Patents

Literature

253results about How to "Cooperate closely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

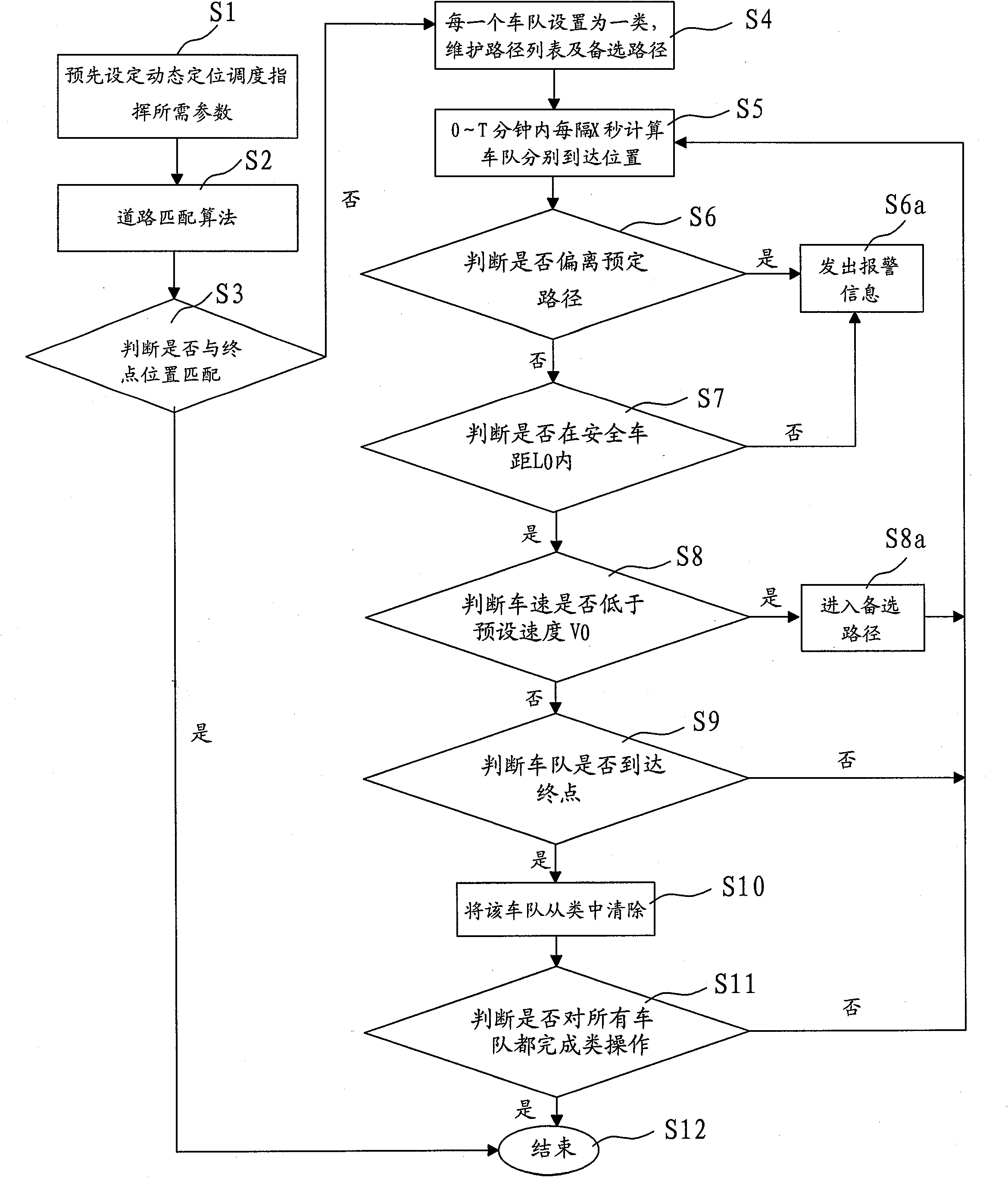

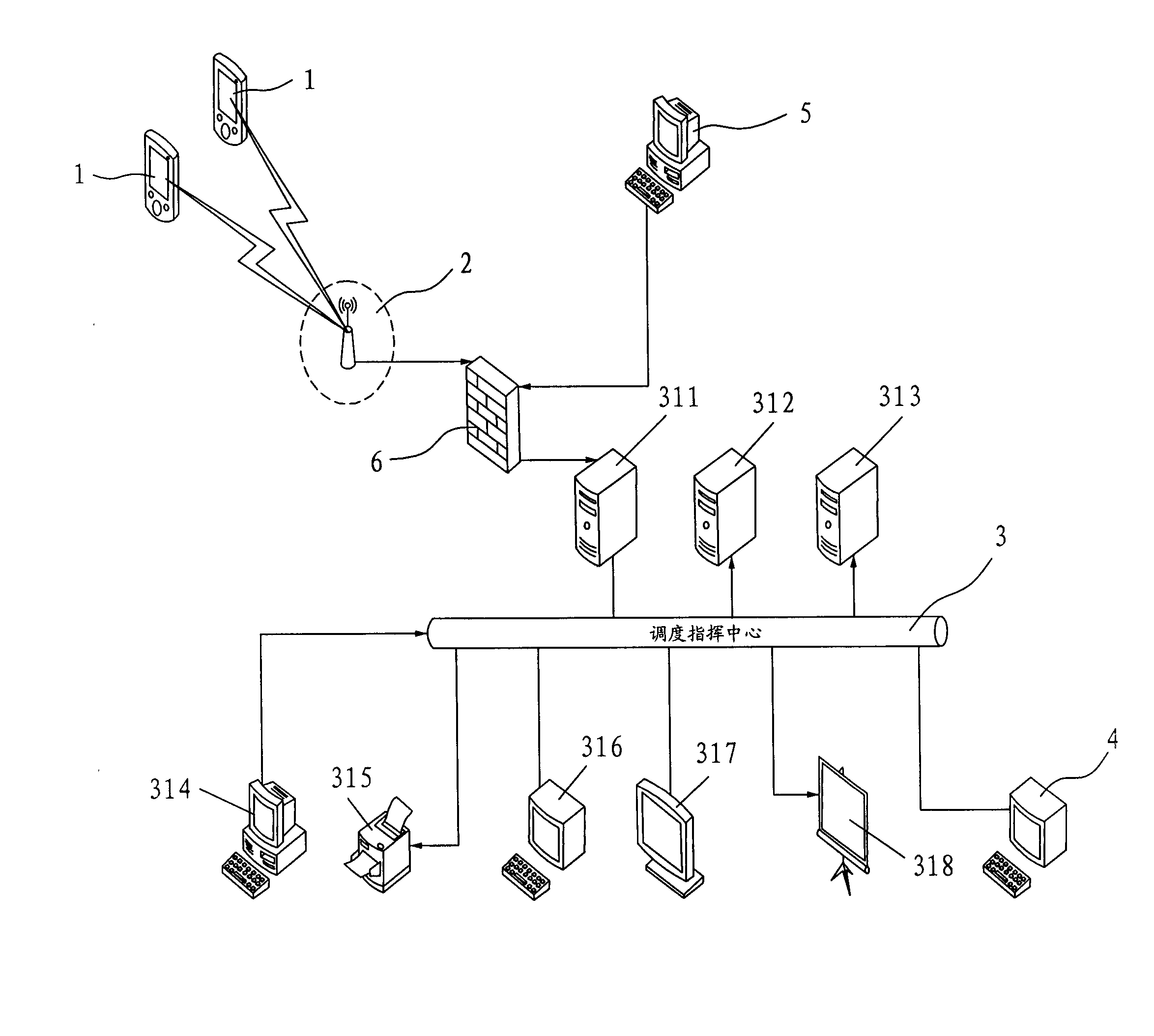

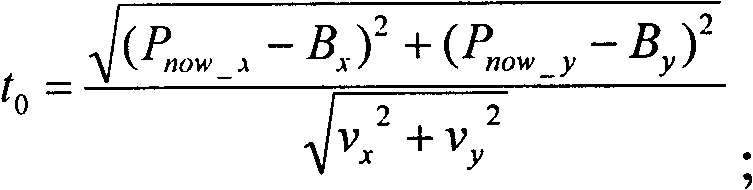

Dynamic positioning and scheduling method and system based on GIS (Geographic Information System)

InactiveCN102129772AGuarantee smooth and orderlySmooth and orderly admissionArrangements for variable traffic instructionsScheduling functionMatch algorithms

The invention relates to a dynamic positioning and scheduling method and system, which integrate satellite positioning, a digital map and a GIS (Geographic Information System) into a whole and are suitable for real time positioning and scheduling of fleets. The dynamic positioning and scheduling method comprises the following steps of: presetting a parameter required by dynamic positioning and scheduling; carrying out road matching algorithm processing according to GPS (Global Positioning System) positioning information and the GIS; setting each fleet as one category; calculating the positionwhere the fleet arrives every X seconds within 0-T min; judging whether the fleet deviates a preassigned path; judging whether other fleets are in a safety car distance value L0; if not, sending alarming information; judging whether the traveling average speed of the fleet is less than a set car speed value V0, if so, transferring to a standby path; judging whether the fleet arrives a destination, if so, clearing the fleet in the categories; repeating the steps until category operations of all fleets are completed. Therefore, by utilizing the dynamic positioning and scheduling method and system, the real time positioning and monitoring of a plurality of fleets can be realized, alarming can be given when conflict conditions occur, and intelligent command scheduling functions can be realized.

Owner:FUJIAN ZHONGGENG SHITONG INFORMATION TECH CO LTD

Chinese herbal medicine fodder additive for egg layer

InactiveCN1820624AImprove egg qualityIncrease egg productionAnimal feeding stuffGinger RhizomeDisease

The Chinese herbal medicine fodder additive for egg layer consists of 21 kinds of Chinese medicinal materials, including angelica, astragalus root, figwort, dandelion, viola yedoensis, etc in certain weight proportion as the basic components, into which, schizonepeta herb and mint are added for spring recipe, elsholizia and ginger are added for summer recipe, Dangshen and white atractylodes rhizome are added for autumn recipe and herbaceous peony and dark plum are added for winter recipe. Its production process includes drying in the sun, weighing, crushing and mixing. It is added into the fodder for egg layer in the amount of 1 wt%, and can increase egg weight, deepen yoke color, prevent disease and raise egg quality.

Owner:HEBEI AGRICULTURAL UNIV.

