Aviation centrifugal pump blade profile optimization design method

An optimization design, centrifugal pump technology, applied in the direction of calculation, computational model, biological model, etc., can solve the problems of long iteration period, complex genetic algorithm coding, limited application of genetic algorithm, etc., to achieve the effect of improving optimization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0093] 1 Airfoil parametric design and numerical simulation

[0094] 1.1 Geometric model and profile parameterization process

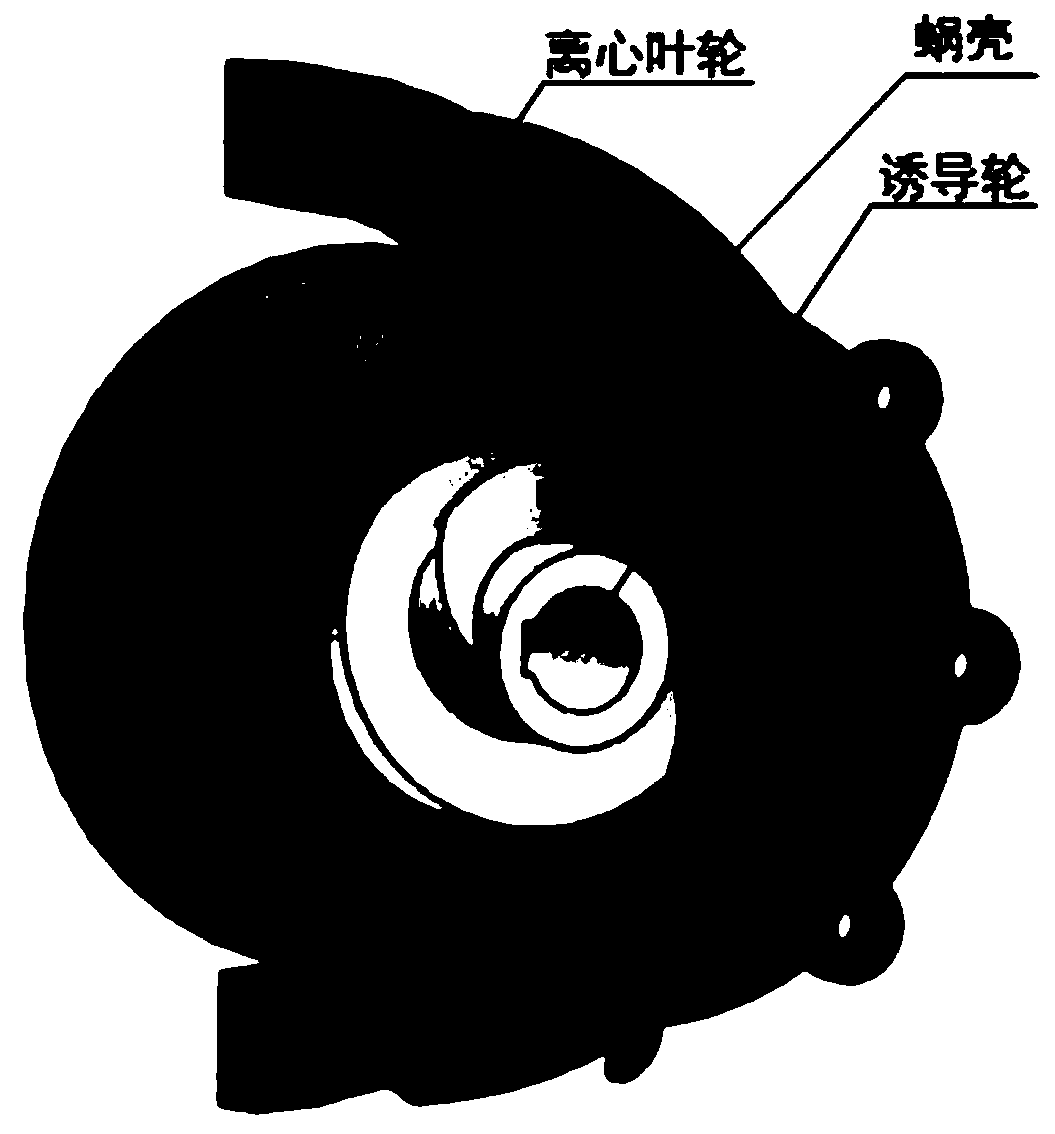

[0095] The object of optimization design is the aviation fuel centrifugal pump with a specific speed of 63.13. Its main flow-passing components include inducer, centrifugal impeller and volute, and the design speed is 7600r / min. figure 1 The three-dimensional model and physical map of the fuel pump are shown.

