Nuclear reactor cooling equipment and its operation method

A technology for cooling equipment and reactors, used in reactors, reactor fuel elements, nuclear power plant auxiliary equipment, etc., can solve the problem of increasing radiation dose, and achieve the effects of reducing radiation dose, increasing decay heat radiation, and eliminating decay heat radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

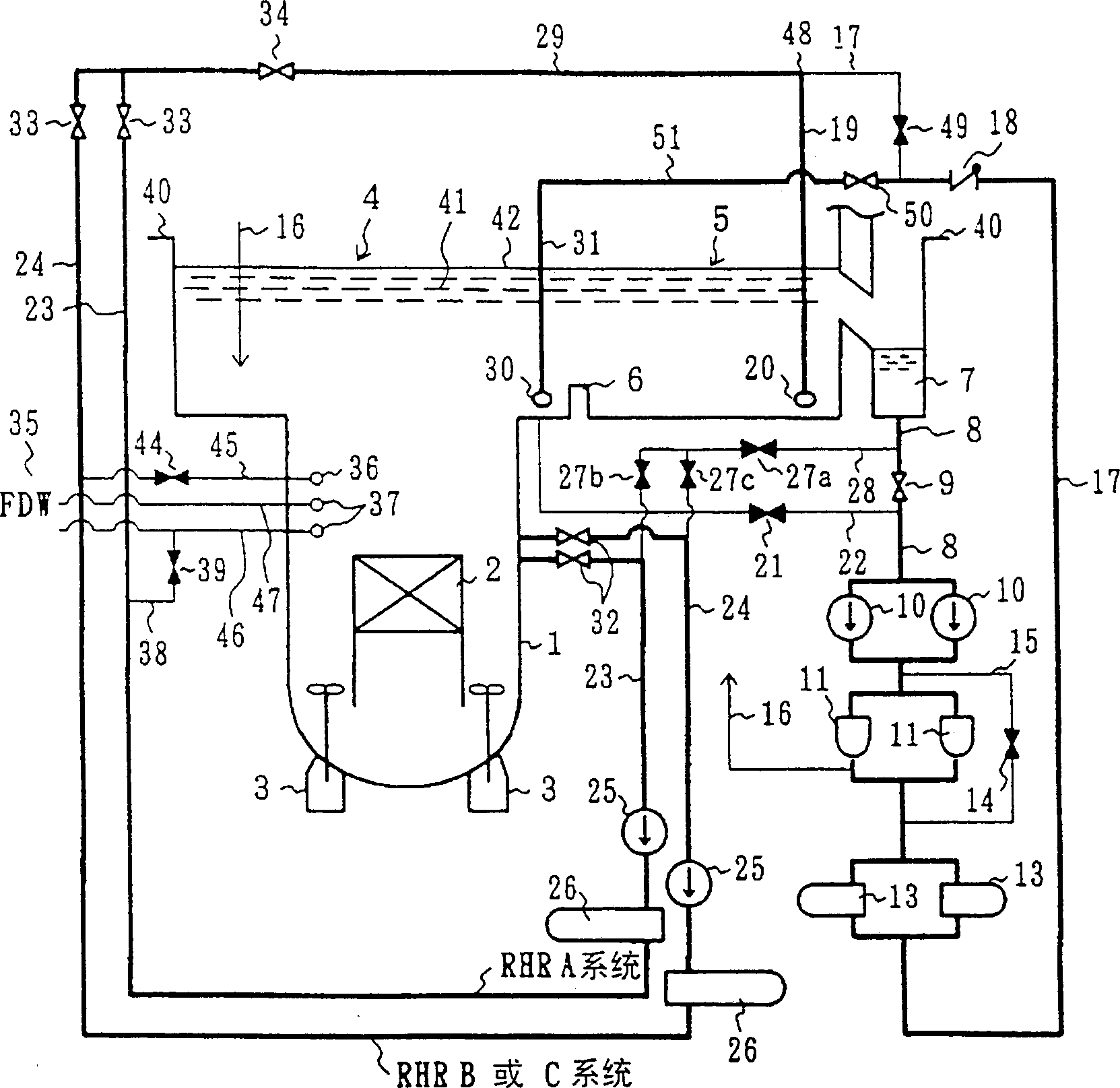

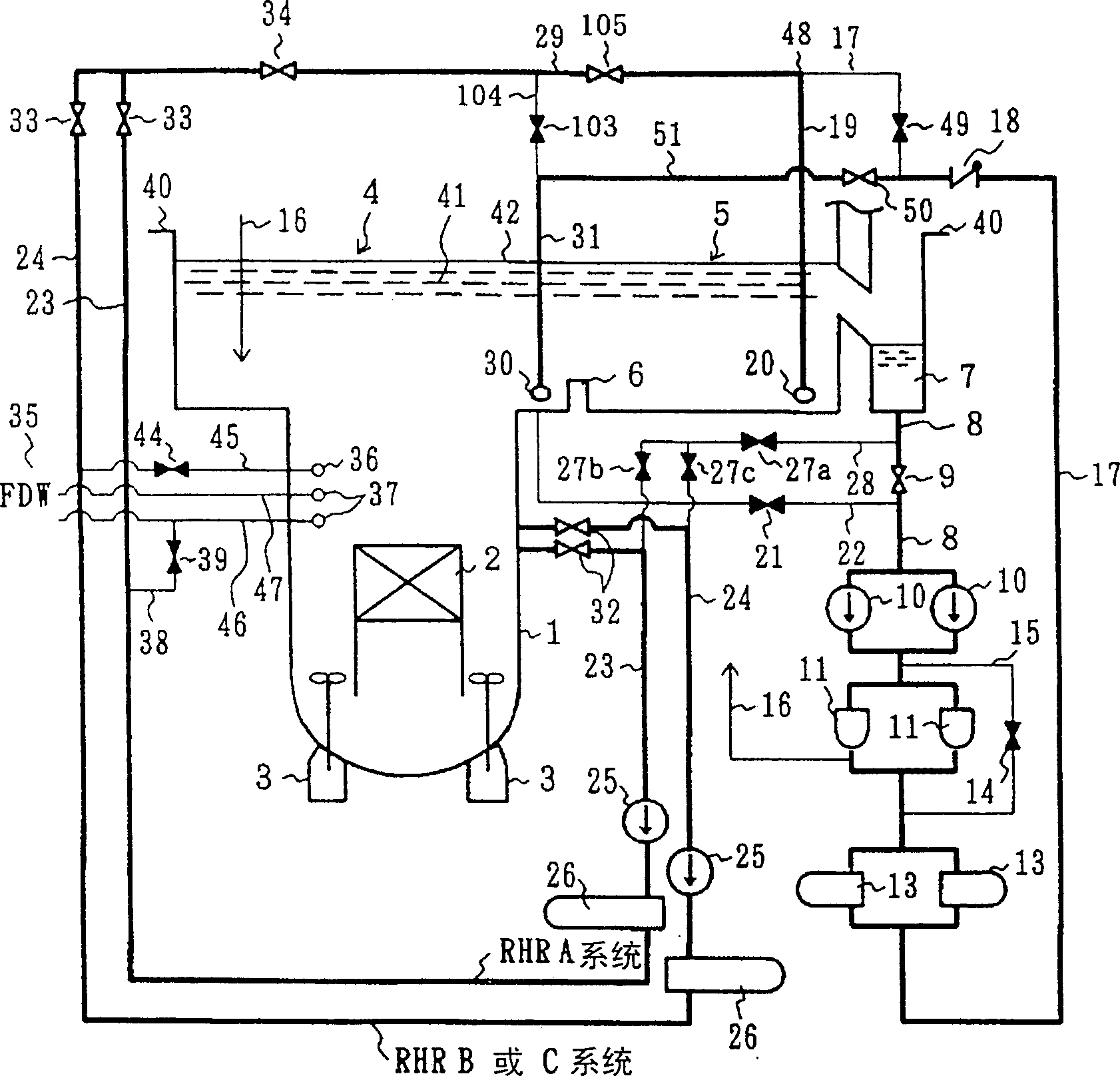