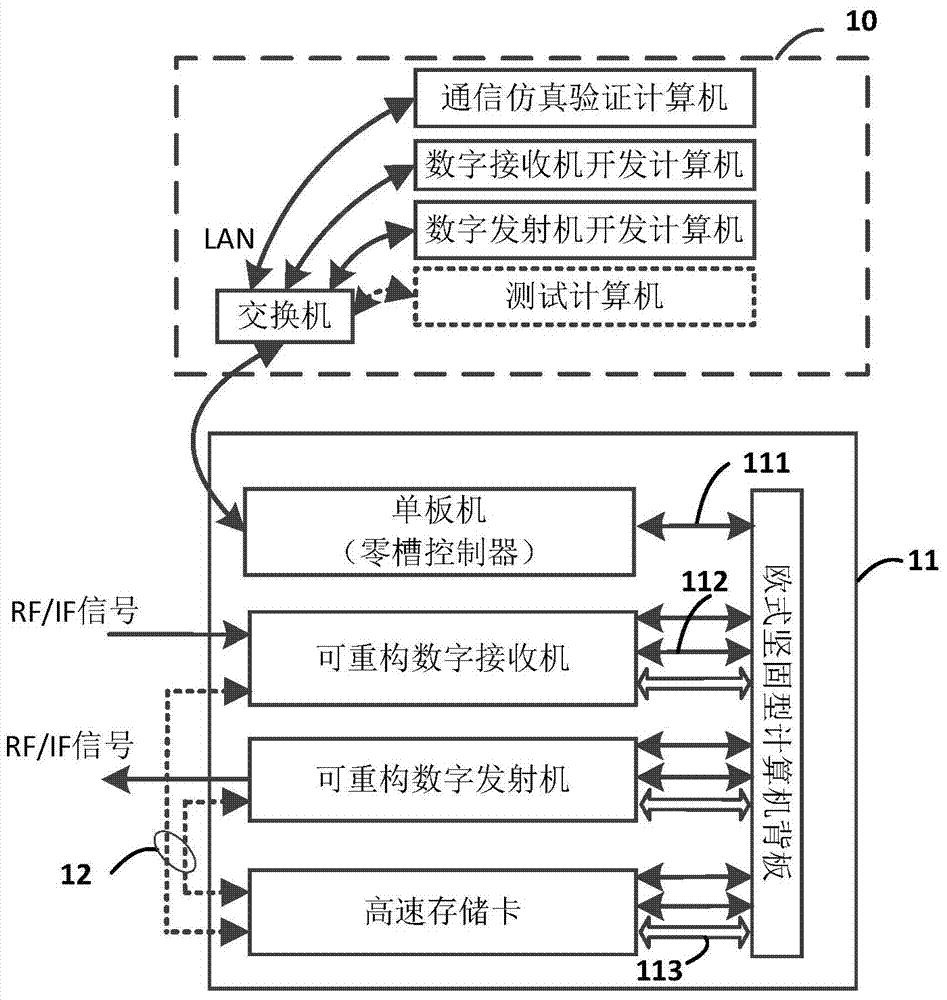

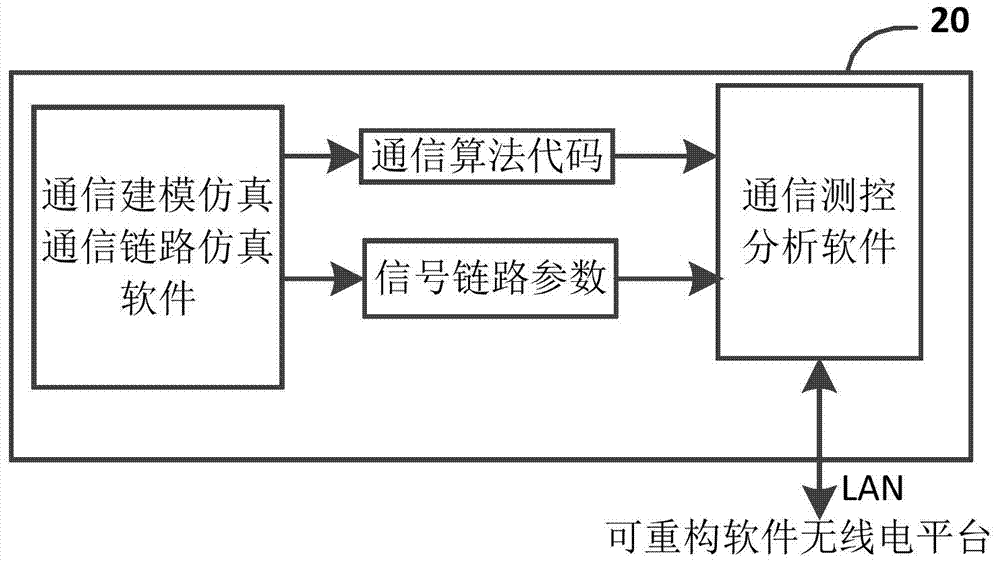

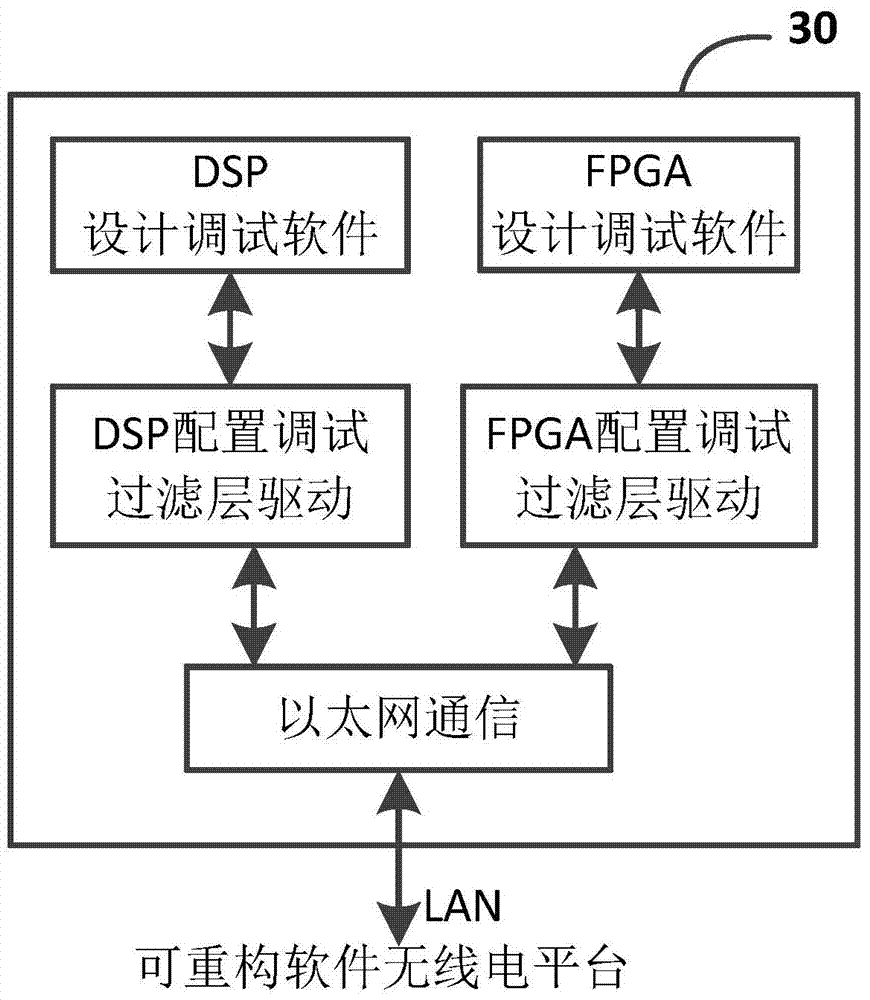

Reconfigurable comprehensive development and test system of wireless product

InactiveCN104331282AImprove efficiencyAvoid repeated design revisionsSoftware testing/debuggingSpecific program execution arrangementsPhases of clinical researchSmall footprint

The invention discloses a reconfigurable comprehensive development and test system of a wireless product and provides a universal reconfigurable wireless product development and test platform. The system consists of a development computer work group / test computer and a reconfigurable software wireless platform, wherein the development computer work group / test computer consists of a computer with purpose of communication simulation verification, a computer with purpose of digital receiver development, a computer with purpose of digital transmitter development or reconfigurable test and the like, and the reconfigurable software wireless platform is accessed through an LAN (local area network); a user can flexibly configure or reconfigure a signal chain, signal processing and a test vector according to needs; repeated design modification is avoided, the total study and development cost is reduced, and the marketing time of the product is greatly shortened. Furthermore, the system is suitable for tests on various wireless products in a system integrating stage, a factory-out check stage, a storage check stage, an in-active maintenance stage and the like, and system level test on different wireless products can be performed by only correspondingly configuring or reconfiguring the software wireless platform through a test program, so that the test system is small in occupation area and convenient in transportation, and the maintenance cost is greatly reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

