A pressure welding system

A welding head and workpiece technology, applied in the field of welding equipment, can solve the problems of increased production cost, high scrap rate of workpieces, waste of production materials, etc., and achieves the effects of reducing maintenance costs, preventing damage, and reducing impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

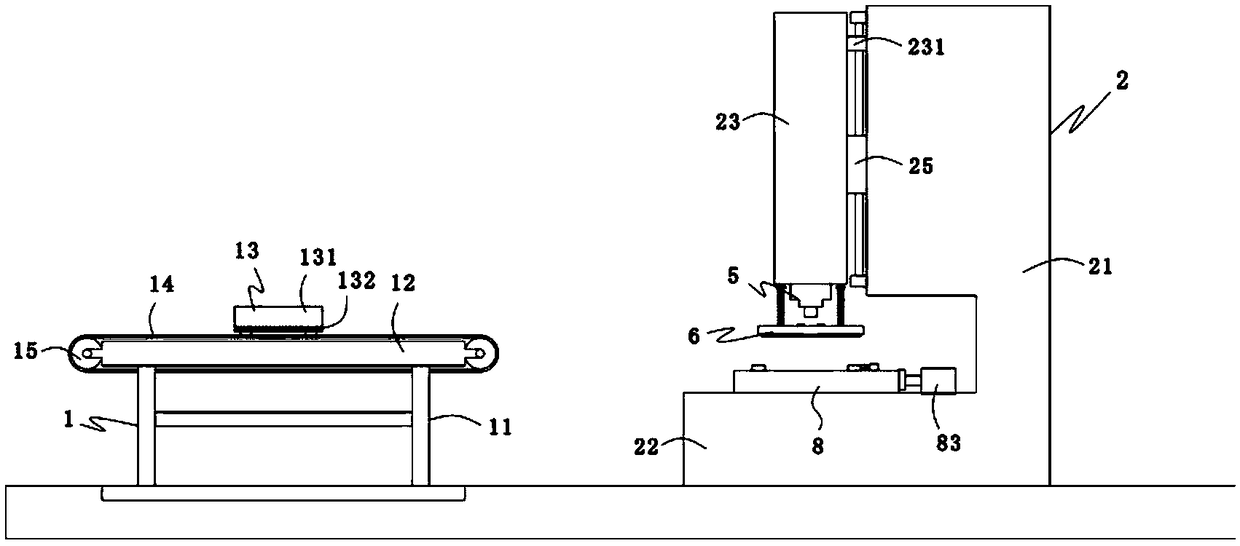

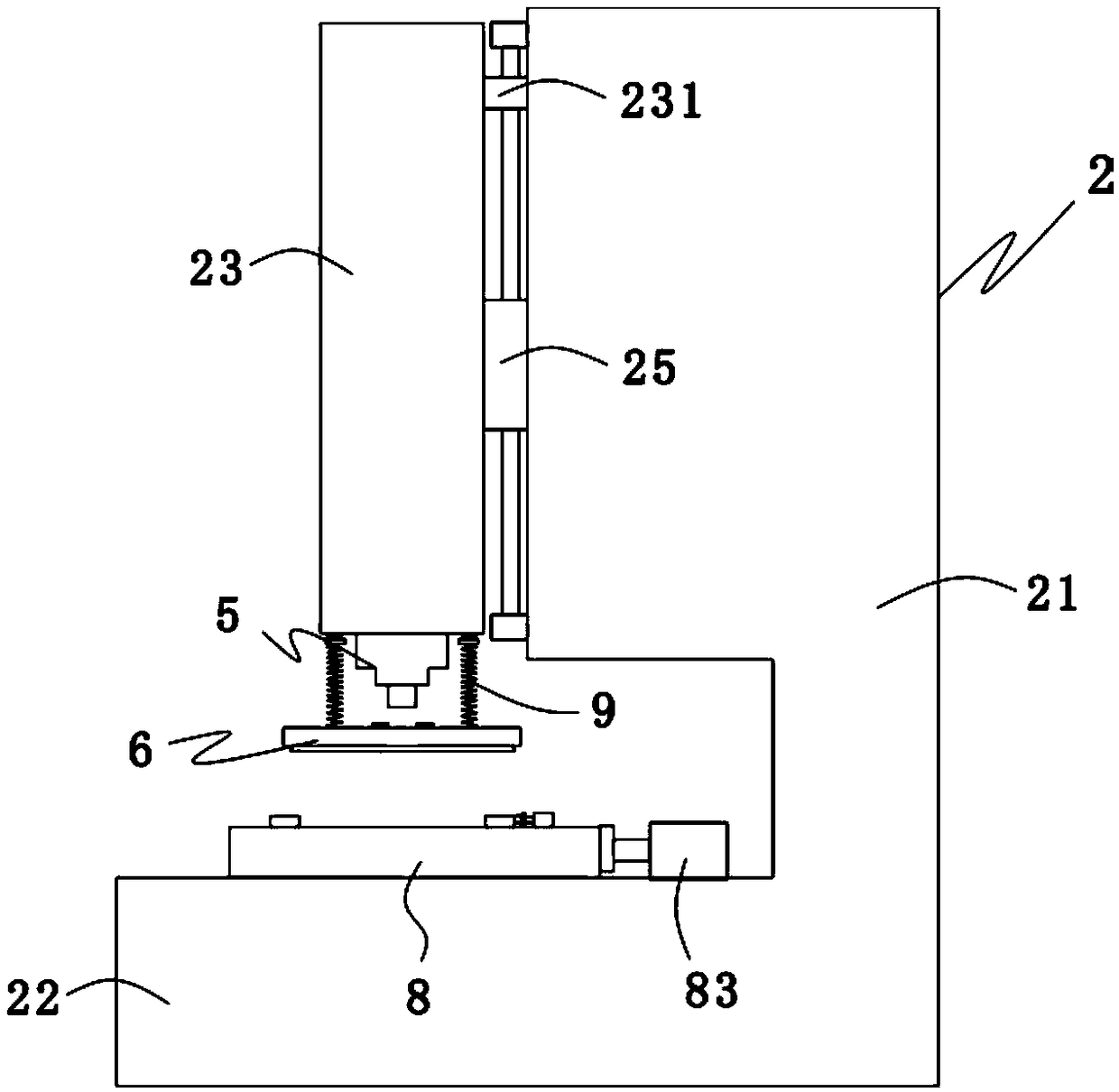

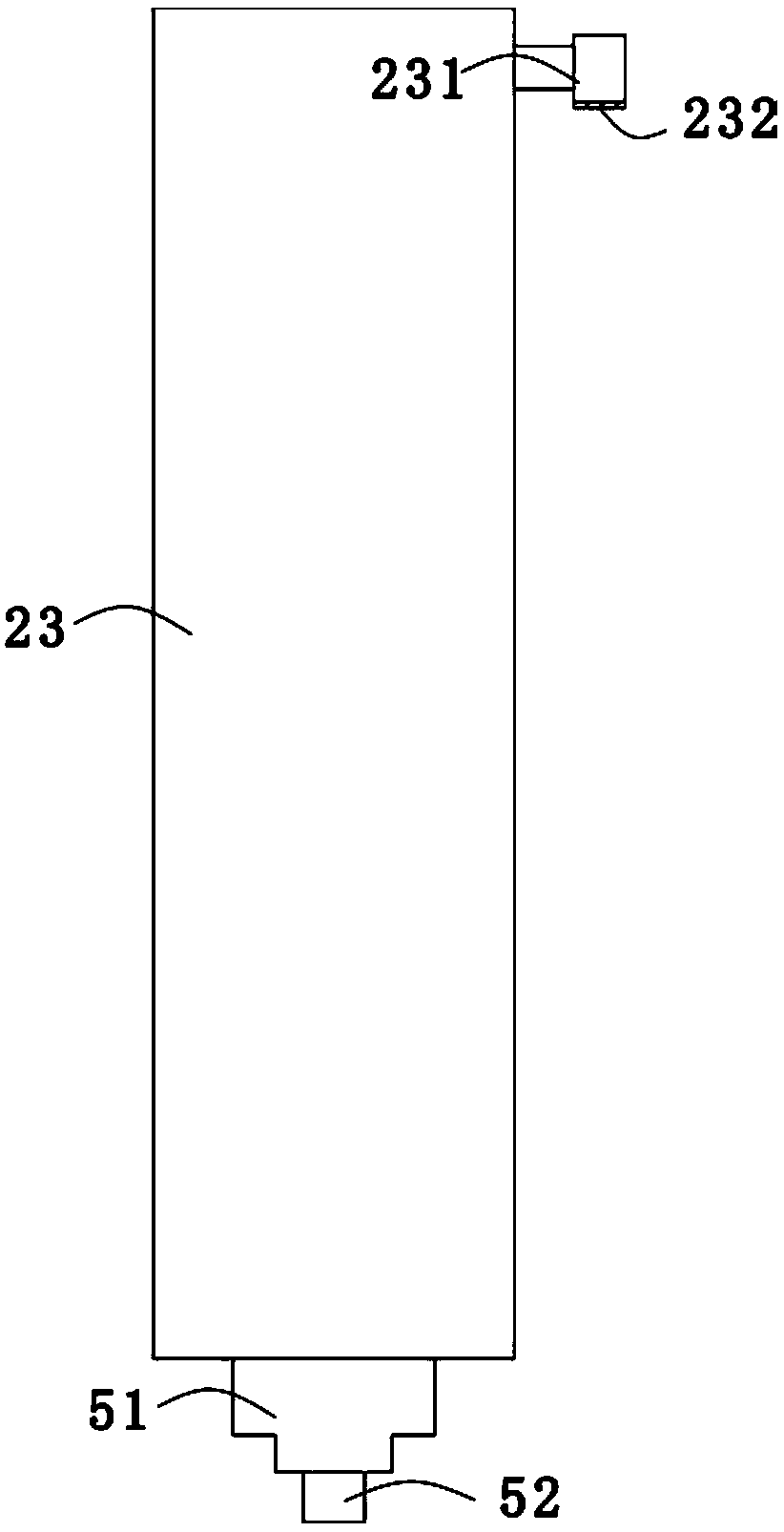

[0029] Such as Figure 1-13 As shown, a pressure welding system includes a cleaning unit 1 for removing impurities on the surface of workpieces to be processed and a pressure welding unit 2 for performing pressure welding operations on workpieces. The pressure welding unit 2 includes a frame 21, a device The workbench 22, the pressure welding power arm 23, the pressure welding assembly, the heating structure and the first driver 25 on the frame; the pressure welding power arm 23 can move up and down along the frame, and the first driver 25 is Rodless cylinder; in order to prevent the pressure welding power arm 23 from shifting in the process of moving up and down, we set two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com