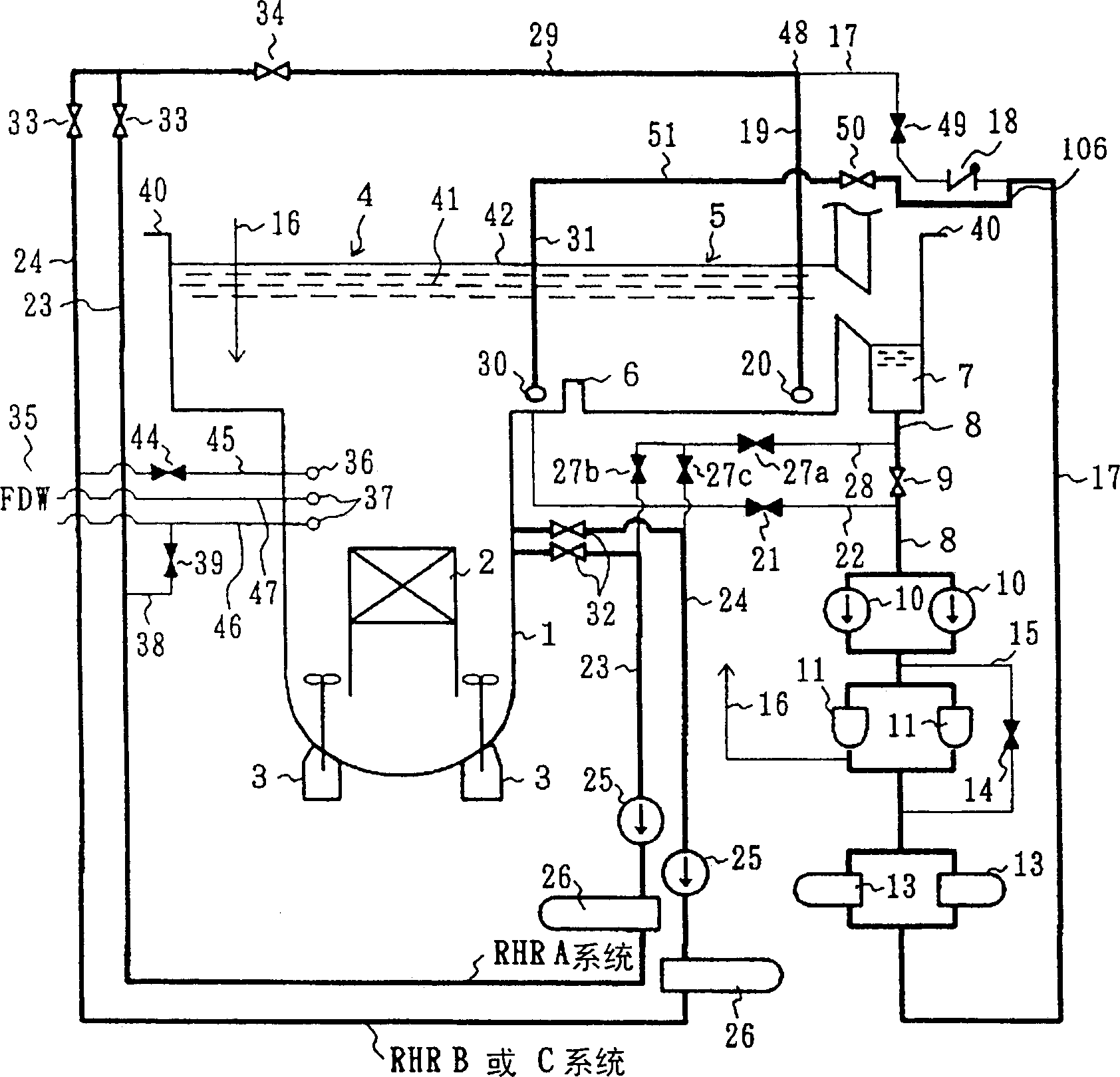

[0087] use figure 1 , the first embodiment of the reactor cooling equipment of the present invention will be described in detail.

[0088] exist figure 1 in, for and Figure 16 The same parts are marked with the same symbols, and the description of the repeated parts is omitted. The difference between this embodiment and the previous example is that the part connecting the downstream side of the fuel pool return line 17 and the downstream side of the RHR-FPC connection line 29 is set as a confluence point 48, and at this confluence point 48 The branch is connected to the FPC return water injection pipeline 19. And, a closing valve 49 is set on the fuel pool return line 17, and then branched from the outlet side of the check valve 18 of the fuel pool return line 17, and the FPC return flow line 51 is connected through the closing valve 50. The flow line 51 is connected to the RHR return water injection line 31 .

[0089] That is to say, the pipeline system of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com