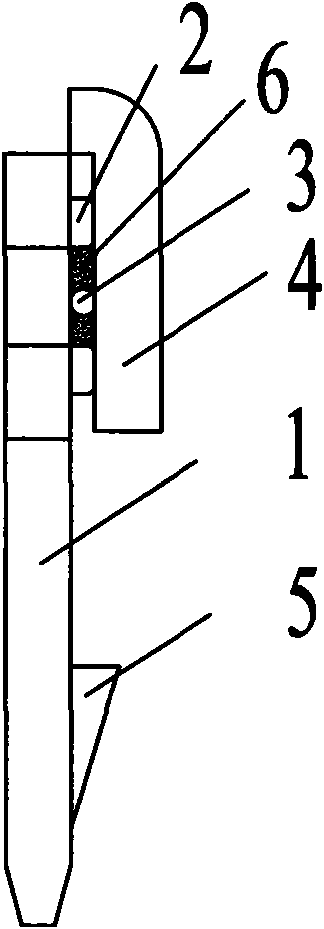

Welding fixture

The invention relates to a welding fixture which comprises an upper pressure plate and a lower pressure plate, wherein the upper pressure plate and the lower pressure plate comprise central positioning holes which are arranged coaxially, the lower pressure plate is provided with a tooth block positioning hole, a tooth block mounting groove is arranged on the lower surface of the lower pressure plate and the welding fixture is characterized in that a tooth block positioning screw rod and a tooth block pressure spring are mounted between the upper pressure plate and the lower pressure plate. The welding fixture is simple in structure and can always keep the fastening connection between a tooth block and the welding surface of a basal body by high-temperature welding and avoid the phenomena of looseness and poor welding.

Owner:江苏华昌工具制造有限公司

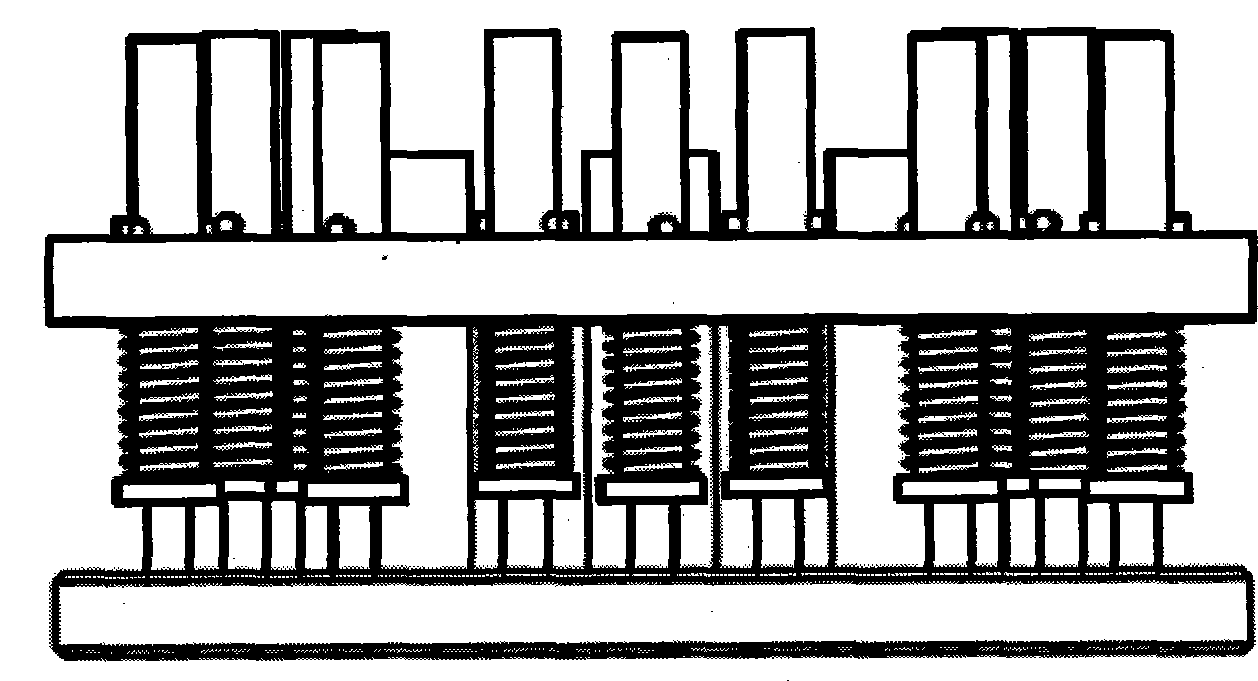

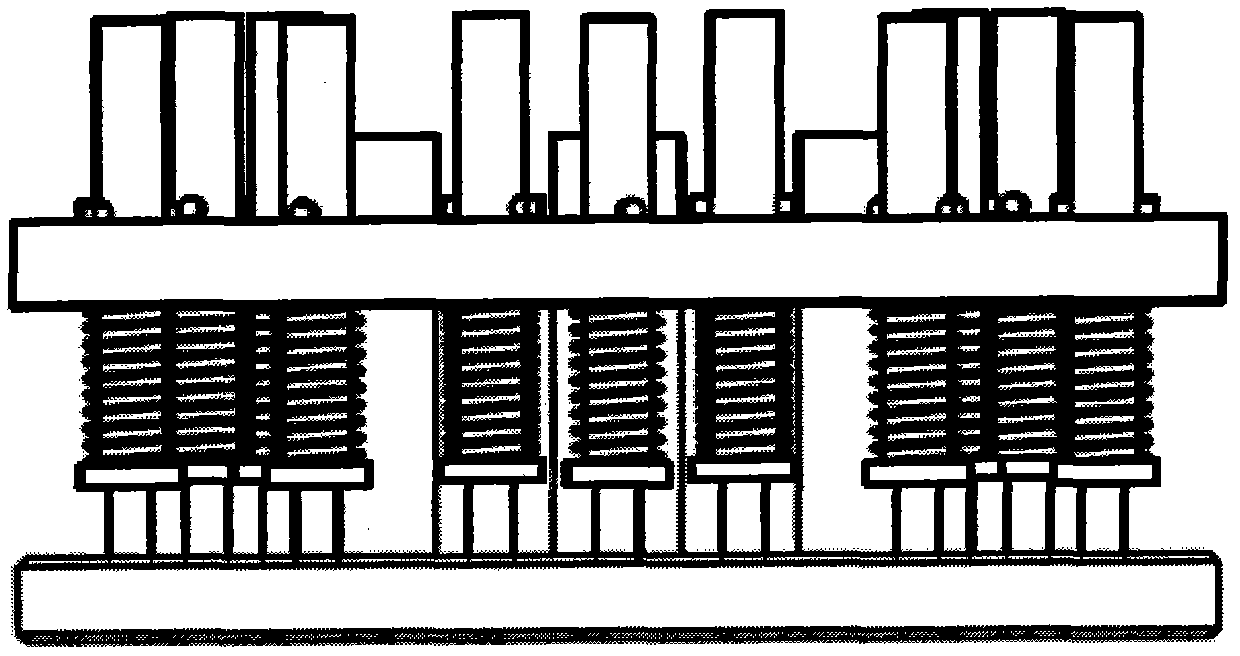

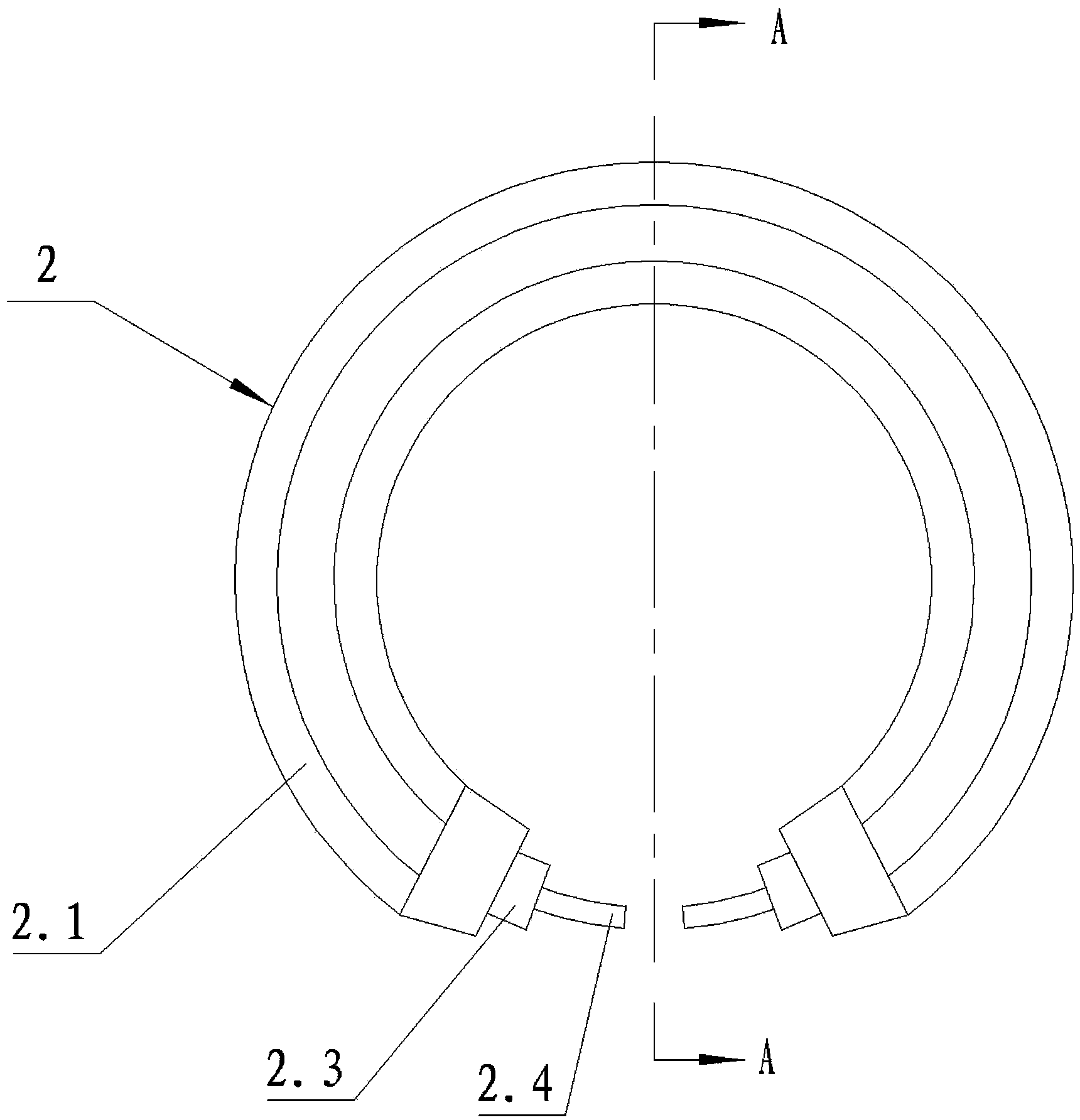

Integral high-frequency brazing process using welding fixtures

ActiveCN102294528ASimple structureEasy to useWelding/cutting media/materialsSoldering mediaAdjuvantFiller metal

The invention relates to a process for carrying out entire high-frequency brazing by a welding jig, which comprises the preparation of a matrix and the preparation of diamond gear blocks. Uniformly stirred silver based brazing filler metal and welding adjuvants are uniformly coated on surfaces to be brazed of the diamond gear blocks, then a millstone matrix and the diamond gear blocks are positioned and fixed by the welding jig, and finally the millstone matrix and the diamond gear blocks are arranged in a vacuum brazing furnace to be brazed. The process for carrying out entire high-frequencybrazing by the welding jig overcomes the technical problems of complex manufacturing process, low production efficiency, unstable quality and high production cost of the diamond millstone in the prior art, and on the premise of ensuring the welding quality to be stable, the brazing efficiency is greatly improved, and the production cost is effectively reduced.

Owner:江苏华昌工具制造有限公司

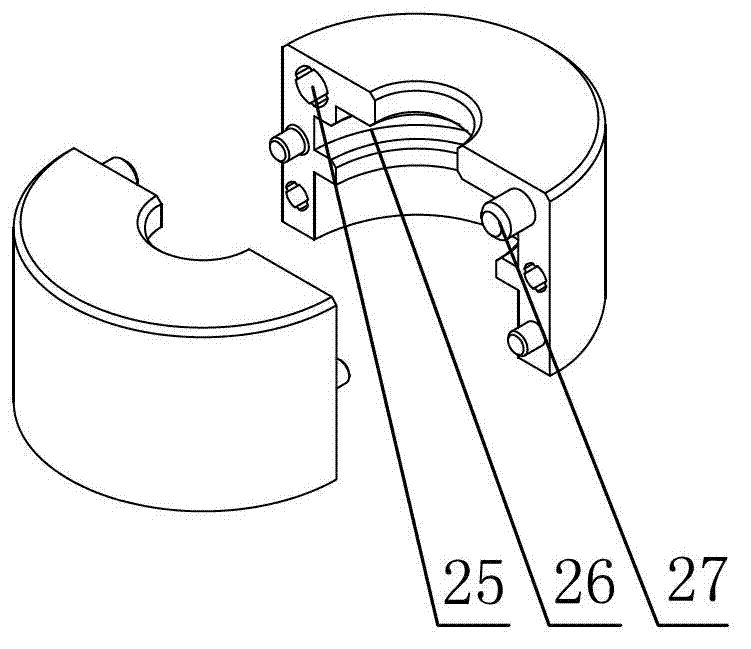

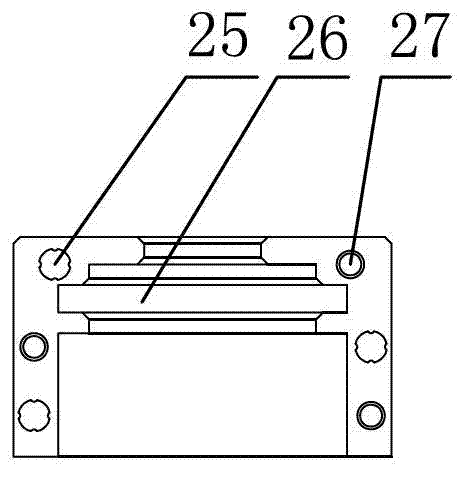

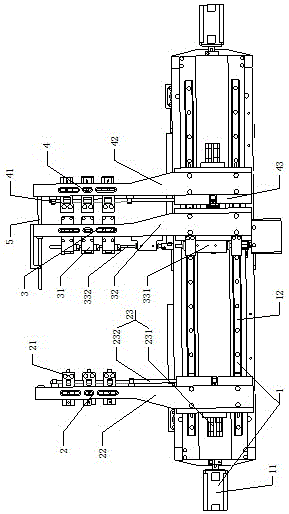

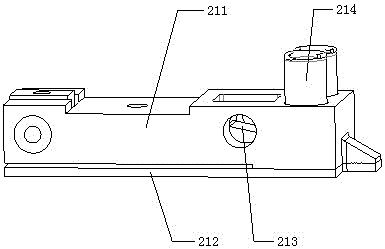

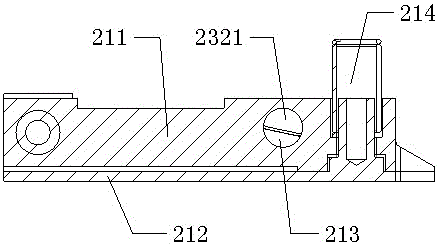

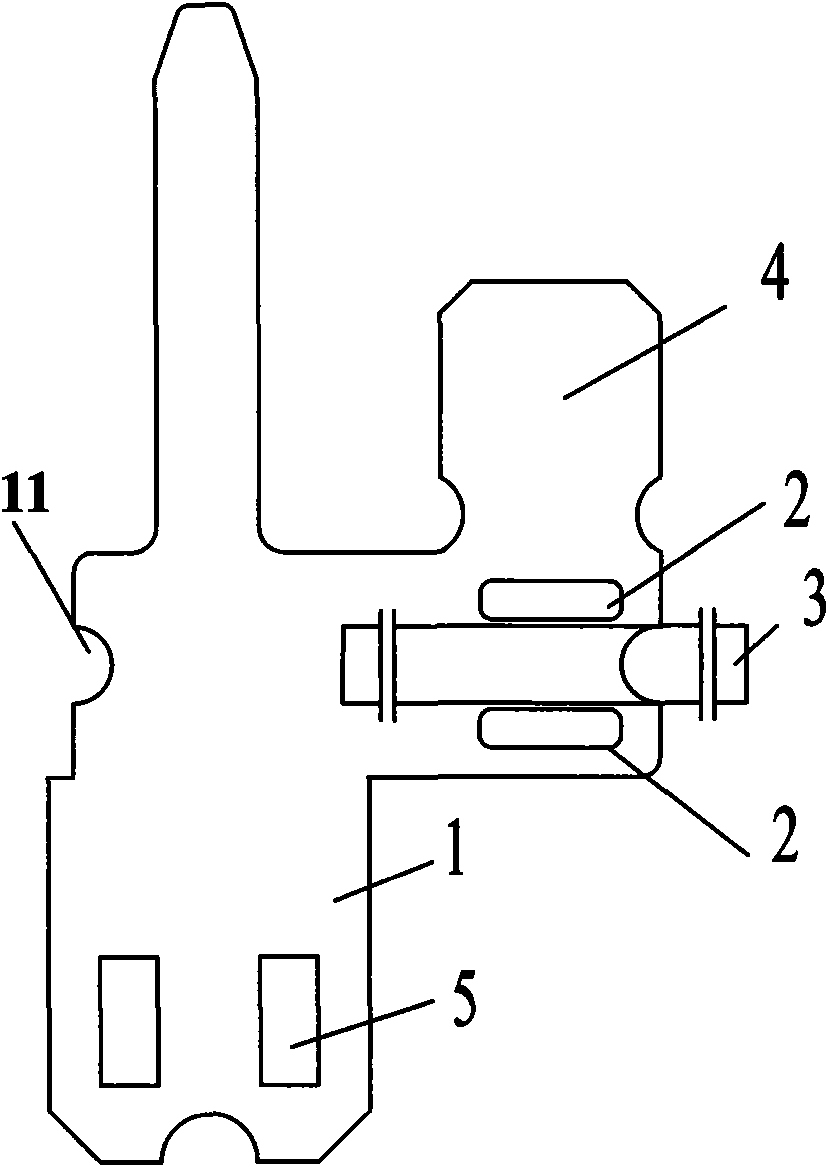

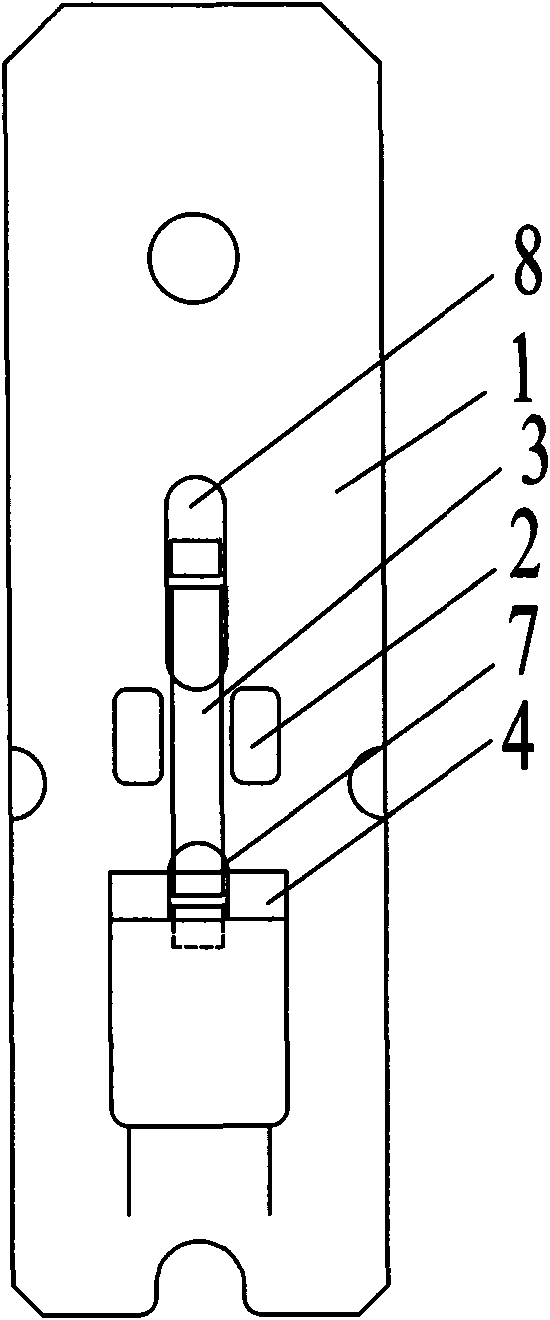

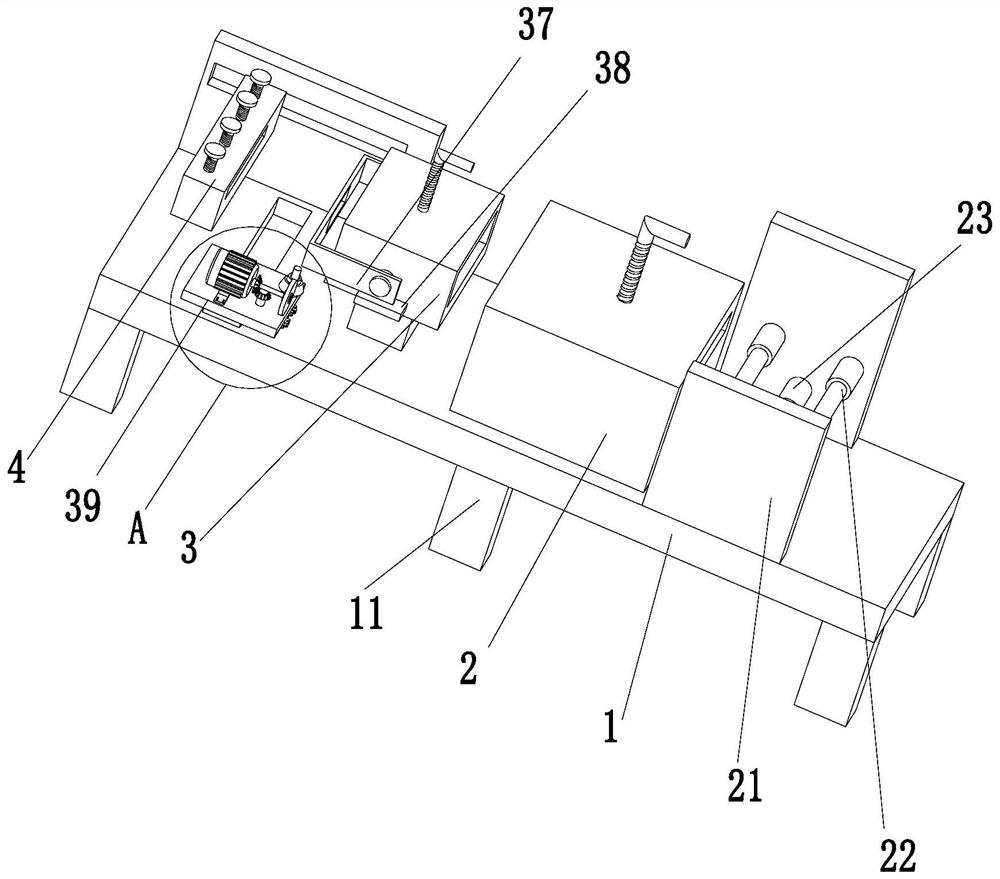

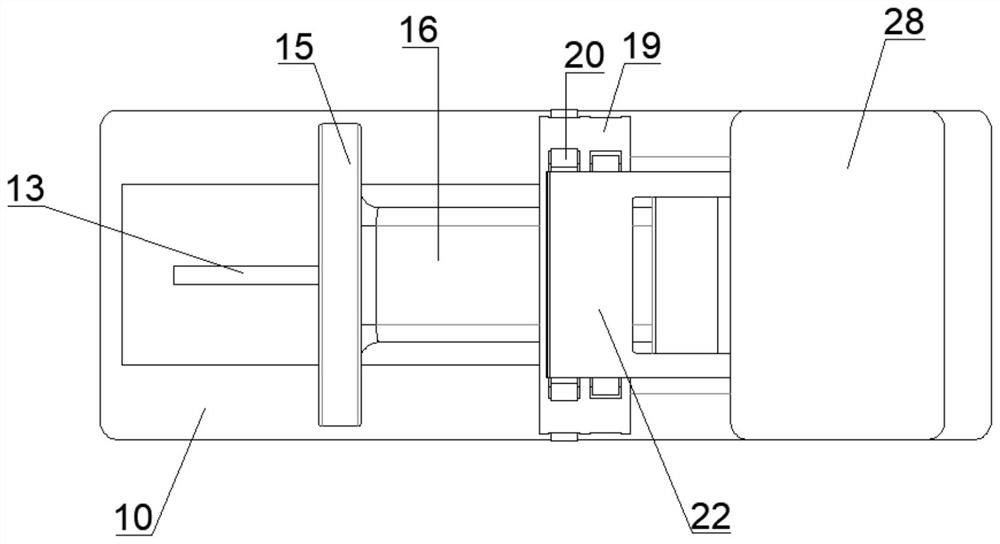

A clamping device and a welding module of a self-restoring fuse thereof

The invention discloses a clamping device and a welding module of a self-restoring fuse thereof, comprising a clamping fixing housing, a clamping pushing assembly, a driving mounting assembly, a firstdriving assembly, a second driving assembly, a first clamping jaw and a second clamping jaw. The invention relates to a clamping device and a welding module of a self-restoring fuse thereof. The clamping pushing assembly, the first jaw and the second jaw are provided, so that the self-restoring fuse can be clamped in a direction that is easy to weld, weld is convenient, and no virtual solderingoccurs. The invention ensures that the pins can be soldered on the body of the self-restoring fuse accurately, ensures that the pins can have good contact with the chip inside the self-restoring fuse,improves the quality of the self-restoring fuse, ensures that the self-restoring fuse can be attached on the circuit board to realize its protection function, and reduces the probability of the circuit board failure.

