Lens module

A lens module and lens barrel technology, applied in the field of optical systems, can solve the problems affecting the imaging effect of the lens, the adhesion of foreign objects to the infrared filter, affecting the production rate of the lens module, etc. The effect of increasing the height and improving the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

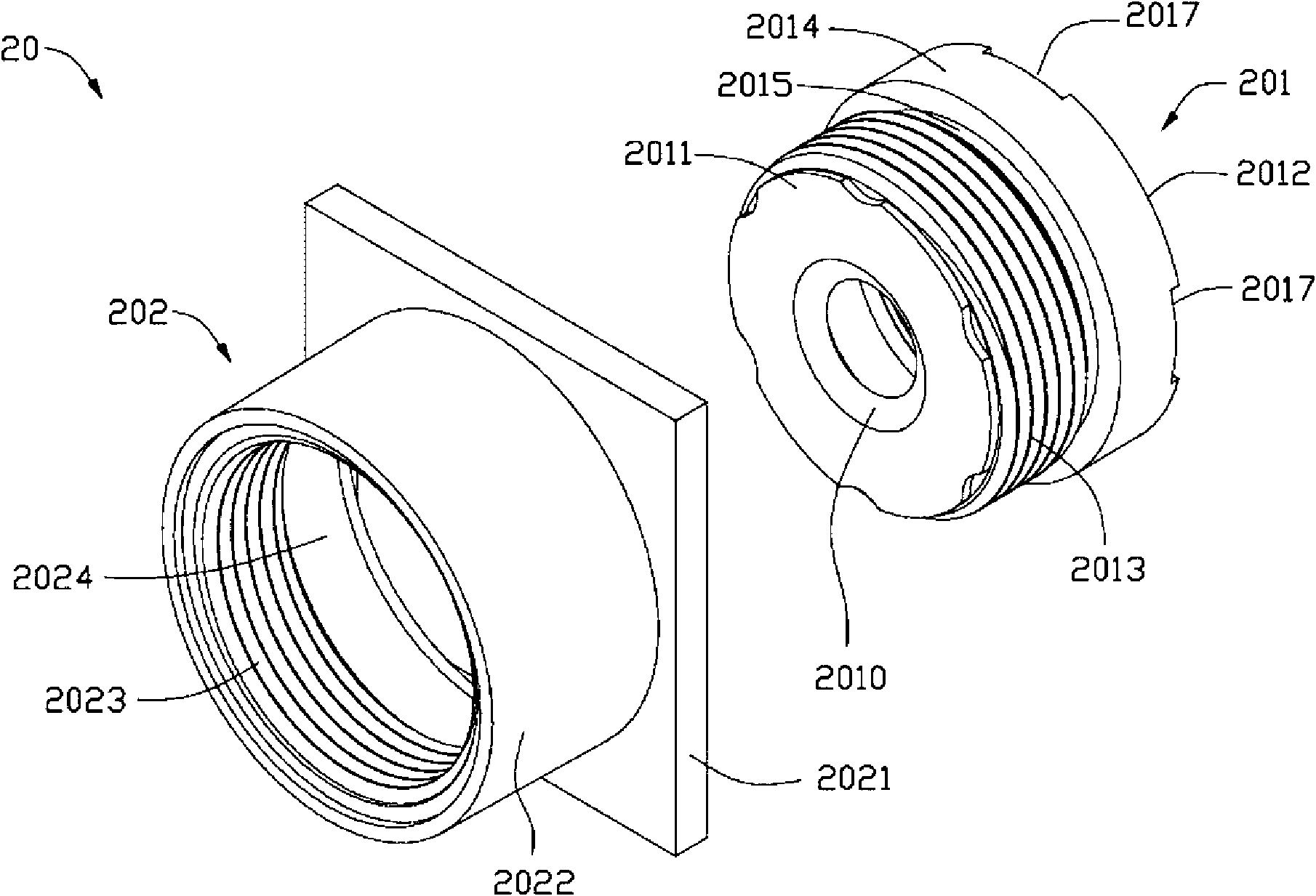

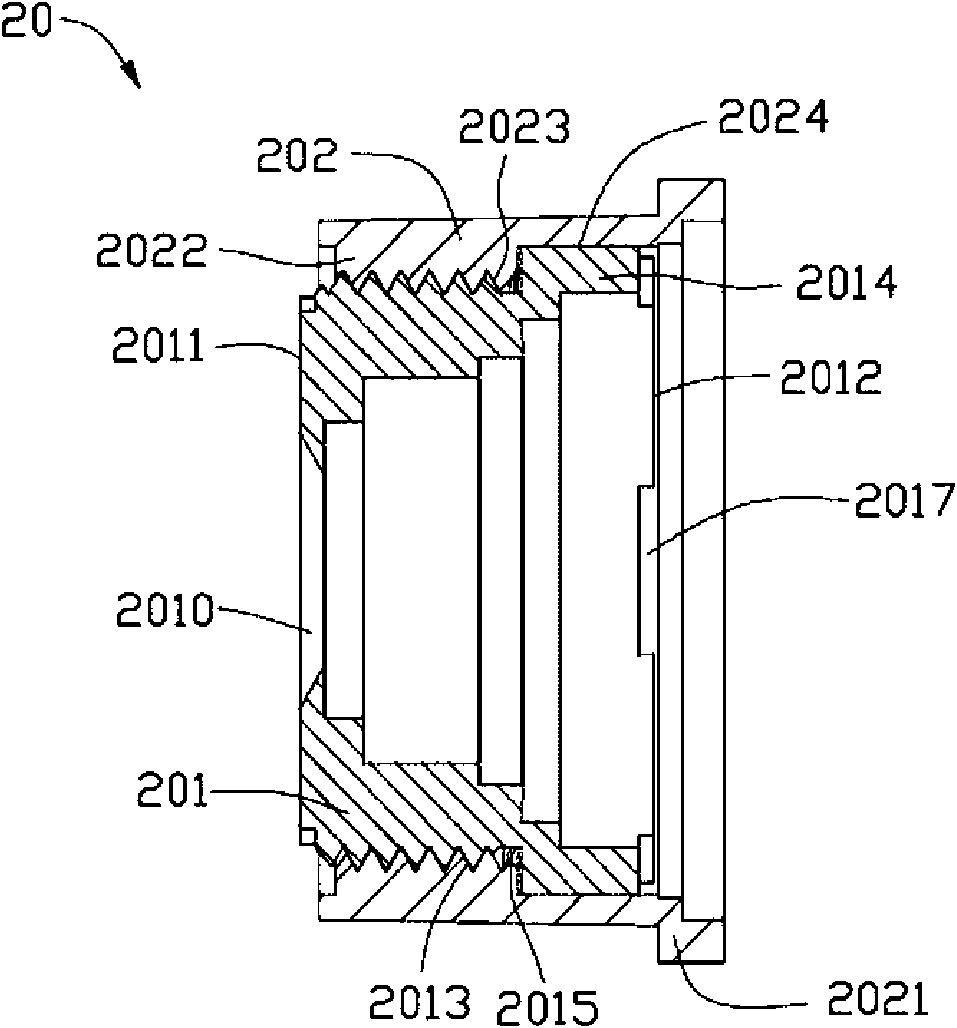

