A device for ultrasonic welding of materials with different inclinations

A technology of ultrasonic welding and inclination, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as virtual welding and damage to welding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

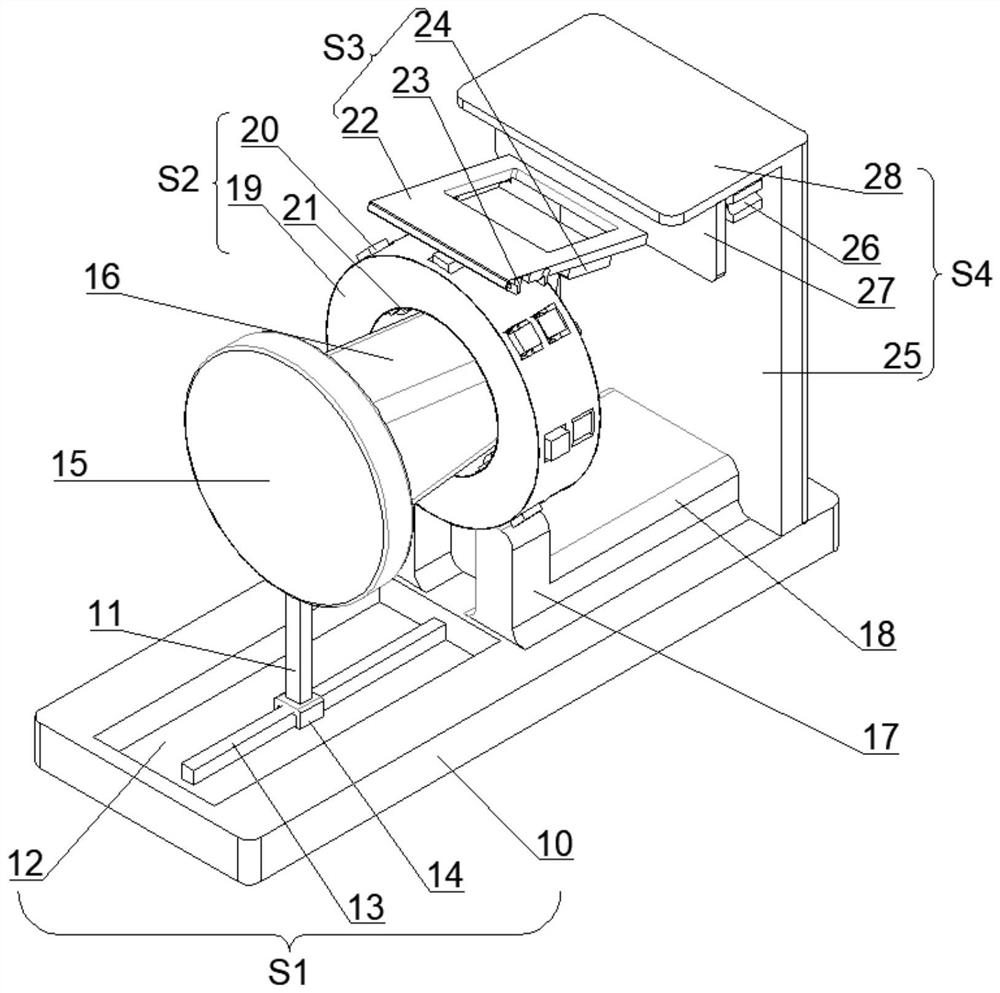

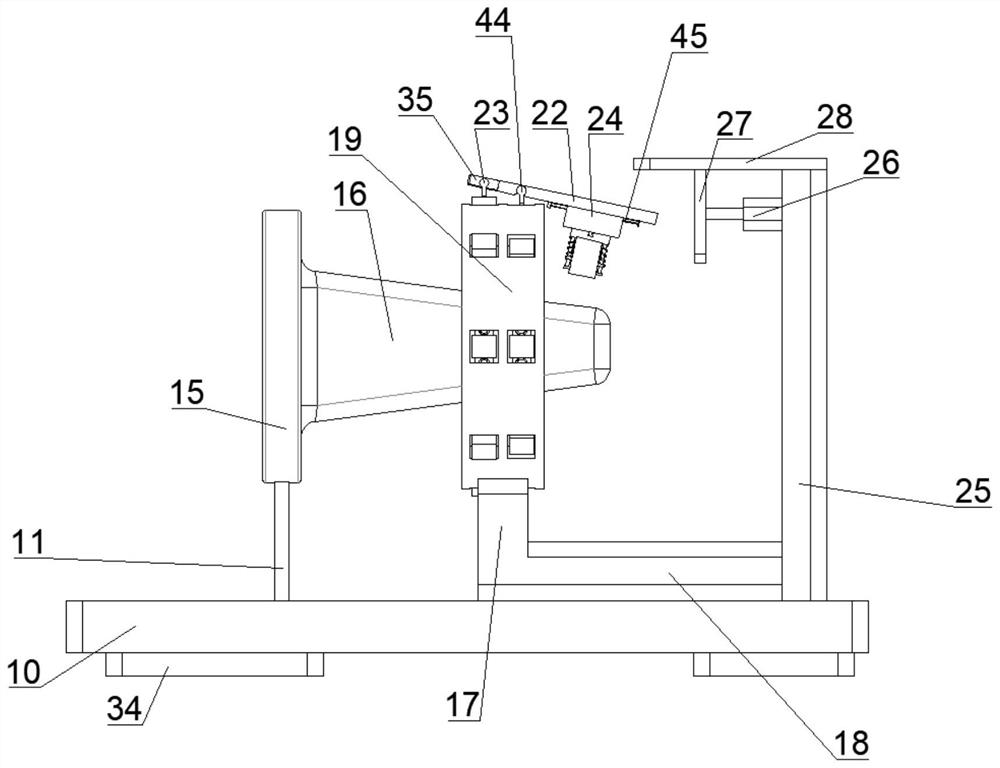

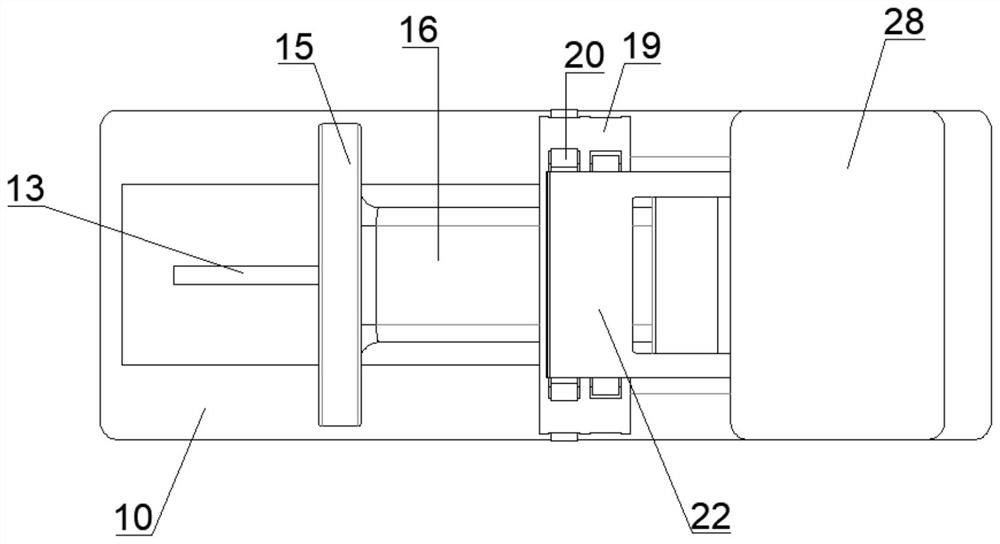

[0033] Example: A device that can perform ultrasonic welding on materials with different inclinations, such as Figure 1-11 As shown, the base plate 10 includes a base plate 10 with feet 34 fixed on the bottom surface. The base plate 10 is respectively provided with an auxiliary device S1, a stability judgment device S2, a welding device S3 and a clamping device S4, wherein the auxiliary device S1 can complete the matching Centering and clamping of the welding block 16, and driving it to move to match the completion of subsequent actions; the stability judgment device S2 is used to judge the inclination of the welding surface of the welding block 16, so that the welding device S3 can be based on the inclination of the welding block 16. The degree of self-adaptive slope is inclined at the same slope, so that the welding device S3 can be parallel to the welding surface of the welding block 16, thereby ensuring that the subsequent welding will not occur the phenomenon of false wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com