Aligning sliding bearing for efficient air valve of subway

A sliding bearing and air valve technology, applied in the field of mechanical parts, can solve the problems of the two ends of the fan blade shaft are not concentric, the service life of the bearing is not long, and achieve the effects of improving the transmission efficiency, reducing the friction and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

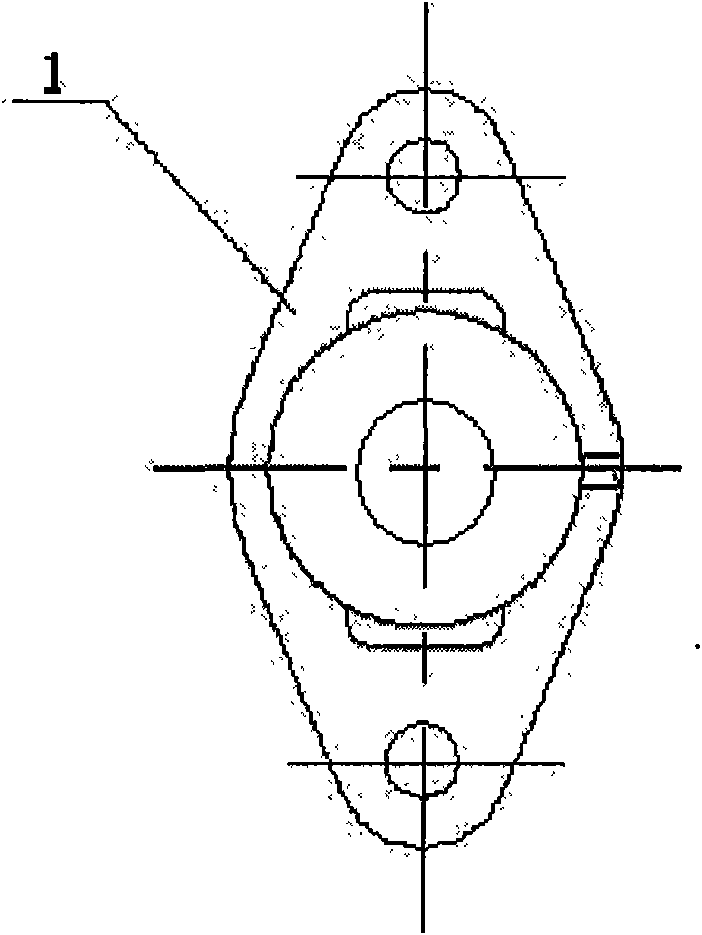

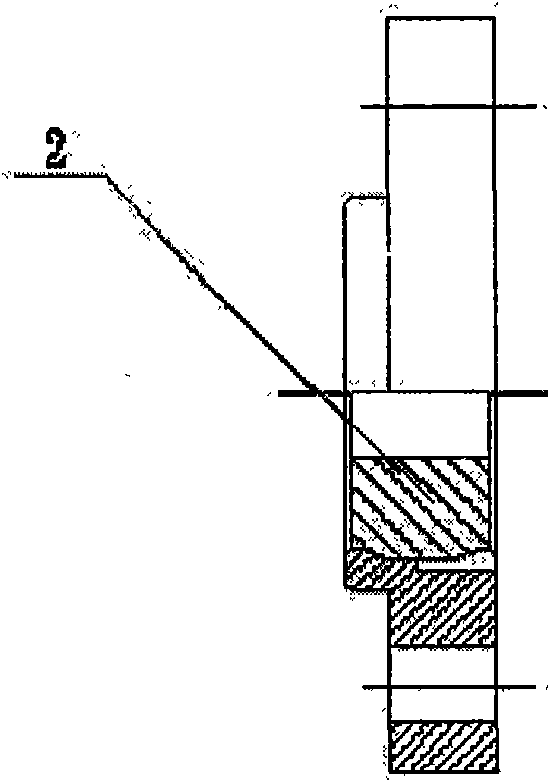

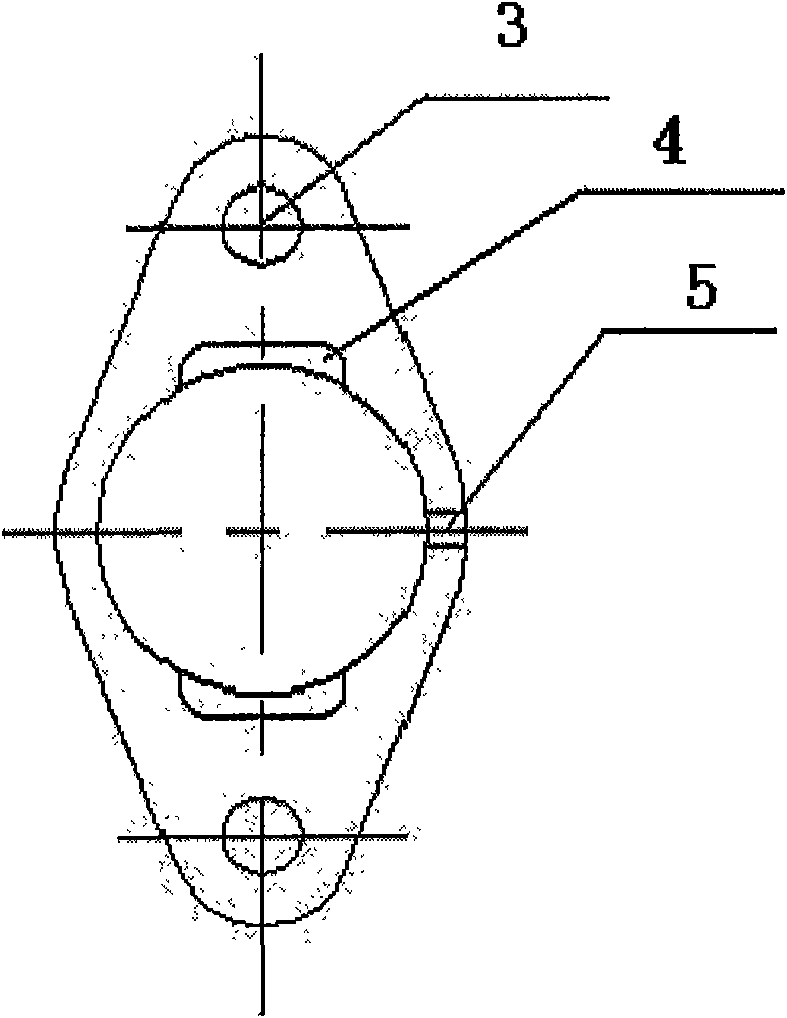

[0017] The self-aligning sliding bearing includes the bearing seat body 1, the sliding bearing 2, the bolt hole 3, the disassembly hole 4, and the oil injection hole 5; the bearing seat body and the damper frame are fixed with bolts, and the sliding bearing is connected with the blade shaft, in the bearing seat The hole is radially square with disassembly holes, and the oil injection hole is set in the bore of the bearing housing and perpendicular to the length of the bearing housing; the sliding bearing is connected with the blade shaft to fix the blade shaft on the one hand, and complete the blade shaft on the other hand. Rotating action: A disassembly hole is arranged in the inner hole of the bearing seat along the radial square. The sliding ball with a spherical outer circle is installed into the inner hole of the bearing seat through this position, and then rotated at any angle to ensure that it will not fall off during normal use. The sliding ball of the sliding bearing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com