Beater disintegrating machine

A hammer mill and hammer technology, used in grain processing and other directions, can solve the problems of easy concave in the middle part of the sieve plate, hinder the powder from passing through the sieve holes, and affect the output of the pulverizer, so as to reduce the quality and ensure the Strength, the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

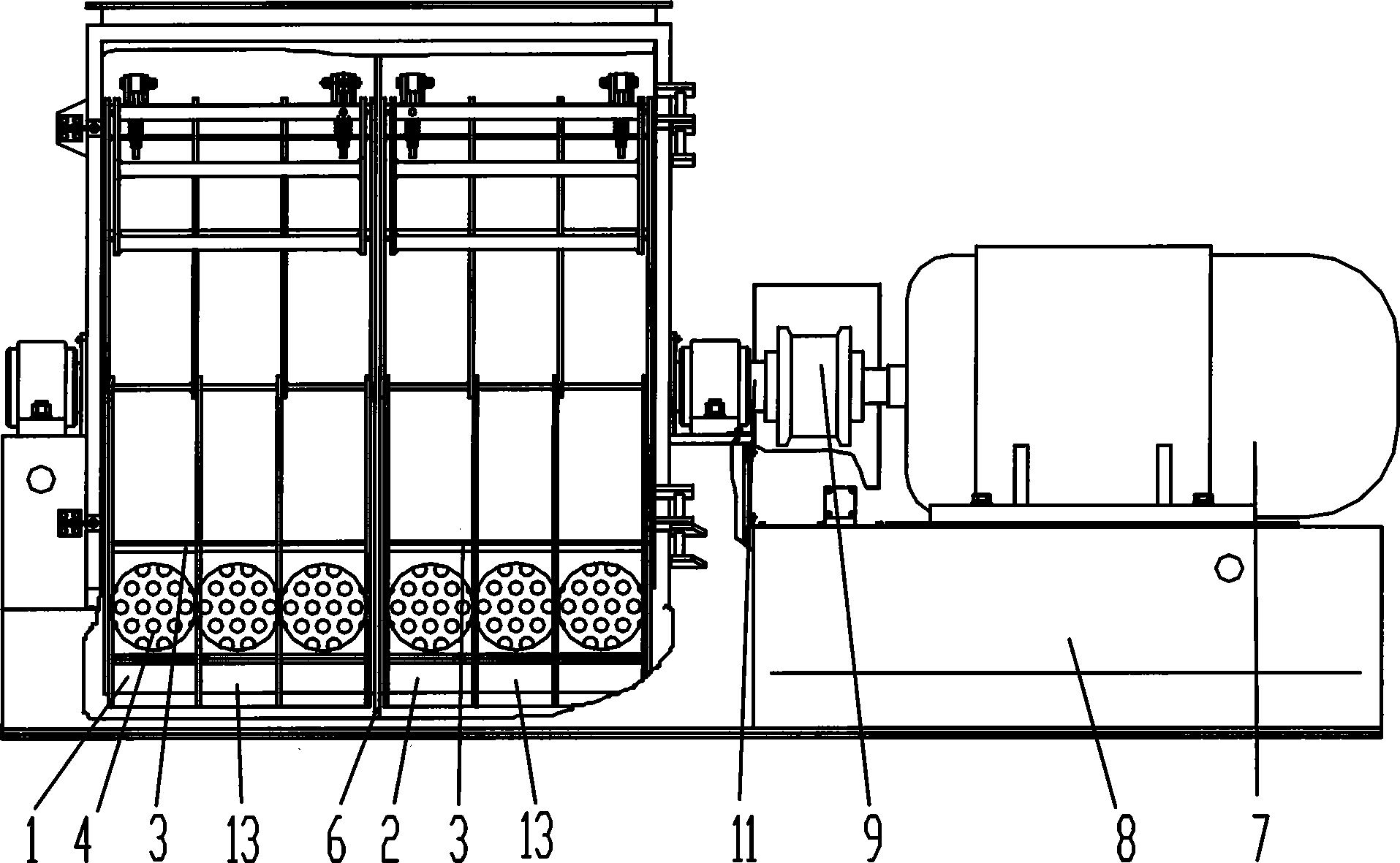

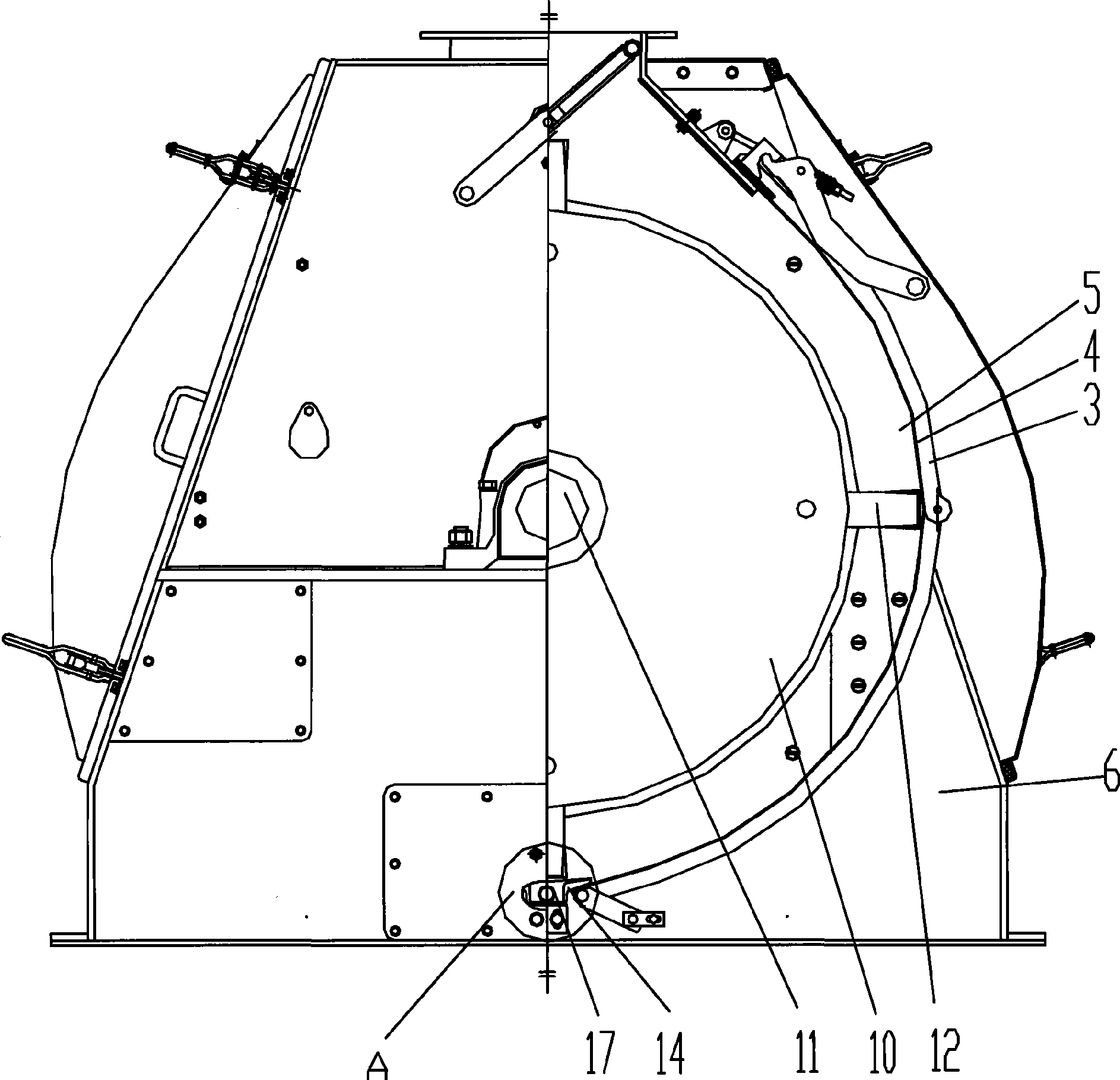

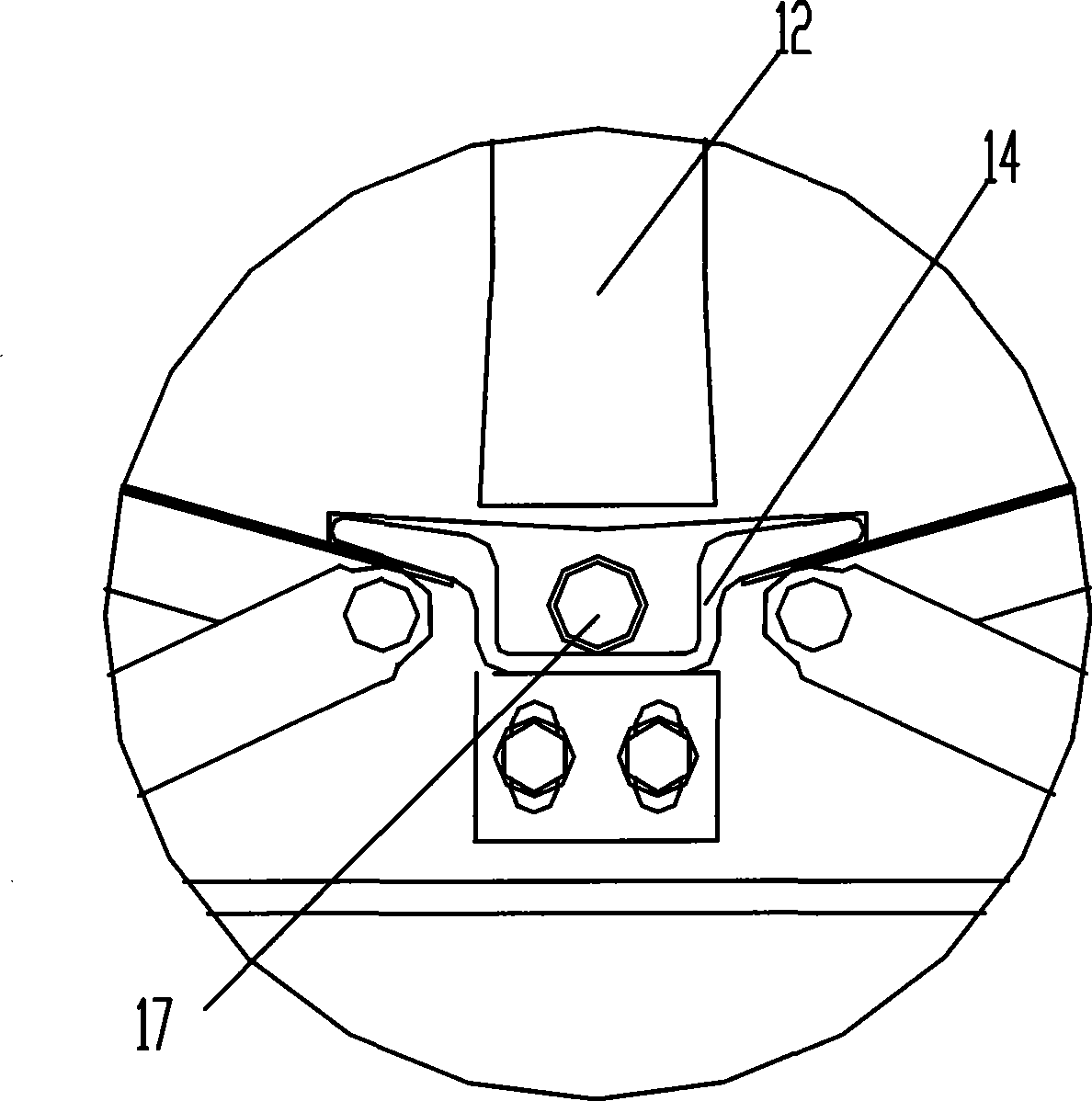

[0030] Such as Figure 1-2 In the embodiment 1 shown in , 7, the hammer mill mainly includes: a press screen frame 3, a sieve plate 4, a sieve plate frame 5, a motor 7, a frame 8, a coupling 9, a rotor 10, and a rotor shaft 11 , Hammer 12, secondary crushing chamber 14 and large spacer. The motor 7 installed on the machine base 8 is connected with the pulverizer rotor 10 through a shaft coupling 9 . The rotor 10, the sieve plate 4 and the sieve plate frame 5 jointly form a large crushing chamber, the secondary crushing chamber 14 is located at the lower end of the large crushing chamber, and the sieve plate 4 is tightly pressed on the sieve plate frame 5 by the pressing screen frame 3. The rotor shaft 11 of the rotor 10 is connected with the shaft coupling 9, and many hammer blades 12 are housed on the rotor 10. A large spacer is arranged between two adjacent hammer frame plates of the rotor shaft 11. The large spacer includes the inner edge of the spacer and the outer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com