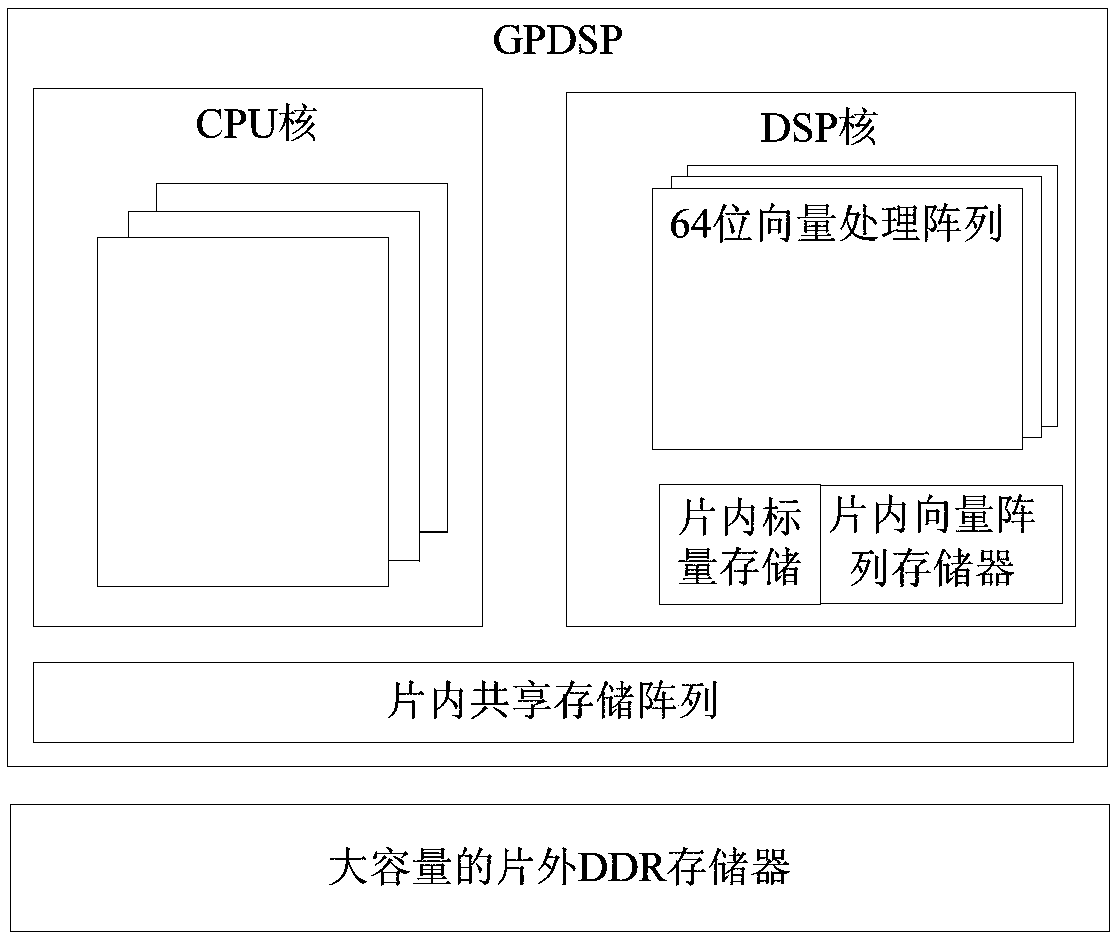

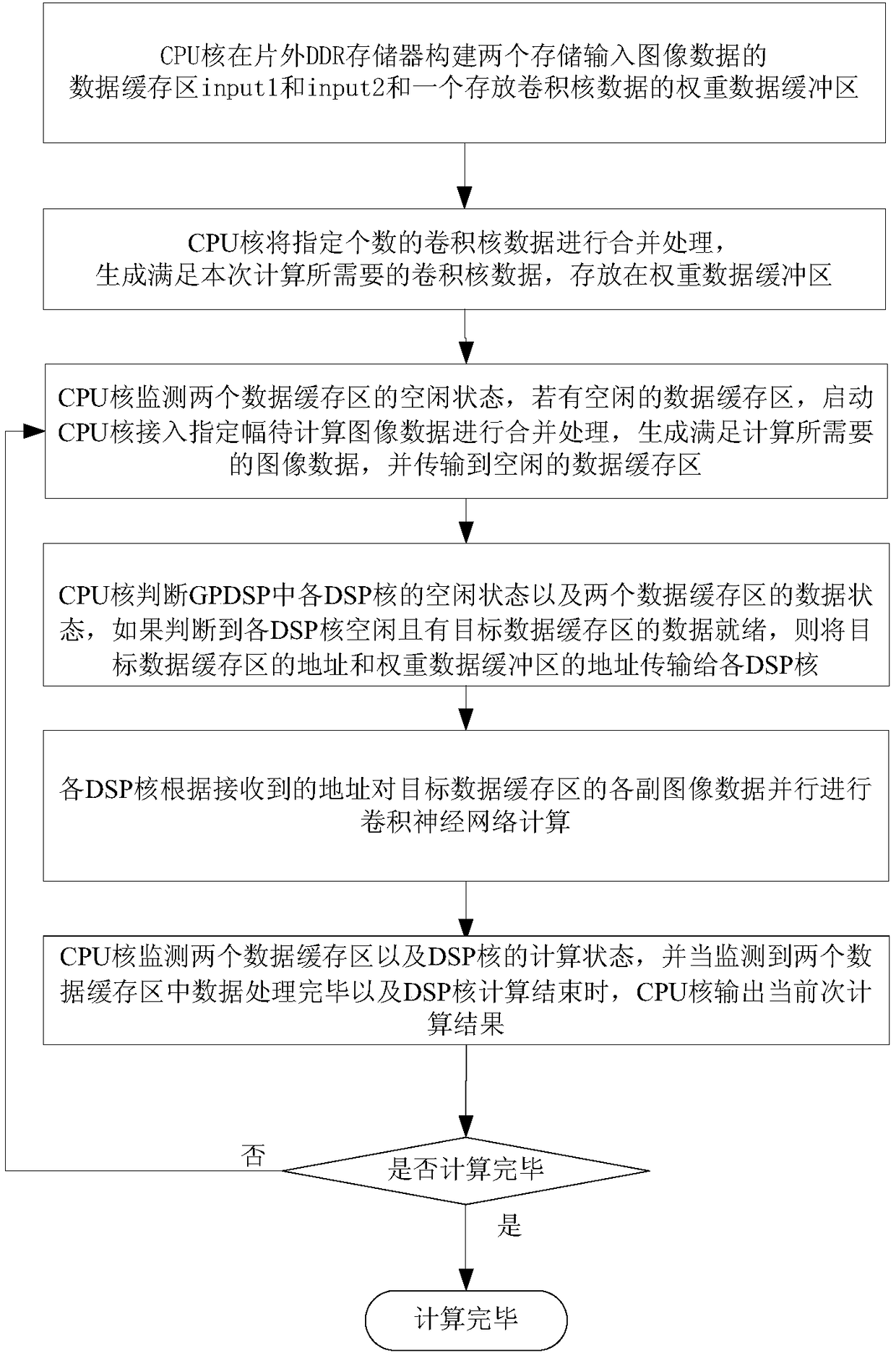

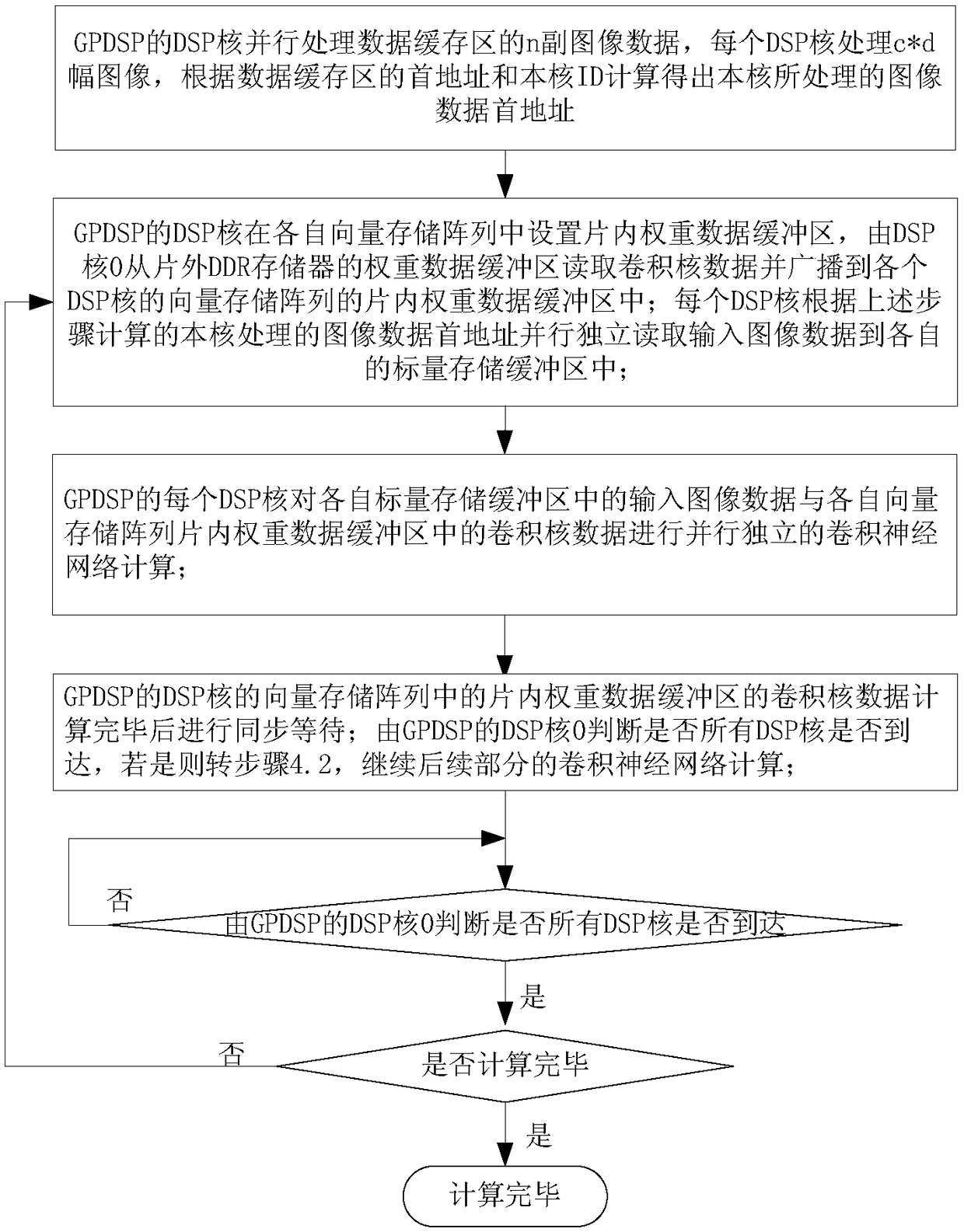

Convolutional neural network multinuclear parallel computing method facing GPDSP

ActiveCN108920413ACooperate closelyGive full play to the powerful vectorized computing capabilitiesNeural architecturesPhysical realisationParallel computingConvolution

The invention discloses a convolutional neural network multinuclear parallel computing method facing GPDSP. The method comprises the following steps that S1, two data cache regions and a weight data cache region are constructed by a CPU core in an off-chip memory; S2, convolution kernel data of the designated number is combined by the CPU core for processing and stored in the weight data cache region; S3, the CPU core accesses to-be-calculated image data of the designated amplitude for combination processing, and the data is transmitted to a free data cache region; S4, if DSP cores are leisure, and data ready of the data cache regions is achieved, an address is transmitted to the DSP cores; S5, all the DSP cores conduct convolution neural network calculation; S6, a calculation result of the current time is output; S7, the steps of S3-S6 are repeated until all the calculations are completed. The performance and multi-level parallelism of the CPU core and the DSP cores in the GPDSP can be fully exerted, and efficient convolutional neural network calculation is achieved.