Owner:致胜电子科技(惠州)有限公司

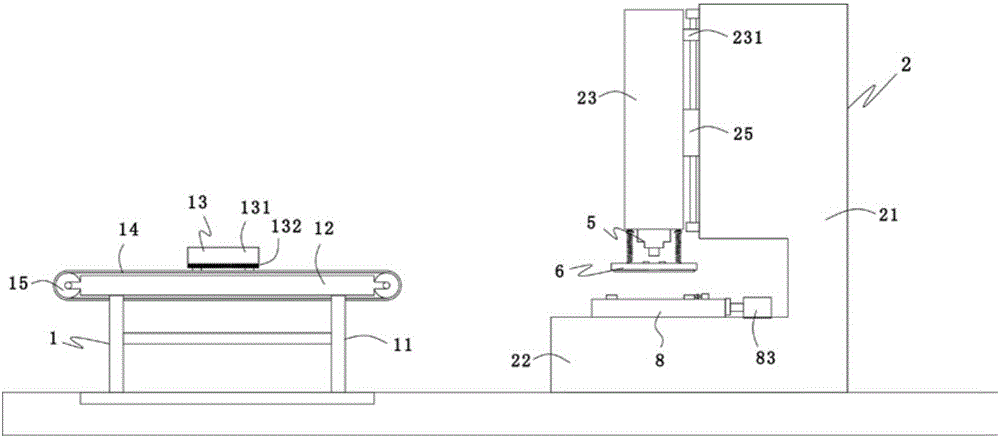

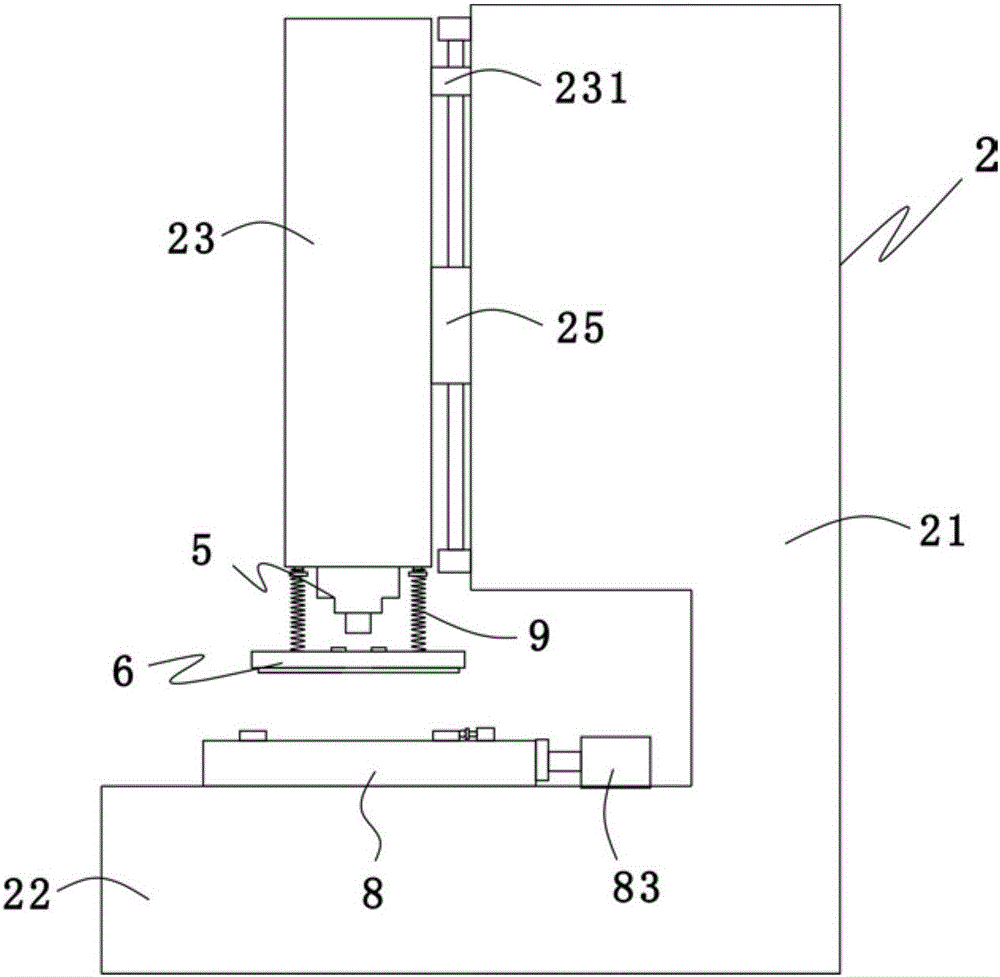

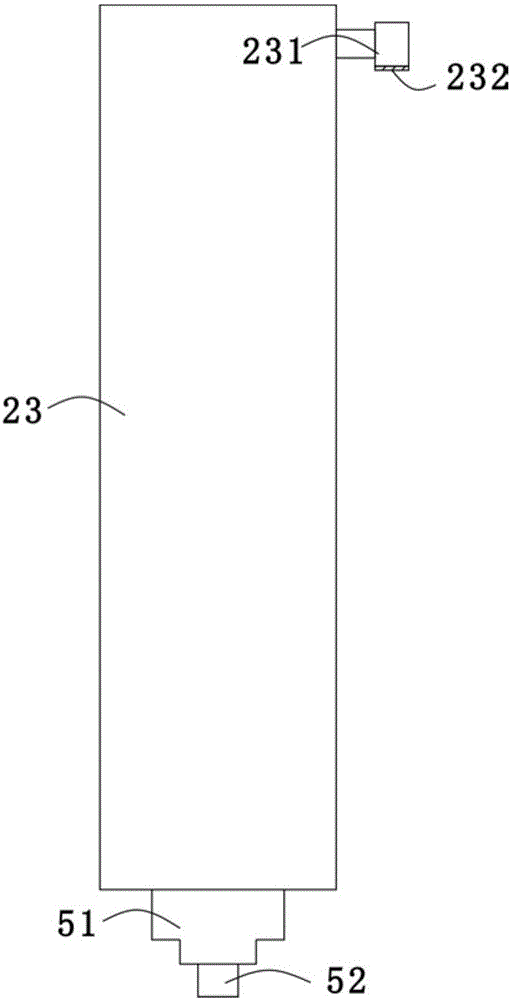

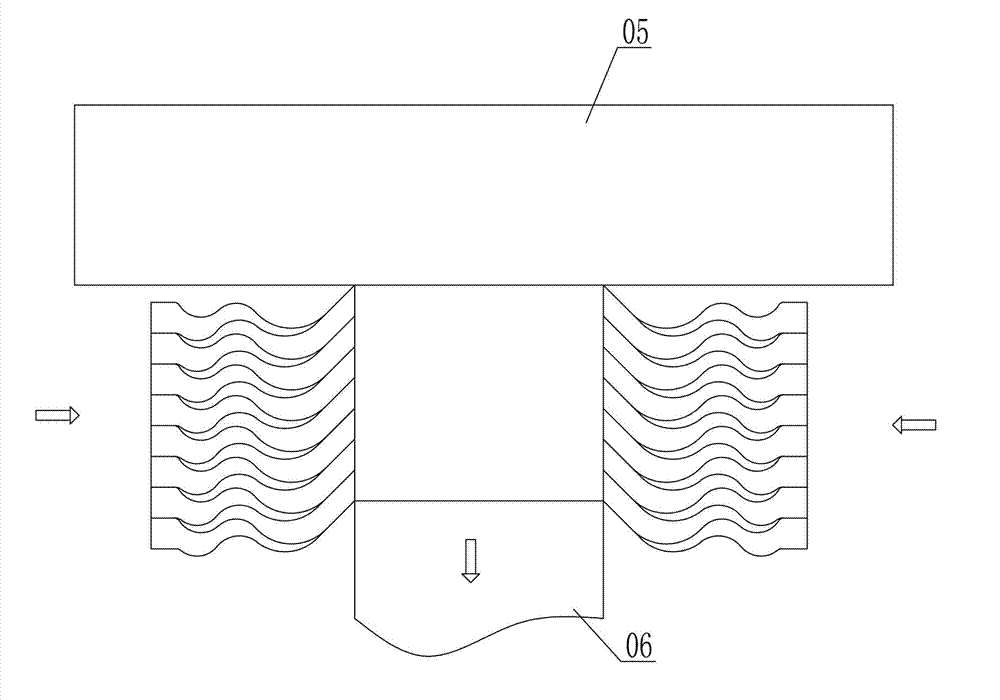

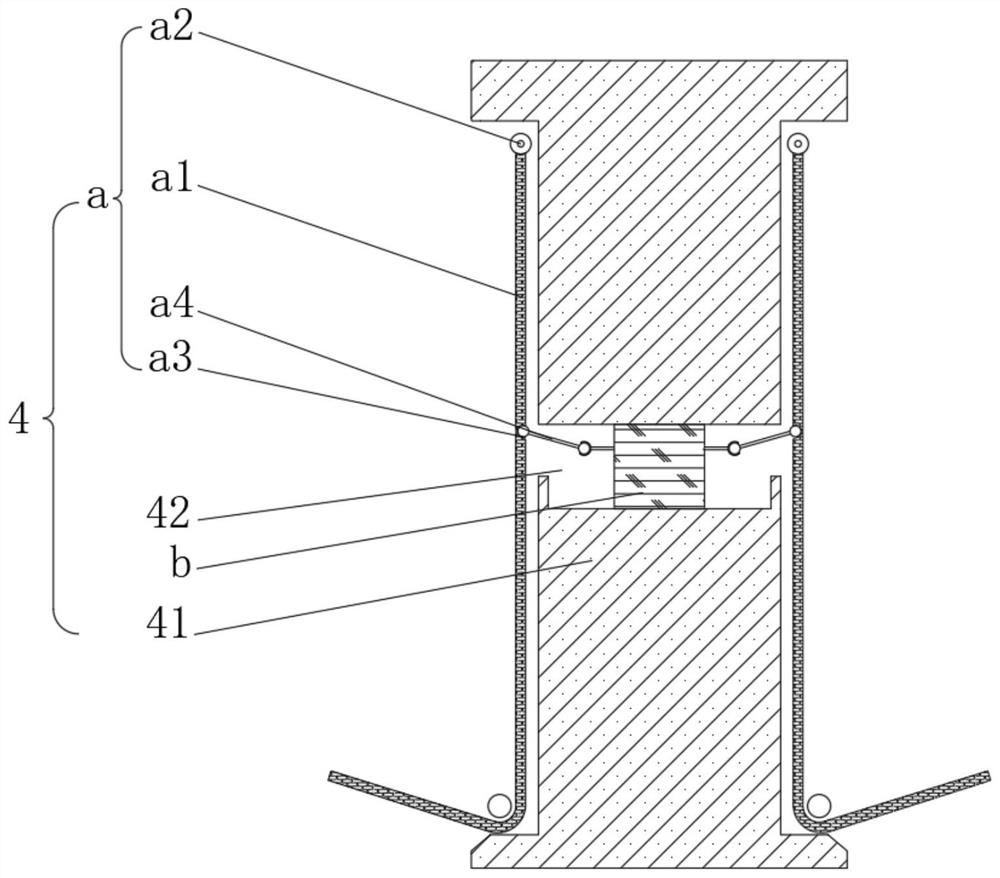

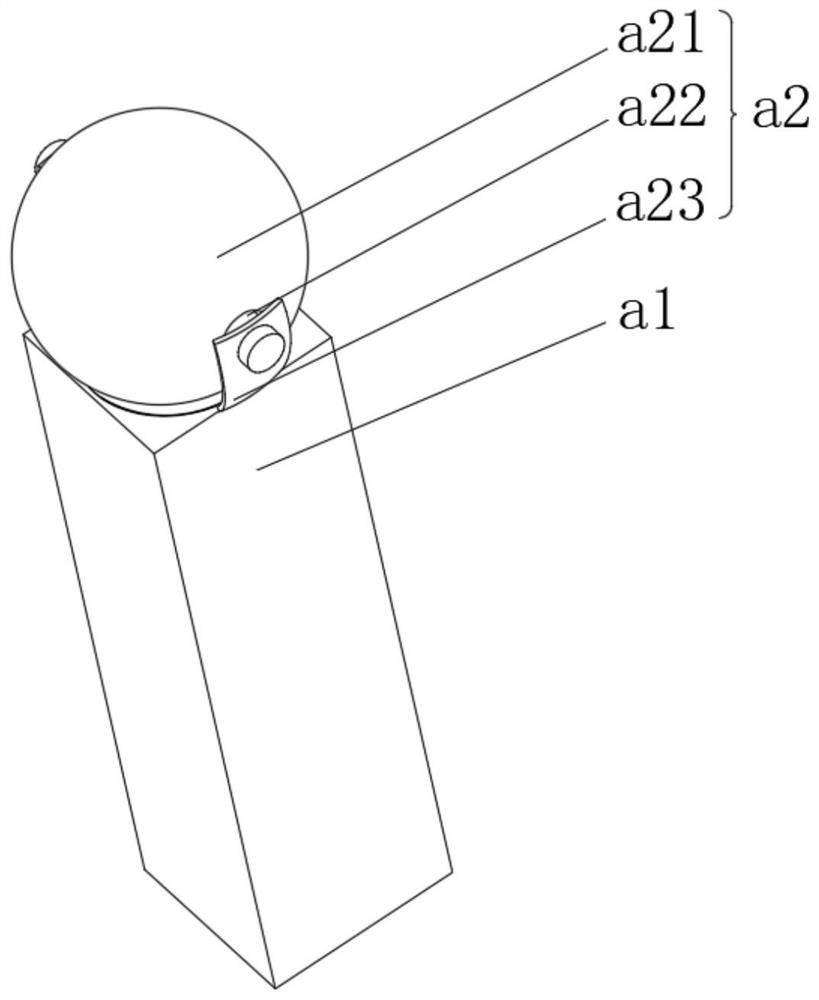

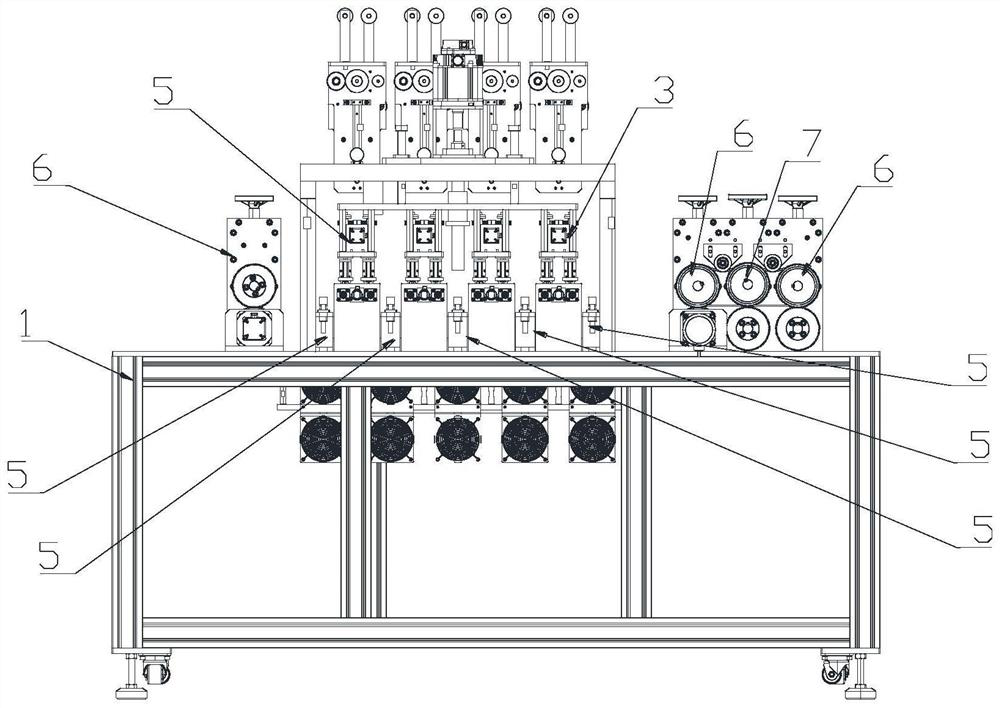

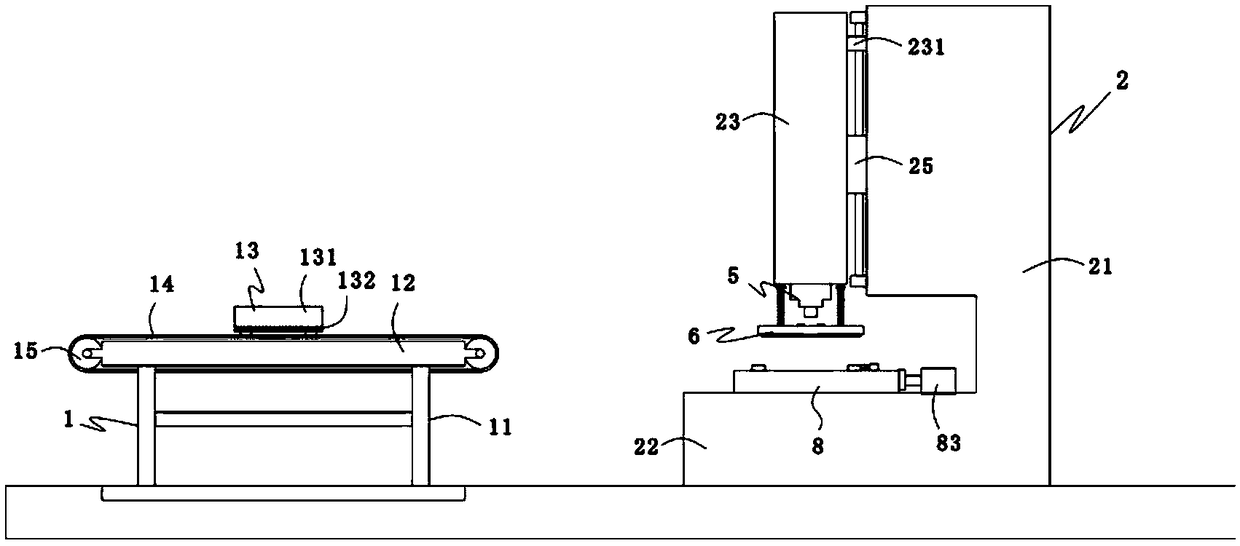

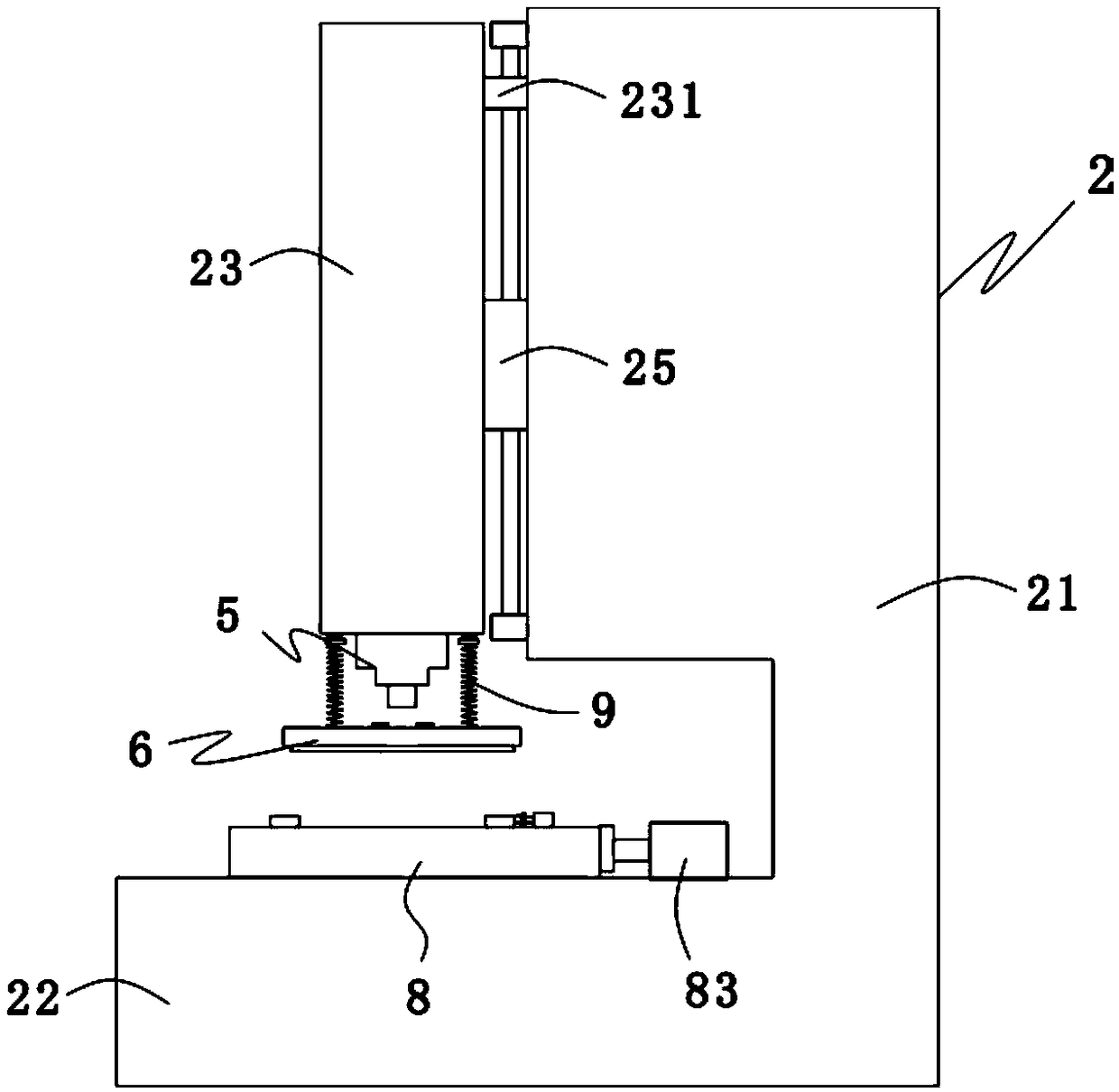

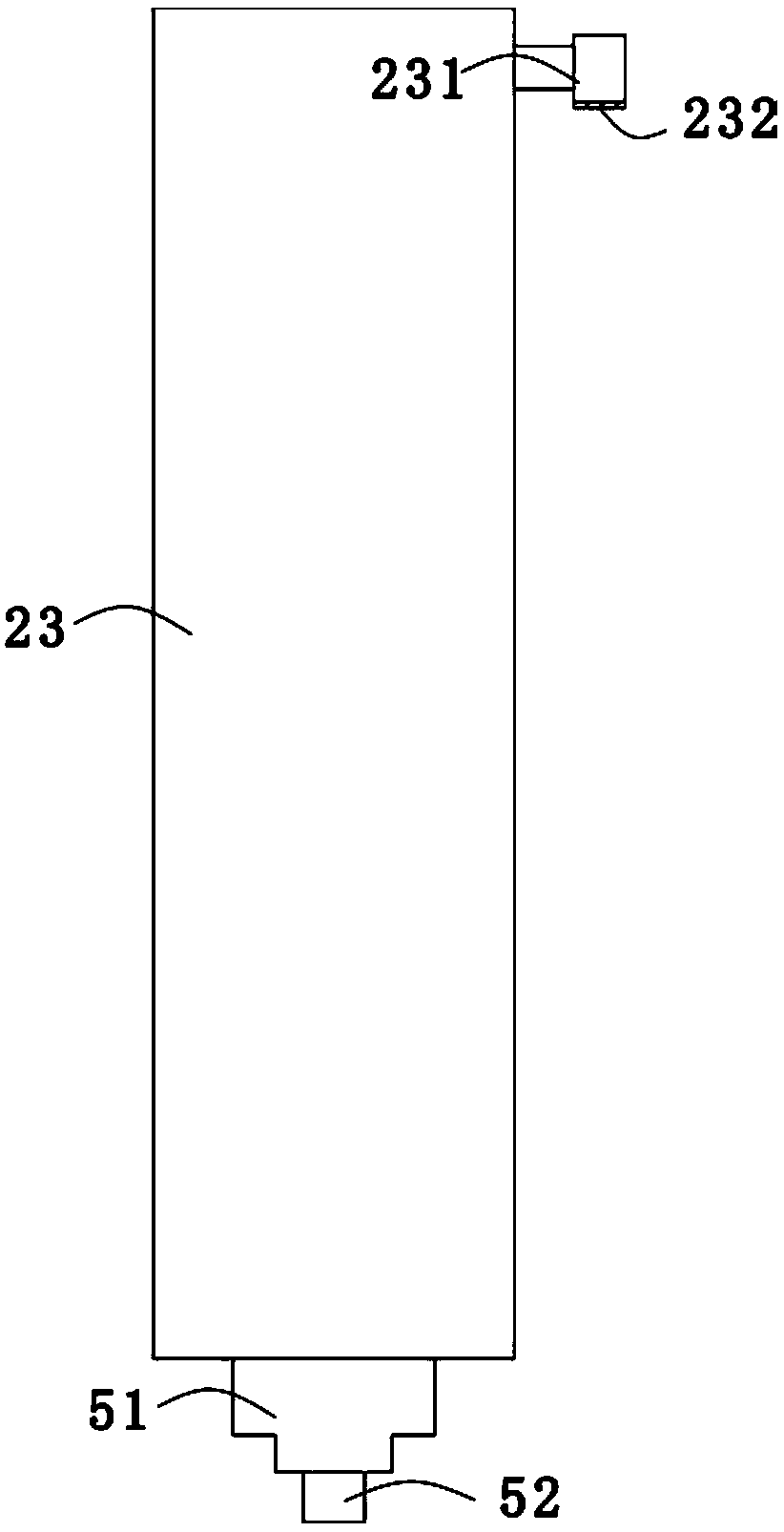

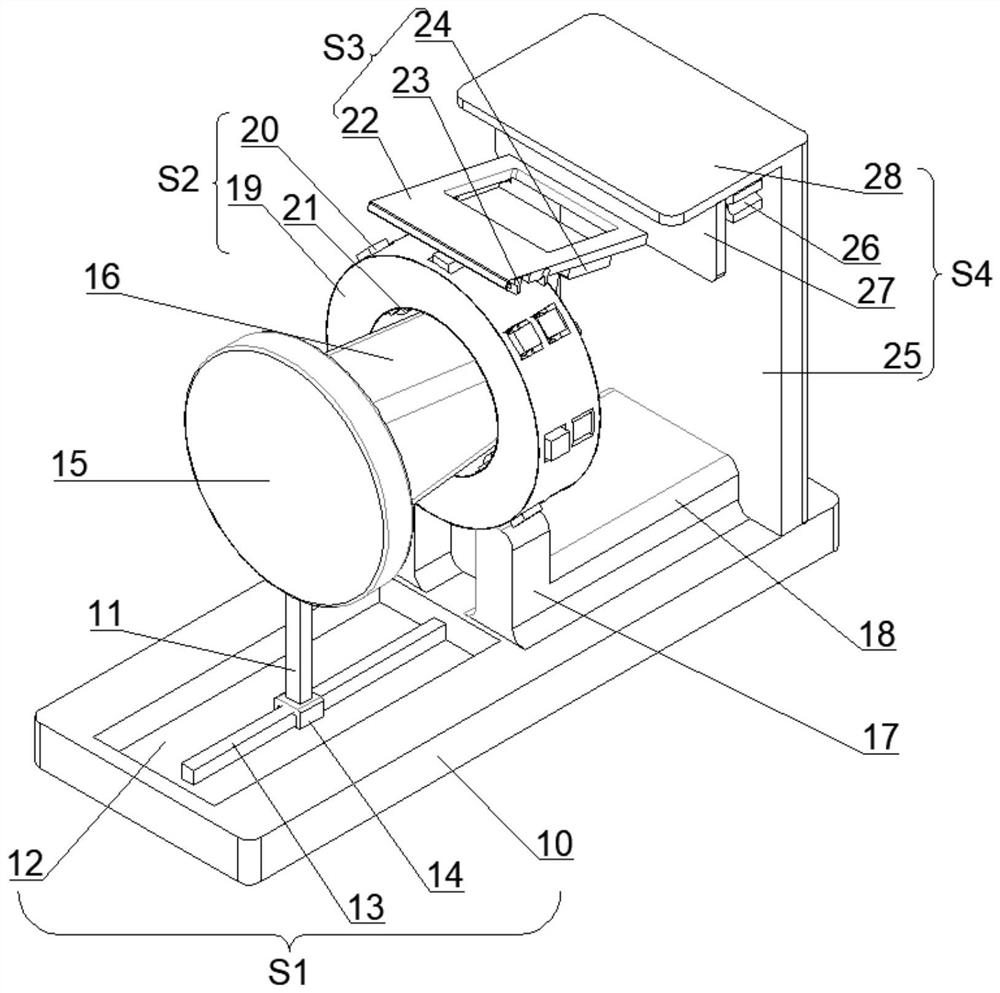

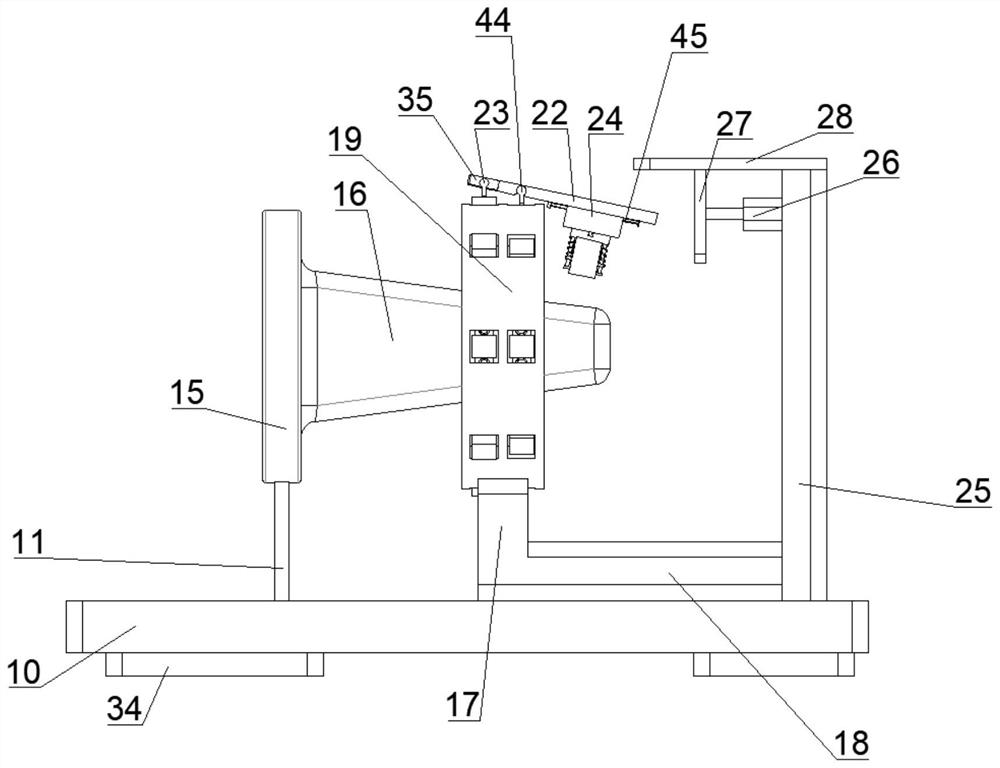

Novel pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

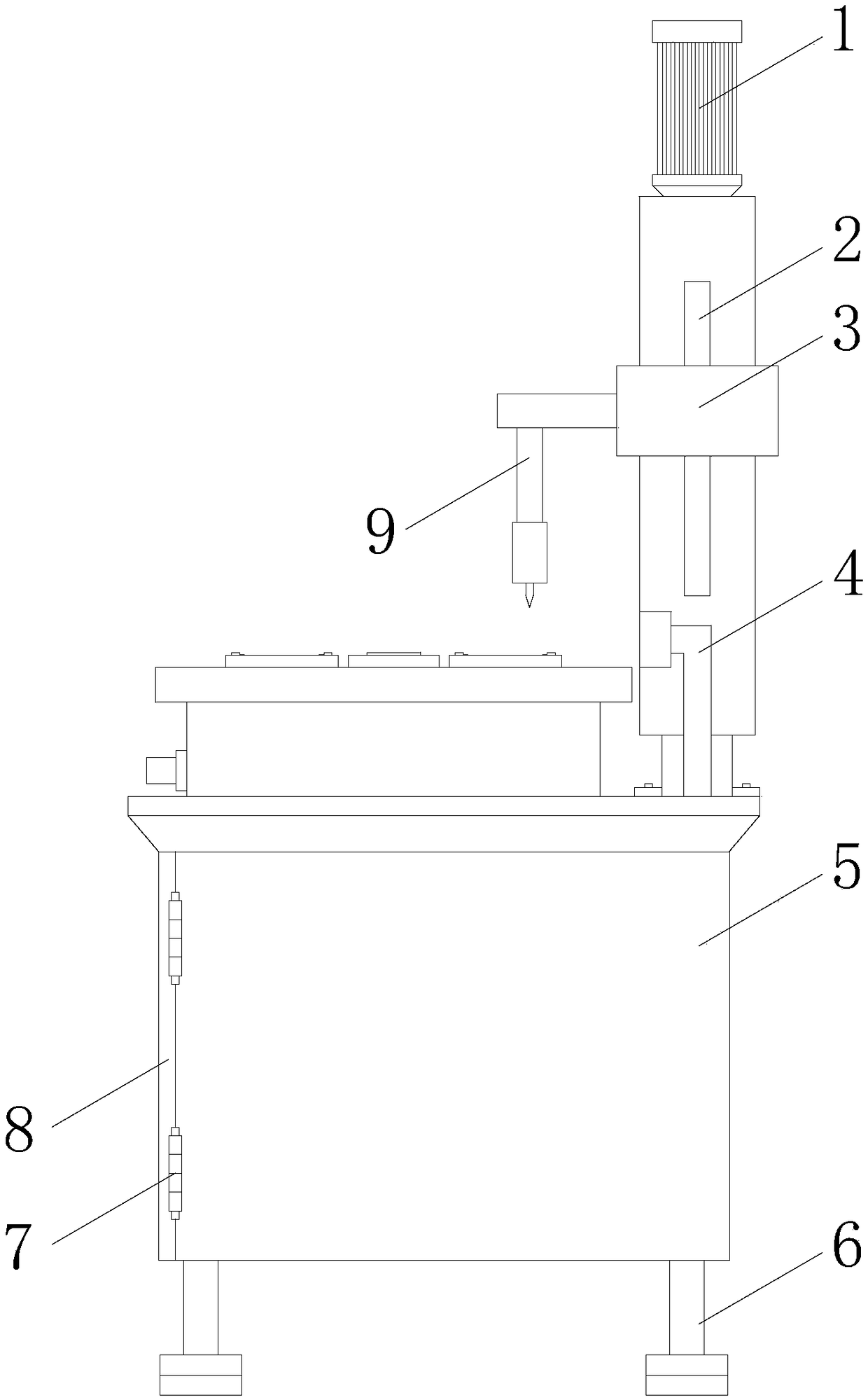

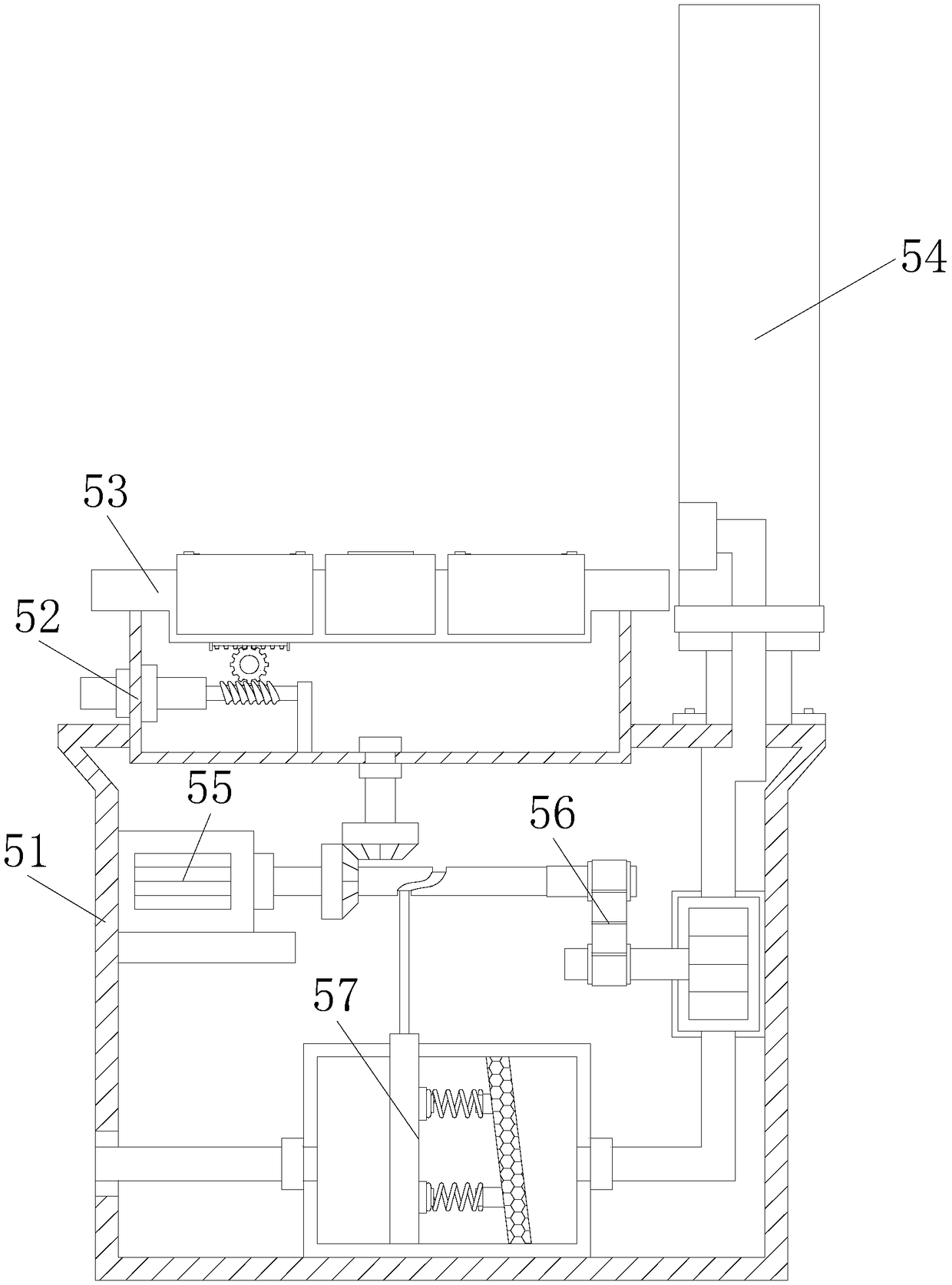

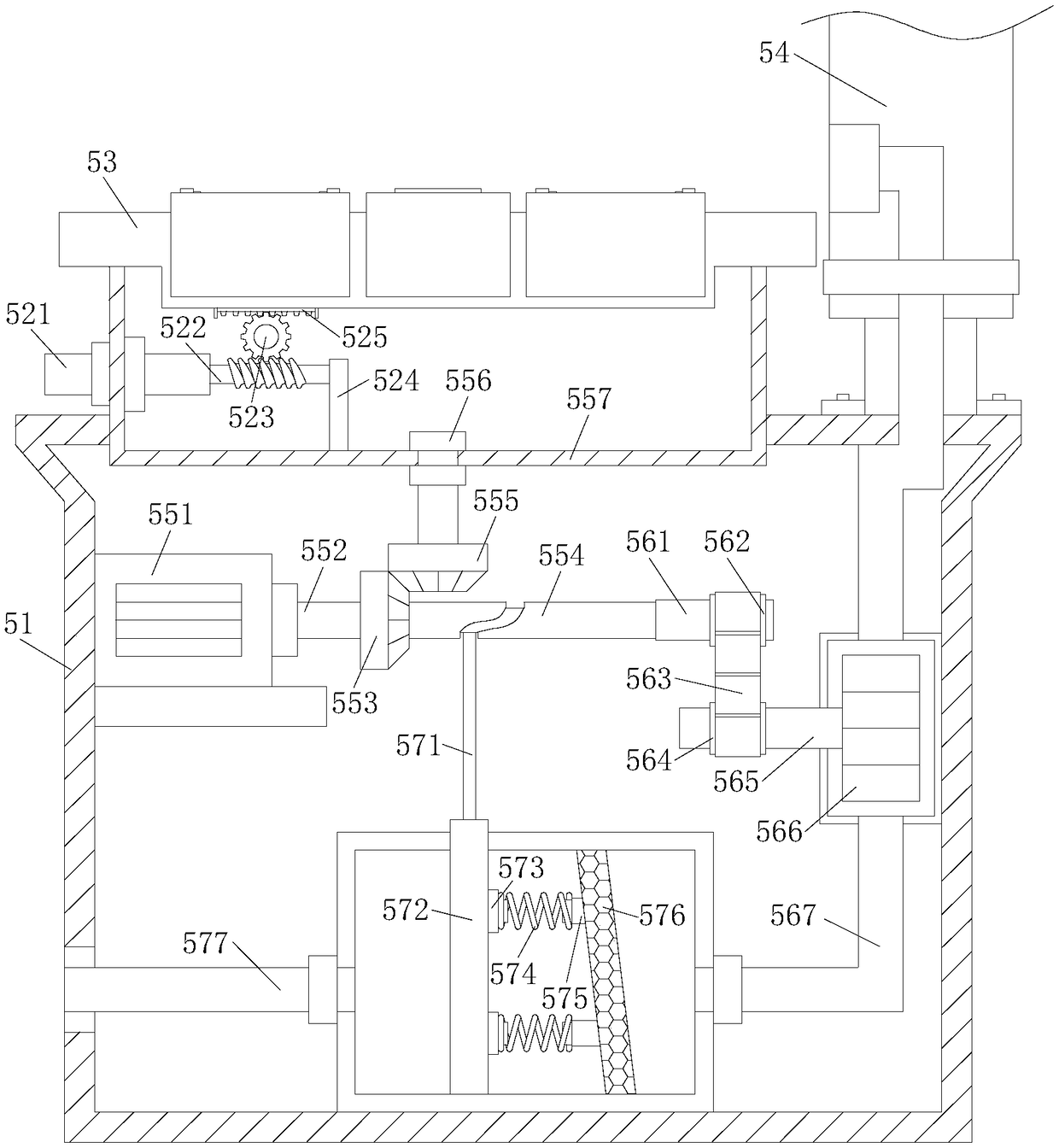

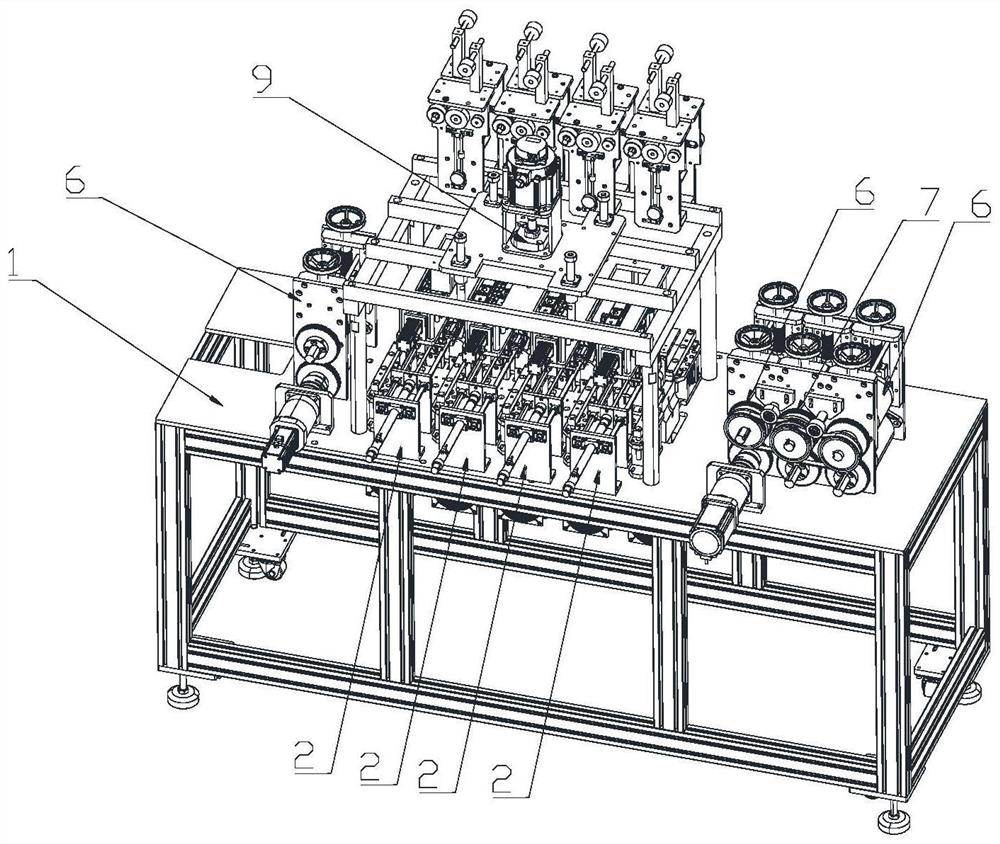

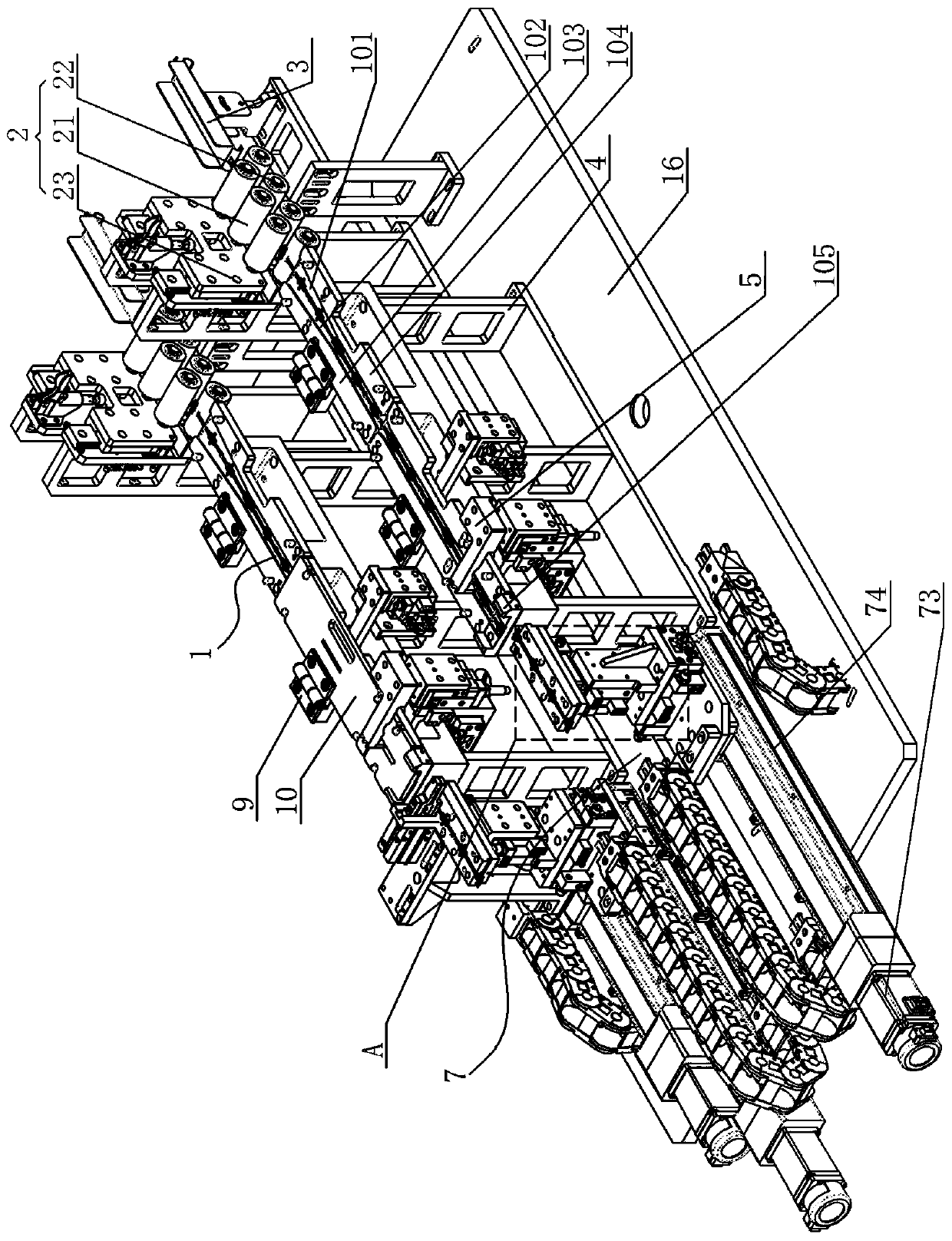

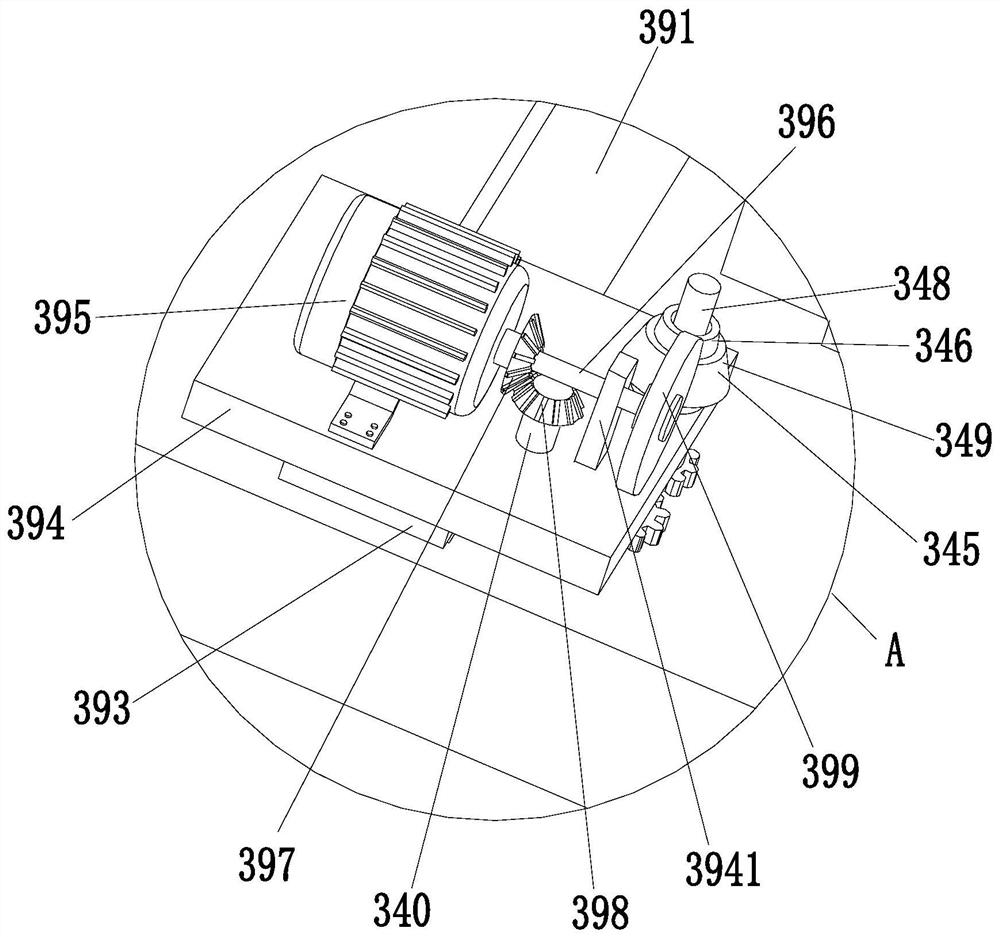

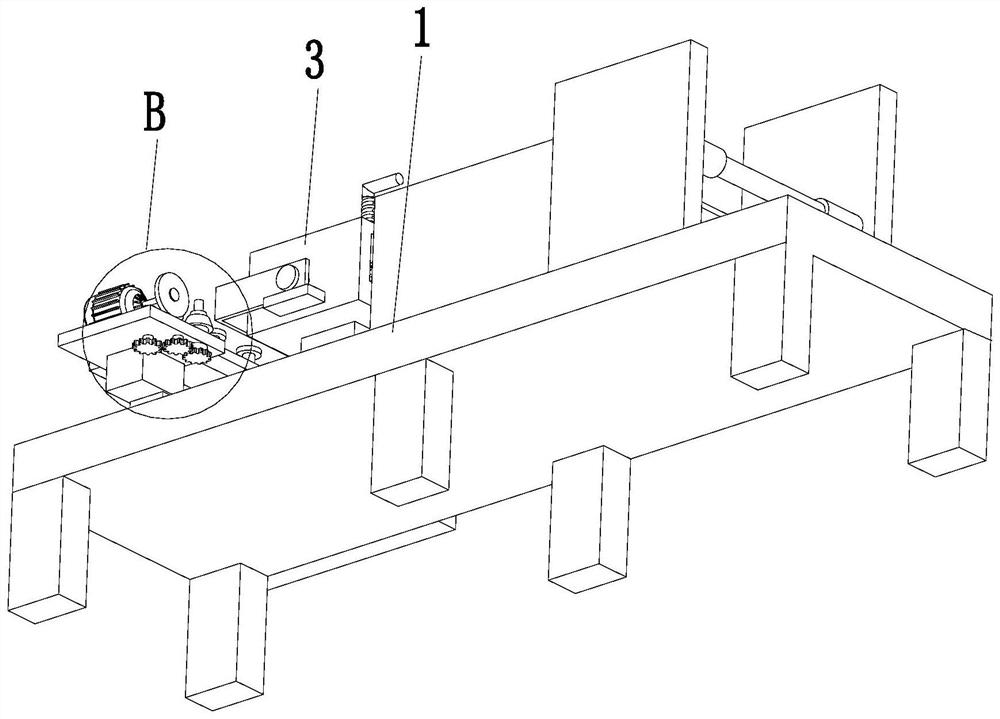

Multi-station metal automatic welding equipment

InactiveCN108817810AAvoid shakingFine alignmentWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention discloses multi-station metal automatic welding equipment. The multi-station metal automatic welding equipment structurally comprises a driving motor, a sliding rail, an adjusting device, an air sucking opening, a welding main machine, supporting legs, a hinge, a box door and a welding gun. The driving motor is fixedly installed at the upper end of the welding main machine, the sliding rail is installed on the outer surface of the upper end of the welding main machine, the adjusting device is installed on the sliding rail, is in clearance fit with the sliding rail, and is provided with the welding gun, and the upper end of the air sucking opening is fixedly installed at the exterior of the upper end of the welding main machine. Through a