A three-component force sensor for measuring the load at the joint of automobile suspension bushing

A technology for automobile suspension and joints, which is used in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of difficulty in measuring the load force at the joints of suspension bushings, etc., to ensure performance and improve stress level. , the effect of improving the overall stiffness and natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For the convenience of those skilled in the art to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

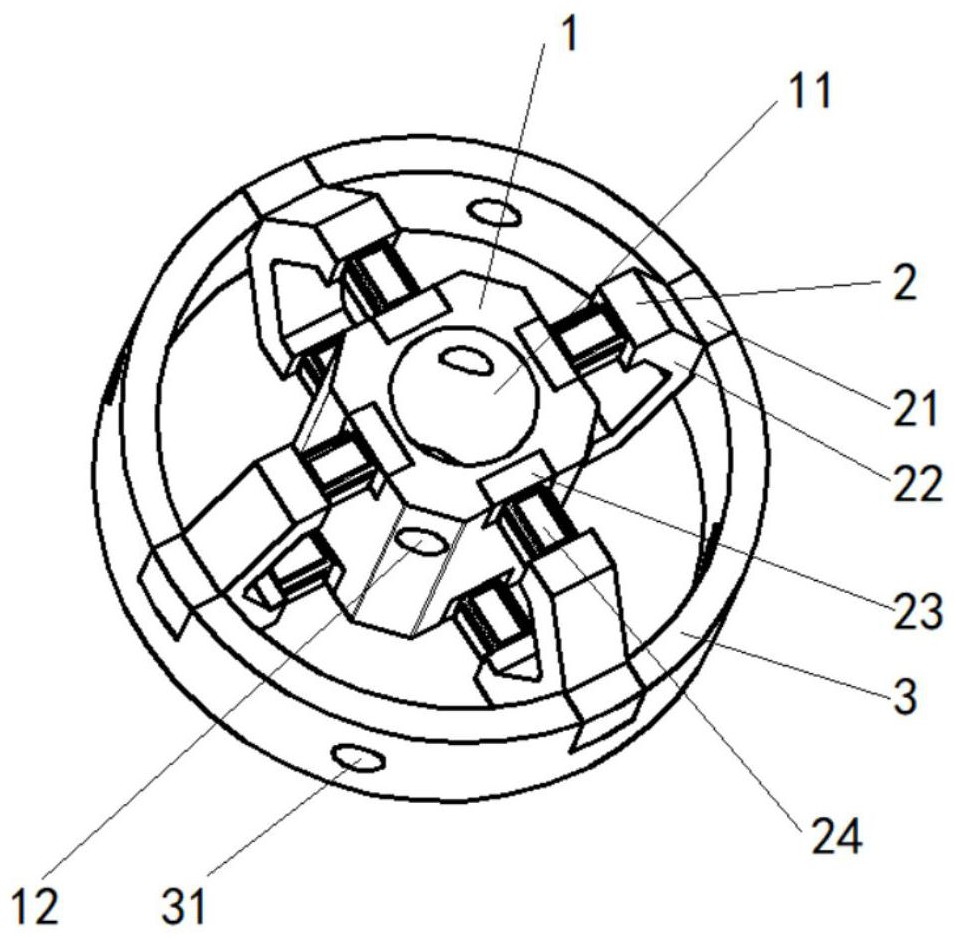

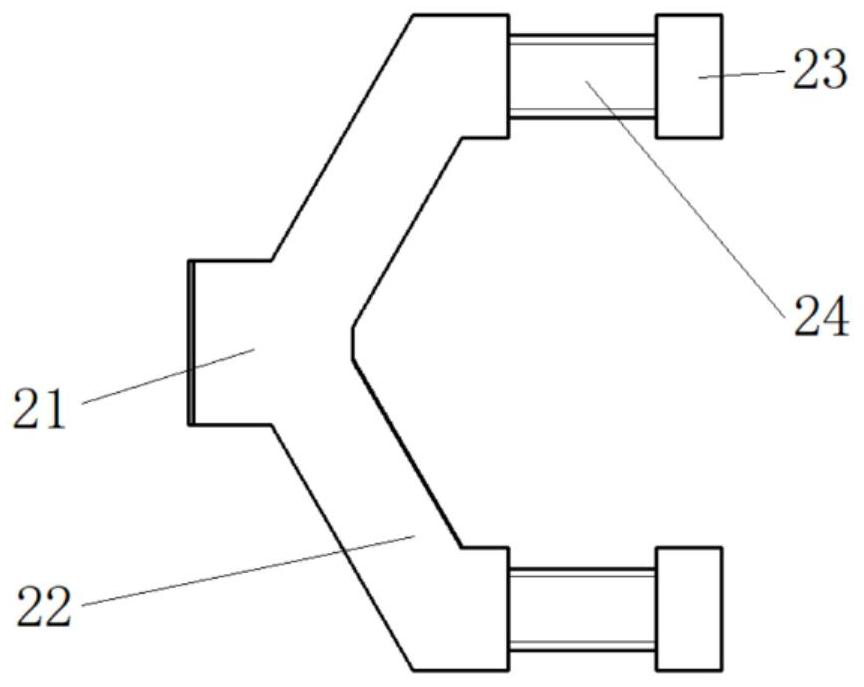

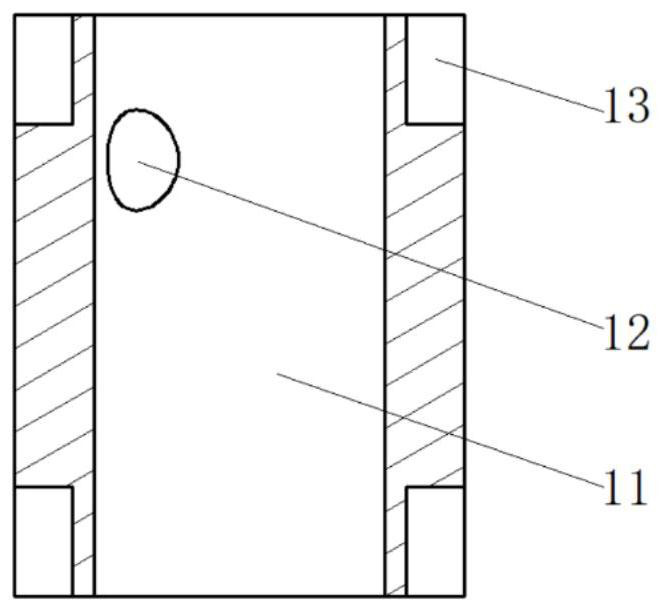

[0031] The invention discloses a three-component force sensor for measuring the load at the joint of the automobile suspension bushing, such as Figure 1 to Figure 3 As shown, it includes a tubular connector 1, an annular connector 3 and four Y-shaped elastic elements 2; the tubular connector 1 is fixed at the center of the annular connector 3 through the Y-shaped elastic element 2; the four Y-shaped elastic elements 2 are elastic elements with the same structure, and are arranged symmetrically at intervals of 90° along the circumferential direction; the Y-shaped elastic element 2 includes an internal fixed end 23, a strain beam 24, a Y-shaped connecting beam 22 and an external fixed end 21; the internal fixed The end 23 is located at the top of the two bifurcated parts of the Y-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com