Oil heater and welding method thereof

An oil heater and welding method technology, applied in welding equipment, metal processing equipment, transportation passenger cars, etc., can solve the problems of more than 60 decibels, actual temperature deviation, high temperature, and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

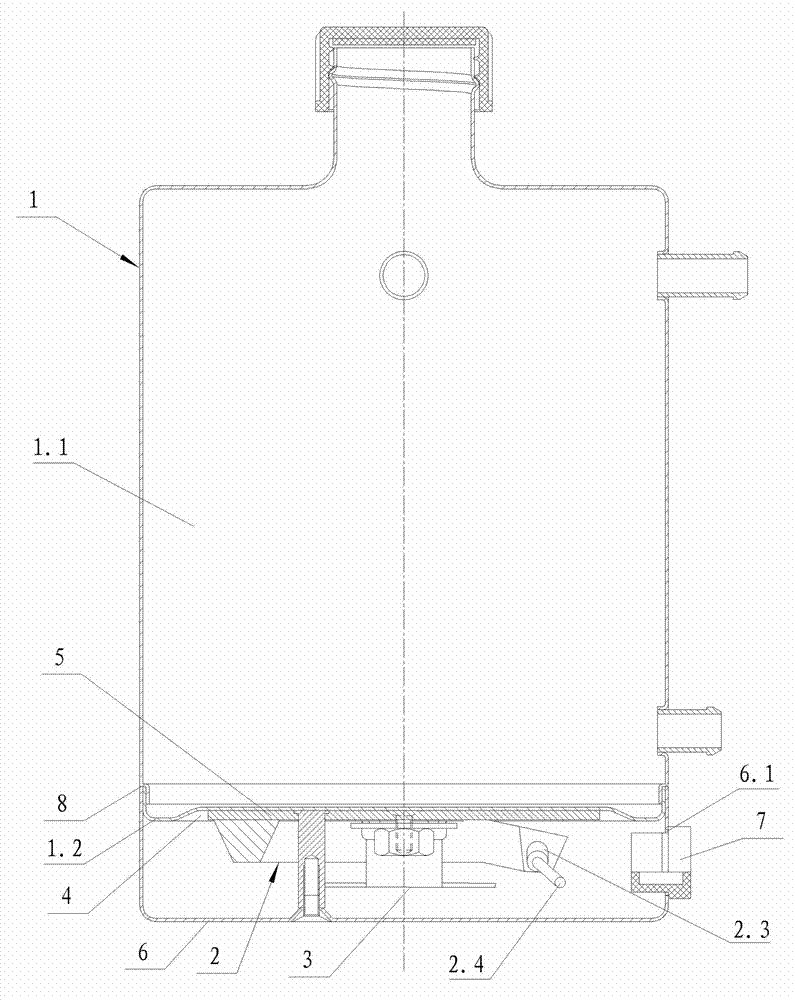

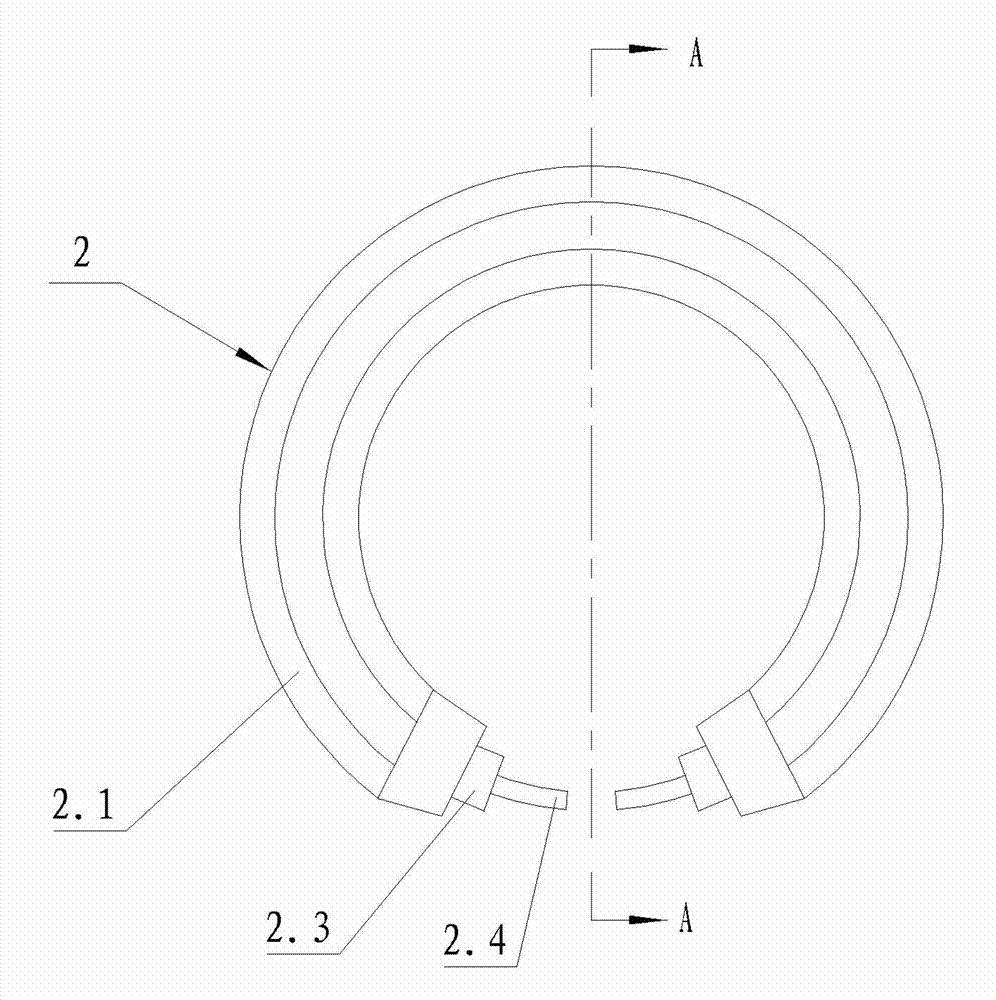

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown oil heater includes a tank body 1, a heating device 2 and a temperature controller 3 (of course, it also includes other components, but since it does not involve the invention of the present invention, it will not be repeated here), The heating device 2 and the temperature controller 3 are all connected to the bottom surface of the tank body 1, the bottom surface of the tank body 1 is provided with a groove 4, and the heating device 2 and the temperature controller 3 are all located in the groove 4 Inside, and between the heating device 2 and the bottom surface of the groove 4, a heat conduction plate 5 is provided, the shape of the heat conduction plate 5 is the same as that of the bottom surface of the groove 4, and a plane of the heat conduction plate 5 is completely attached to the bottom surface of the groove 4 , the heating device 2 and the temperature controller 3 are connected to the...

Embodiment 2

[0052] Such as Figure 6 and Figure 7 A kind of oil heater shown, it comprises tank body 1, heating device 2 and temperature controller 3, described heating device 2 and temperature controller 3 are all connected to the bottom surface of tank body 1, the tank body 1 The bottom surface is provided with a groove 4, the heating device 2 and the