fine adjustment and a welding gun lifting mechanism, no dead corner can be generated in the brass solder process, all positions of a workpiece can be welded, and the manual welding workload of a worker is reduced; meanwhile, a containingstrengthening mechanism on a containing mechanism can be used for strengthening workpieces in different sizes, so that the workpieces are firmer in the brass solder process, and cold solder joints caused by workpiece swing are prevented; and a vibration filtering mechanism is used for filtering poisonous gas generated in the brass solder process, and health of the worker is protected.

Owner:FOSHAN JIELAN ROBOT CO LTD

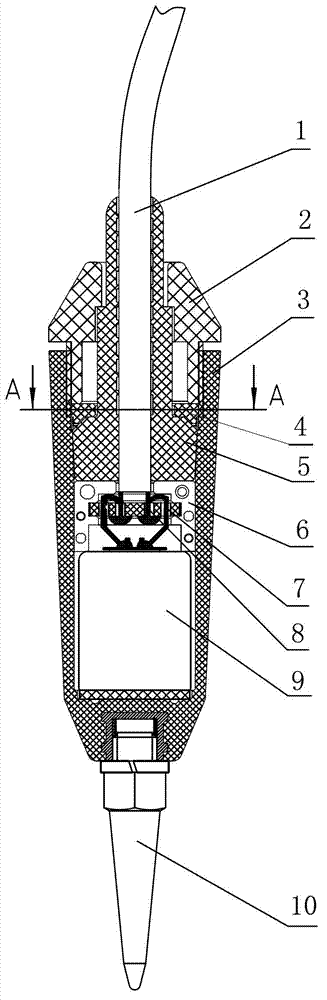

Marsh geophone

The invention relates to a marsh geophone which solves the technical problems that a connecting wire core of the existing marsh geophone is difficult to weld; the production efficiency is low during batch production; quality defects of cold solder joint, welding slags of welding spots and the like occur frequently; the maintenance is difficult; the stretching resistance between an outgoing cable and a geophone core is weak; and the welding spot is easy to snap and short out because of the twisting force. The marsh geophone is provided with an outer protecting shell, a geophone core, a supporting shock insulator, a sealing guide sleeve, a compression plug, a pressure pad, an outgoing cable and a tail core, wherein the supporting shock insulator, which is a tensile supporting shock insulator, is provided with a tensile notch and a tensile connecting circuit board; and the pressure pad is a torsion-proof pressure pad. The marsh geophone can be widely used for marsh and shoal geophones.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