Owner:NAT UNIV OF DEFENSE TECH

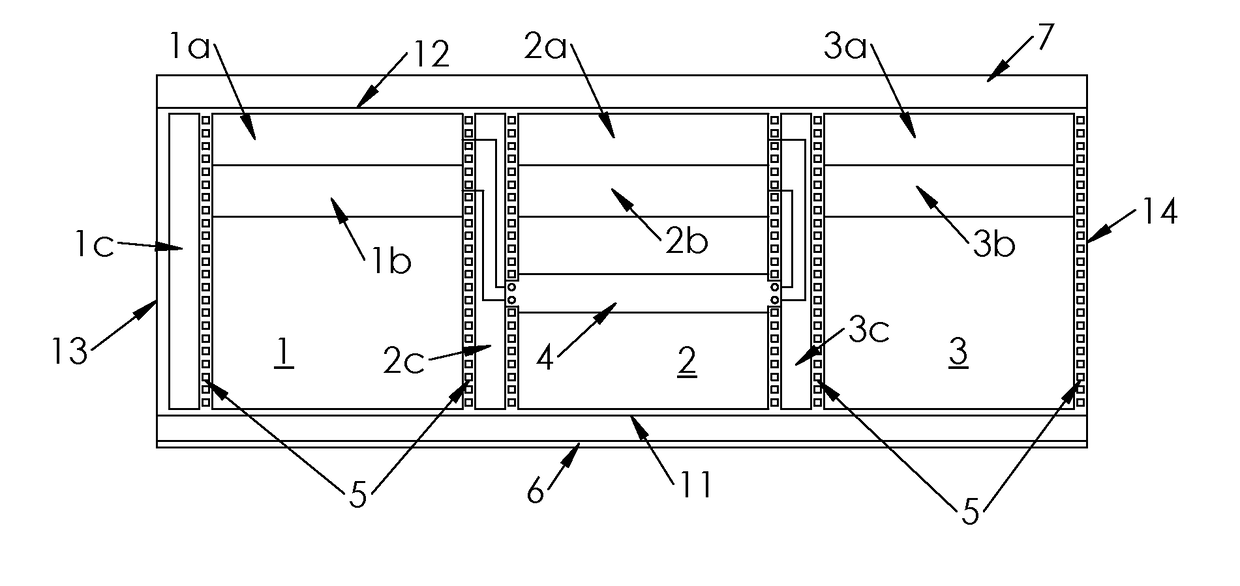

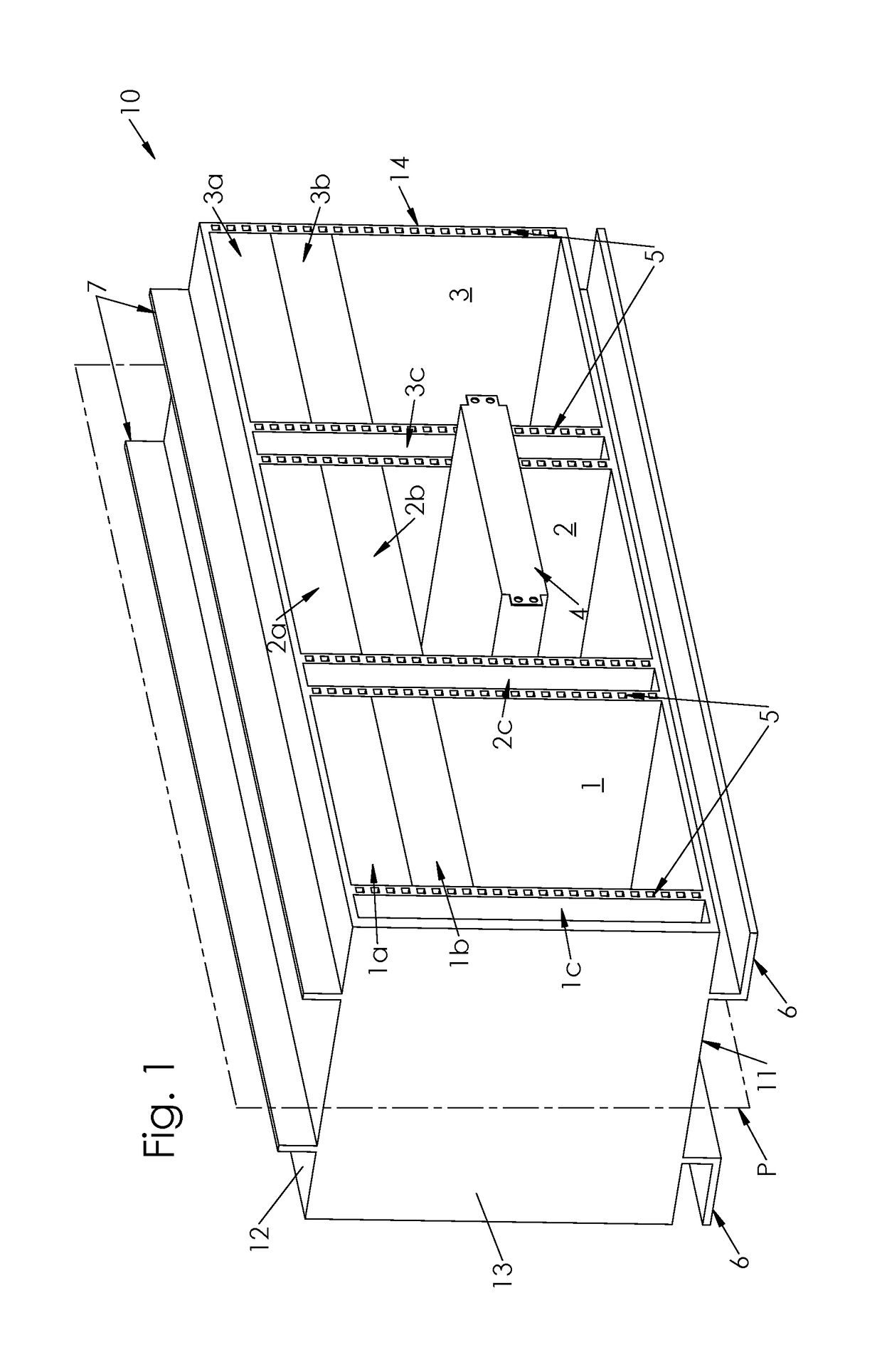

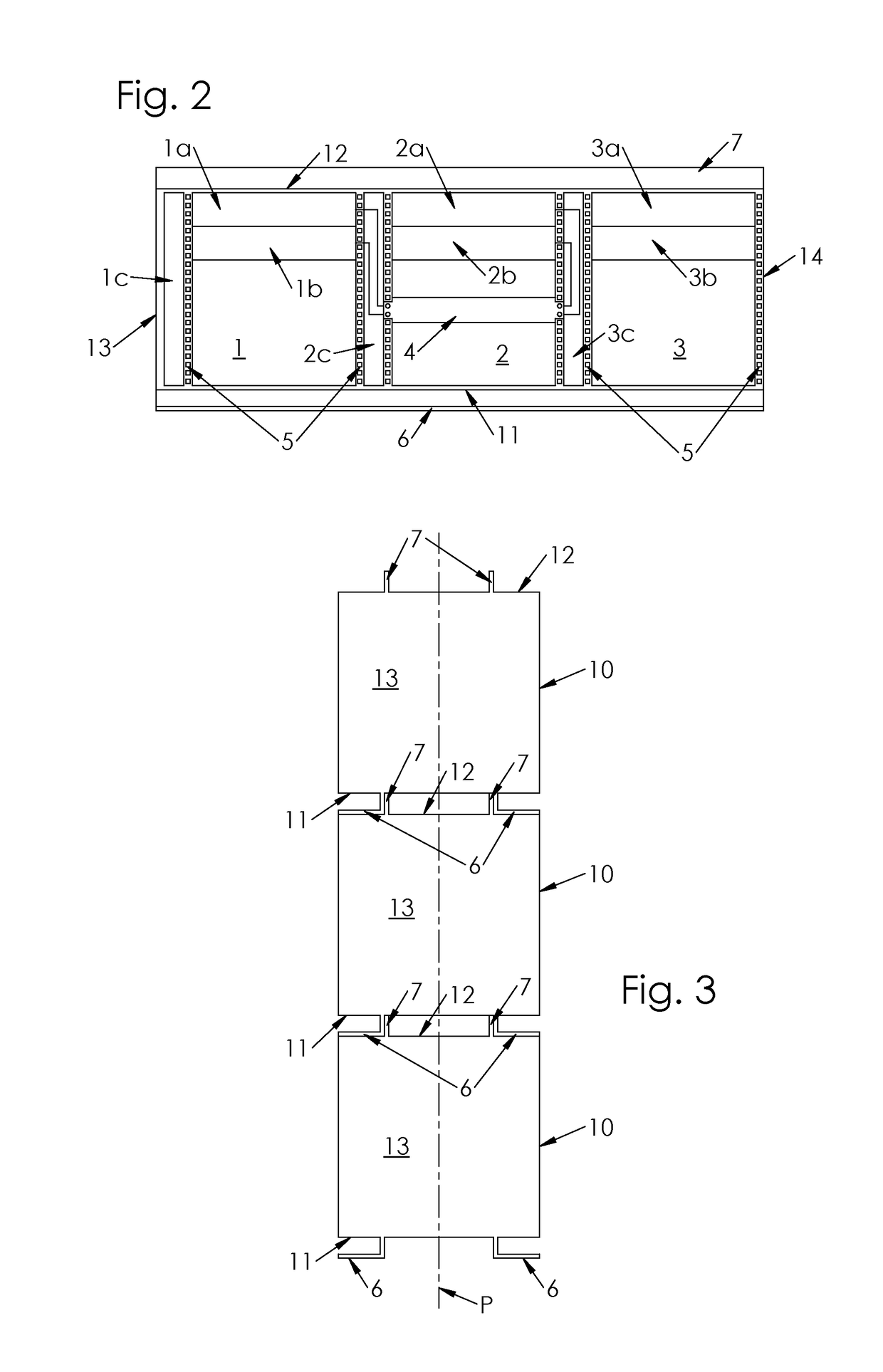

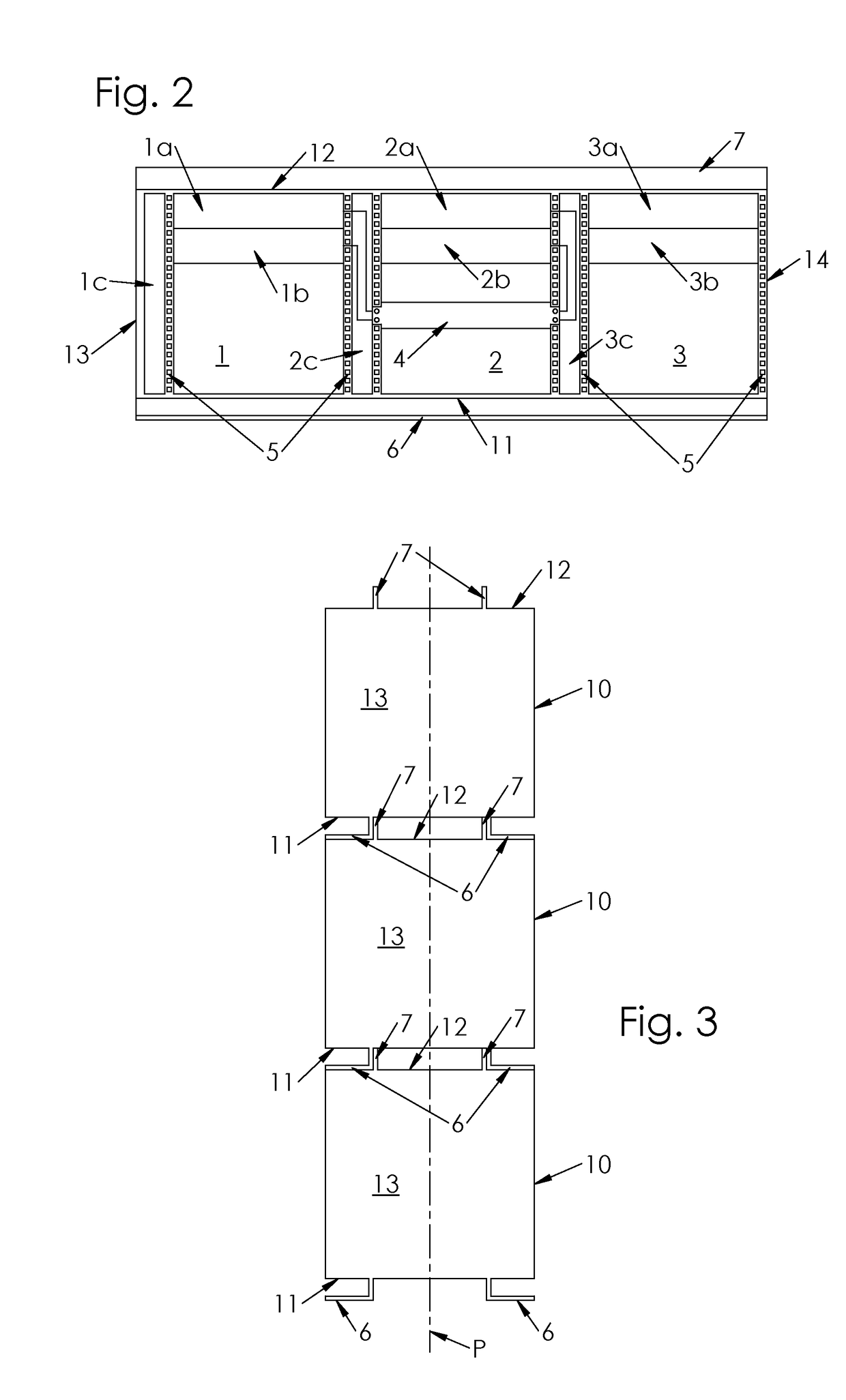

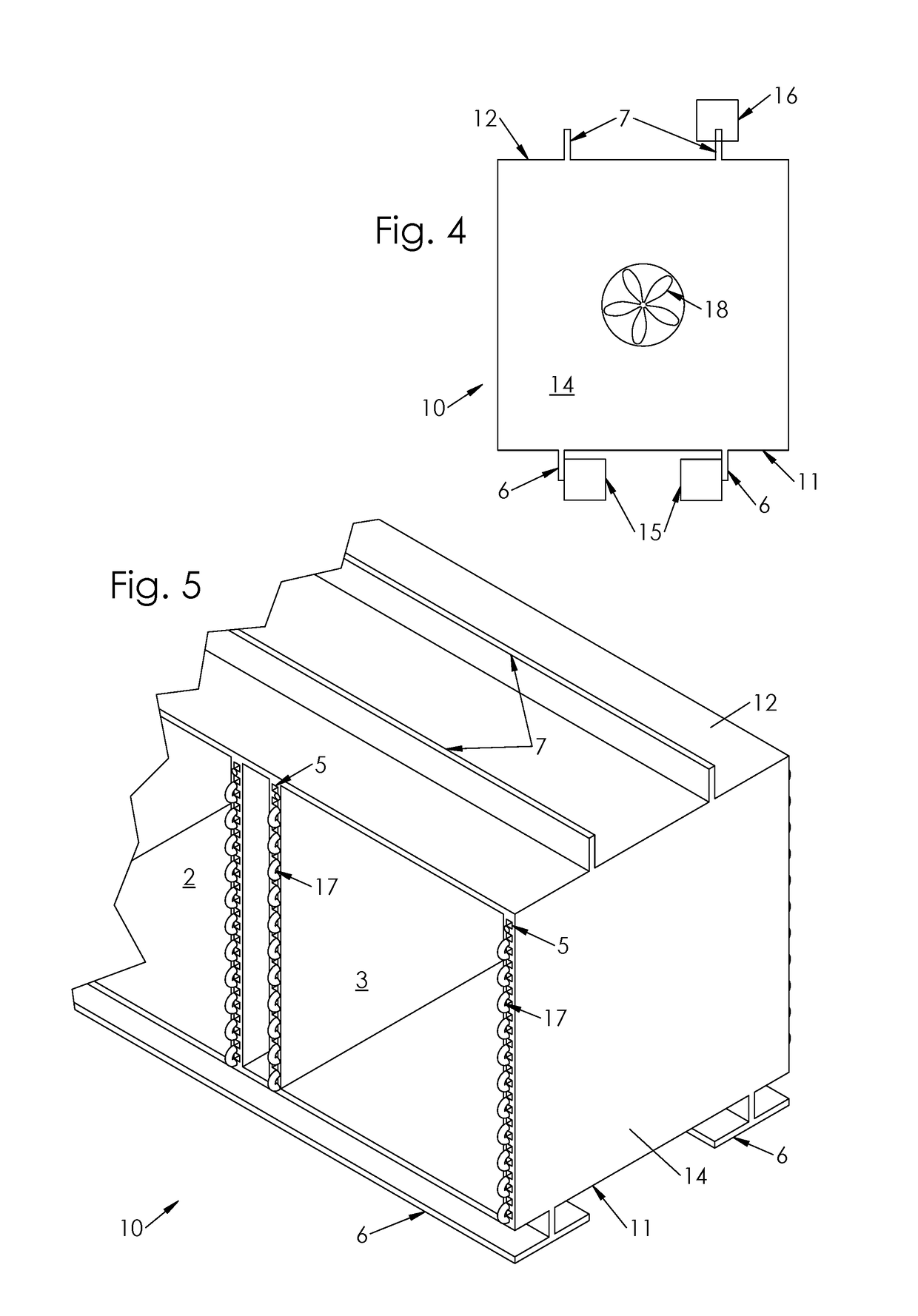

Transportable and stackable server racks

ActiveUS20170359918A1Transportation safetyCooperate closelySide-by-side/stacked arrangementsServersWaste management

A server rack including a bottom panel, a top panel opposite to said bottom panel, a plurality of housing units configured for receiving rack-mountable equipment, the plurality of housing units being horizontally side-by-side arranged between the top panel and the bottom panel, the bottom panel comprising two support rails for supporting the server rack.

