Seal structure for fuel pump

A technology of sealing structure and fuel pump, which is applied in the direction of engine sealing, liquid fuel feeder, charging system, etc., can solve problems such as assembly problems, and achieve the effect of compact radial size and enlarged shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

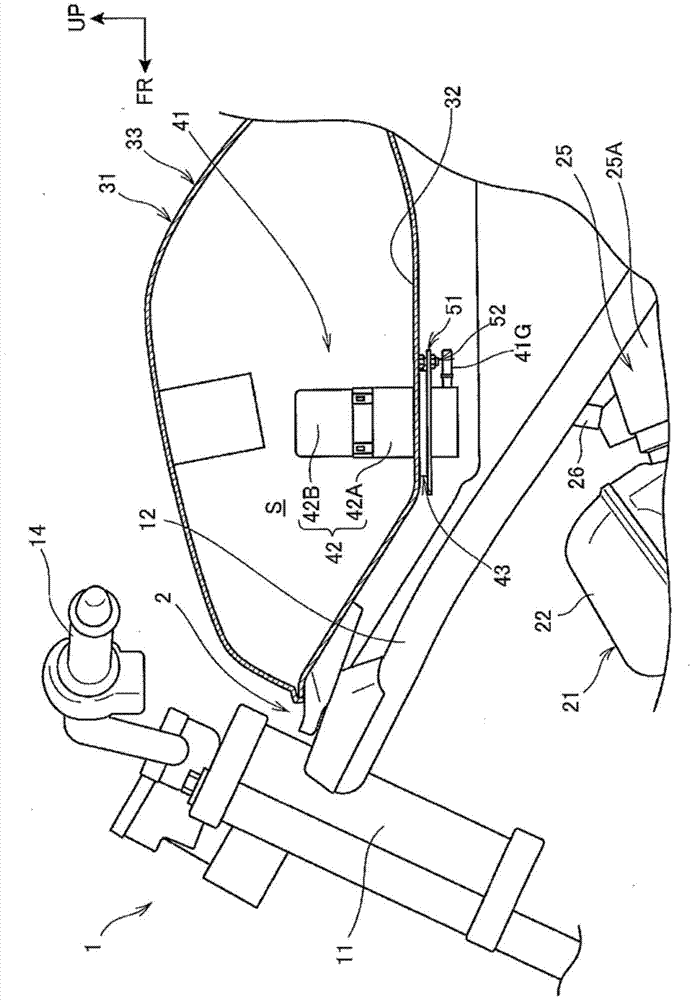

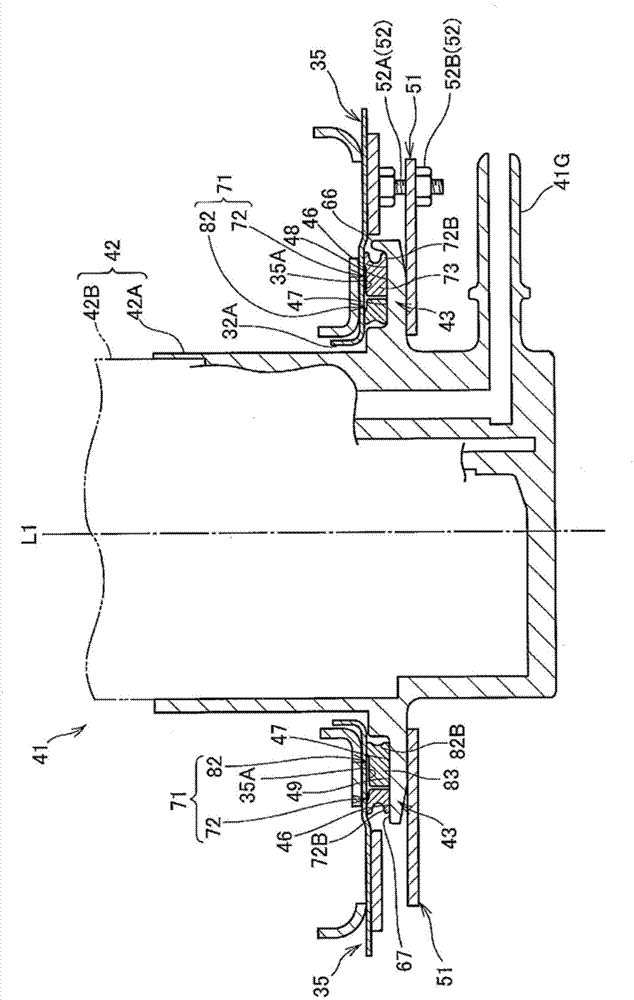

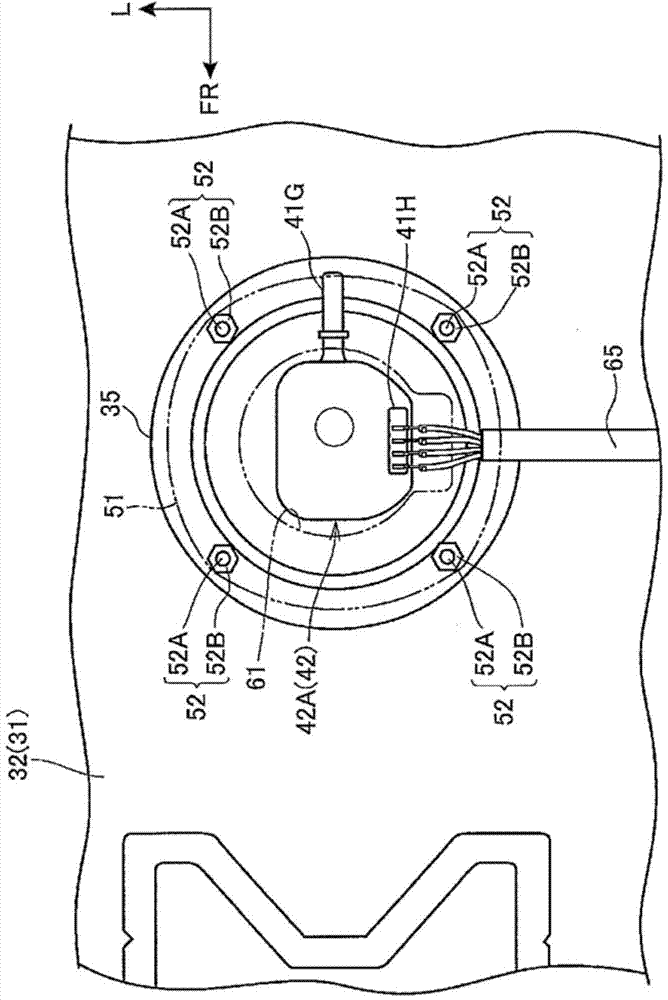

[0036] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. It should be noted that, in the description, descriptions of directions such as front, rear, left, right, and up and down mean that they are the same as directions relative to the vehicle body unless otherwise specified. In addition, the reference sign FR shown in each figure shows the front of a vehicle body, the reference sign UP shows the upper side of a vehicle body, and the reference sign L shows the left side of a vehicle body.

[0037] figure 1 The front part structure of the motorcycle to which the embodiment of this invention is applied is shown.

[0038] The frame 2 of the motorcycle 1 is a combination of various metal parts by welding or the like, including a head pipe 11, a pair of left and right main frames 12 extending backward and downward from the head pipe 11, and an engine 21 supported on the head pipe 11. The fuel tank 31 is supported behind the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com