Reactor control-rod driving mechanism with adjustable magnetic damper

A driving mechanism and magnetic damper technology, applied in the control of nuclear reactions, reactors, climate sustainability, etc., can solve the problems of long transmission chain, scratches, sensitivity, etc., to increase the damping arm, simple processing and manufacturing, Stable and reliable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

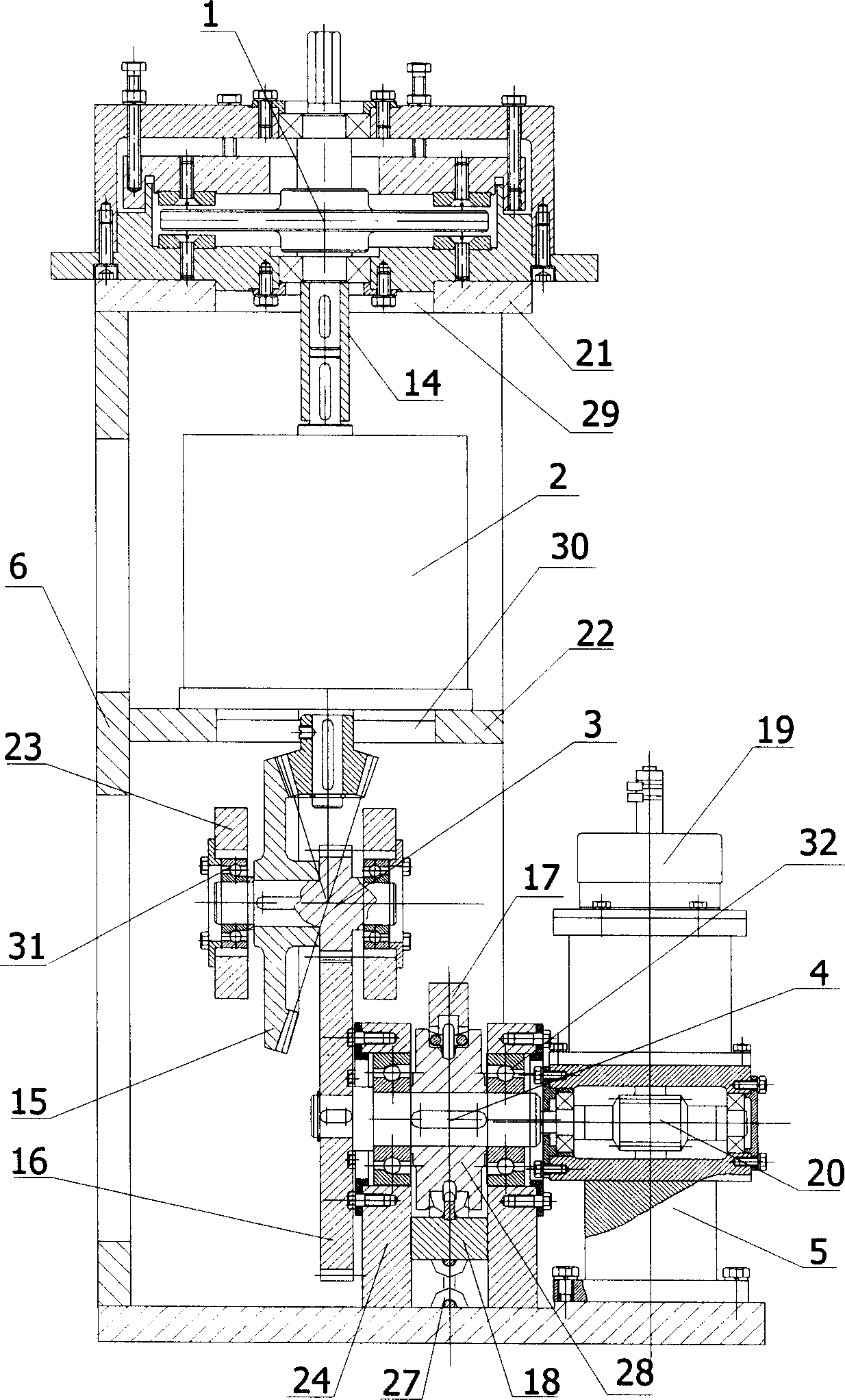

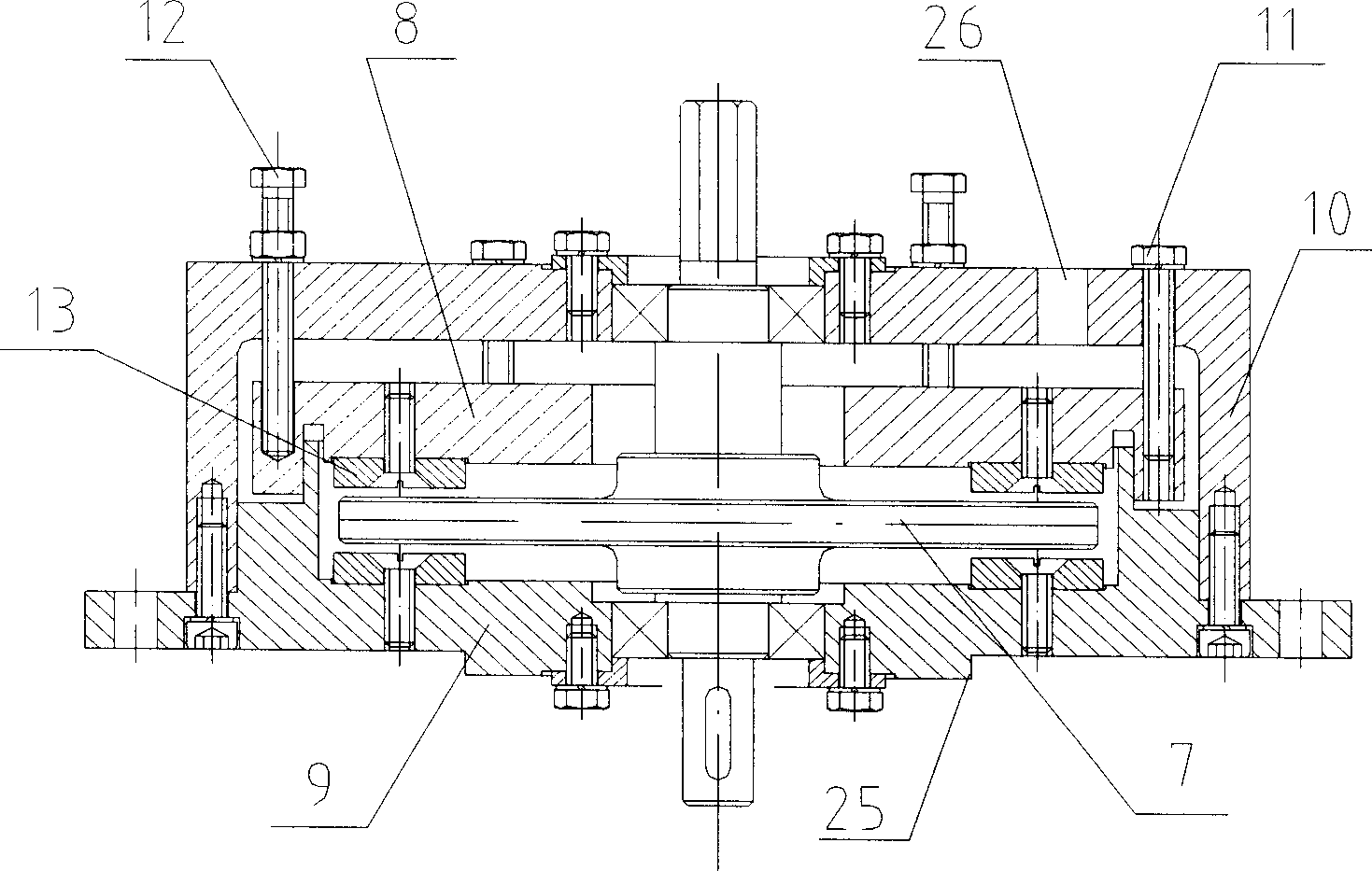

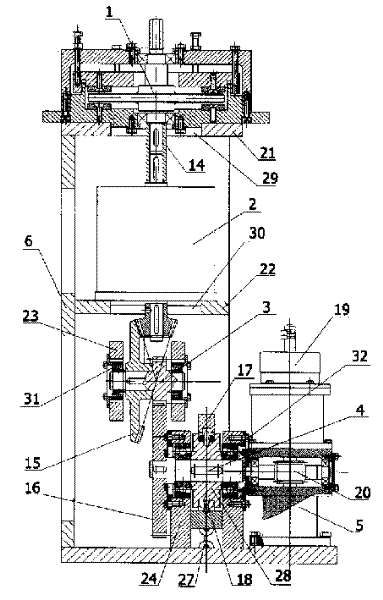

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] The reactor control rod drive mechanism with an adjustable magnetic damper provided by the present invention consists of an adjustable magnetic damper 1, a motor 2, a gear reduction mechanism 3, a sprocket device 4, a rod position measurement system 5 and a drive mechanism bracket 6 and other parts. The adjustable magnetic damper 1 includes: a moving disk 7, an upper disk 8, a lower disk 9, an upper bearing seat 10, an adjusting screw 11, a locking screw 12, a magnetic block 13 and the like. The magnetic damper 1 is installed on the outer top of the driving mechanism, and is connected with the motor 2 by a shaft sleeve 14 . In order to make the structure of the magnetic damper more compact, not only samarium cobalt permanent magnet material Sm is housed on the lower disk 9 2 (Co, Cu, Fe, Zr) 17 The magnetic block 13 made is also equipped with a bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com