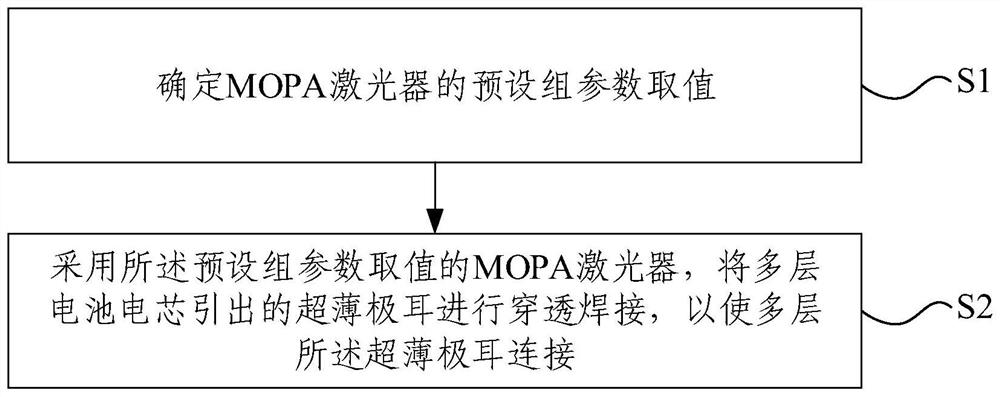

Ultra-thin electrode tab welding method

PendingCN112894137AImprove securityReduce the temperatureLaser beam welding apparatusEngineeringErbium lasers

The invention provides an ultra-thin electrode tab welding method. An MOPA laser with a preset set of parameter values is adopted to weld ultra-thin electrode tabs which are led out from multiple layers of battery cells and have the thickness of being smaller than 0.2mm, so that the multiple layers of ultra-thin electrode tabs are connected. Due to the fact that the single-point power of the MOPA laser is high, the welding speed can be increased; and due to the fact that the Q pulse width of the MOPA laser is in a nanometer level, the time of a laser point for staying in a welding area can be shorter, then the temperature of the welding area in the welding process can be reduced, the temperature requirement can be met, the situation that the phenomenon of welding point failure and the phenomenon of insufficient welding cannot appear when the multiple layers of ultra-thin electrode tabs are subjected to penetration welding can be guaranteed, the smoothness of a welding line is ensured, the risk of generating potential safety hazards is reduced, and the battery safety is improved. In addition, due to the selection of the preset set of parameter values, the welding result can meet the tension requirement.

Owner:WUHAN YIFI LASER EQUIP CO LTD

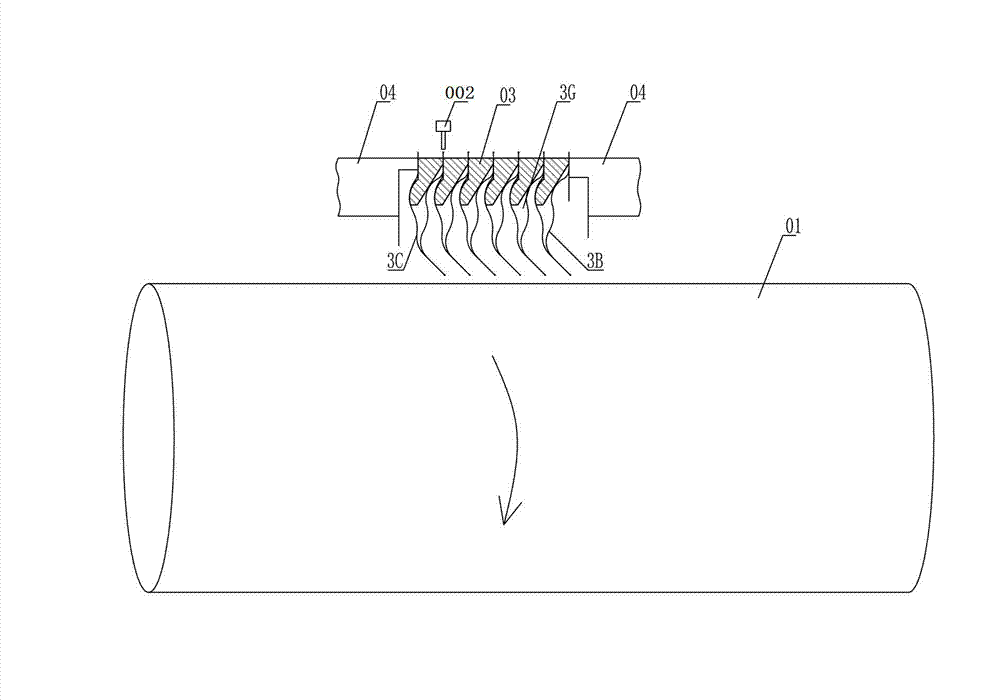

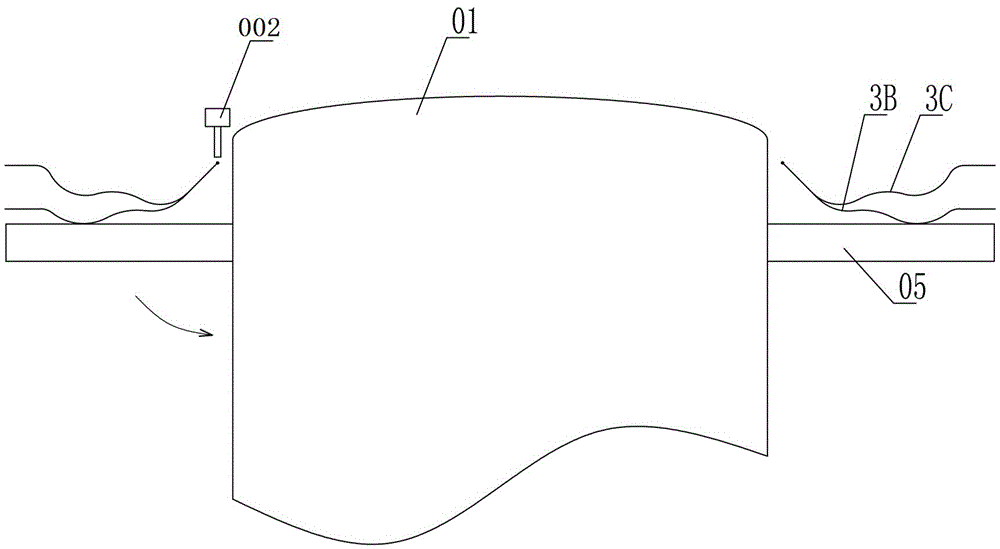

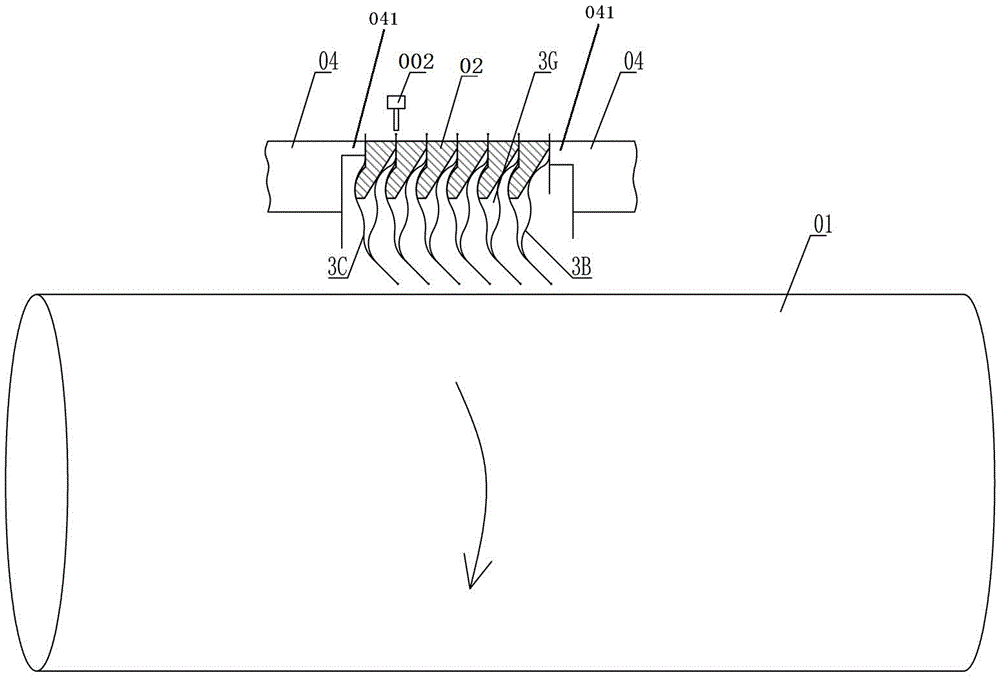

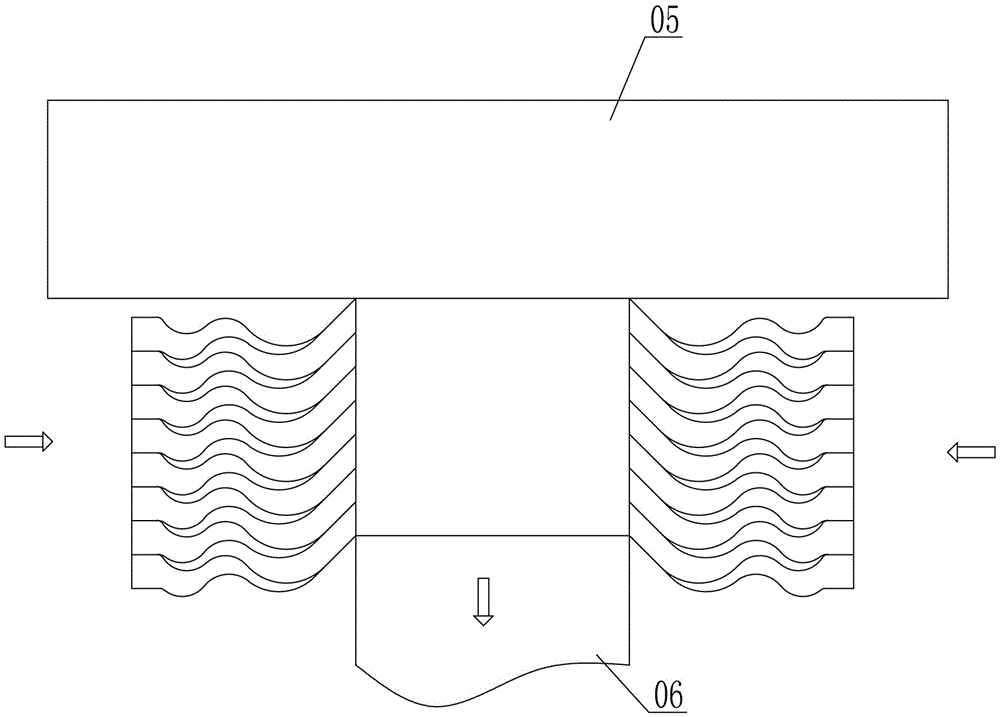

Welding process and application device of corrugated pipe assembly

ActiveCN103753038AHigh strengthImprove cooling effectPump componentsPumpsStructural engineeringMechanical engineering

