Manufacturing method for double-screw-rod compressor rotor

A compressor rotor and twin-screw technology, applied in the field of compressor manufacturing, can solve problems such as synchronous gear power loss, polymer material aging, material erosion, etc., to reduce energy consumption and vibration and noise levels, and to achieve good water film sealing and lubrication Conditions, the effect of reducing leakage in the compression chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

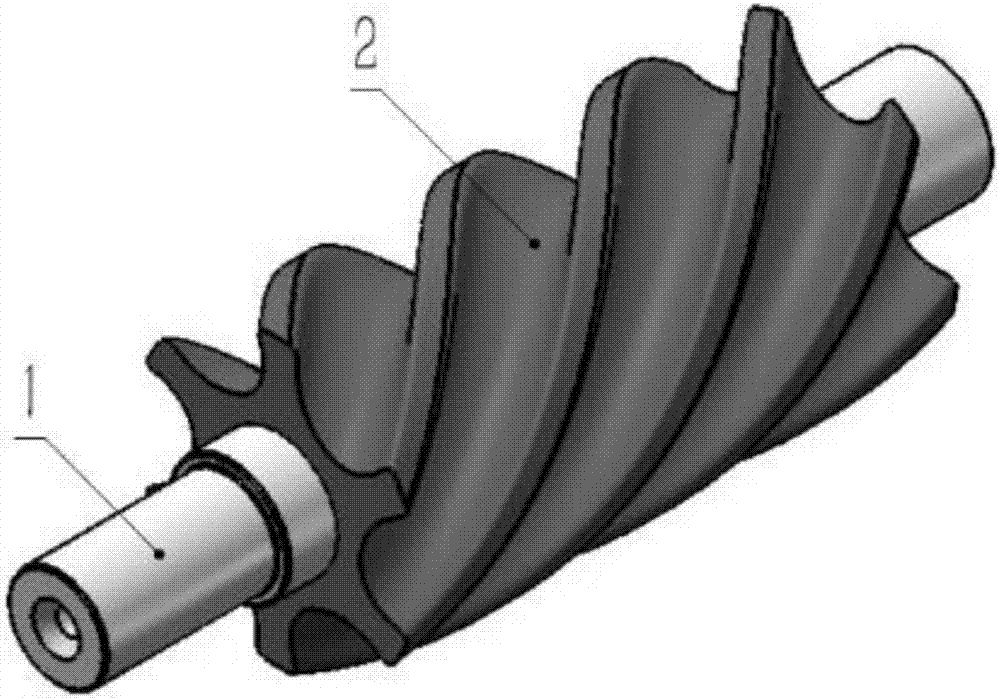

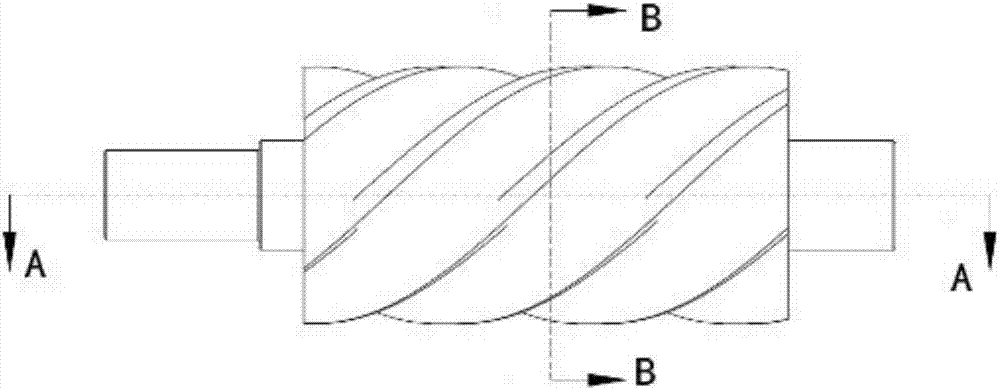

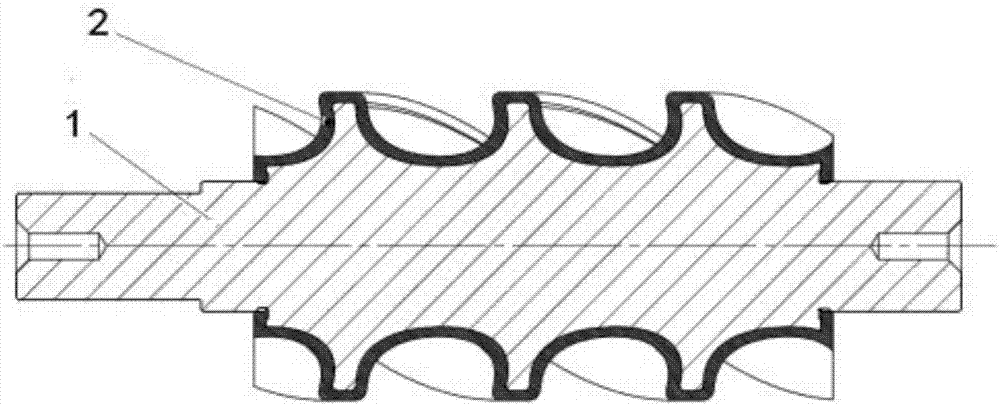

[0029] A method for preparing a rotor of a twin-screw compressor, which includes a female rotor stainless steel core 1, a female rotor PEEK engineering plastic tooth-shaped shell 2, a female rotor end face circular pit 3, a male rotor stainless steel core 4, and a male rotor PEEK engineering plastic tooth shape The shell 5 and the circular pit 6 on the end face of the male rotor, the stainless steel core 1 of the female rotor and the PEEK engineering plastic toothed shell 2 of the female rotor are combined together by high temperature molding process.

[0030] figure 1 This is the structural diagram of the female rotor manufactured by this preparation method. The female rotor is mainly composed of the female rotor stainless steel core 1 and the female rotor PEEK engineering plastic tooth-shaped shell 2 through high-temperature molding process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com