A wire drawing and cutting device

A wire cutting and wire drawing technology, which is applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of not being able to adapt to automated production, reduce the effect of battery string welding, and fail to meet welding requirements, etc., to improve welding Good quality, balanced tension and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

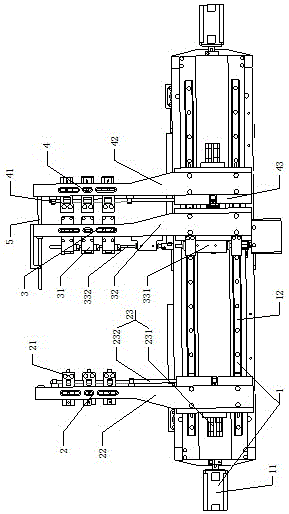

[0033] A wire drawing and cutting device for straightening and cutting ribbon, comprising:

[0034] The horizontal moving device, the horizontal moving device 1 includes a motor 11 , a screw rod (not shown) connected to the motor 11 and two sliding rails 12 arranged side by side.

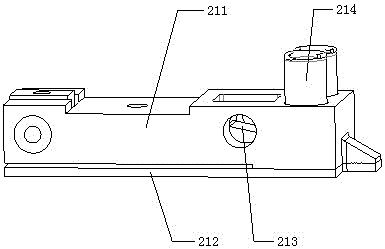

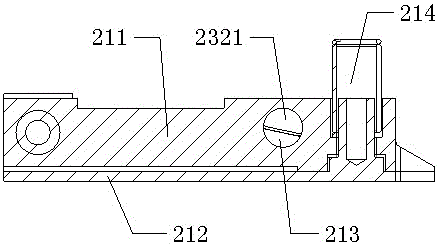

[0035] The wire drawing device 2 is set on the horizontal moving device 1 and is slidably connected to the slide rail 12. The wire drawing device 2 is provided with a gripper 21 for clamping the welding strip and pulling it to a designated station; the wire drawing device 2 also includes a gripper installation The frame 22 and the jaw drive 23; the jaw 21 is fixedly connected to the jaw mounting frame 22, and the jaw drive 23 is connected to the jaw 21 and enables the jaw 21 to open and close.

[0036] The jaw drive 23 includes a cylinder 231 and a rotating mechanism connected to the cylinder 231. The rotating mechanism is connected to the jaw 21. The rotating mechanism includes a rotating rod 232. ...

Embodiment 2

[0047] The rest is the same as the above embodiment, except that at least one clamping surface of the jaw 21 is a corrugated surface or a toothed surface.

Embodiment 3

[0049] The rest is the same as the above embodiment, the difference is that the width of the inlet end of the guide track is greater than the width of the outlet end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com