Multi-station metal automatic welding equipment

An automatic welding, multi-station technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as increased workload, workpiece shaking, welding position errors, etc., to improve work efficiency, reduce dead ends, welding beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

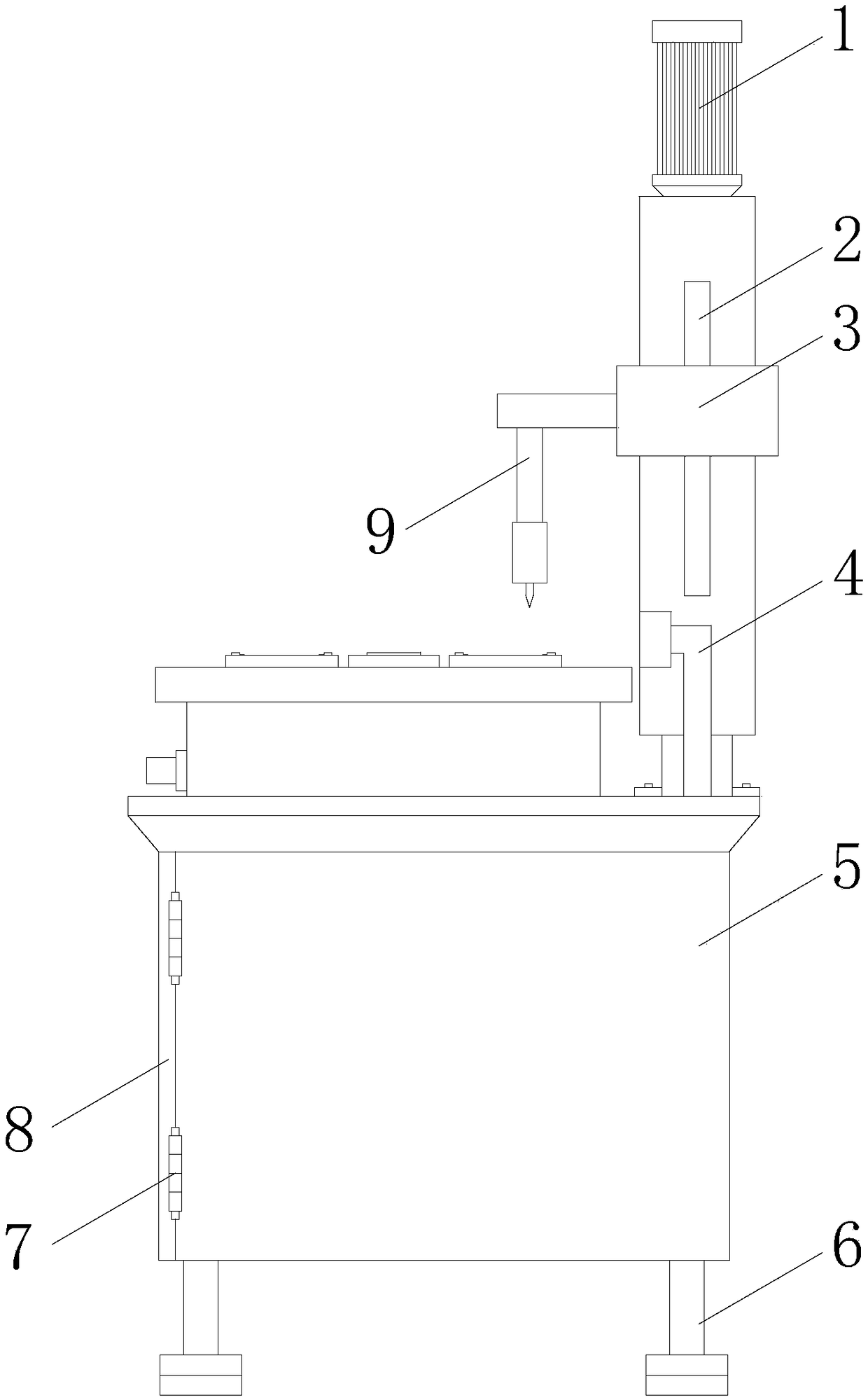

[0025] see Figure 1-Figure 6 , the present invention provides multi-station metal automatic welding equipment, its structure includes driving motor 1, slide rail 2, regulator 3, suction port 4, welding host 5, supporting foot 6, hinge 7, box door 8, welding torch 9, The driving motor 1 is fixedly installed on the upper end of the welding main machine 5, the slide rail 2 is installed on the outer surface of the upper end of the welding main machine 5, the adjuster 3 is installed on the slide rail 2 and adopts clearance fit, and the adjuster 3 is provided with There is a welding torch 9, the upper end of the suction port 4 is fixedly installed outside the upper end of the welding host 5, the lower surface of the welding host 5 is welded to the upper end of the support leg 6, the outer surface of the lower end of the welding host 5 is welded with a hinge 7, the box Door 8 is hinged with welding main frame 5 lower end outer surface by hinge 7.