temperature controller 3 are located in the groove 4, and a heat conducting plate 5 is arranged between the heating device 2 and the bottom surface of the groove 4, and the heat conducting plate 5 The shape is the same as that of the bottom surface of the groove 4. One plane of the heat conduction plate 5 is completely attached to the bottom surface of the groove 4. The heating device 2 and the temperature controller 3 are connected to the other plane of the heat conduction plate 5, and the temperature must be ensured during installation. The probe of the controller 3 is attached to the heat conducting plate 5.

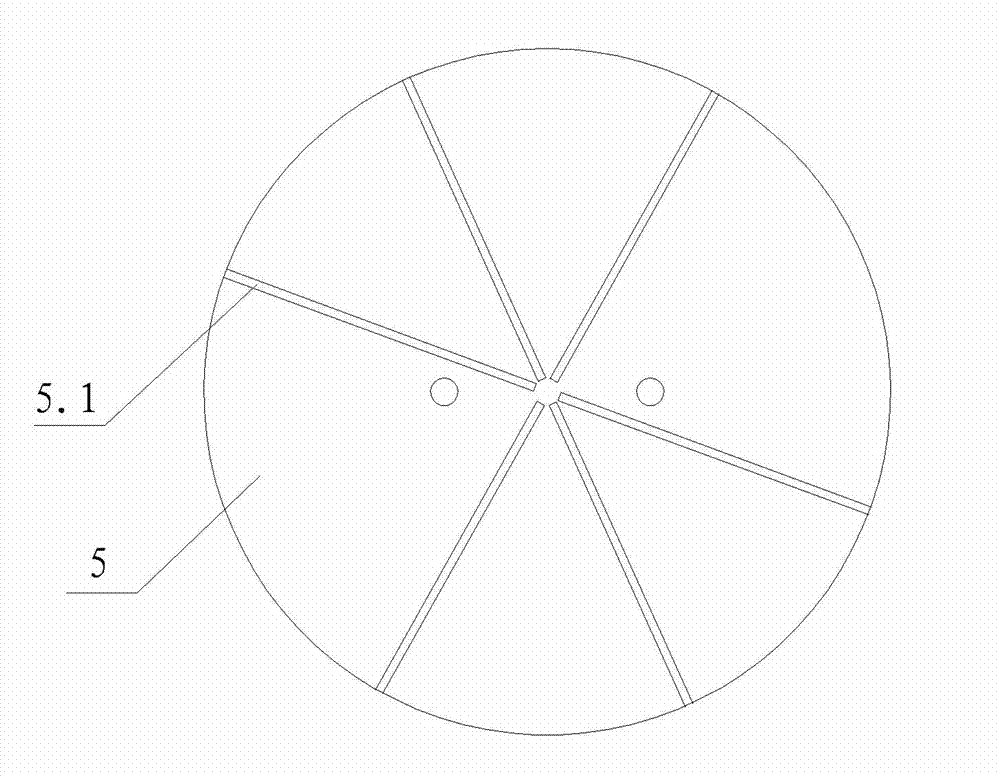

[0053] Eight radial air...

Embodiment 3

[0070]An oil heater, which includes a tank body 1, a heating device 2 and a temperature controller 3, the heating device 2 and the temperature controller 3 are connected to the bottom surface of the tank body 1, and the bottom surface of the tank body 1 is set There is a groove 4, the heating device 2 and the temperature controller 3 are located in the groove 4, and a heat conducting plate 5 is arranged between the heating device 2 and the bottom surface of the groove 4, and the shape of the heat conducting plate 5 is the same as The shape of the bottom surface of the groove 4 is the same, one plane of the heat conduction plate 5 is completely attached to the bottom surface of the groove 4, the heating device 2 and the temperature controller 3 are connected to the other plane of the heat conduction plate 5, and the temperature controller must be ensured during installation. The probe of 3 is attached to the heat conducting plate 5.

[0071] Four radial air guide grooves 5.1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com