Owner:OVH

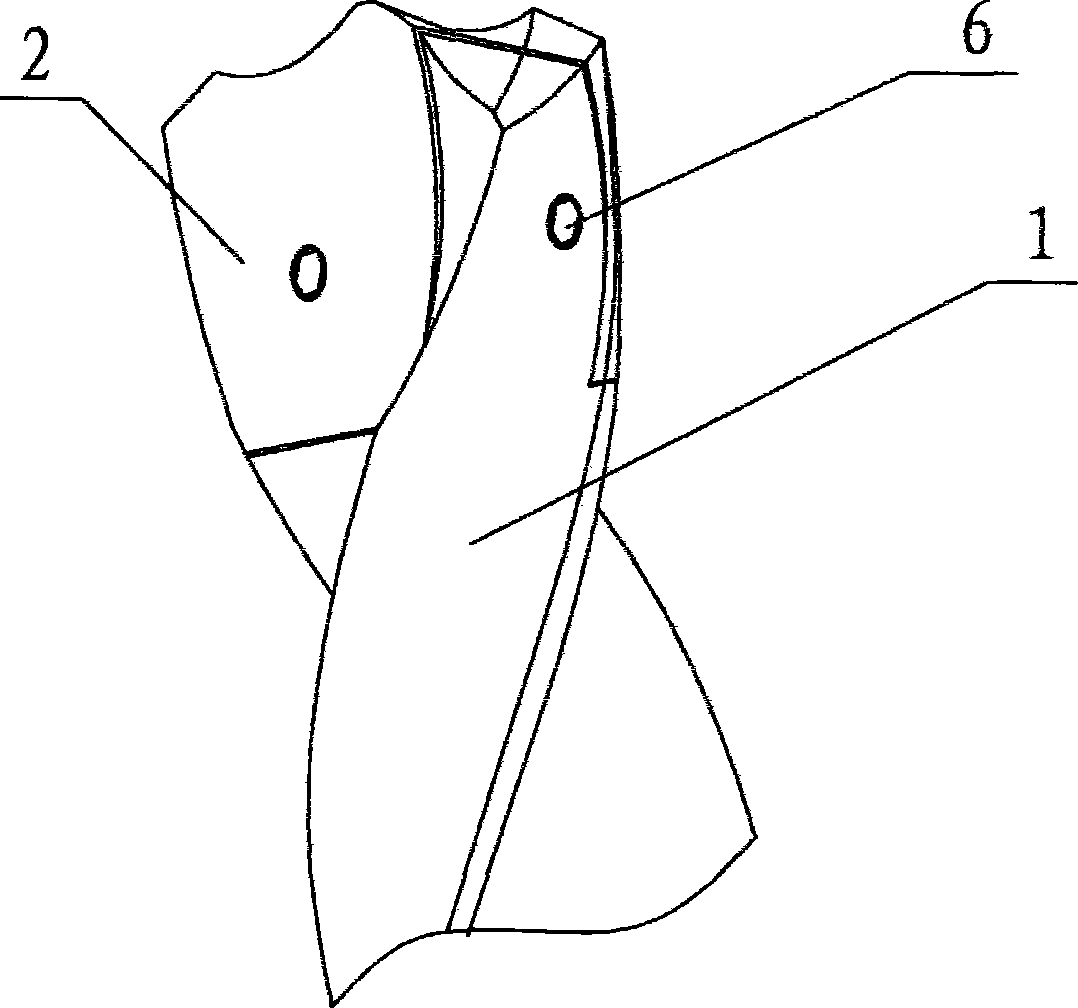

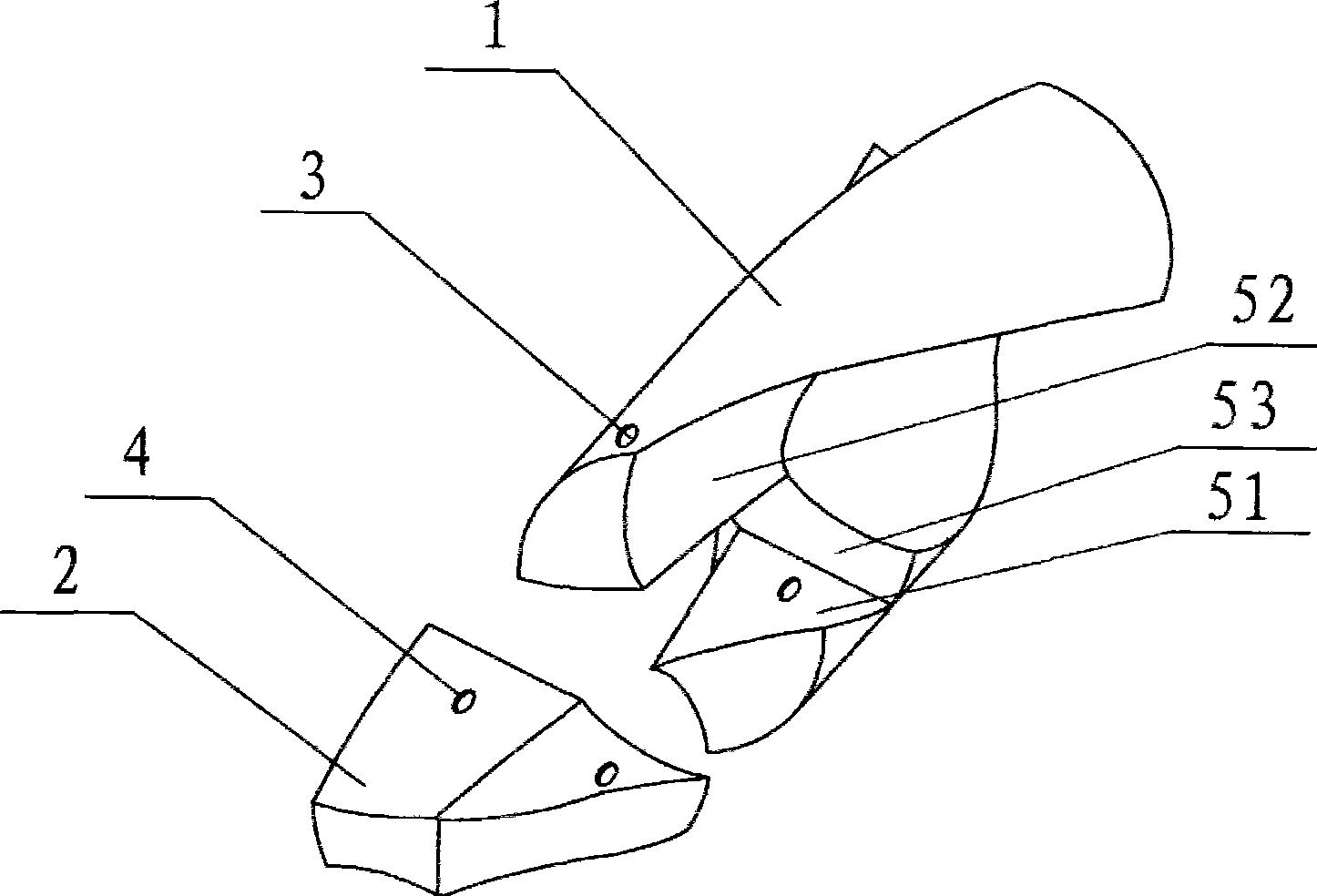

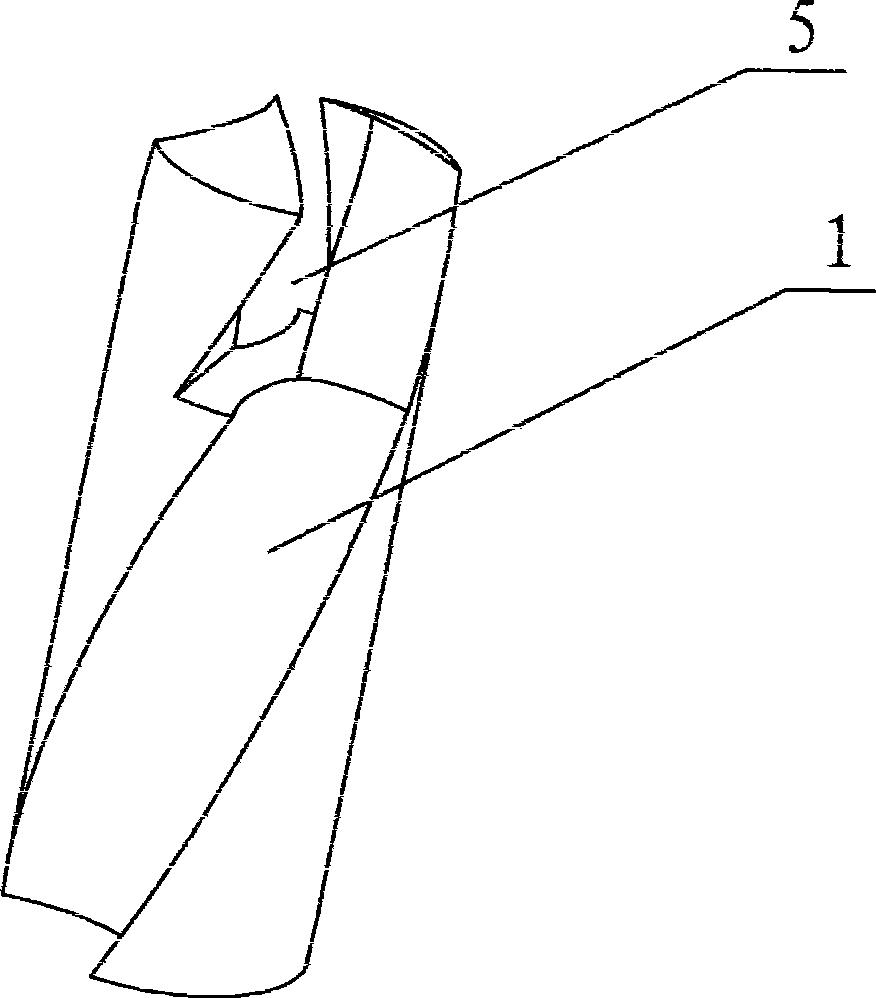

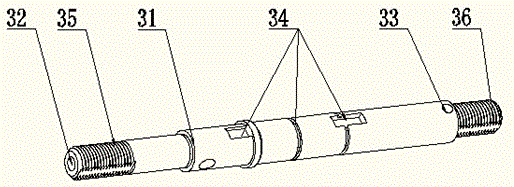

Method for preparing grinding-free drill head and drill head

The invention provides a manufacturing method of a grinding-free drill bit, which comprises a drill body and a detachable cutting blade connected on the front end of the drill body; the manufacturing method is characterized by comprising the following steps: (1) according to the set depth and width, the front end of the drill body is equipped with a spiral groove for holding the cutting blade; both inner side walls of the spiral groove are arcwall faces, and the two arcwall faces are of central symmetry, so that the entire outline of the spiral groove is of S shape; each arcwall surface is a parallelogram after being unfolded; (2) the cutting blade with side walls being two symmetrical arcwall faces and matched with the inner wall shape of the spiral groove is prepared; (3) the cutting blade is placed into the drill spiral groove, and connected to prepare the grinding-free drill bit. No sequence exists between step (1) and step (2). The manufacturing method also provides the grinding-free drill bit prepared by using the method.