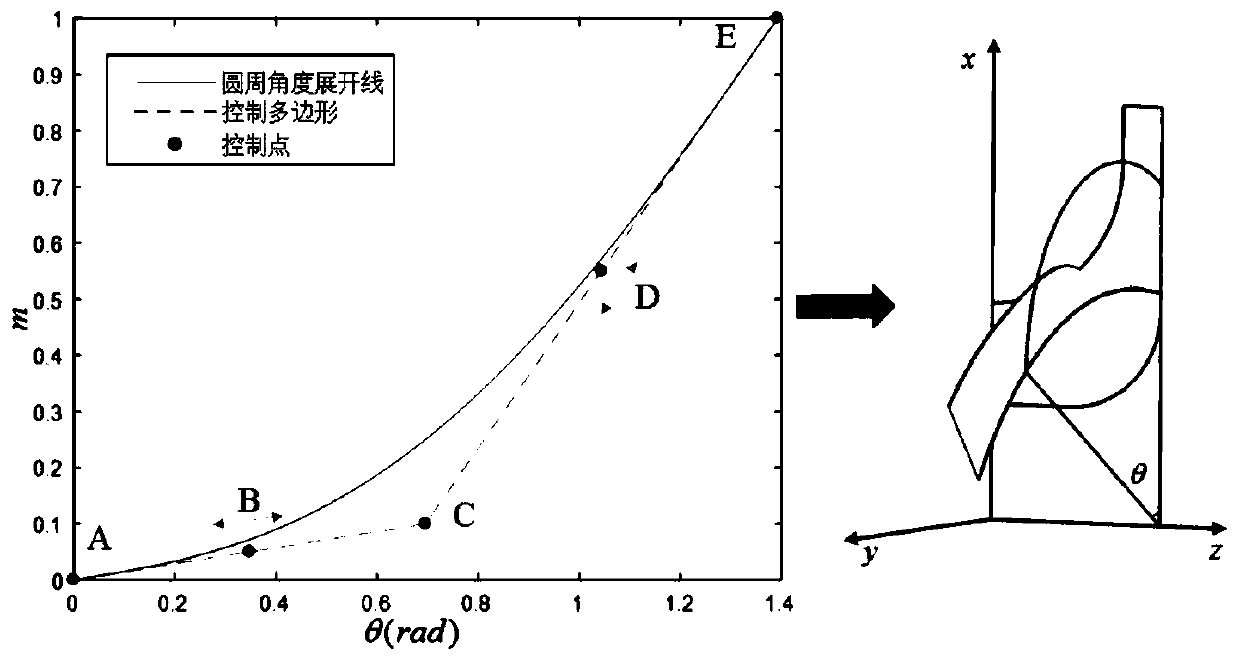

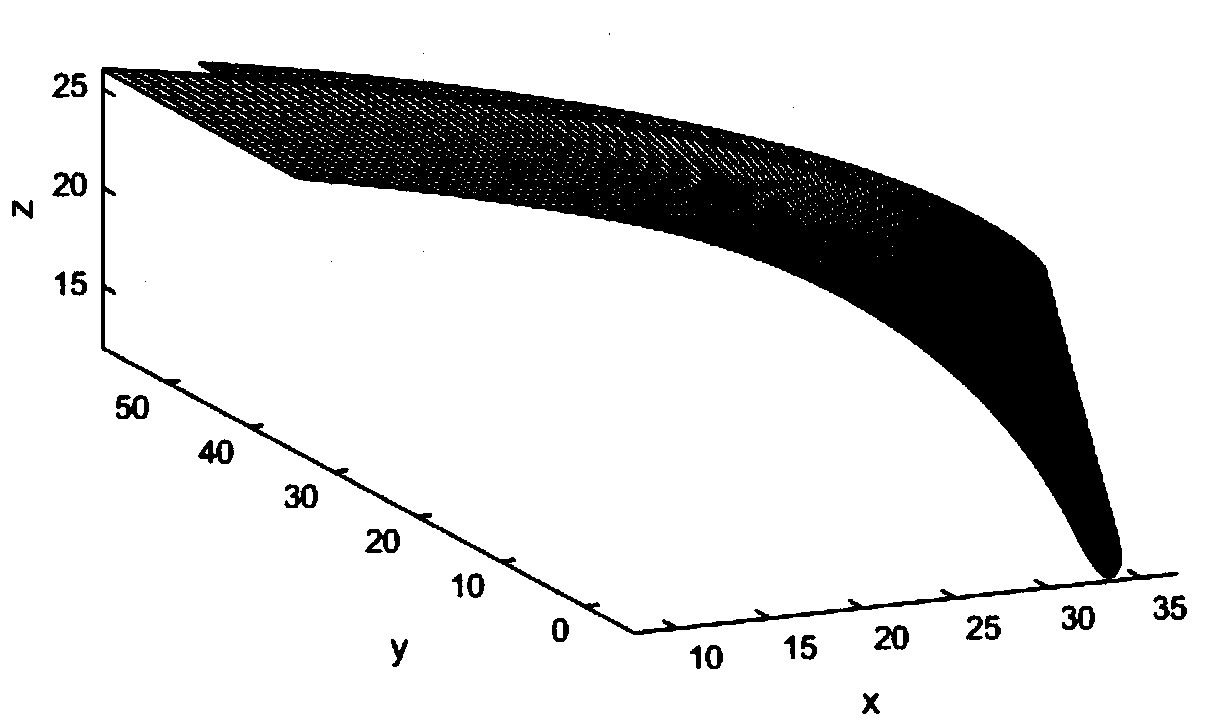

[0096] The center plane of the centrifugal impeller blade can be regarded as the spatial expansion of the streamline on the axial plane. The research adopts the 5-point 4th Bezier curve to realize the parametric modeling of the blade shape by controlling the circumferential angle of the streamline of the hub and the rim. Such as figure 2 The shown abscissa θ is in radians...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com