The invention discloses a welding process and an application device of a corrugated pipe assembly. The welding process includes steps that a, primary and secondary pieces are formed by welding; b, a corrugated pipe core is formed by welding; c, a corrugated pipe is formed by welding; d, the corrugated pipe assembly is formed by welding; a sealing performance test is performed. A corrugated pipe sealing device is characterized by comprising the corrugated pipe assembly, a casing, a stationary ring and a moving ring, wherein the left end of the casing is embedded into a groove face, the stationary ring is arranged in a step surface, the moving ring is attached to the end face of the stationary ring, and a contact face forms a sealing end face. The welding process and the application device of the corrugated pipe assembly have the advantages that the welding efficiency is high, the accuracy is good, the elastic compensation is stable, and the service life is long.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

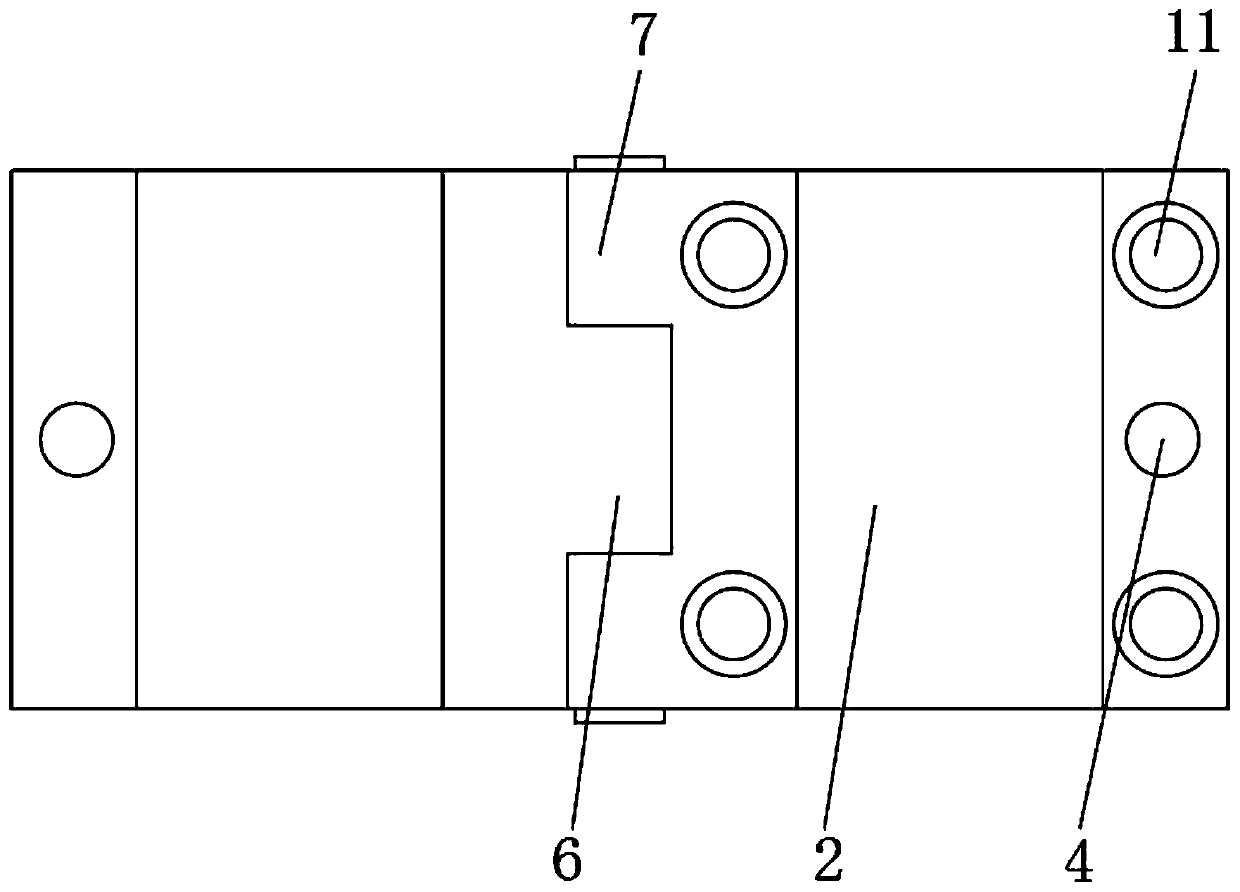

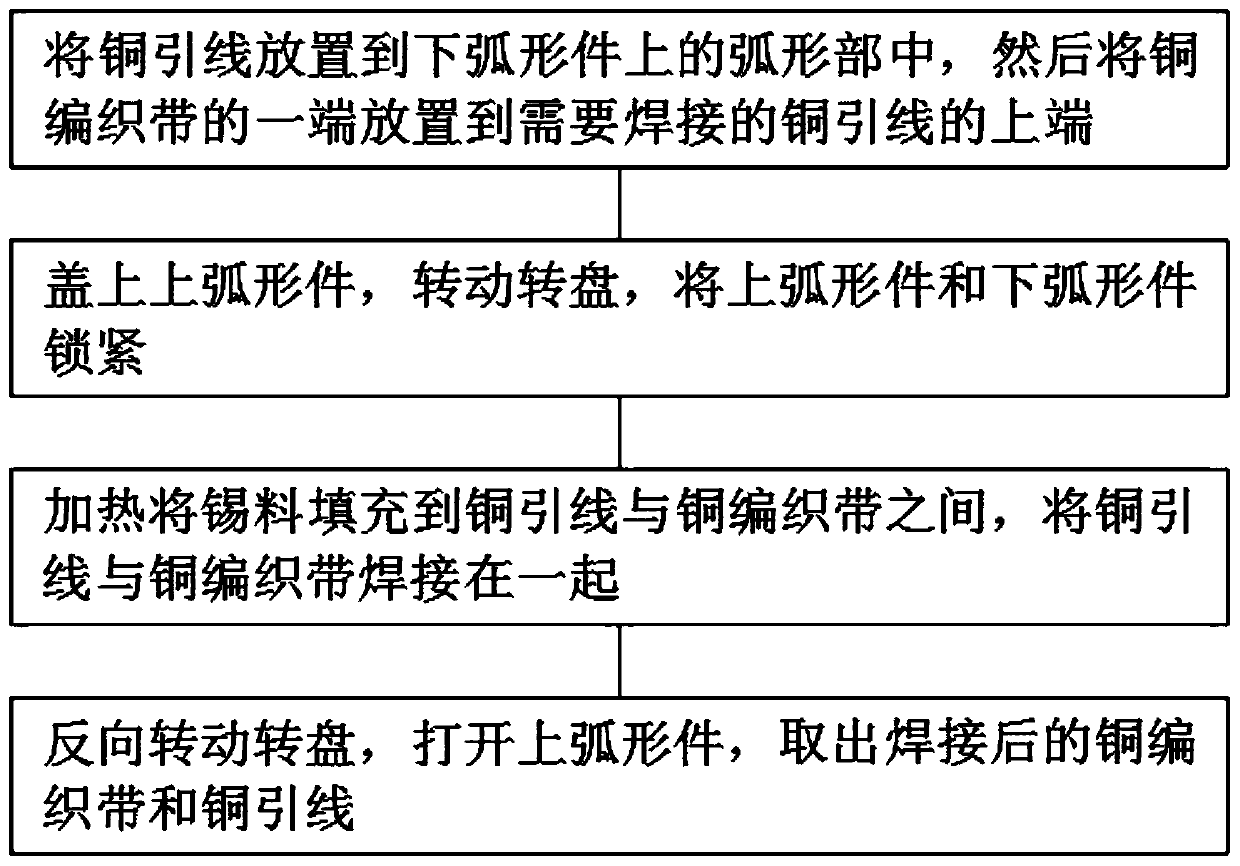

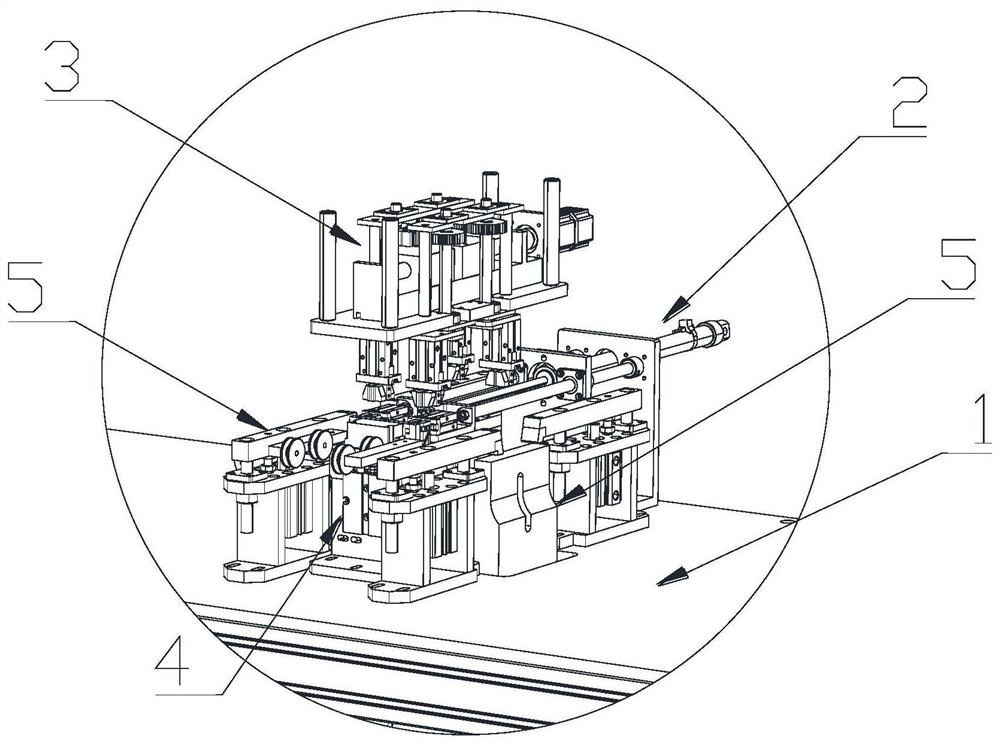

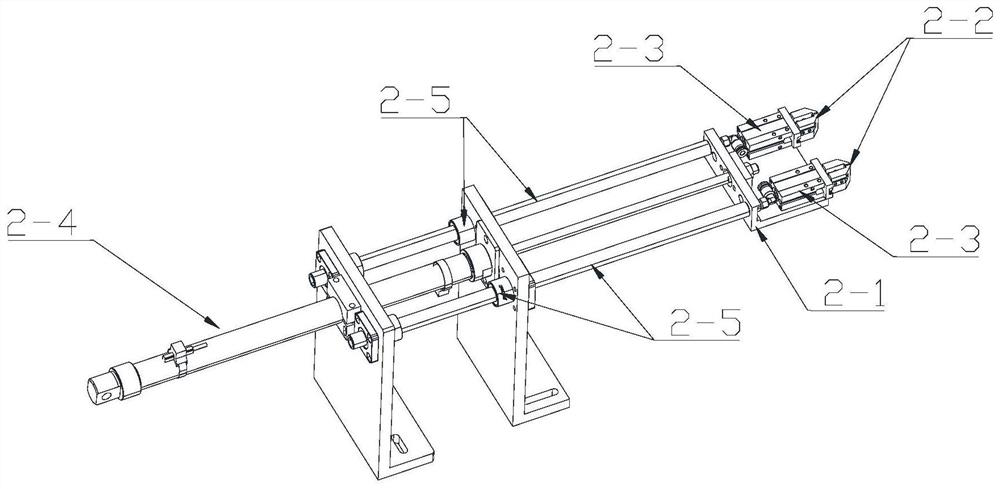

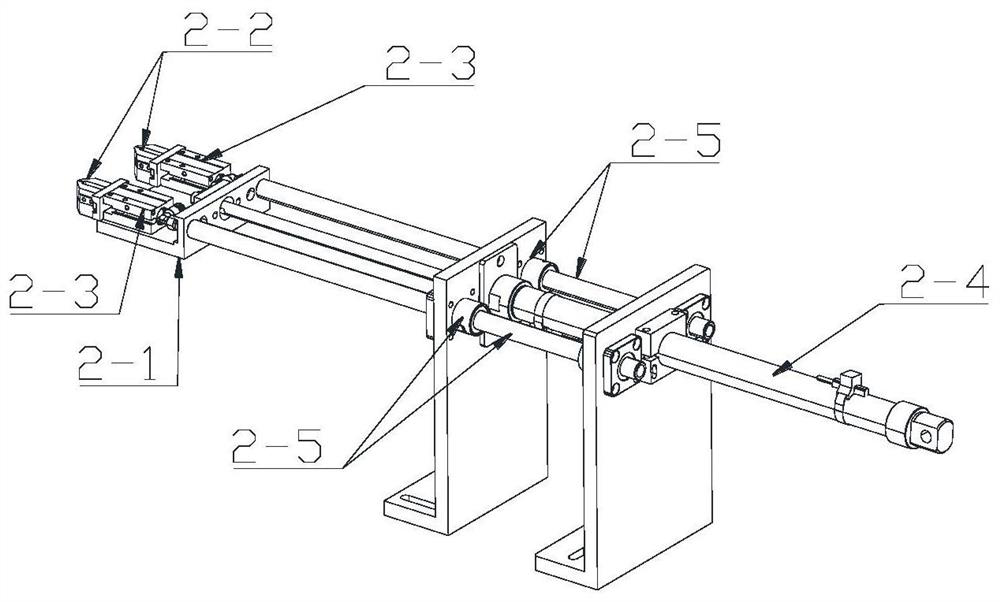

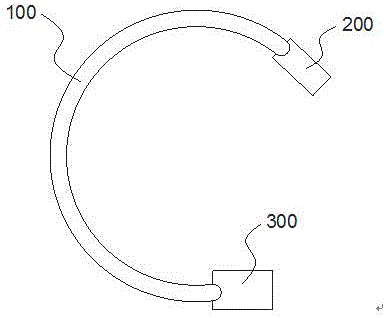

Welding tool and method for copper woven belt and copper lead

InactiveCN111001892AReduce welding costsReduce the degree of oxidationLine/current collector detailsMetal working apparatusSolderingCopper

The invention discloses a welding tool and method for a copper woven belt and a copper lead. The welding tool comprises an upper arc-shaped piece, a lower arc-shaped piece, a locking bolt and a connecting device. According to the welding tool and method for the copper woven belt and the copper lead, firstly, the copper woven belt and the copper lead are fixed through the welding tool, the whole welding process of the copper woven belt and the copper lead can be completed by one person, and the welding cost is low; secondly, the area, exposed to air, of the copper woven belt is reduced during welding, so that the oxidation degree of the copper woven belt is reduced, tin materials can be conveniently accumulated, and then welding flux at the welding position is dense and fastened; and finally, the copper woven belt is pressed during welding, so that one side of the copper woven belt is smooth and full during welding, burrs and other edges and corners generated during welding are reduced,the situation of pseudo soldering is avoided, the welded copper woven belt and the copper lead can be conveniently assembled, the workload of operators is reduced, and better use prospects are brought.