Owner:苏茂均

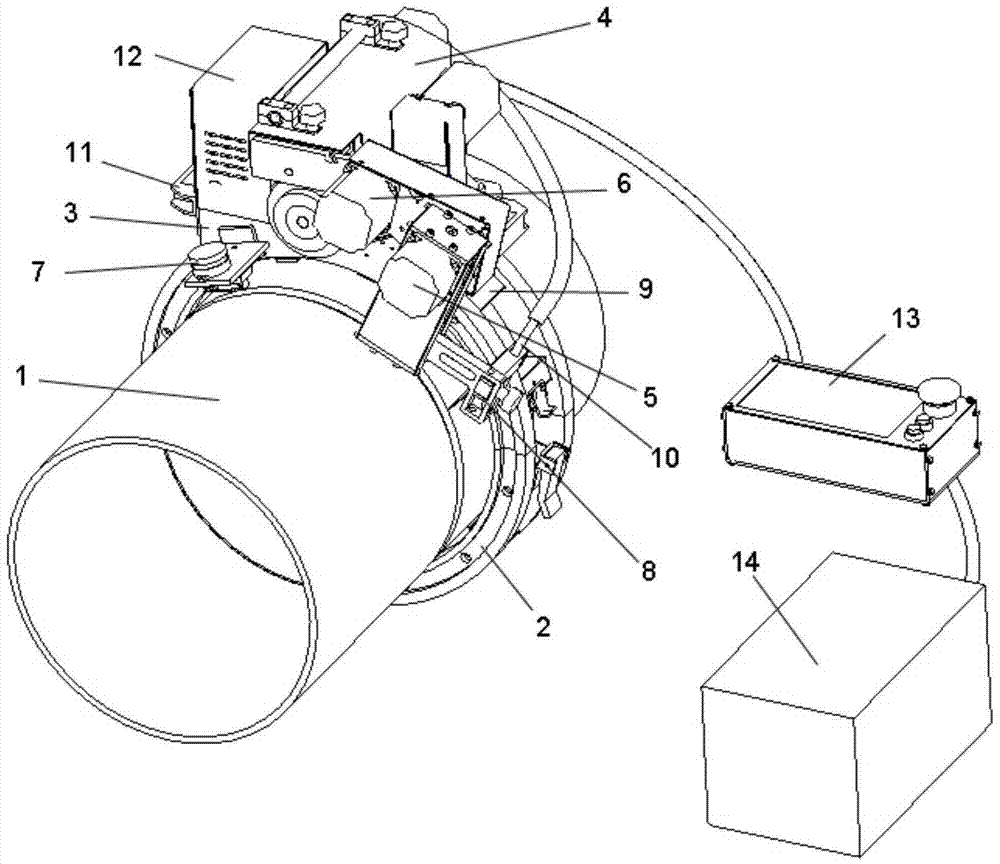

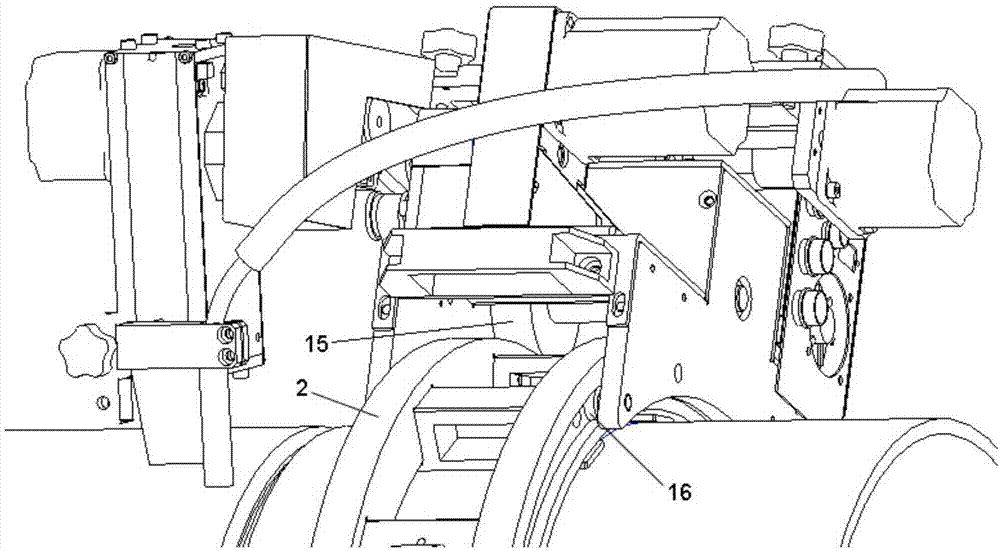

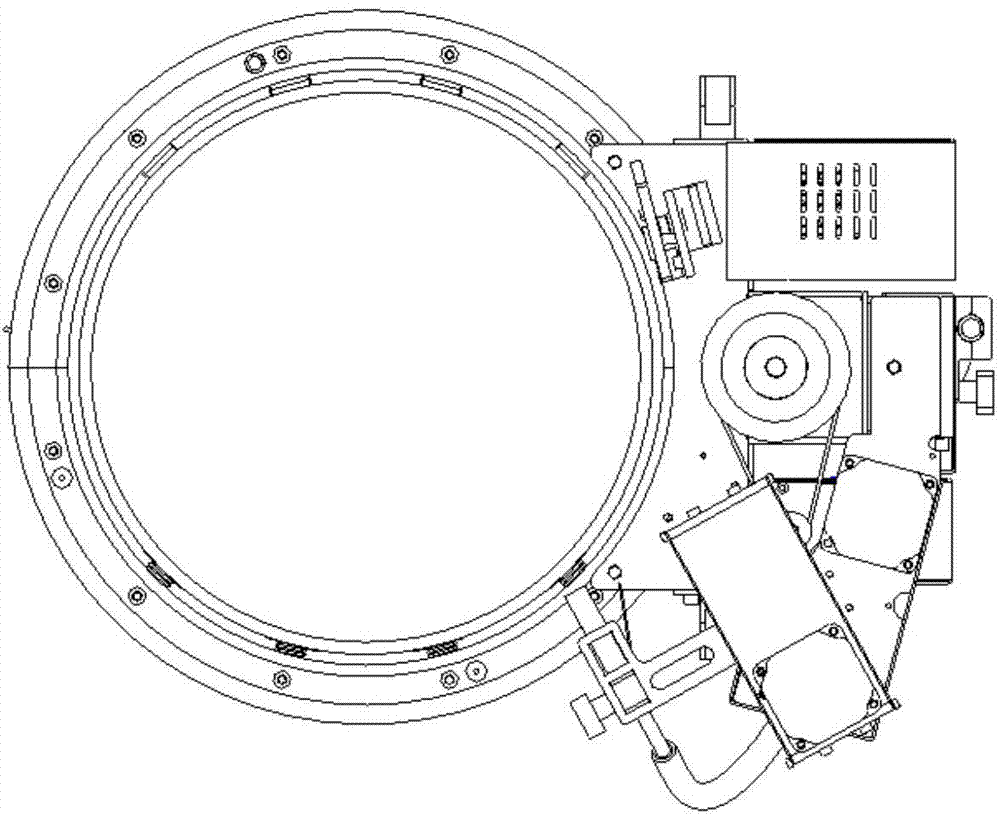

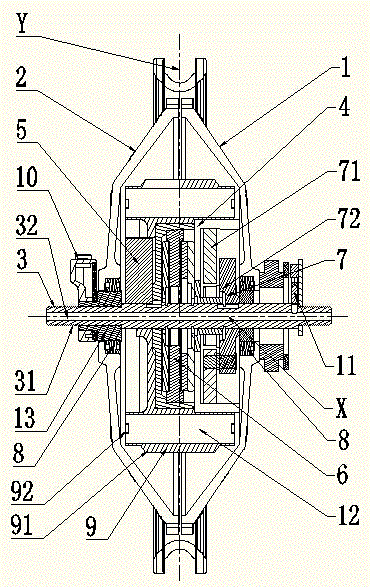

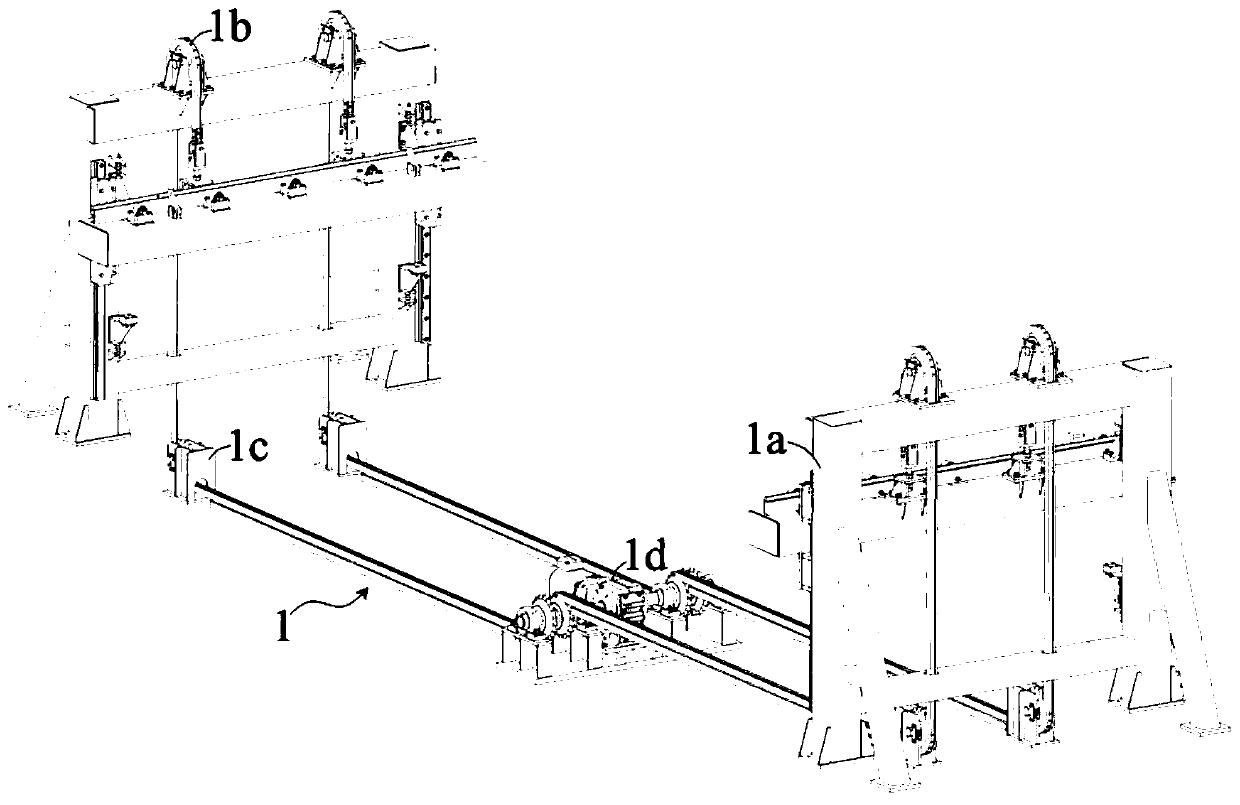

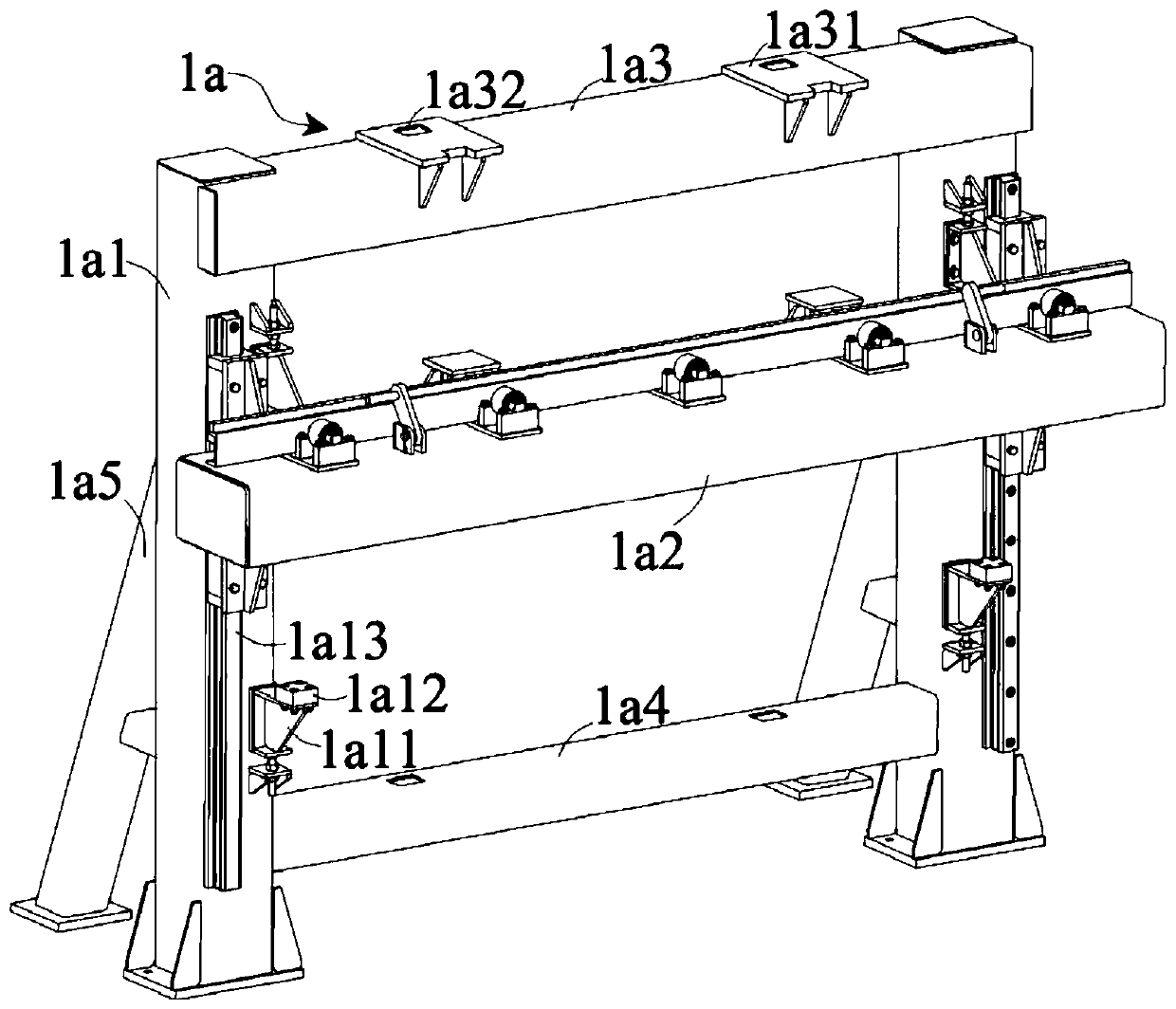

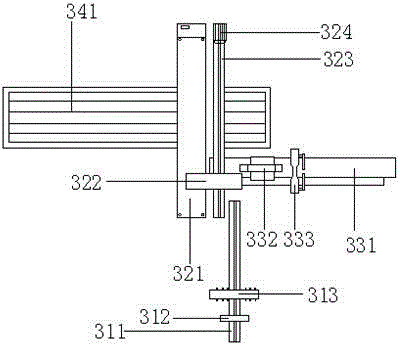

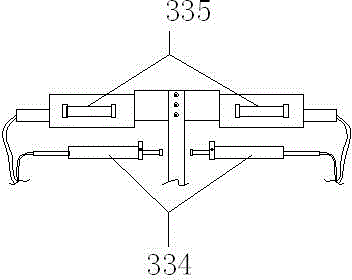

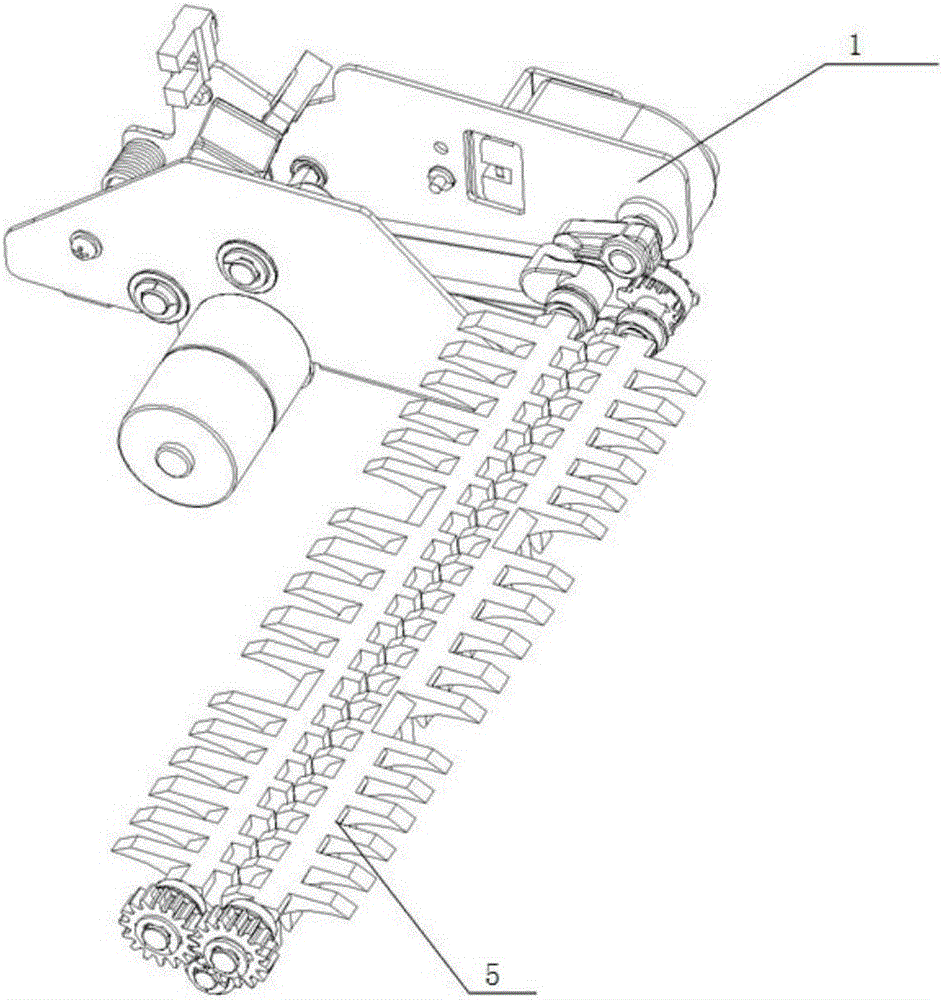

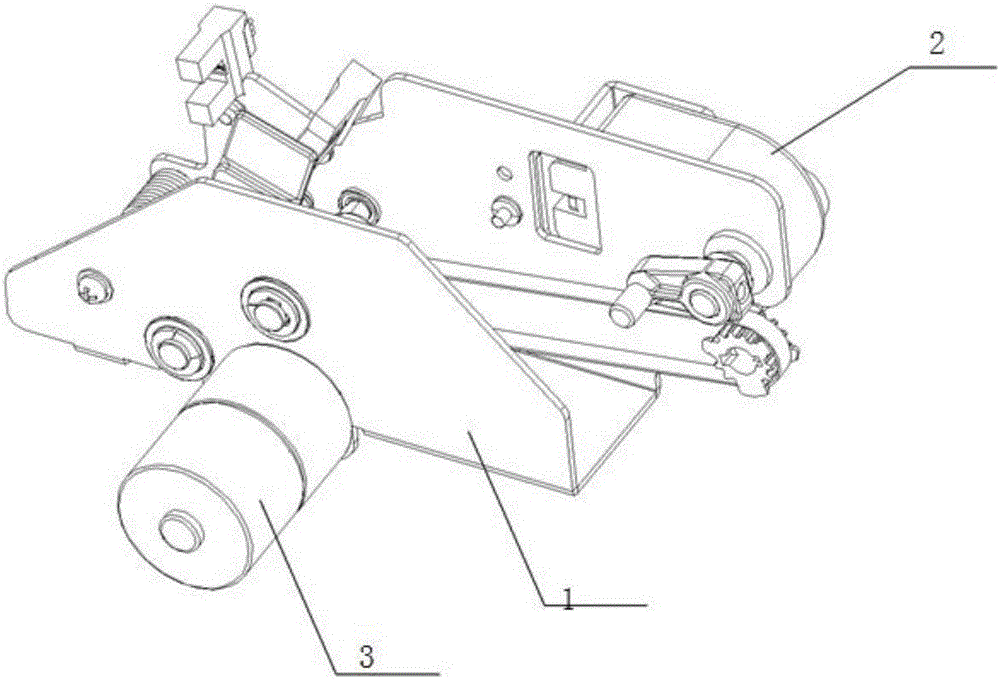

Pipeline all-position operation machine and control method thereof

ActiveCN104708220AFix workSolve quality problemsWelding/cutting auxillary devicesAuxillary welding devicesRadial motionIndependent motion

