Roller laser roughening machining equipment and machining method thereof

A technology of laser texturing and processing methods, applied in laser welding equipment, metal processing equipment, other manufacturing equipment/tools, etc., can solve problems affecting the consistency of the surface quality of rolled steel sheets, high equipment investment costs, and difficulty in cold-rolled sheet production lines big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

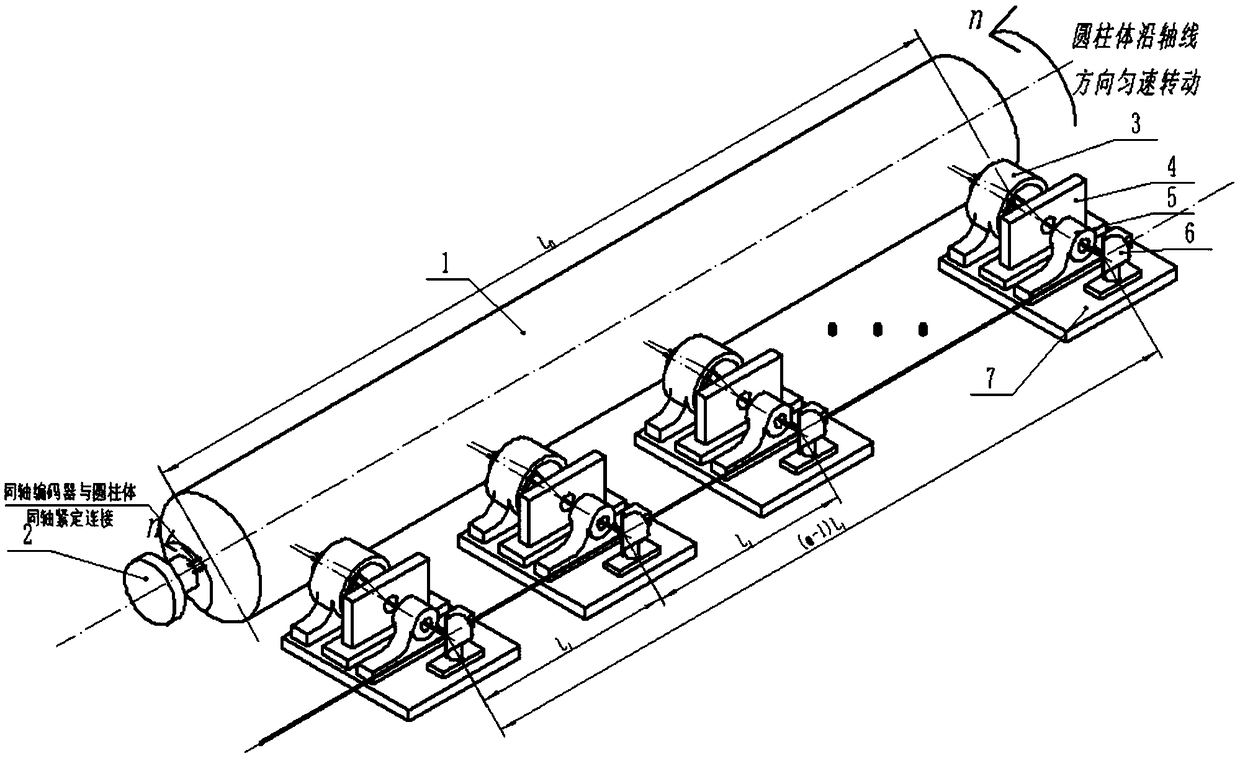

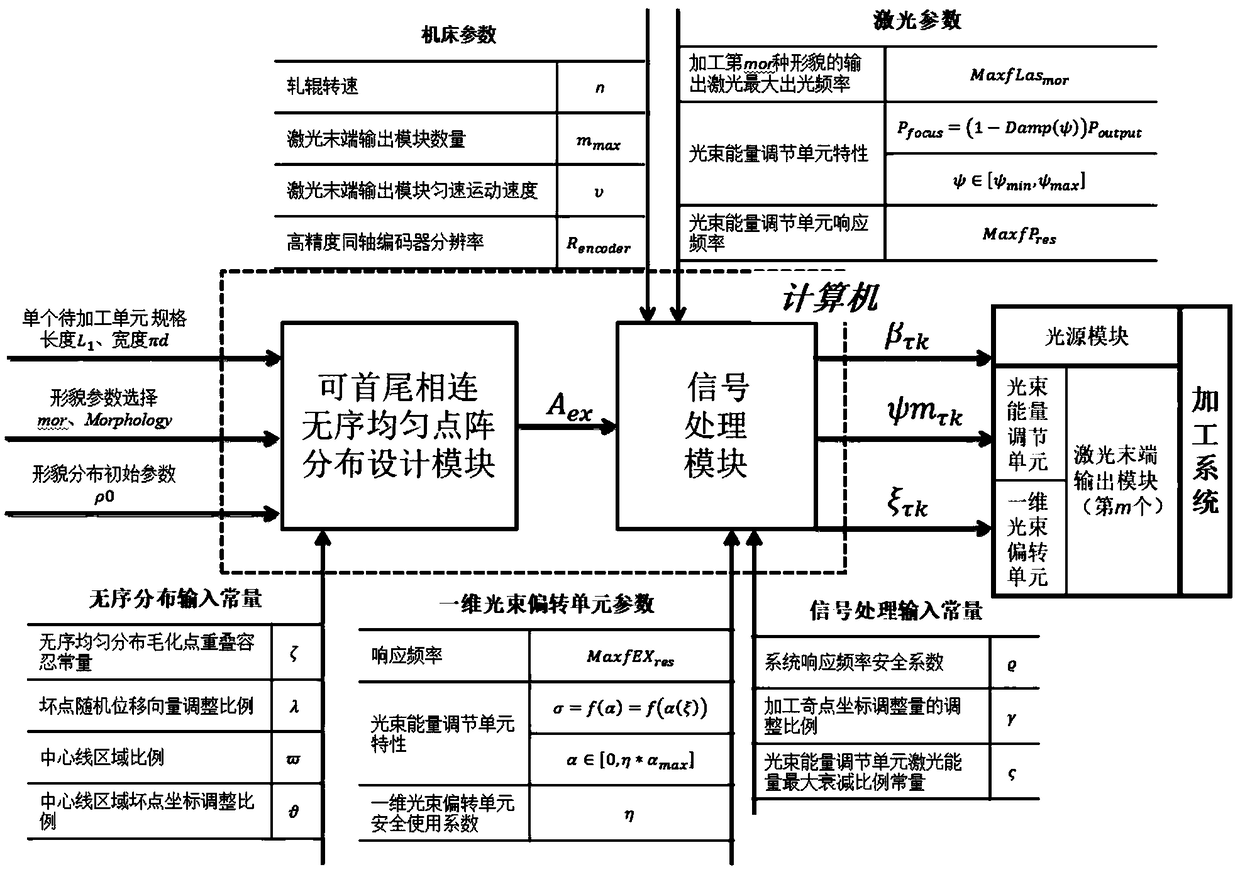

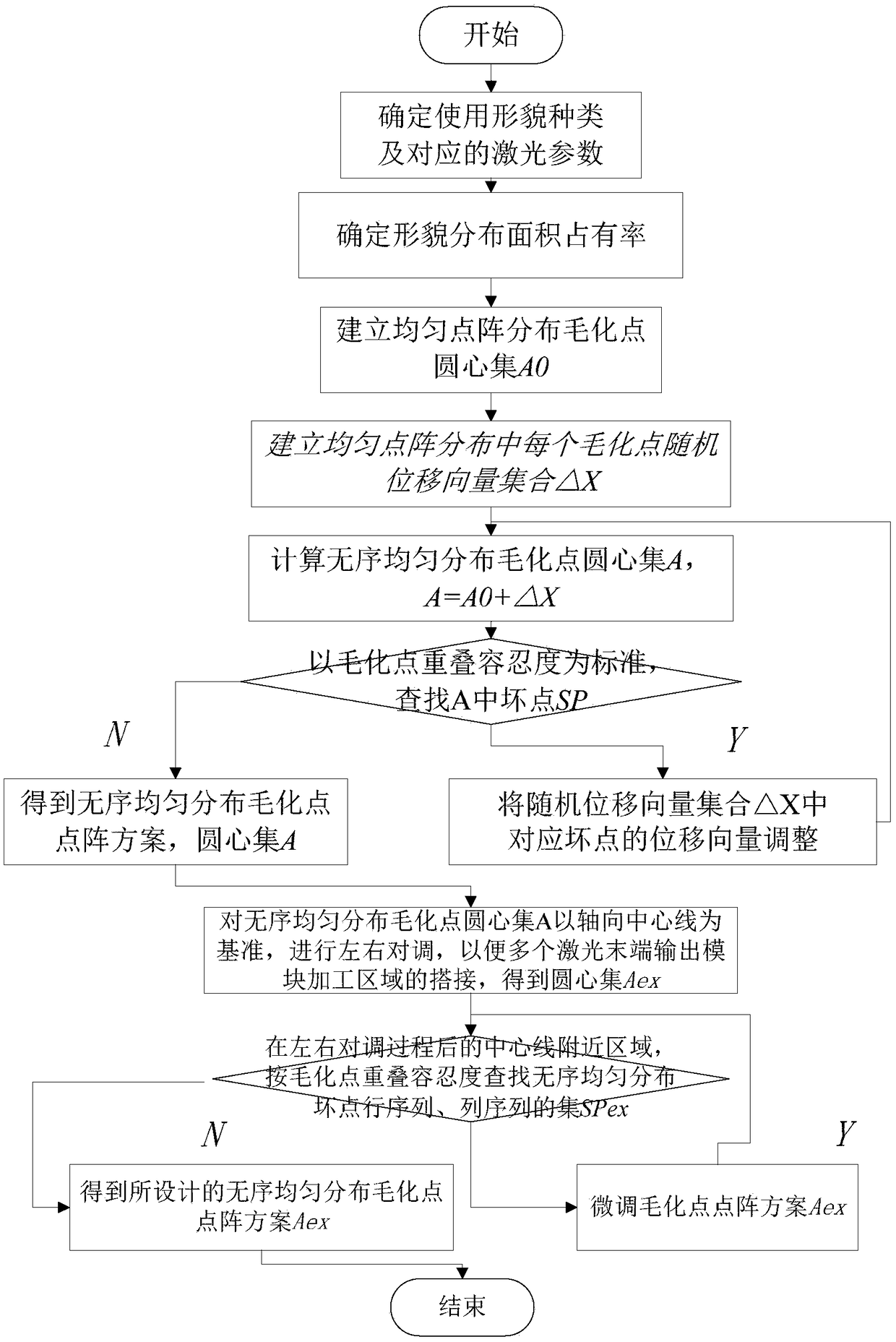

[0137] Such as figure 1 As shown, the roll laser texturing processing equipment described in the present invention includes a computer, a light source module and a laser terminal output module; the computer includes a design module and a signal processing module that can be connected end to end to a disordered uniform lattice distribution; according to the roll processing unit Parameters and shape parameters, through the end-to-end connection disordered uniform lattice distribution design module to output the end-to-end connection disordered uniform distribution textured lattice distribution scheme; according to the end-to-end connection disordered uniform distribution textured lattice distribution scheme, machine tool parameters and laser parameters, the laser light emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com