Connector and plug thereof

A technology for plugs and plug housings, applied in connection, two-part connection devices, parts of connection devices, etc., can solve problems such as cumbersome operations, achieve simple unlocking methods, avoid large radial dimensions, and facilitate miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

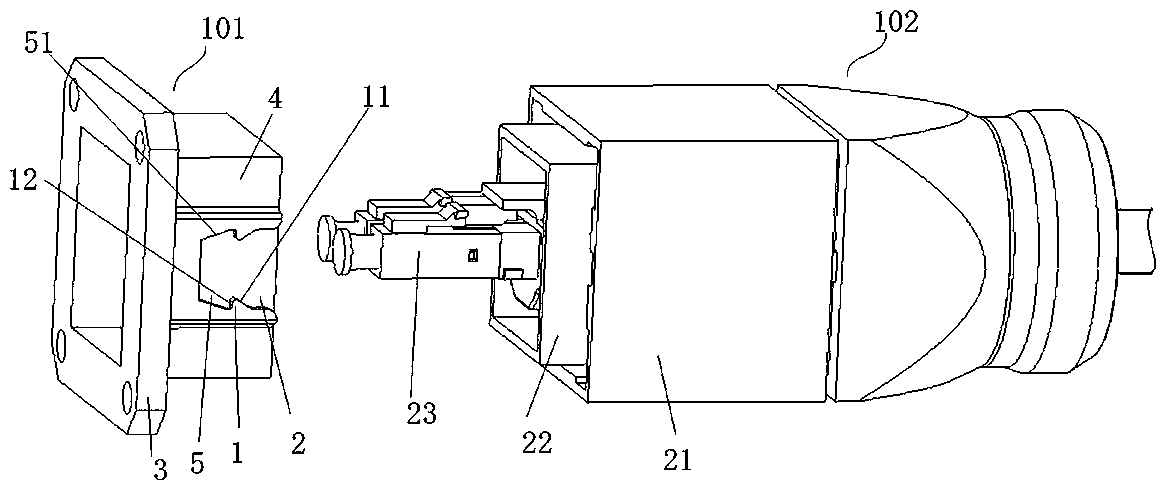

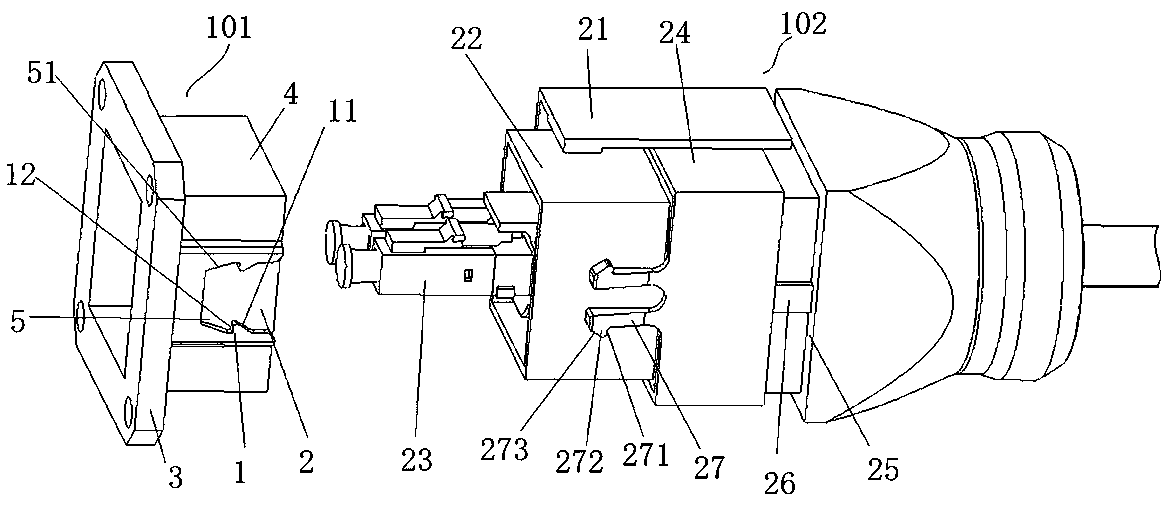

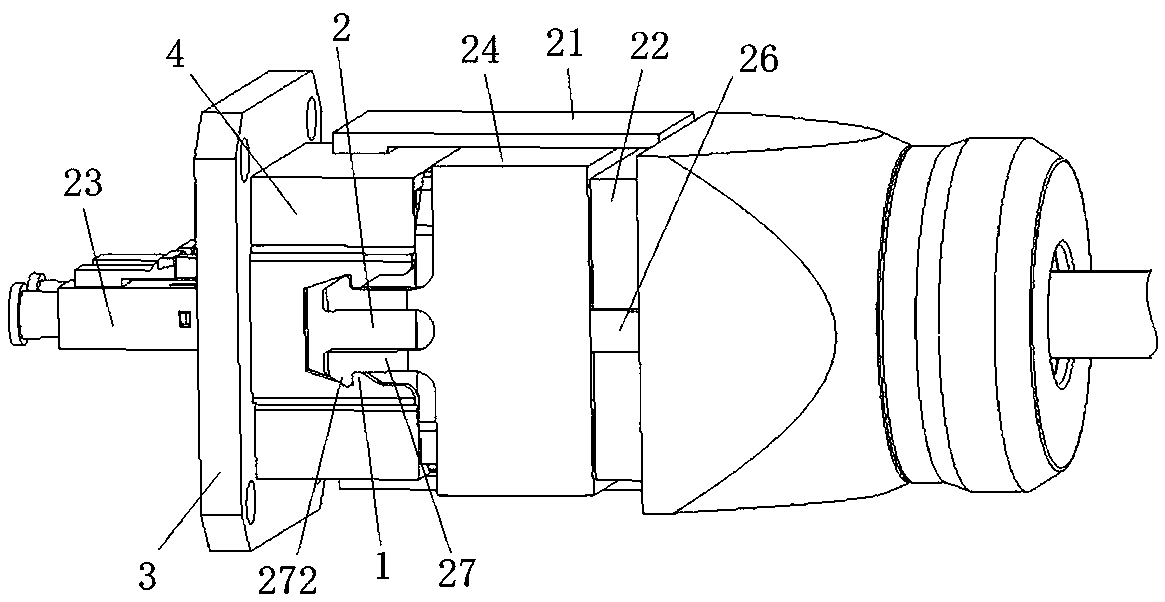

[0060] Such as Figure 1 to Figure 3 As shown, the connector includes a receptacle 101 and a plug 102 that are suitable for plugging. In this embodiment, the receptacle 101 and the plug 102 are both rectangular connectors, and the plug ends of the receptacle 101 and the plug 102 are defined as front ends. The socket 101 includes a socket housing 4, the socket housing 4 is fixed with a socket inner core (not shown), the plug 102 includes an inner housing 22, and the inner housing 22 is fixed with a plug inner core 23, between the socket 101 and When the plug 102 is inserted, the socket shell 4 and the inner shell 22 are docked, and the plug inner core 23 is also docked with the socket inner core. In other embodiments, the socket and plug may be polygonal connectors, or waist circular connectors.

[0061] Specifically, a locking sleeve 24 is set on the inner housing 22, and the locking sleeve 24 constitutes a locking member. The rear end of the inner housing 22 is provided with...

specific Embodiment 6

[0086] The difference between the specific embodiment 6 of the connector of the present invention and the specific embodiment 1 of the connector is that the hooking part is arranged along the radial direction of the plug housing, and is located on the inner side of the claw. During the rearward movement, the hooking part moves along the circumferential direction of the plug housing to realize unlocking with the hooking matching part, thereby realizing the separation of the plug and the socket.

[0087] The specific embodiment of the plug of the present invention, the structure of the plug in this embodiment is the same as that of the plug in any one of the specific embodiments 1-6 of the above-mentioned connector, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com