Welding fixture

A technology for welding fixtures and pressure plates, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as loose tooth block fixation and inconsistent clamping force, to ensure bond strength, simple structure, and improve brazing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

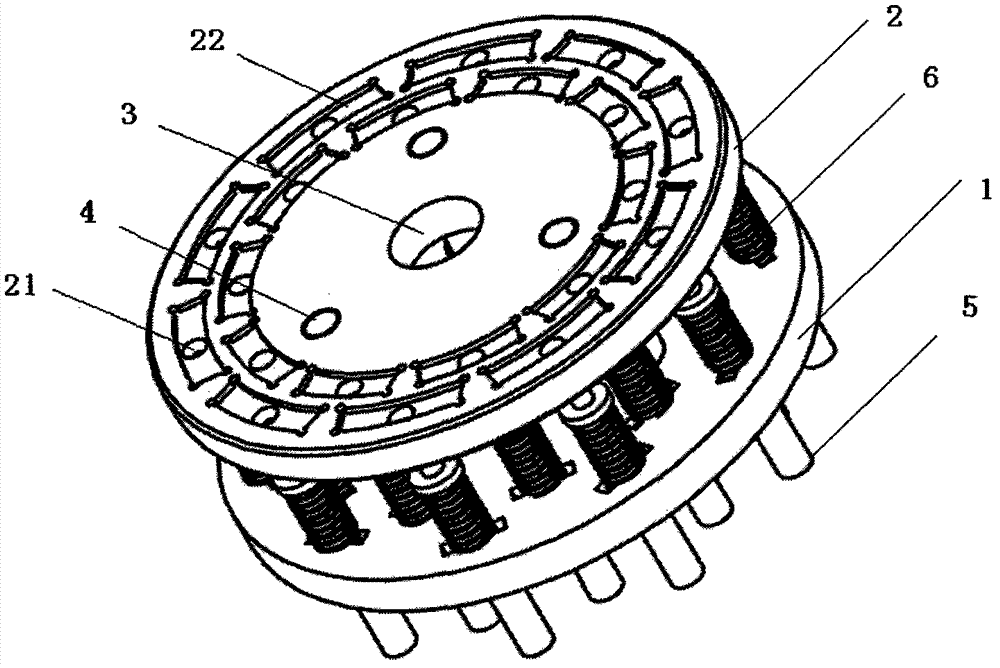

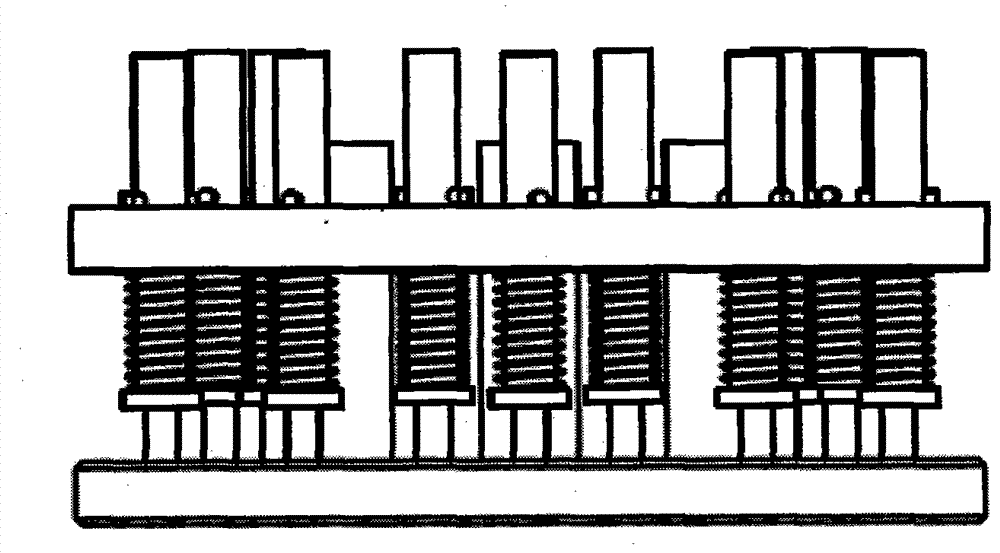

[0021] see Figure 1-2 It is a component schematic diagram and a component assembly schematic diagram of a welding fixture according to an embodiment of the present invention. Depend on Figure 1-2 It can be seen that the welding fixture of the present embodiment comprises a disc-shaped upper pressing plate (1) and a disc-shaped lower pressing plate (2), and the upper pressing plate (1) and the lower pressing plate (2) all have central positioning holes arranged coaxially (3), the lower pressing plate (2) is provided with a tooth block positioning hole (21), and the lower surface of the lower pressing plate (2) is provided with a tooth block installation groove (22), which is characterized in that the upper pressing plate (1) and the lower pressing plate (2) Install tooth block positioning screw (5) and tooth block compression spring (6); said lower pressing plate is also provided with 3 auxiliary positioning holes (4) evenly along the concentric ring; wherein the upper press...

Embodiment 2

[0023] The structure of the welding fixture is the same as in Example 1; the difference is that the spring steel used for the compression spring has the following composition and content: the composition and content of the spring steel are: C: 0.25-0.32wt%, Si: 1.25-1.50wt% , Mn: 1.0-1.25wt%, Cr: 1.20-1.80wt%, Ni: 2.20-4.25wt%, Mo: 0.30-0.50wt%, V: 0.015-0.025wt%, Nb: 0.01-0.02wt%, Cu : 0.25-0.35wt%, Zn: 0.15-0.25wt%, P≤0.0015wt%, S≤0.0015wt%, the balance is Fe and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com