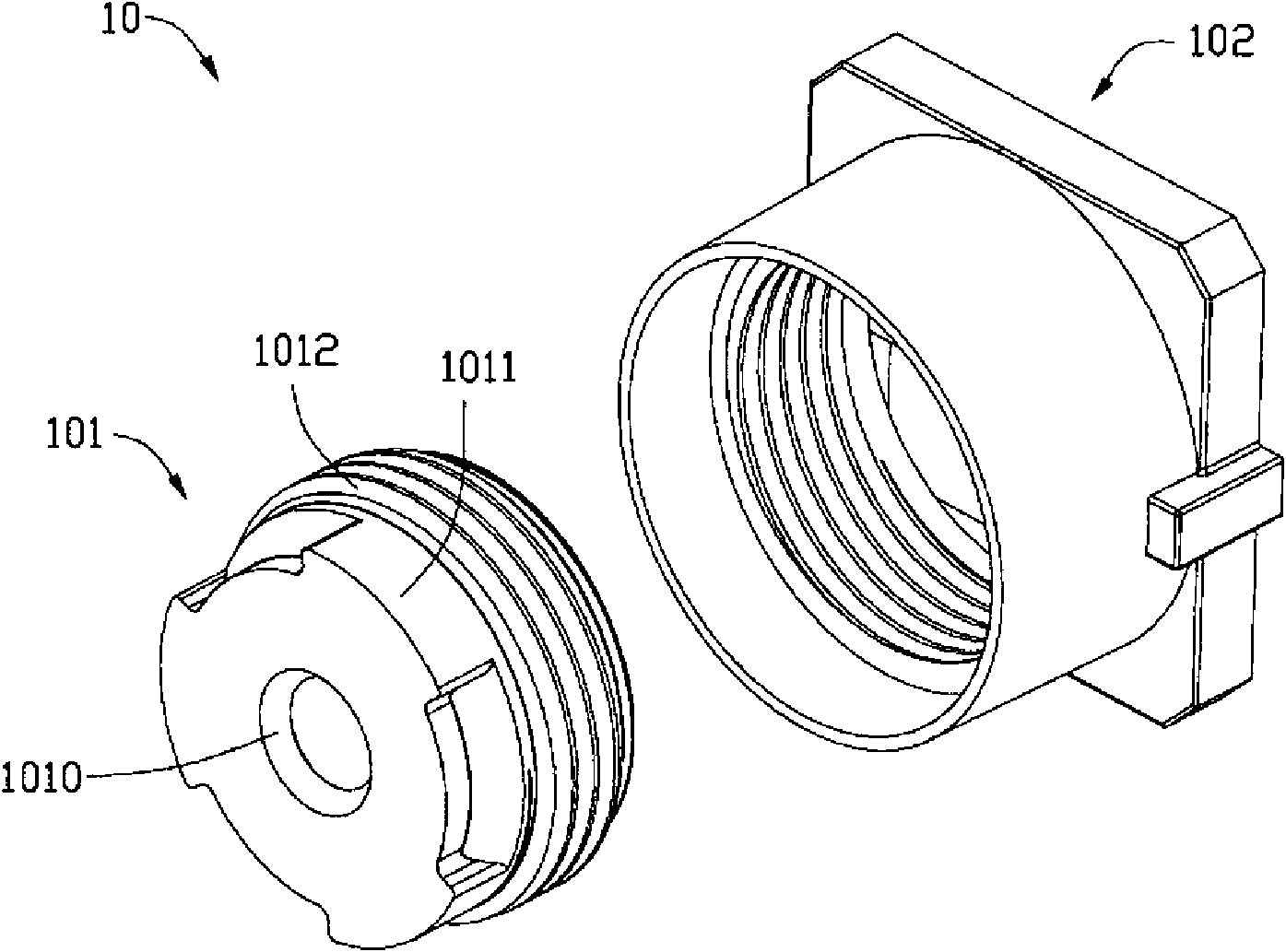

[0014] see figure 1 In one embodiment of the present invention, the lens module 20 includes a lens barrel 201 and a lens holder 202 matched with the lens barrel 201 .

[0015] The lens barrel 201 is a hollow structure, and optical elements (not shown in the figure) such as a lens group, a spacer ring, and a filter are accommodated inside the lens barrel 201 . The lens barrel 201 has a first end 2011 and a second end 2012 opposite to each other. The first end portion 2011 has a light inlet 2010 , and an external thread 2013 is provided on the outer peripheral surface of the first end portion 2011 . A flange 2014 is disposed on the outer peripheral surface of the second end portion 2012 . The outer diameter of the flange 2014 is larger than the outer diameter of the outer thread 2013 .

[0016] The mirror base 202 has a hollow structure wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com