Owner:合肥科聚低温技术有限公司

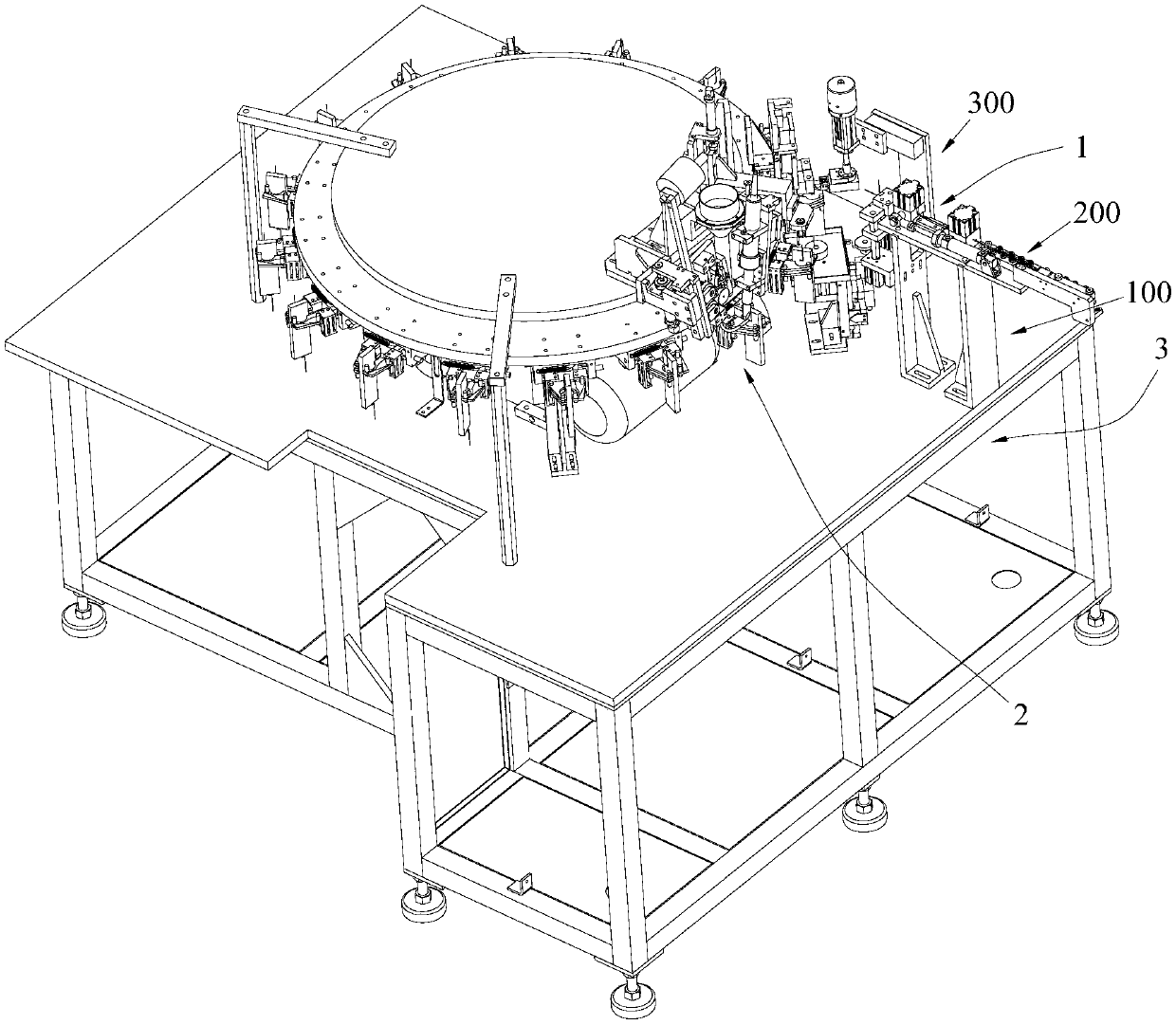

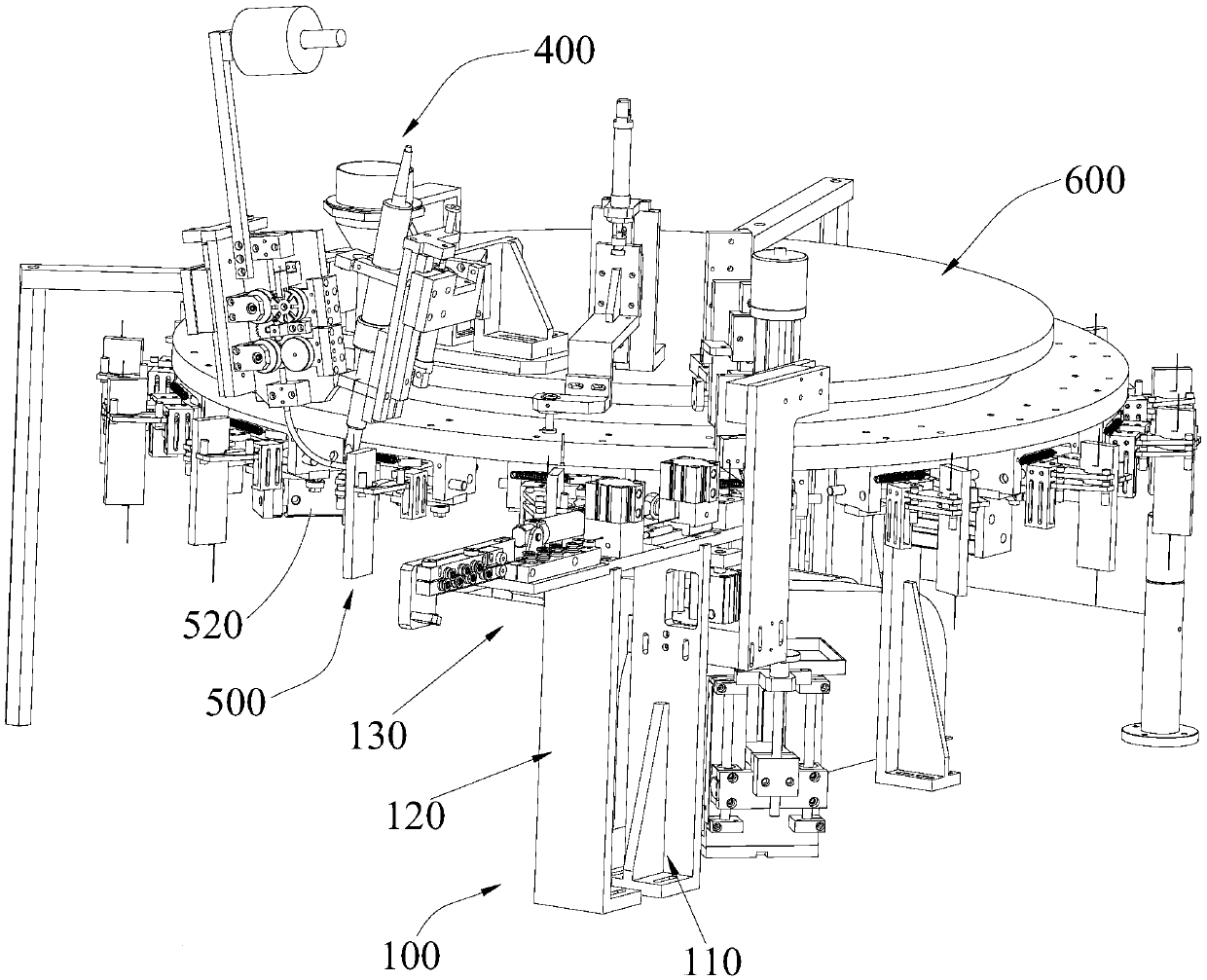

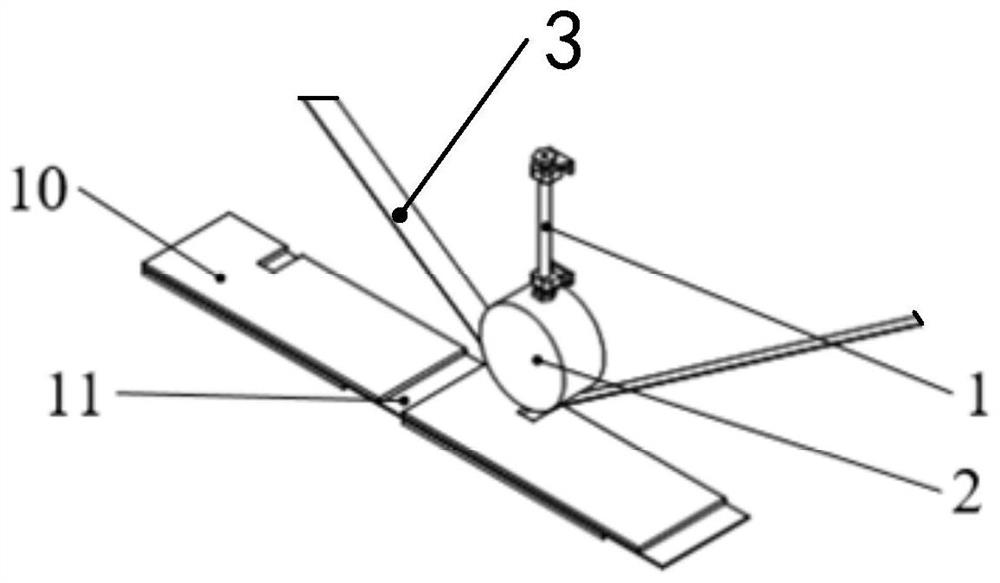

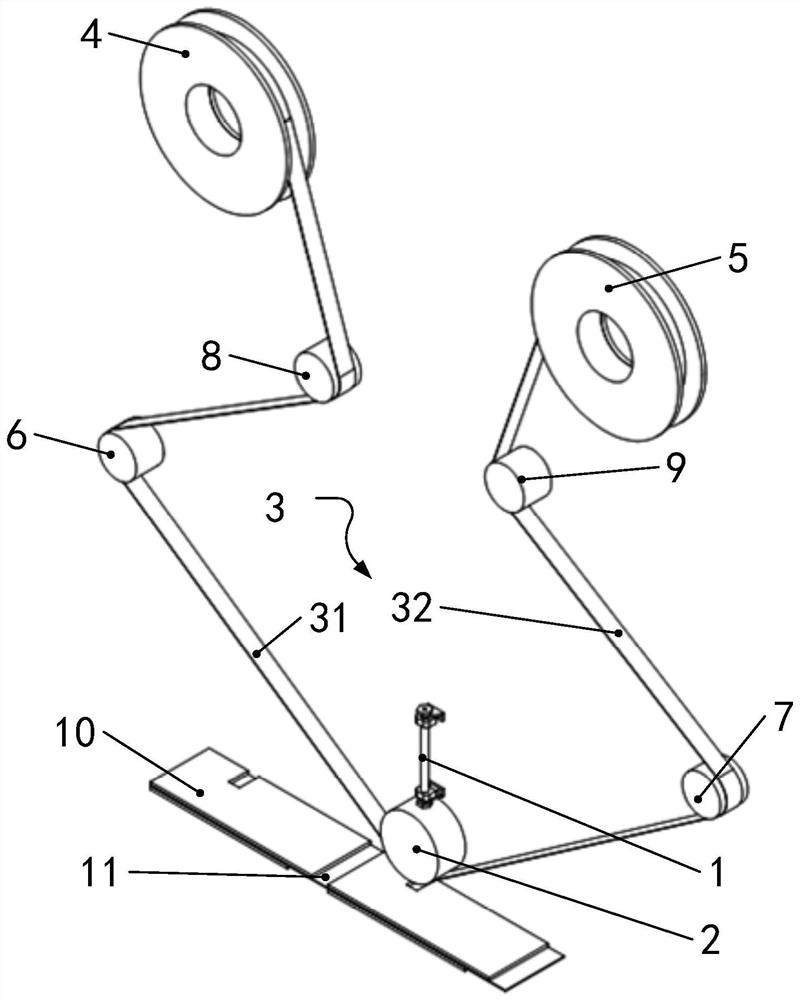

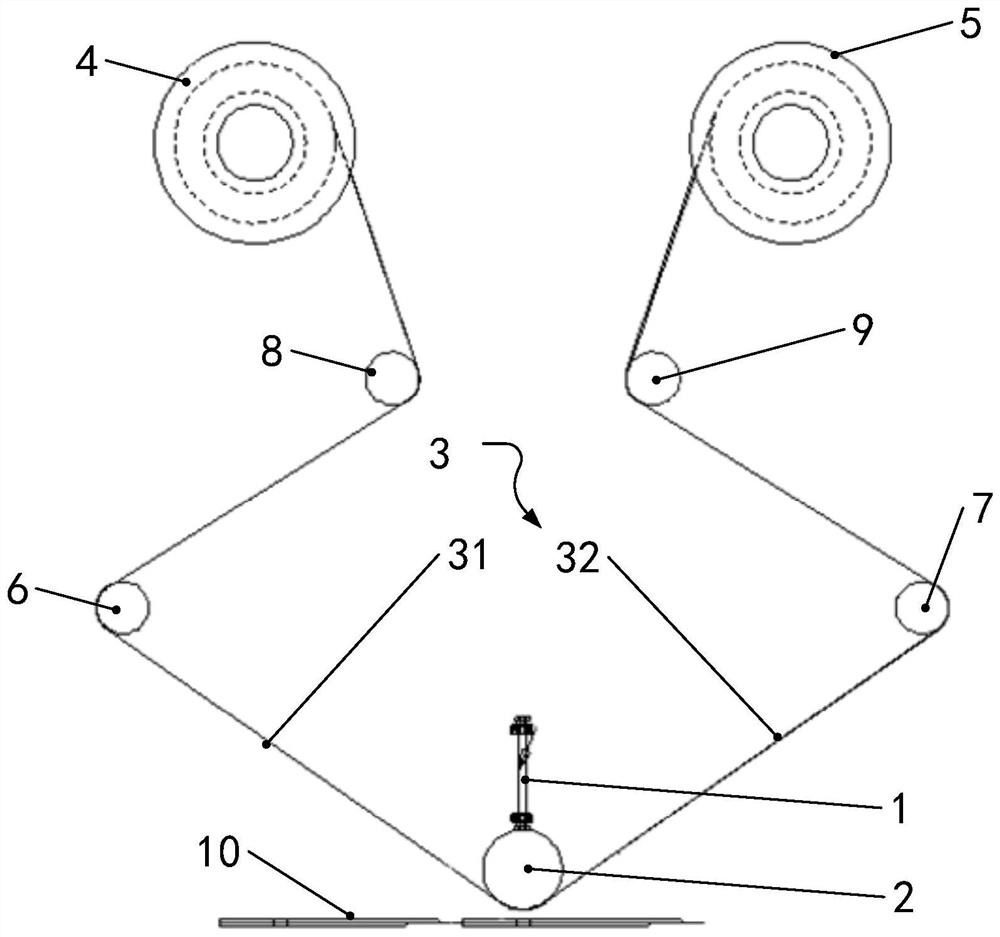

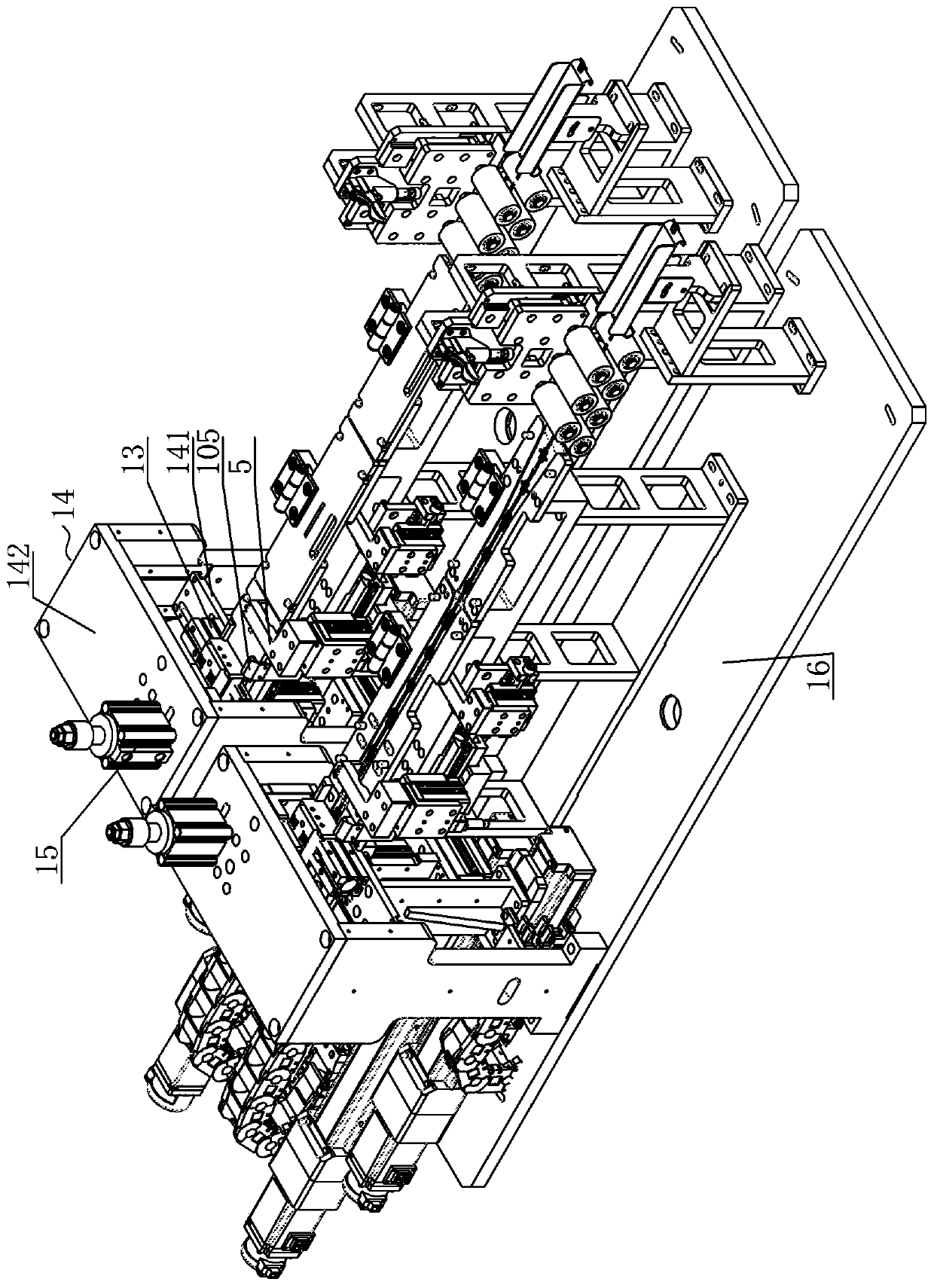

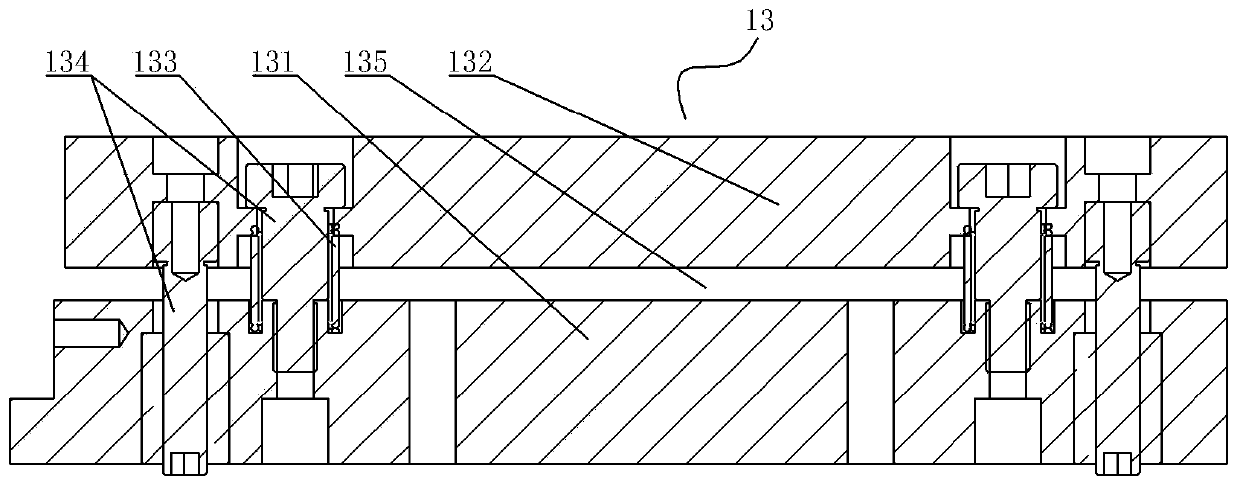

Ear wire welding device for planar mask machine

ActiveCN111993673AImprove positional accuracyProduct quality and high yield ratePhysicsMechanical engineering

The invention discloses an ear wire welding device for a planar mask machine, comprising a frame, an ear wire loading apparatus and an ear wire welding apparatus. The ear wire loading apparatus comprises an ear wire conveying apparatus, an ear wire clamping and carrying apparatus and an ear wire shearing apparatus; the ear wire conveying apparatus comprises a clamping base, a first clamping mechanism and a clamping conveying mechanism; the ear wire clamping and conveying apparatus comprises a bracket, a second clamping mechanism, a vertical driving mechanism and a rotary driving mechanism; therotary driving mechanism is used for driving the second clamping mechanism in the same set to reversely rotate at the same time; the ear wire shearing apparatus is used for shearing an ear wire afterthe second clamping mechanism clamps the ear wire; and the ear wire welding apparatus comprises an ultrasonic welding head, a movable mold and a movable mold driving mechanism. The ear wire welding device of the invention is suitable for welding the ear wire of a mask body conveyed on a guide rail in the length direction of a mask; and the welded ear wire is positioned within the edge of a mask basal body to facilitate subsequent packaging.

