S-band and C-band double-frequency controllable high-power microwave device

A high-power microwave and microwave device technology, applied in the field of S, can solve the problems of strong guiding magnetic field, large volume, high energy consumption, etc., and achieve the effect of reducing energy demand, reducing system volume, and simple structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

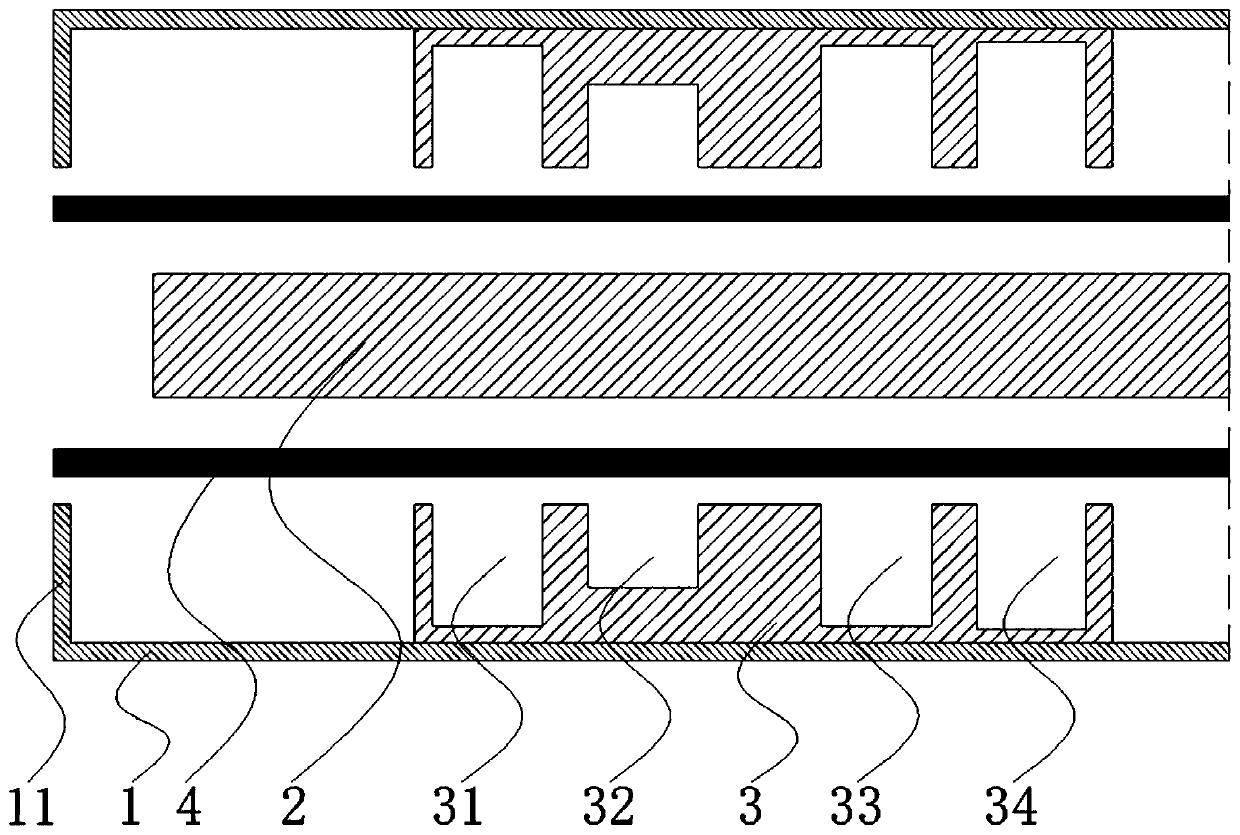

[0033] like figure 1 As shown, a kind of S, C-band dual-frequency controllable high-power microwave device of the present embodiment comprises a circular waveguide outer cylinder, an inner conductor coaxially arranged in the circular waveguide outer cylinder, arranged in the circular waveguide outer cylinder and coaxial with the circular waveguide outer cylinder. Coaxial hollow four-cavity slow-wave structure, the left end of the microwave device is provided with a circular closed structure with the same inner diameter as the four-cavity slow-wave structure, and a vacuum electron beam transmission channel is formed between the inner conductor and the four-cavity slow-wave structure. A ring-shaped electron beam transmitted in the transmission channel;

[0034] The four-cavity slow-wave structure can adjust its relative position in the microwave device, its total axial length is 170 mm, and its inner diameter is 76 mm;

[0035] The four-cavity slow-wave structure can axially ad...

