A protective device for a universal testing machine

A universal testing machine and protective device technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of increased maintenance workload, affecting the smooth progress of experiments, increasing the failure of universal testing machines, etc., and achieving the effect of improving lubrication conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

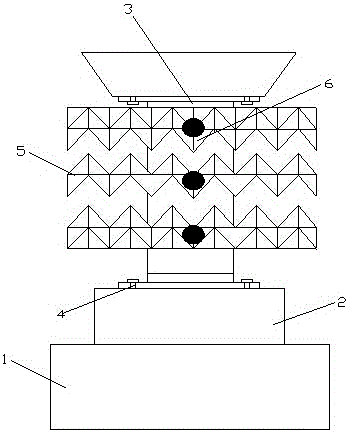

[0012] refer to figure 1 As shown, a protective device for a universal testing machine includes a base 1, a protective cover 2 and a nut 3, the base 1, the protective cover 2 and the nut 3 are fixed and arranged sequentially from bottom to top, and the protective cover 2 is a circle In a cylindrical arrangement, the protective cover 2 is provided with corresponding fixing screws 4, and more than one magnet 5 is fixed on the wire nut 3, and the wire nut 3 is covered with more than one iron metal mesh 6 , the length of the iron metal mesh 6 can just circle around the wire mother 3, and the structure of each iron metal mesh 6 is suitable, and the structure of the iron metal mesh 6 on the top is matched with the structure of the iron metal mesh 6 below, Specifically, it can be manifested as a tooth-shaped clamping combination or other types of combined splicing and combination. When the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com