Owner:广州智灵动技术有限公司

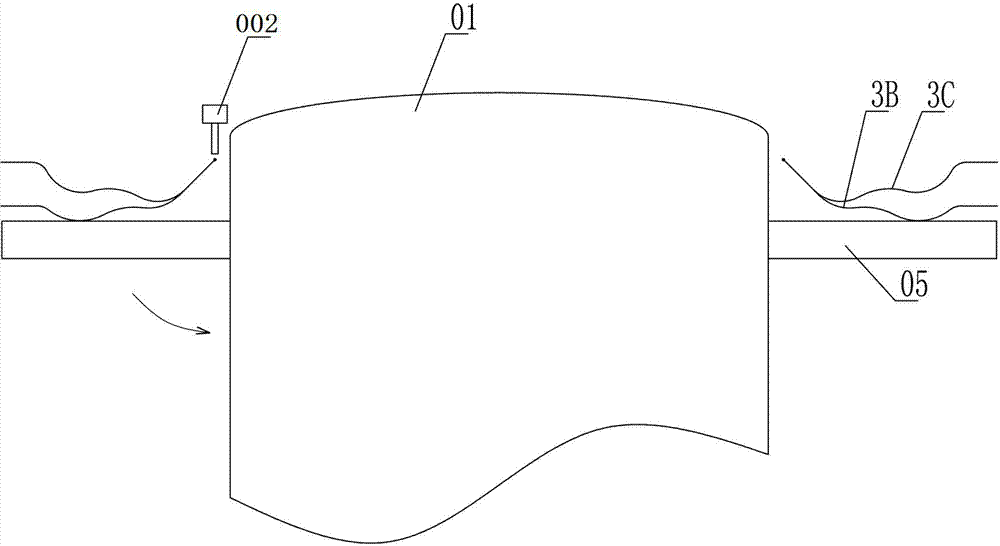

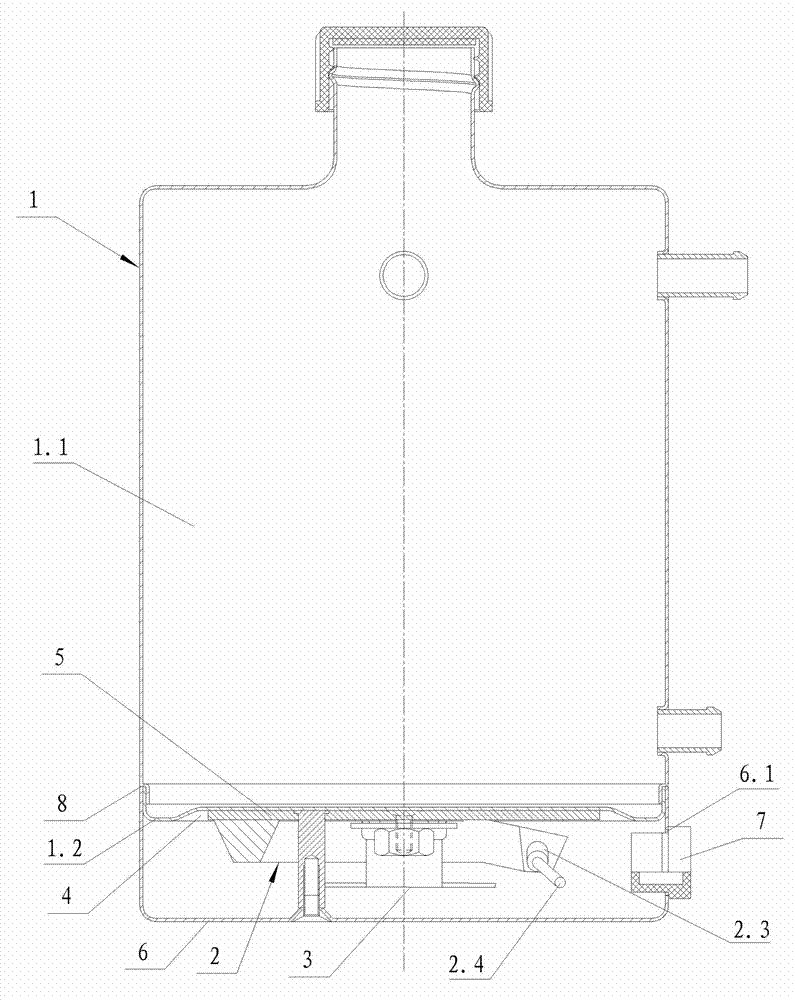

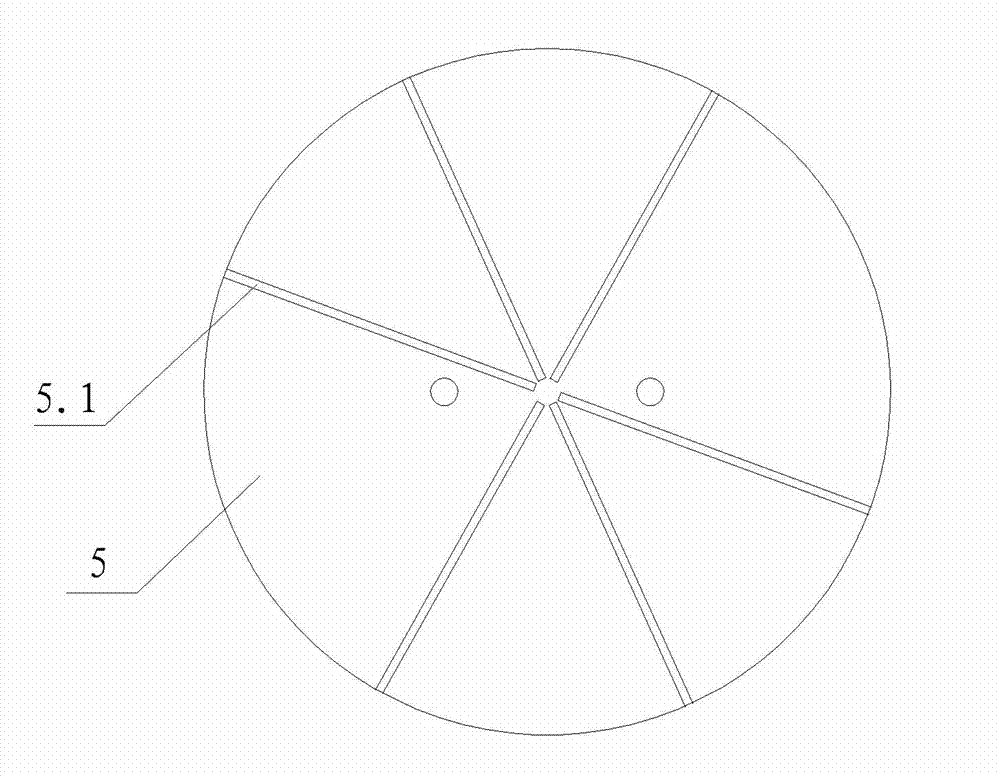

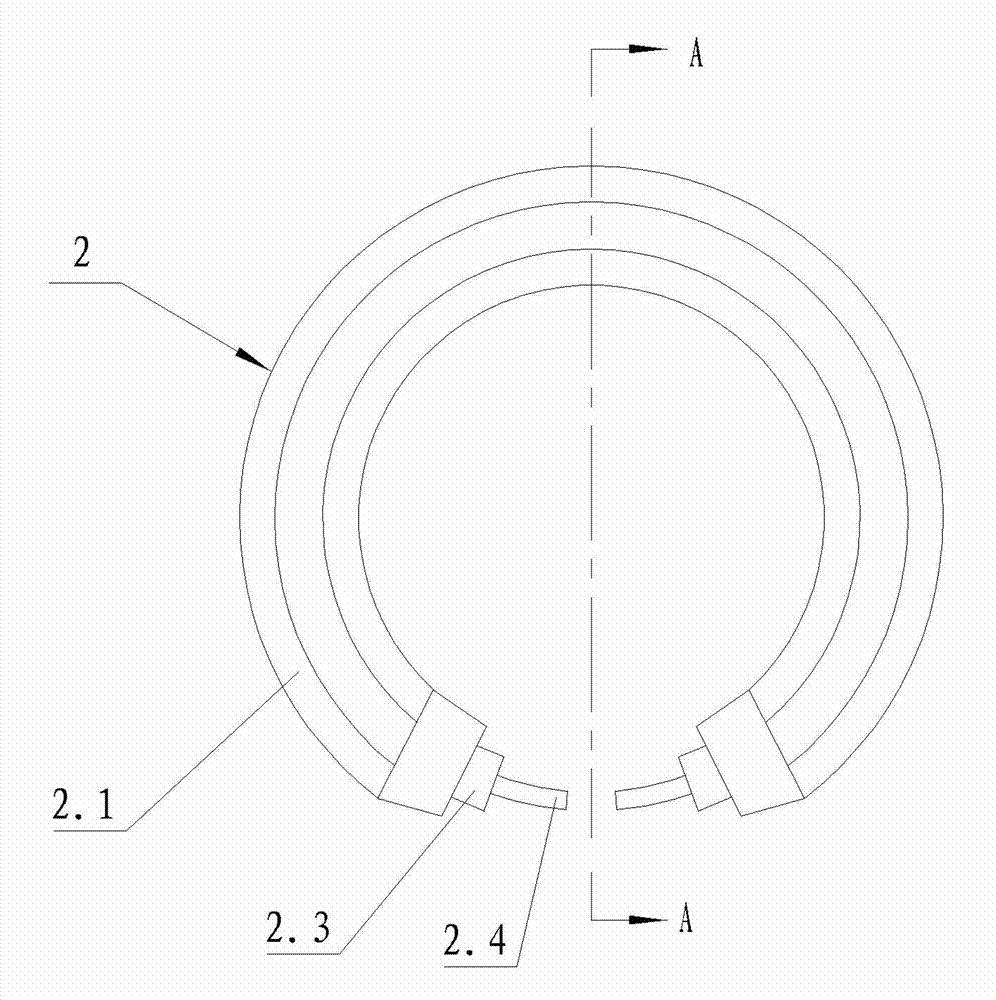

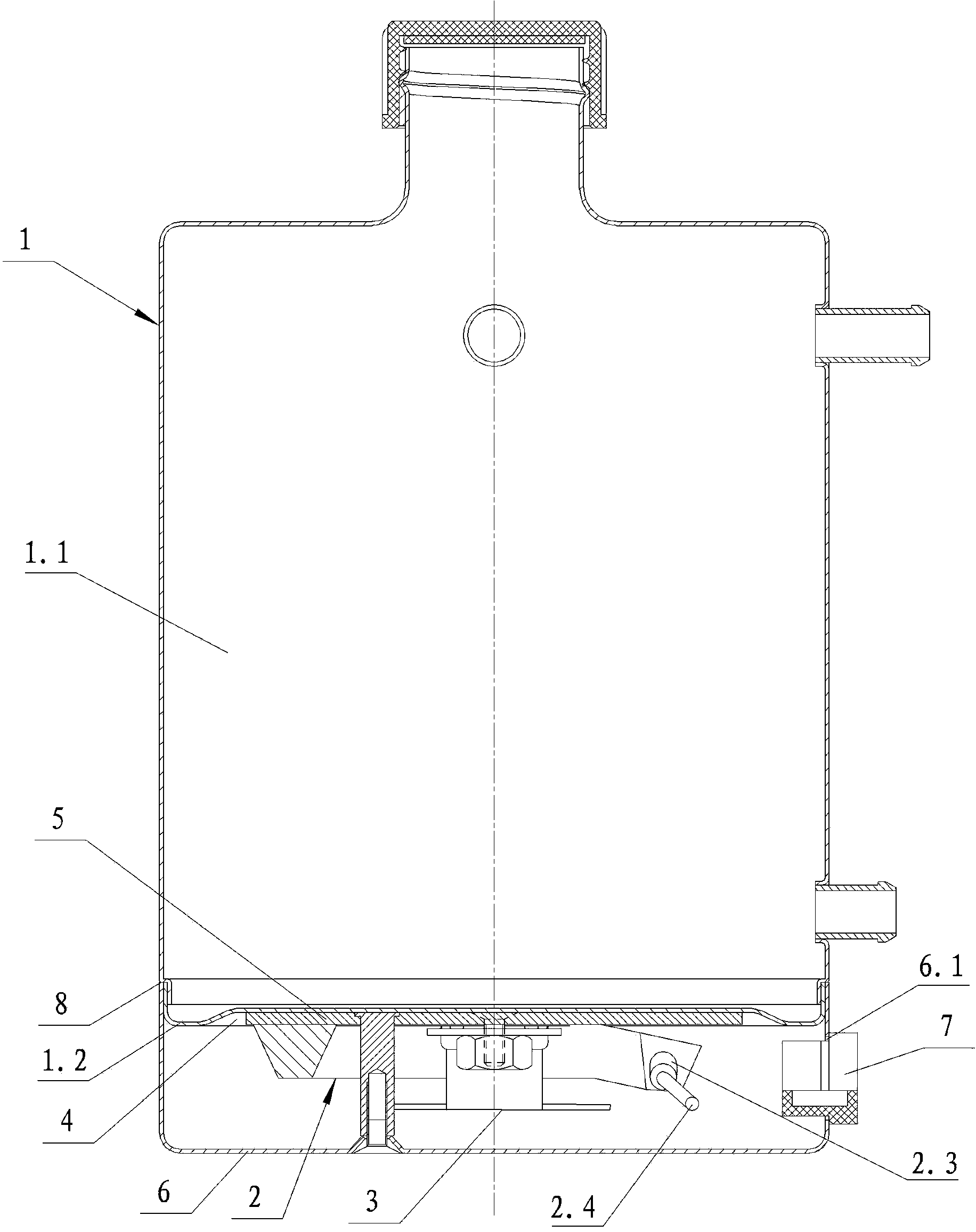

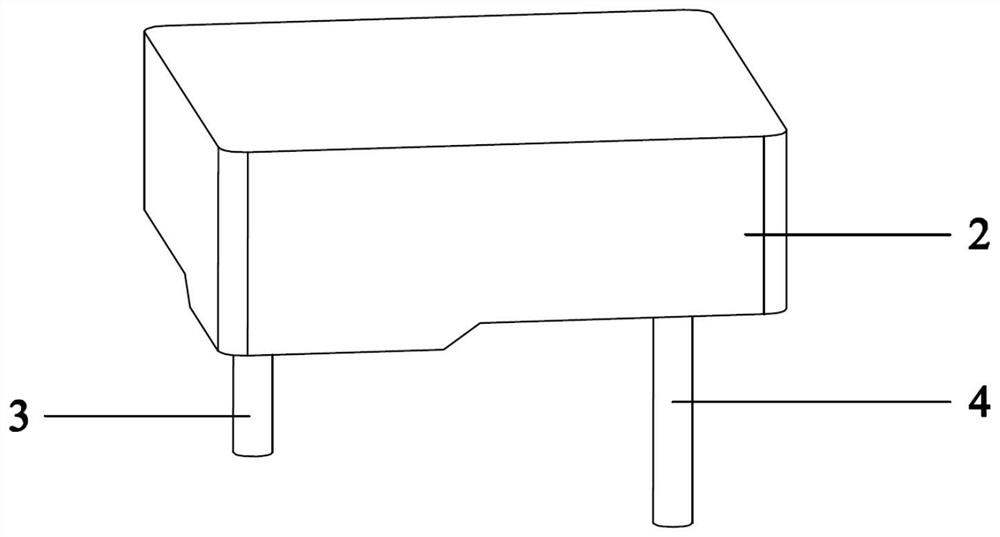

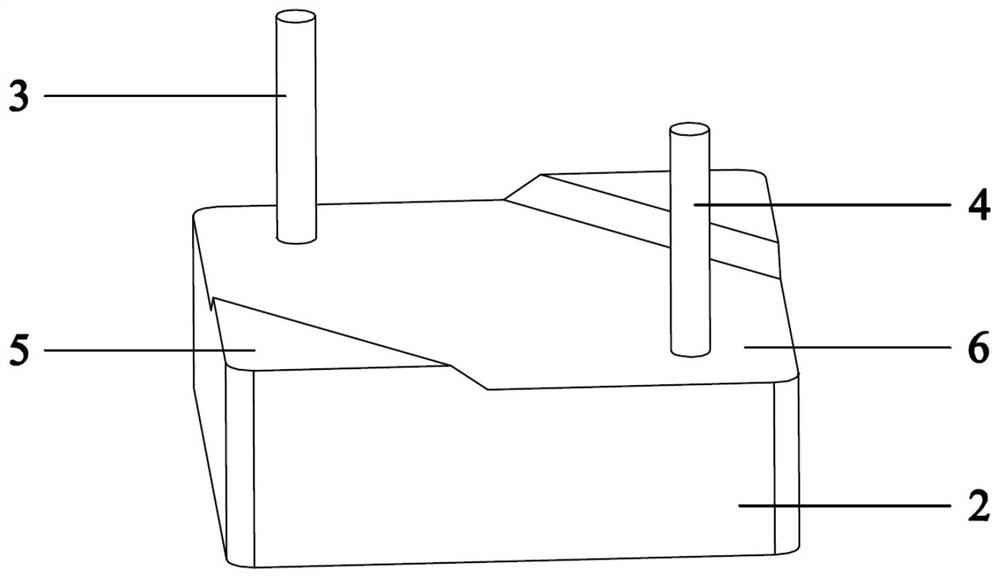

Oil heater and welding method thereof

The invention discloses an oil heater. A heating device (2) and a temperature controller (3) are connected to the bottom surface of a tank body (1); a groove (4) is arranged on the bottom surface of the tank body (1); the heating device (2) and the temperature controller (3) are located in the groove (4); a heat conducting plate (5) is arranged between the heating device (2) and the bottom surface of the groove (4); the shape of the heat conducting plate (5) is the same as that of the bottom surface of the groove (4); one plane of the heat conducting plate (5) is completely fitted with the bottom surface of the groove (4); and the heating device (2) and the temperature controller (3) are connected to the other plane of the heat conducting plate (5). The welding method of the oil heater comprises the following steps for welding the heating device (2) and the heat conducting plate (5): 1) preparing base solution and dry powder; 2) applying the base solution; 3) sprinkling the dry powder on the base solution; 4) turning on a soldering machine and preheating a cushion block of the soldering machine; 5) putting the heating device (2) and the heat conducting plate (5) on the cushion block; 6) pressing the heating device (2) and the heat conducting plate (5); and 7) applying gypsum paste. Compared with the prior art, the oil heater disclosed by the invention has the characteristics that the sound is lower during heating and the difference between the temperature measured by the temperature controller and the actual temperature of the oil is smaller.

Owner:宁波联合华发五金机械有限公司

Welding fixing device

PendingCN112355429AEliminate inner wall crushReinforced outer surface elasticWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention discloses a welding fixing device. The welding fixing device comprises a welding fixing device body composed of a tray, a base and a supporting rod, wherein the top of the tray is fixedly connected with the bottom of the base; a groove is formed in the top of the base; the bottom of the inner wall of the groove is fixedly connected with the bottom of the supporting rod; the supporting rod is sleeved with a first welding piece; a second welding piece is connected into the first welding piece in a sliding manner; the supporting rod comprises a rod body; a fixing mechanism and a correcting mechanism are arranged in the rod body; the fixing mechanism comprises a rotating rod; and a sliding mechanism is arranged on the top of the rotating rod. The invention relates to the technical field of welding. The welding fixing device solves the problems that due to transverse welding, welding defects such as unsmooth welding seams on the surface of a welding part, uneven and full fillet filling, base metal corrosion, over-burning blackening, undercut (pipe opening burning), overlap height, cracks, air holes and impurities are caused.

Owner:雒明伟

Sulfur hexafluoride density relay and density table C-shaped pipe and making technology thereof

PendingCN106057570AThere will be no false weldingImprove welding efficiencyElectric switchesSolderingOxide

The present invention relates to a sulfur hexafluoride density relay and a density table C-shaped pipe. The pipe comprises a C-shaped pipe body, a pedestal and an end base, the pedestal and the end base are respectively connected with two ends of the C-shaped pipe body, and tin layers area arranged at the outer surfaces of the C-shaped pipe body, the pedestal and the end base. The making technology comprises the following steps: (1) performing pickling of the surfaces of the C-shaped pipe body, the pedestal and the end base, and removing the oxide and the impurity of the surface of the brass; (2) disposing the C-shaped pipe body, the pedestal and the end base into the dissolved tin liquor, and plating the tin layers on the surfaces of the C-shaped pipe body, the pedestal and the end base; and (3) connecting the pedestal and the end base with the two ends of the C-shaped pipe body through soldering. When the C-shaped pipe body is soldered with the pedestal and the end base, because there is a layer of tinning at the surface of the C-shaped pipe body, the pseudo soldering condition can not generate at soldering, and the efficiency and the reliability of the soldering are greatly improved.

Owner:上海上芃电气有限公司

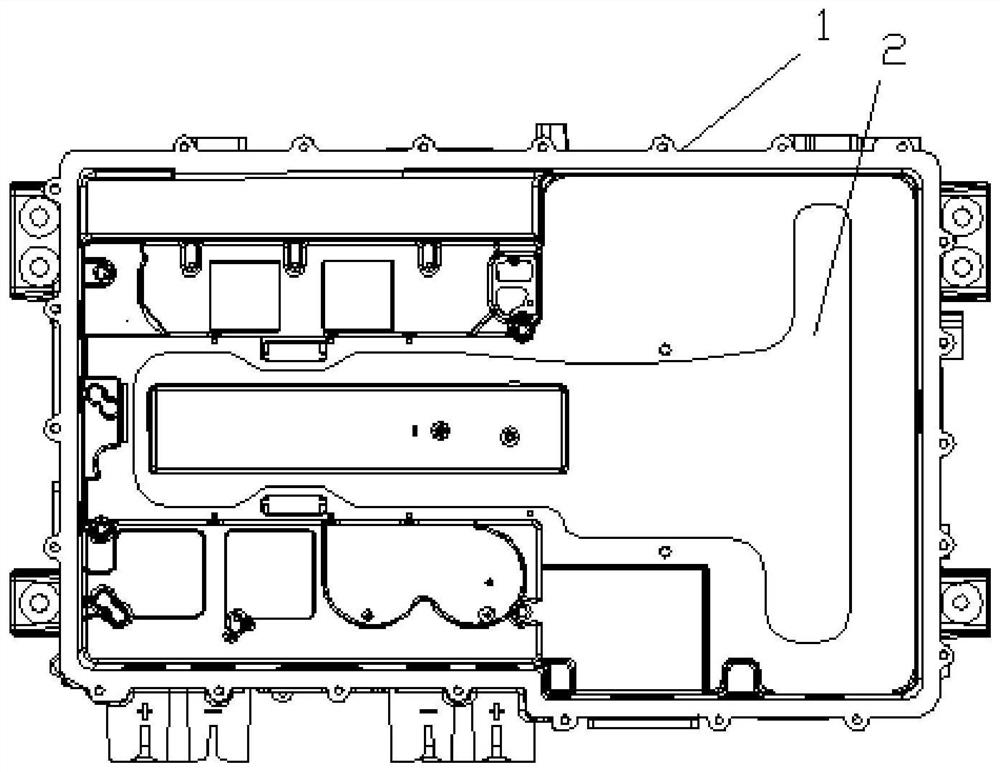

Manufacturing method for automobile central control box and new energy automobile

InactiveCN111822948AHighly integratedImprove air tightnessNon-electric welding apparatusFriction weldingPressure casting

The invention discloses a manufacturing method for an automobile central control box. A low-pressure casting mode is adopted to manufacture a central control box body with a water channel; a water channel cover plate with a water flow groove is flushed in a CNC mode; and then the water channel cover plate is welded to the water channel of the central control box body through friction welding, andthe welded water channel cover plate and the central control box body form a sealed cavity. The central control box body with the water channel is manufactured in the low-pressure casting mode, the water channel cover plate with the water channel is manufactured in the CNC mode, and the central control box body and the water channel cover plate are welded in the friction welding mode, a brand-newprocess is formed. When the process is used for manufacturing the central control box, the mold opening cost is low, the mold opening period is short, the process is simplified, the produced automobile central control box is good in air impermeability and mechanical performance, the production cost is saved, and the formed central control box is high in integration level.

Owner:广东九九华立新材料股份有限公司

Cleaning mechanism and cleaning machine

PendingCN113798272AAvoid damageThere will be no false weldingCleaning using toolsPull forceEngineering

The invention discloses a cleaning mechanism and a cleaning machine. The cleaning mechanism comprises a driving part, a first roller, a cleaning belt and a connecting mechanism; the cleaning belt is provided with a cleaning surface; the driving end of the driving part is fixedly connected with the first roller; two ends of the cleaning belt are connected with the connecting mechanism respectively so that the connecting mechanism can provide pulling force for the cleaning belt; the cleaning belt is wound on the first roller through the pulling force, and the cleaning surface deviates from the first roller; and the driving part drives the first roller to move between a first position close to workpieces and a second position away from the workpieces. According to the cleaning mechanism and the cleaning machine, residual dust after the electrode plates (workpieces) are cleaned can be removed, so that it is ensured that the condition of insufficient welding or welding failures is avoided during subsequent tab welding.

Owner:SHENZHEN BYD LITHIUM BATTERY

Welding fixture

The invention relates to a welding fixture which comprises an upper pressure plate and a lower pressure plate, wherein the upper pressure plate and the lower pressure plate comprise central positioning holes which are arranged coaxially, the lower pressure plate is provided with a tooth block positioning hole, a tooth block mounting groove is arranged on the lower surface of the lower pressure plate and the welding fixture is characterized in that a tooth block positioning screw rod and a tooth block pressure spring are mounted between the upper pressure plate and the lower pressure plate. The welding fixture is simple in structure and can always keep the fastening connection between a tooth block and the welding surface of a basal body by high-temperature welding and avoid the phenomena of looseness and poor welding.

Owner:江苏华昌工具制造有限公司

A kind of plane mask production equipment and production method

ActiveCN112026186BAvoid the defects of the production methodHigh positioning accuracyDomestic articlesClothes making applicancesWelding

Owner:广州智灵动技术有限公司

A pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Oil heater and welding method thereof

ActiveCN102765564BFast heat conductionClose contactSoldering apparatusTank wagonsHeat conductingEngineering

The invention discloses an oil heater. A heating device (2) and a temperature controller (3) are connected to the bottom surface of a tank body (1); a groove (4) is arranged on the bottom surface of the tank body (1); the heating device (2) and the temperature controller (3) are located in the groove (4); a heat conducting plate (5) is arranged between the heating device (2) and the bottom surface of the groove (4); the shape of the heat conducting plate (5) is the same as that of the bottom surface of the groove (4); one plane of the heat conducting plate (5) is completely fitted with the bottom surface of the groove (4); and the heating device (2) and the temperature controller (3) are connected to the other plane of the heat conducting plate (5). The welding method of the oil heater comprises the following steps for welding the heating device (2) and the heat conducting plate (5): 1) preparing base solution and dry powder; 2) applying the base solution; 3) sprinkling the dry powder on the base solution; 4) turning on a soldering machine and preheating a cushion block of the soldering machine; 5) putting the heating device (2) and the heat conducting plate (5) on the cushion block; 6) pressing the heating device (2) and the heat conducting plate (5); and 7) applying gypsum paste. Compared with the prior art, the oil heater disclosed by the invention has the characteristics that the sound is lower during heating and the difference between the temperature measured by the temperature controller and the actual temperature of the oil is smaller.

Owner:宁波联合华发五金机械有限公司

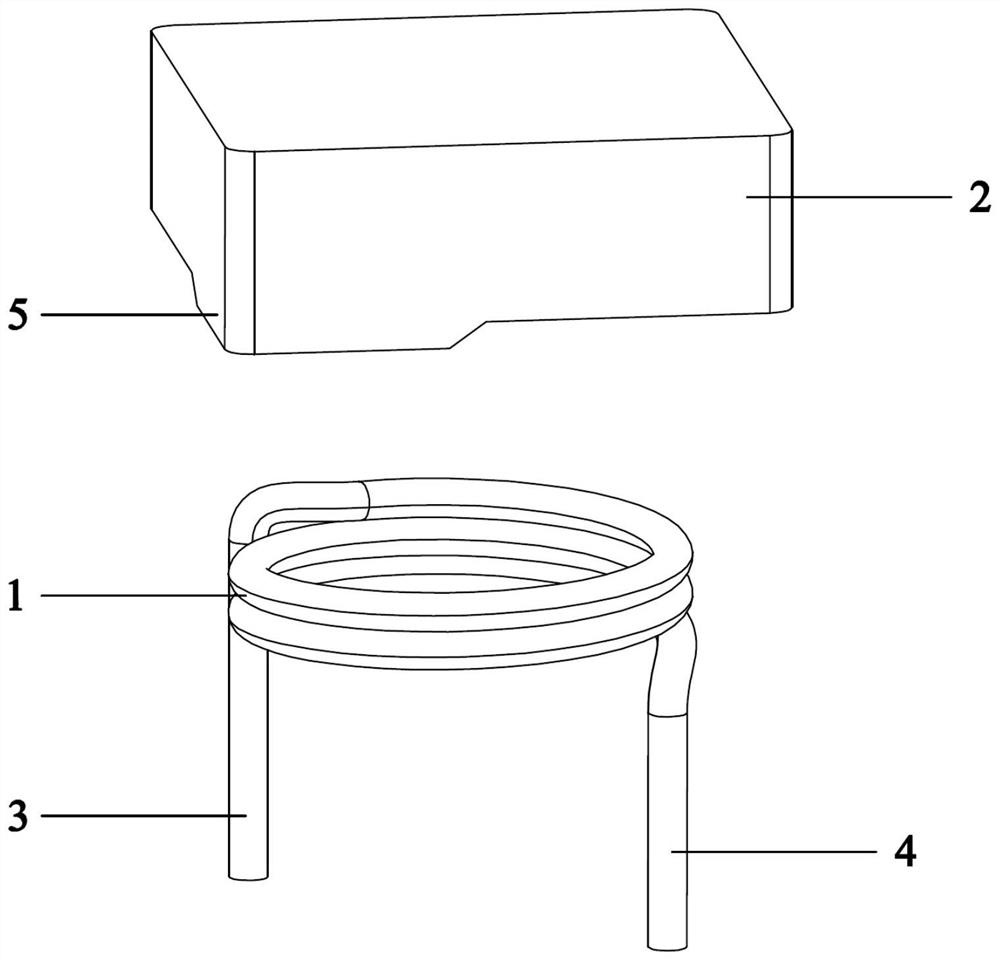

Plug-in type integrally-formed inductor

PendingCN111653417AGood anti-EMI performanceIncrease saturation currentTransformers/inductances coolingTransformers/inductances coils/windings/connectionsInductorSoldering

The invention discloses a plug-in type integrally-formed inductor, comprising a coil and a magnetic main body wrapping the outer side of the coil. A first welding pin and a second welding pin which extend downwards are arranged at the two ends of the coil respectively, a plurality of bosses are arranged at the bottom of the magnetic main body, and a plurality of heat dissipation grooves are formedbetween the bosses. According to the invention, the connector directly passes through the PCB in a plugging manner. The first welding pin and the second welding pin are firmly welded with the bottomsurface of the PCB, pseudo soldering is avoided, a high-requirement drop test can be passed, and the inductor is good in EMI resistance, large in saturation current, long in service life and small insize, and can be widely applied to automobile navigation, mobile phones, liquid crystal televisions, notebook computers, communication equipment and instruments.