Embodiment 2

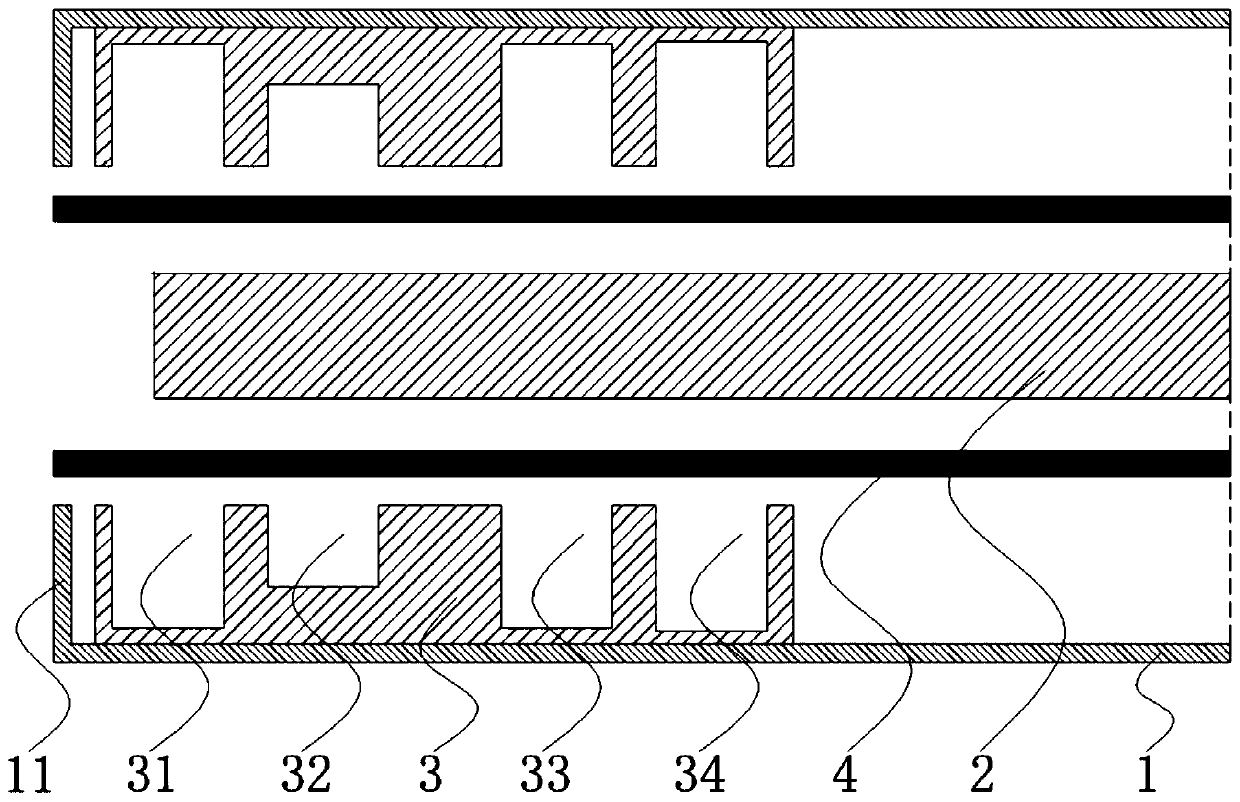

[0044] like figure 2 As mentioned above, the difference between this embodiment and Embodiment 1 is: in the embodiment, the axial distance between the rightmost side of the four-cavity slow wave structure and the leftmost end of the coaxial inner conductor is 162.5mm, and a high voltage is applied between the cathode and anode 380kV, the cathode emission produces a ring-shaped electron beam with an inner and outer diameter of 60mm and 70mm, and a beam intensity of 6kA. The ring-shaped electron beam is transmitted into the device under the guidance of a 0.5T axial magnetic field, and the electron beam transfers energy to the microwave field, and the microwave device radiates high-power microwaves in the C-band.

[0045] In summary, the use of a S, C-band dual-frequency controllable high-power microwave device of the present invention can greatly reduce the volume and weight of the high-power microwave source system; can greatly reduce the energy demand of the magnetic field fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com