The invention belongs to the field of mechanical automation, and particularly relates to a pipeline all-position operation machine and control method thereof. The operation machine comprises a guide rail, a motion unit, an executive terminal, a driving unit and a control unit, wherein the motion unit conducts peripheral motion along the guide rail; one end of the motion unit is connected with the executive terminal; the output end of the control unit is connected with the input end of the driving unit; the output end of the driving unit is connected with a driving motor of the motion unit; the driving unit receives pulse signals sent out by the control unit and drives the driving motor of the motion unit to conduct corresponding motions; the motion unit comprises a peripheral motion mechanism, an axial motion mechanism, a radial motion mechanism and a swing mechanism which are capable of conducting independent motion driven by motors; the peripheral motion mechanism is provided with a scan mechanism. The operation machine has the function of automatically conducting pipeline cutting and welding, the defect of manual operation on irregular pipelines is overcome, and real-time detection and automatic adjustments are achieved.

Owner:深圳雷瑞智动机械设备有限公司

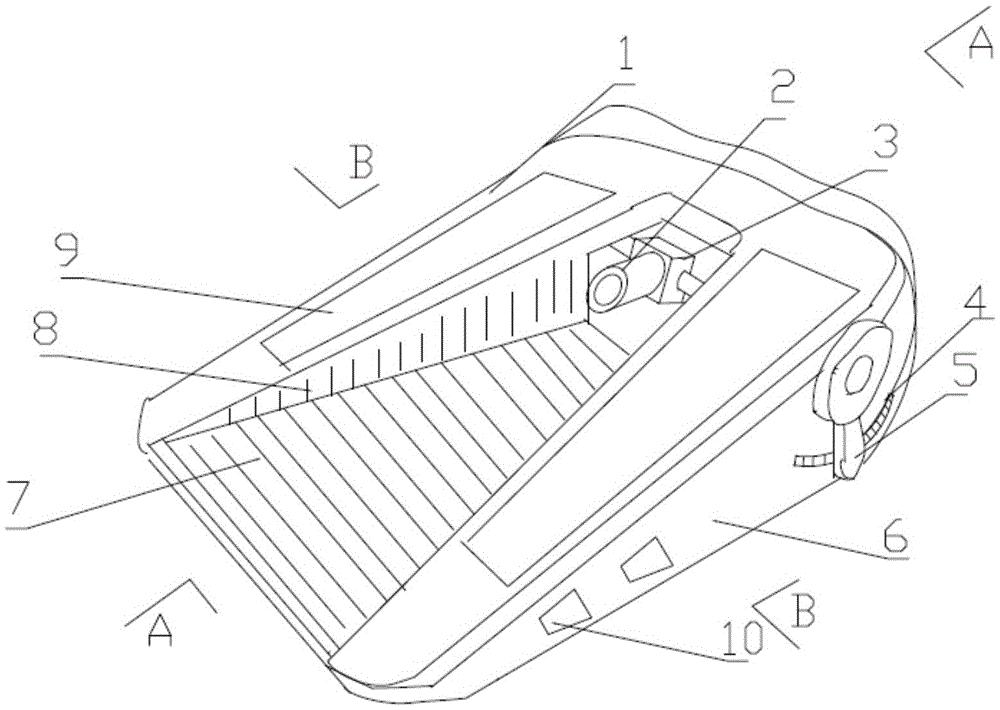

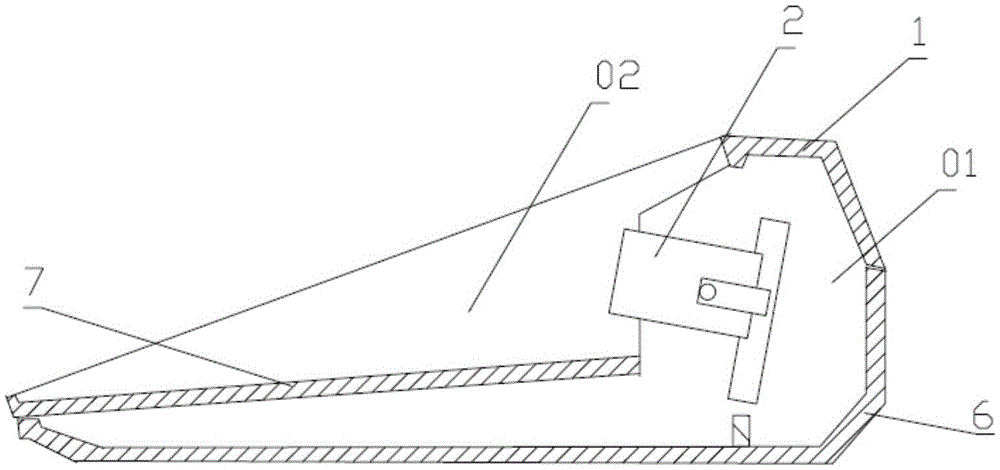

Image pickup device for vehicle driving image acquisition

ActiveCN105491350AGuaranteed stabilityGuarantee authenticityClosed circuit television systemsVehicle componentsEngineeringVehicle driving

The invention belongs to the vehicle driving monitoring technical field and relates to an image pickup device for vehicle driving image acquisition. The image pickup device includes a box body and a camera; a camera mounting cavity is formed in the box body; the camera is mounted in the mounting cavity through a mounting bracket; a camera light shielding cavity communicated with the outside of the box body is formed at the front part of the box body; two sides of the light shielding cavity are attached surfaces; the box body comprises a rear cover and a front cover which are buckled to each other; the camera mounting cavity is formed at the upper part of the box body; the middle of the front cover is recessed inwards so as to form the camera light shielding cavity communicated with the outside of the box body; two sides of the front cover are attached surfaces; and the light shielding cavity is communicated with the mounting cavity. Since the camera is enclosed in the light shielding cavity, no matter how light inside and outside a vehicle changes, interference images will not appear on windshield glass corresponding to the light shielding cavity, and therefore, the camera in the light shielding cavity will not be affected, and the stability and authenticity of acquired images can be ensured.