Owner:江门市开源电子有限公司

Tin soldering oil smearing treatment method for COF flexible printed circuit board

ActiveCN112105172AThere will be no false weldingImprove soldering effectPrinted circuit assemblingScreen printingSoldering

The invention relates to the technical field of COF flexible printed circuit boards, and discloses a tin soldering oil smearing processing method for a COF flexible printed circuit board, and the method comprises the following steps: S1, carrying out the preliminary cleaning of the COF flexible printed circuit board; s2, wiping the cleaned COF flexible printed circuit board by using an alcohol cotton ball; s3, selecting a proper amount of soldering tin oil, and putting the soldering tin oil into a container; s4, heating the soldering tin oil placed in the container; s5, adding an activating agent during heating, and continuously heating; and S6, stirring during heating for fully mixing the activating agent and the soldering tin oil together. By improving an existing smearing method, the tin soldering oil is treated, a silk-screen printing film and a steel needle are used in the smearing process, it is guaranteed that the situation of insufficient soldering caused by bubbles cannot occur in the later-period welding process, and the purpose of a good later-period tin soldering effect is achieved.

Owner:衡阳华灏新材料科技有限公司

A kind of soldering oil smearing treatment method for cof flexible printed circuit board

ActiveCN112105172BThere will be no false weldingImprove soldering effectPrinted circuit assemblingScreen printingSoldering

The present invention relates to the technical field of COF flexible printed circuit boards, and discloses a method for smearing solder oil on COF flexible printed circuit boards, comprising the following steps: S1, firstly cleaning the COF flexible printed circuit board; S2, cleaning The final COF flexible printed circuit board is wiped with alcohol cotton ball; S3, choose the appropriate amount of solder oil, put the solder oil in a container; S4, heat the solder oil in the container; S5, heat the Then add the activator, and then continue heating; S6, stir during heating, so that the activator and solder oil are fully mixed together. The invention improves the existing smearing method, uses solder oil to process, and uses screen printing film and steel needles when smearing, so as to ensure that there will be no false soldering caused by air bubbles in the later welding process , to achieve the purpose of good soldering effect in the later stage.

Owner:衡阳华灏新材料科技有限公司

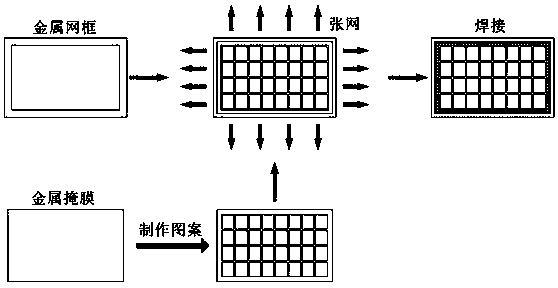

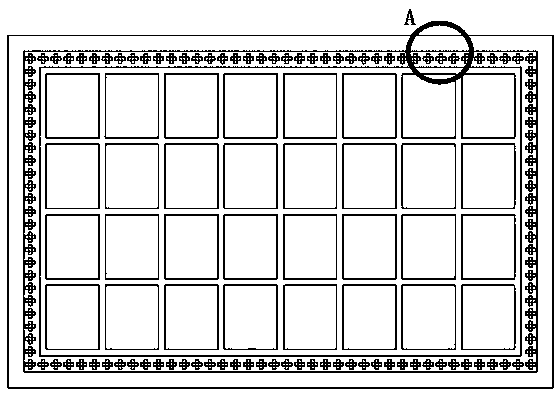

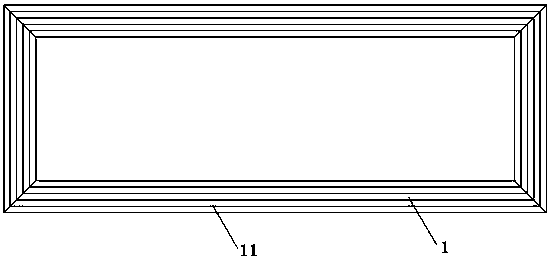

Metal mask manufacturing method and metal screen frame

PendingCN109825798AImprove bindingDoes not cause poor vapor depositionVacuum evaporation coatingSputtering coatingPrinting inkElectroplating

The invention discloses a metal mask manufacturing method and a metal screen frame. The metal mask manufacturing method comprises the following steps of: step (1), processing a convex-concave structure on the upper surface of the metal screen frame; step (2), filling a hollow part of the metal screen frame with a filler, and combining the metal screen frame and the filler to form a combined frame;step (3), cleaning the combined frame; step (4), carrying out electric conduction treatment on the filler; step (5), coating the combined frame; step (6), carrying out exposure reaction on a part where an opening is required, of the coated combined frame; step (7), developing by using developing equipment, and exposing the metal screen frame and the filler on an unexposed part; step (8), electroplating the upper surface of the combined frame, wherein a plating layer gradually grows to a place of the combined frame, which is not covered by printing ink, and forming a metal mask on the electroplating layer; and step (9), removing the coating, to be specific, putting the electroplated combined product in coating removal equipment for coating removal, and dissolving the printing ink and the filler completely by coating removal liquid medicine in the coating removal equipment to form the metal mask finished product.

Owner:NANJING TOPTO MATERIALS CO LTD

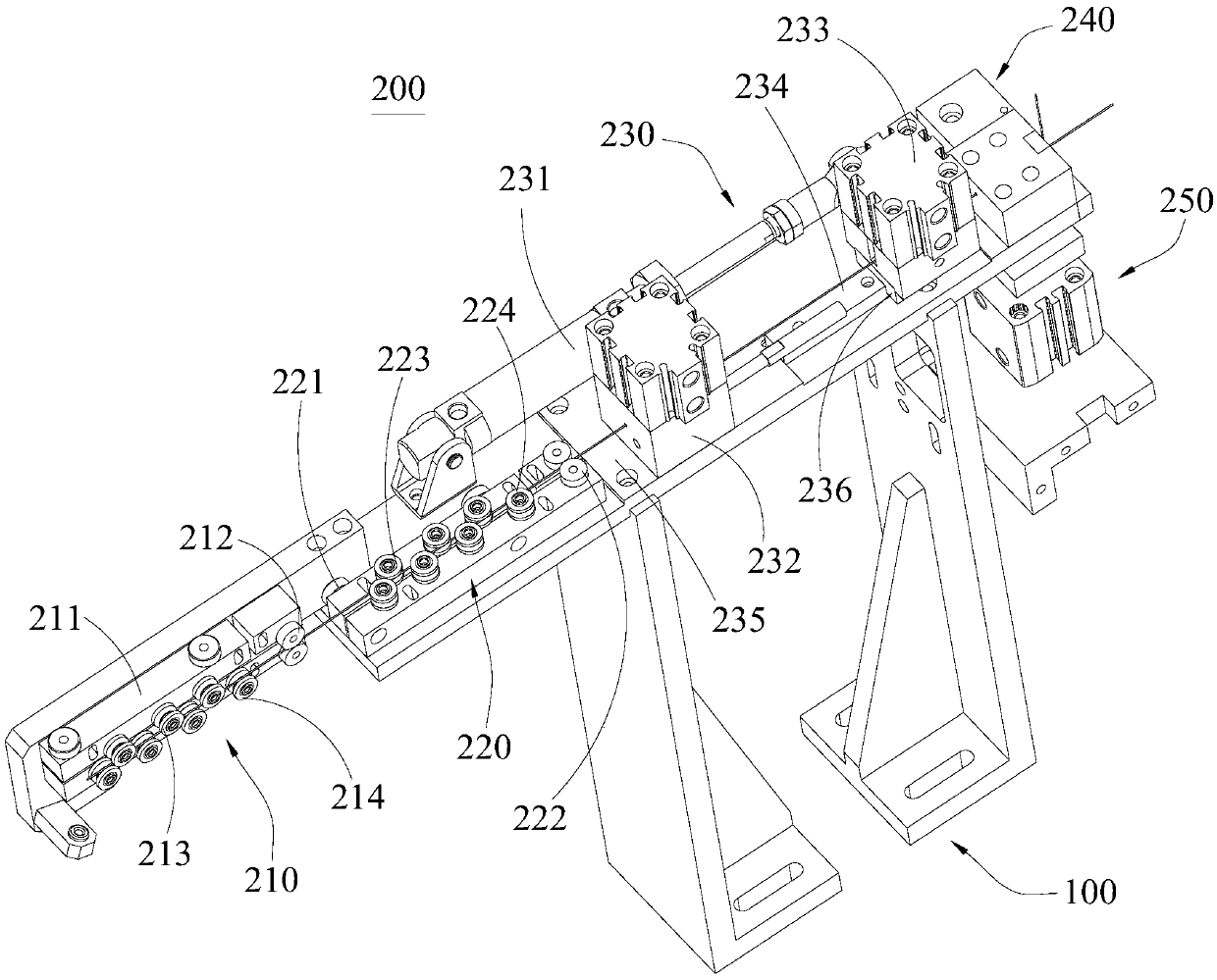

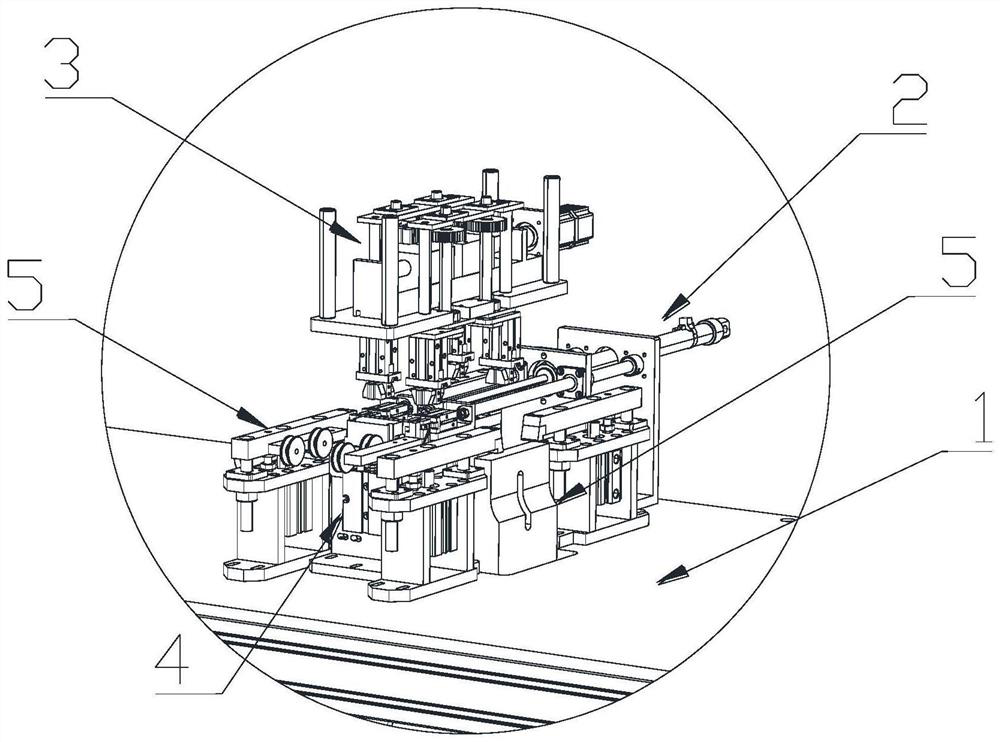

A wire drawing and cutting device

ActiveCN104416358BWill not damage the structureFlexible movementOther manufacturing equipments/toolsMetal working apparatusControl systemWire cutting

The invention discloses a wire drawing and cutting device for straightening and cutting a solder strip. The wire drawing and cutting device comprises a horizontal moving device, a wire drawing device, a wire cutting device, a wire moving track and a control system, wherein the wire drawing device is arranged on the horizontal moving device; clamping claws are arranged on the wire drawing device and used for clamping the solder strip and drawing the solder strip to a specified worksite; the wire cutting device is arranged on the horizontal moving device; a cutter is arranged on the wire cutting device and used for cutting off the solder strip which is drawn out by the wire drawing device; the wire moving track is arranged inside the wire cutting device and used for providing a running passage for the solder strip; the control system is electrically connected with the wire drawing device and the wire cutting device and used for controlling the wire drawing device and the wire cutting device to move forwards and backwards on the horizontal moving device. By adopting the wire drawing and cutting device disclosed by the invention, the solder strip can be automatically straightened and cut off during a welding process of the solder strip and a battery piece, so that the welding quality and the welding frequency are improved, and relatively high automation degree is realized.

Owner:SUZHOU AUTOWAY SYST

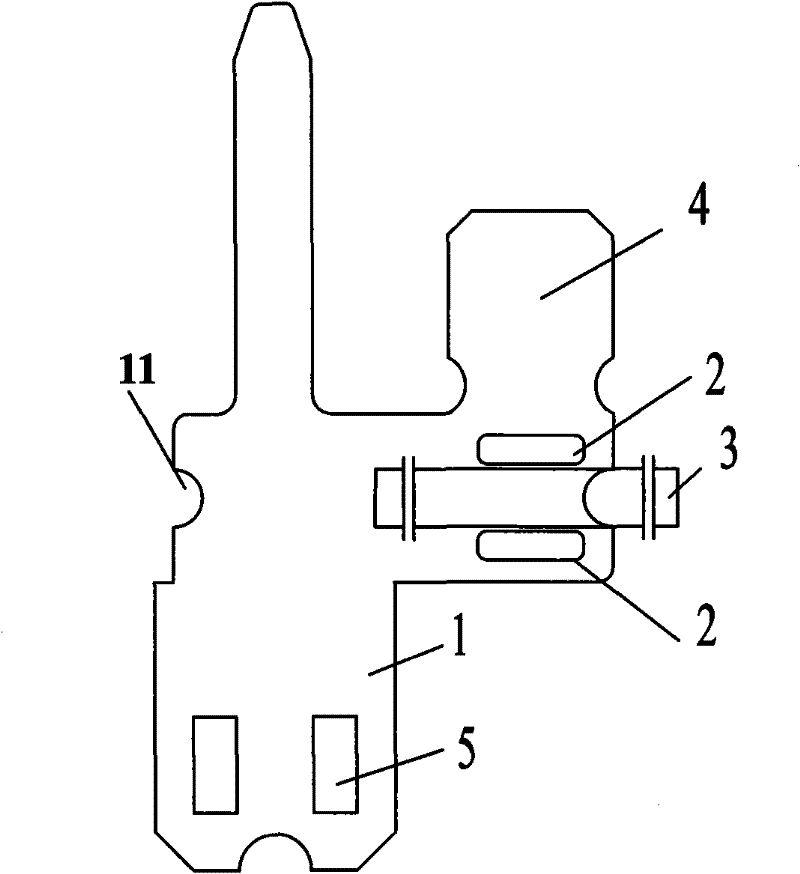

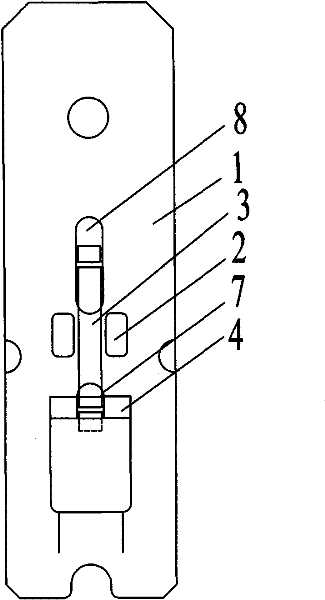

Micro-electrical conductor solder terminal

InactiveCN101656356BThere will be no false weldingThere will be no over-solderingSoldered/welded conductive connectionsElectrical conductorEngineering

The invention discloses a micro-electrical conductor solder terminal, comprising a soldering flat part for holding a soldering electric conductor. The micro-electrical conductor solder terminal is characterized by further comprising a flexible cover plate part which is used for clamping the soldering electric conductor and is connected with the flat part, wherein the soldering flat part is provided with more than one bugles for limiting the interval between the flexible cover plate part and the soldering flat part. The micro-electrical conductor solder terminal of the invention greatly improves soldering efficiency, the key is that general soldering equipment capable of controlling pressure, time and current can be utilized if only in accordance with soldering requirements, the solder junctions after soldering are natural, plum, thick and solid; meanwhile, due to the protection of bugles on the electric conductor, the phenomena of insufficient solder and over soldering can not occur.

Owner:于国强

Micro-electrical conductor solder terminal

InactiveCN101656356AThere will be no false weldingThere will be no over-solderingSoldered/welded conductive connectionsElectrical conductorEngineering

The invention discloses a micro-electrical conductor solder terminal, comprising a soldering flat part for holding a soldering electric conductor. The micro-electrical conductor solder terminal is characterized by further comprising a flexible cover plate part which is used for clamping the soldering electric conductor and is connected with the flat part, wherein the soldering flat part is provided with more than one bugles for limiting the interval between the flexible cover plate part and the soldering flat part. The micro-electrical conductor solder terminal of the invention greatly improves soldering efficiency, the key is that general soldering equipment capable of controlling pressure, time and current can be utilized if only in accordance with soldering requirements, the solder junctions after soldering are natural, plum, thick and solid; meanwhile, due to the protection of bugles on the electric conductor, the phenomena of insufficient solder and over soldering can not occur.

Owner:于国强

Welding process and application device of bellows assembly

ActiveCN103753038BHigh strengthImprove cooling effectPump componentsPumpsStructural engineeringWelding process

The invention discloses a welding process of a corrugated pipe assembly and an application device thereof. The welding process steps include: a. welding to form a master piece; b. welding to form a corrugated tube core; c. welding to form a corrugated tube; d. welding to form a corrugated tube Tube assembly; leak test. A bellows sealing device, characterized in that it includes a bellows assembly, a casing, a static ring and a moving ring, wherein: the left end of the casing is embedded in a groove surface, the static ring is arranged in a step surface, and the The moving ring is arranged close to the end face of the static ring, and the contact surface forms a sealing end face. High welding efficiency, good precision, stable elastic compensation and long service life.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

Wire drawing device for welding strip

PendingCN110576276AImprove welding qualityUniform tensionWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a wire drawing device for a welding strip. By means of the device, wire drawing of the welding strip is achieved through mechanical standard operation, the wire drawing qualityis guaranteed, and the wire drawing efficiency is improved. The input end of a horizontal conveying guide groove is provided with a press roller assembly, the input end of the press roller assembly isprovided with a feeding guide groove, and the horizontal conveying guide groove is formed in the upper end face of a vertical support; the middle rear conveying end of the horizontal conveying guidegroove is provided with a wire press clamping jaw, the wire press part of the wire press clamping jaw is vertical to an inner groove body of the horizontal conveying guide groove, and a vertical air cylinder is connected to the input end of the wire press clamping jaw; a wire drawing device is distributed at the outer side of the tail conveying end of the horizontal conveying guide groove and comprises a wire drawing base plate, a wire drawing base and a wire drawing driving device, the bottom of the wire drawing base is supported at a wire drawing rail and connected with the power input end of the wire drawing driving device, and the wire drawing base plate is located on the upper end face of the wire drawing base.

Owner:SUZHOU AUTOWAY SYST

Cold-rolled tin-welded steel strip manufacturing and welding machining system

InactiveCN112872817AWon't affect homeworkThere will be no problem of false weldingOther manufacturing equipments/toolsTinningButt joint

The invention relates to a cold-rolled tin-welded steel strip manufacturing and welding machining system which comprises a workbench, a pressing mechanism, a fixing mechanism and a butt-joint mechanism. Multiple sets of supporting frames are installed at the lower end of the workbench, the pressing mechanism is installed on the right side of the upper end of the workbench, the fixing mechanism is installed on the left side of the pressing mechanism, and the fixing mechanism is installed on the workbench. A butt joint mechanism is arranged on the left side of the fixing mechanism. By means of the cold-rolled tin-welded steel strip manufacturing and welding machining system, the problem that in the prior art, in the welding process of a steel coil, the whole steel coil needs to be moved, and operation is quite inconvenient can be solved; and the problems that the sequence of steel coil welding in the whole technological process is not considered in the prior art, although the welding problem is solved in the prior art, the position of the steel coil in the whole assembly line is not considered, the practicability is not achieved, and the welded steel coil does not adapt to the whole assembly line work can be solved.

Owner:刘艳军

A device for ultrasonic welding of materials with different inclinations

ActiveCN113510360BThere will be no false weldingStable welding environmentFinal product manufactureWelding/cutting auxillary devicesUltrasonic weldingClassical mechanics

The invention discloses a device for ultrasonic welding of materials with different inclinations, comprising a base plate, an auxiliary device, a stability judgment device and a welding device are respectively arranged on the base plate, and the auxiliary device comprises a clamp capable of clamping the welding block The holding mechanism can be moved under the driving of the power source; the stability judgment device includes a judgment ring, and the judgment ring is provided with several groups of movable blocks along the circumferential direction that can move along the axial direction of the judgment ring, and the at least two movable blocks of each group are The overhanging length corresponds to the inclination degree of the welding block; the welding device includes an inclined plate and an ultrasonic welding mechanism arranged on the inclined plate, the inclined plate is connected with the outer end of the movable block, and the inclination degree of the inclined plate corresponds to the inclination degree of the welding block. . The invention can judge the inclination degree of the welding surface of the welding block, so that the welding device can adaptively incline with the same slope according to the inclination degree of the welding block, so as to ensure that the phenomenon of false welding does not occur in subsequent welding.

Owner:绍兴精宸智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com