Cold-rolled tin-welded steel strip manufacturing and welding machining system

A processing system and technology of tin-plated steel strip, applied in the field of steel strip manufacturing, can solve the problems of inconvenient operation, failure to consider the welding sequence of steel coils, unsuitable steel coils to adapt to the entire assembly line, etc., and achieve the effect of accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

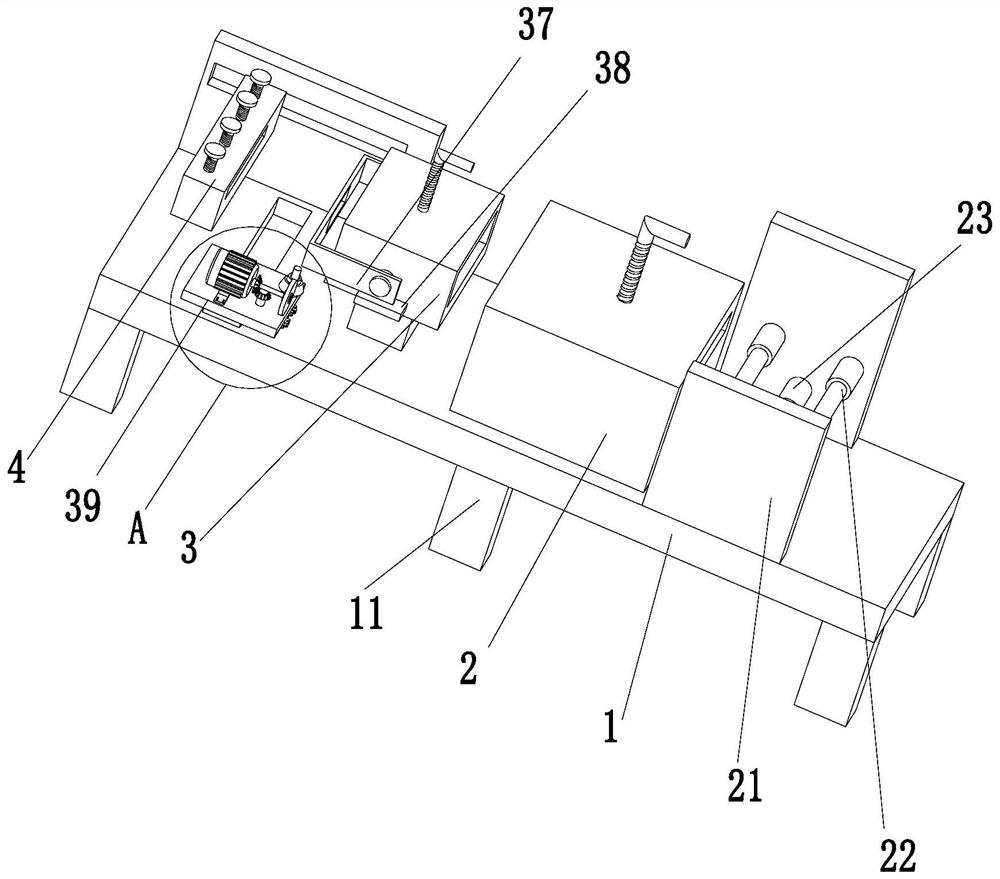

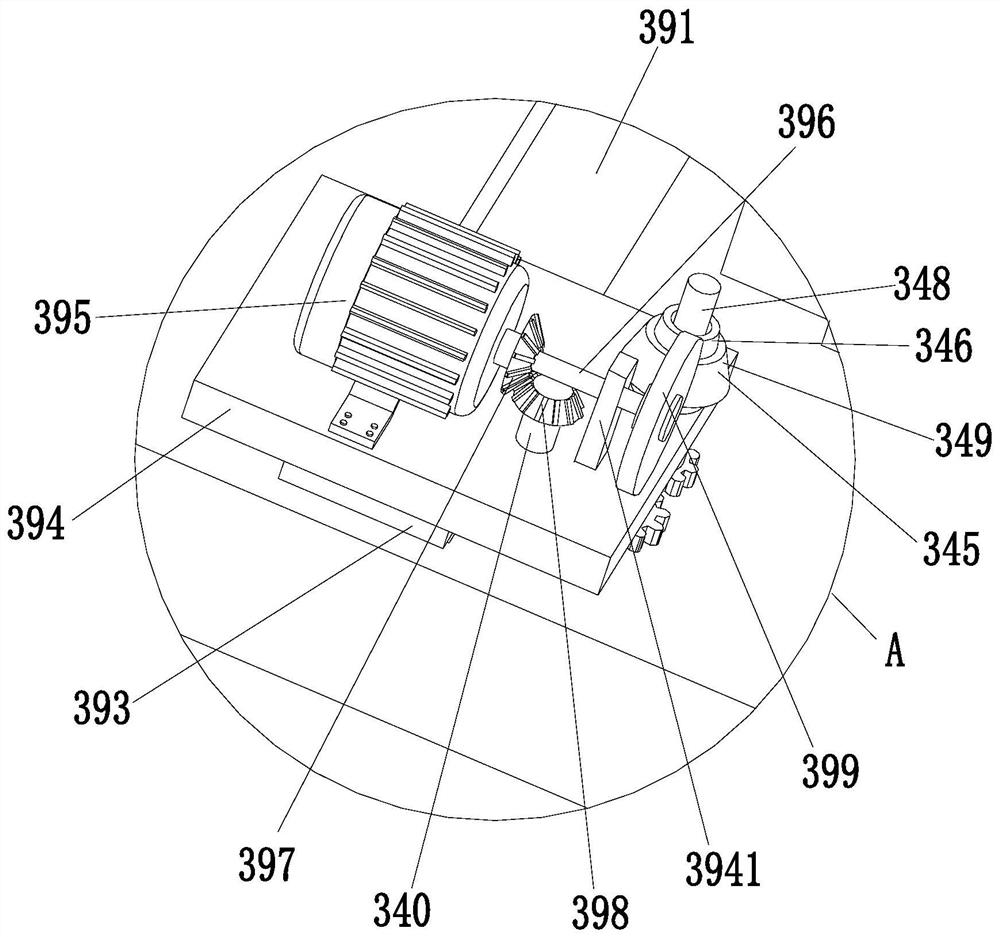

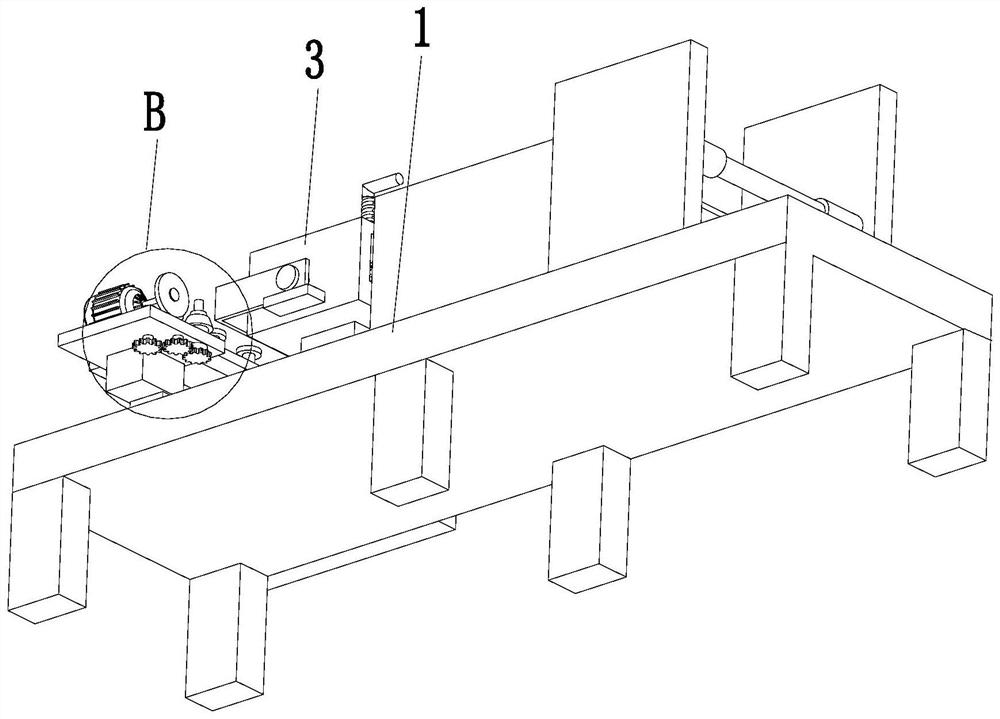

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0033] A welding and processing system for manufacturing cold-rolled and tin-plated steel strips, including a workbench 1, a pressing mechanism 2, a fixing mechanism 3 and a docking mechanism 4. The lower end of the workbench 1 is equipped with multiple sets of support frames 11, and the upper end of the workbench 1 is A pressing mechanism 2 is installed on the right side, and a fixing mechanism 3 is installed on the left side of the pressing mechanism 2. The fixing mechanism 3 is installed on the workbench 1, and the left side of the fixing mechanism 3 is provided with a docking mechanism 4, wherein:

[0034] The pressing mechanism 2 includes a vertical plate 21, a direction changing roller 22, a rewinding roller 23, a pressing box 24, a pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com