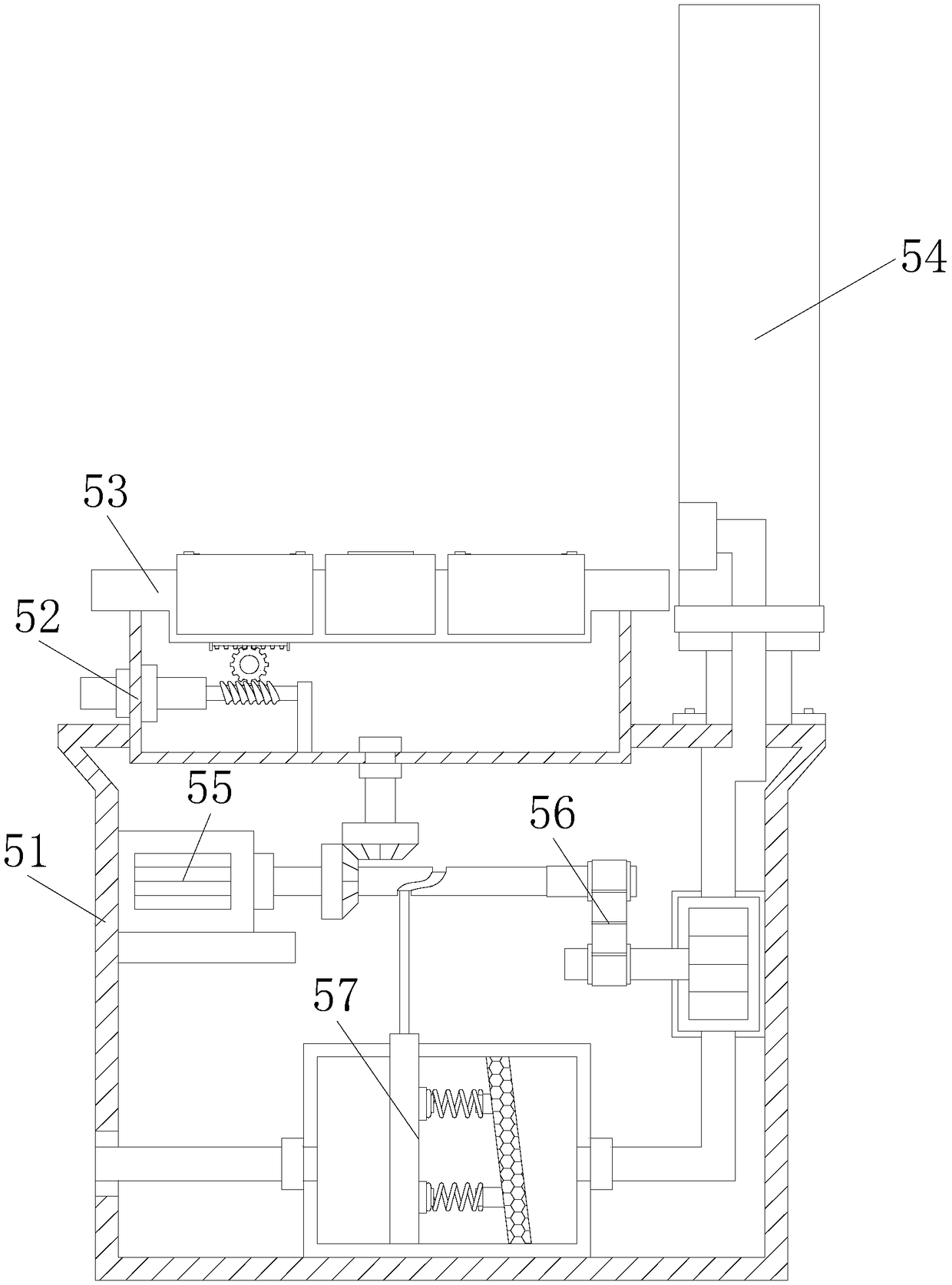

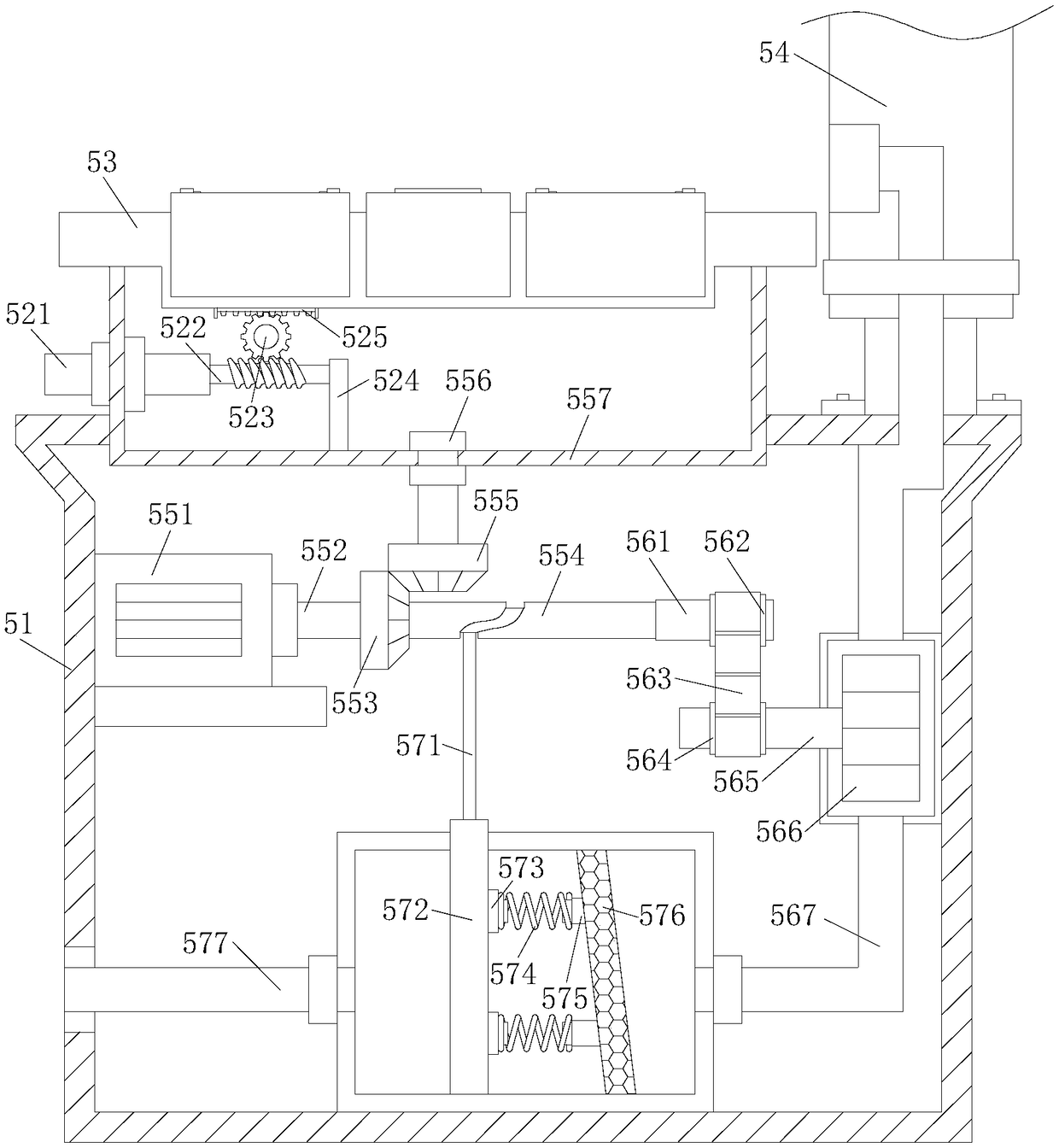

[0026] The welding host 5 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com