Owner:烟台中正新技术有限公司

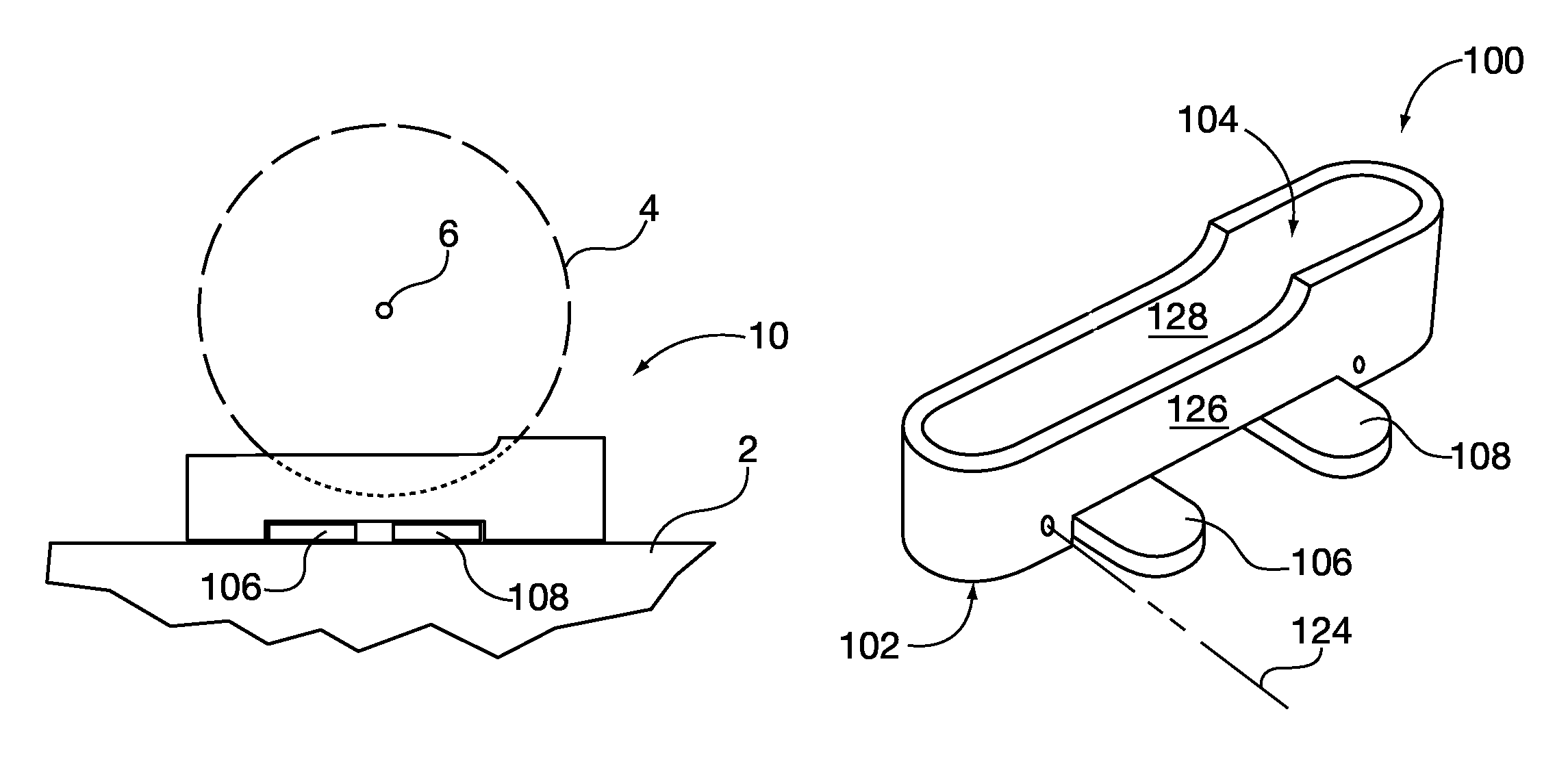

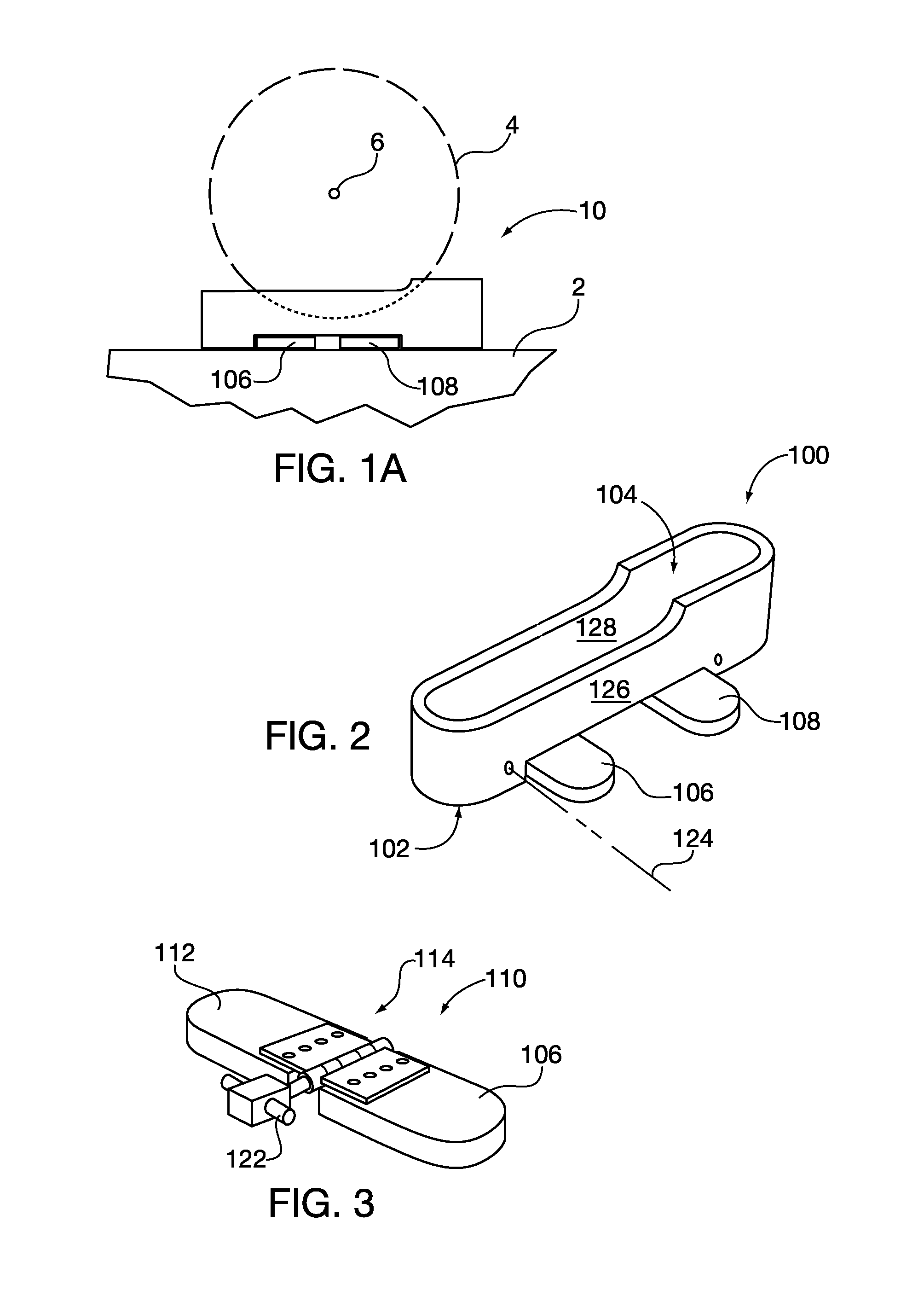

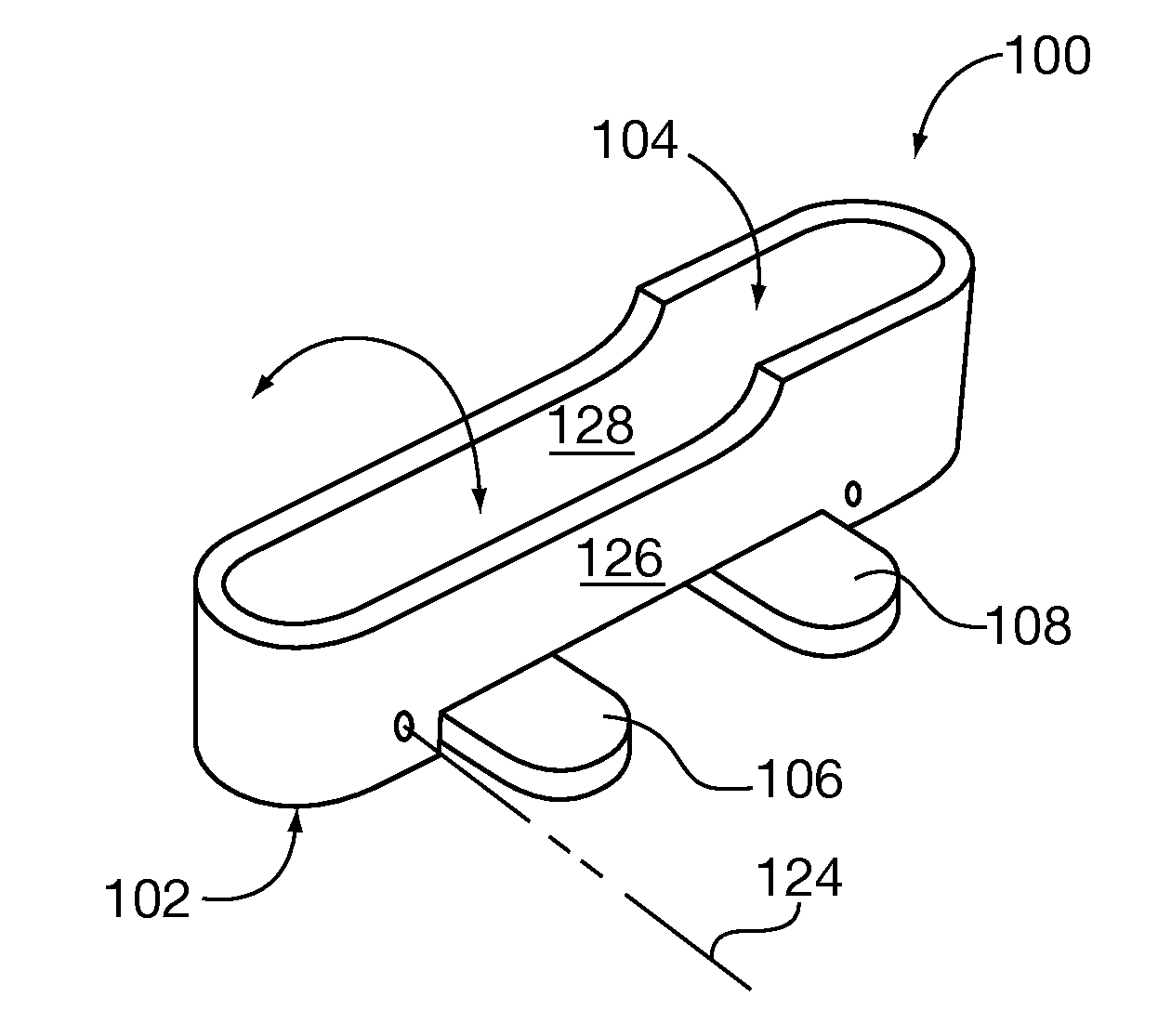

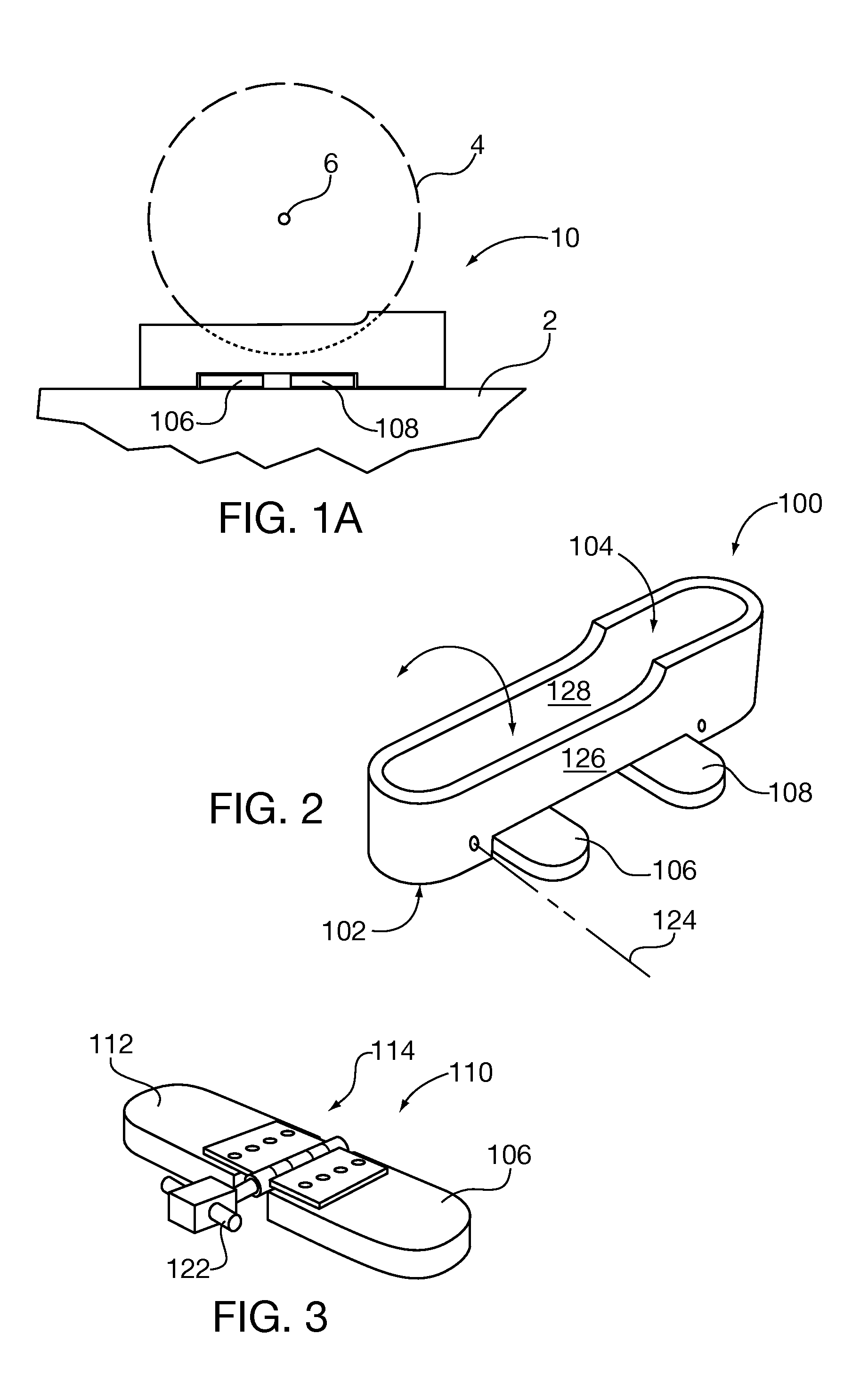

Portable bicycle stand

A stand for a bicycle having a wheel, which stand holds the bicycle in an upright position of use on a horizontal surface. The stand comprises a trough having an upwardly open receptacle which is dimensioned and configured to receive the wheel in close cooperation therewith. One or more feet may be manually coupled to the trough to project laterally therefrom to steady the trough on the horizontal surface. The feet may slide fit to the trough, fasten by threaded fasteners, or may fold for stowage within the trough and swing out into a deployed position. The trough may include a storage compartment for bicycle tools and repair materials.

Owner:PARKINS HOWARD

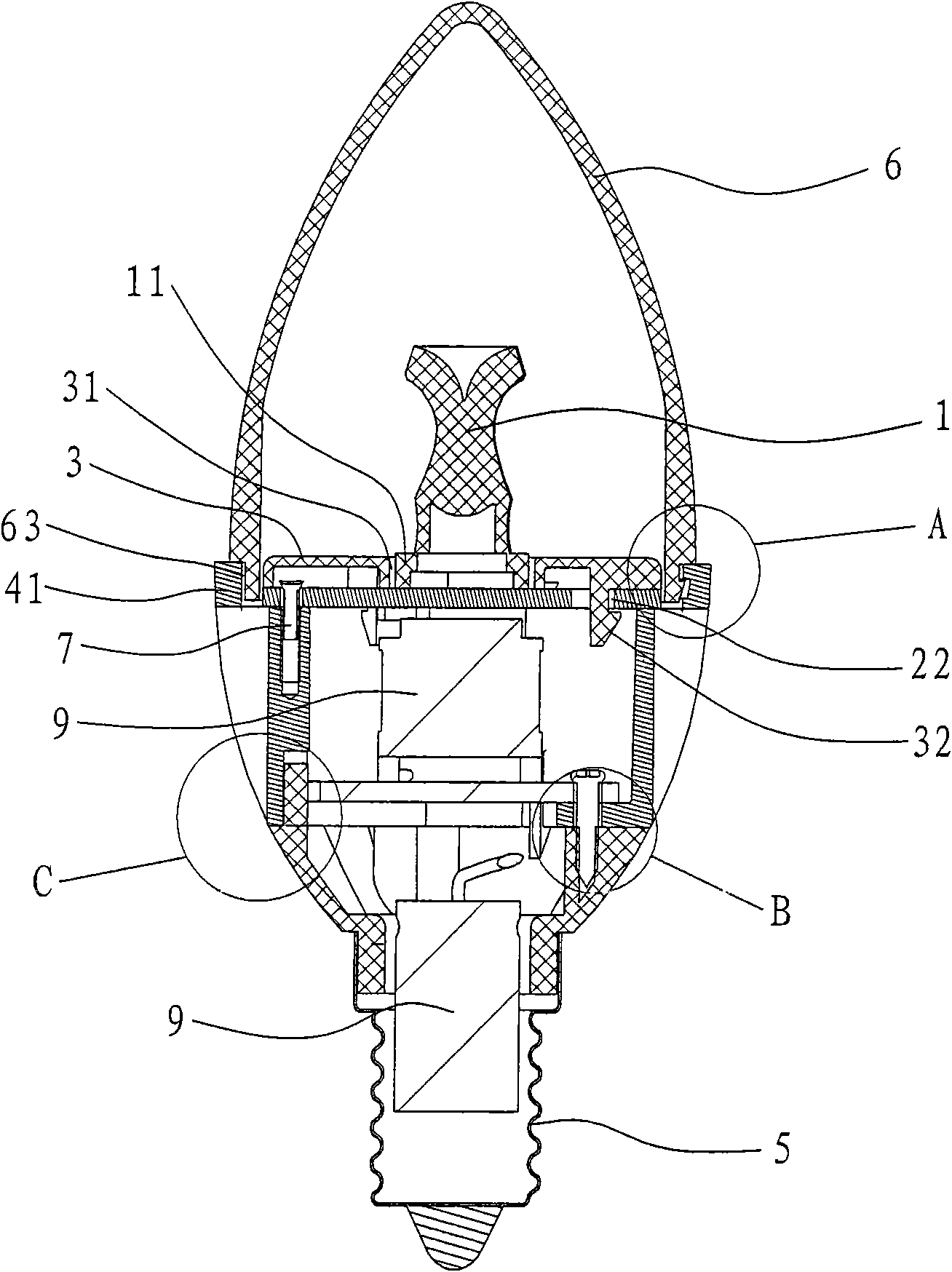

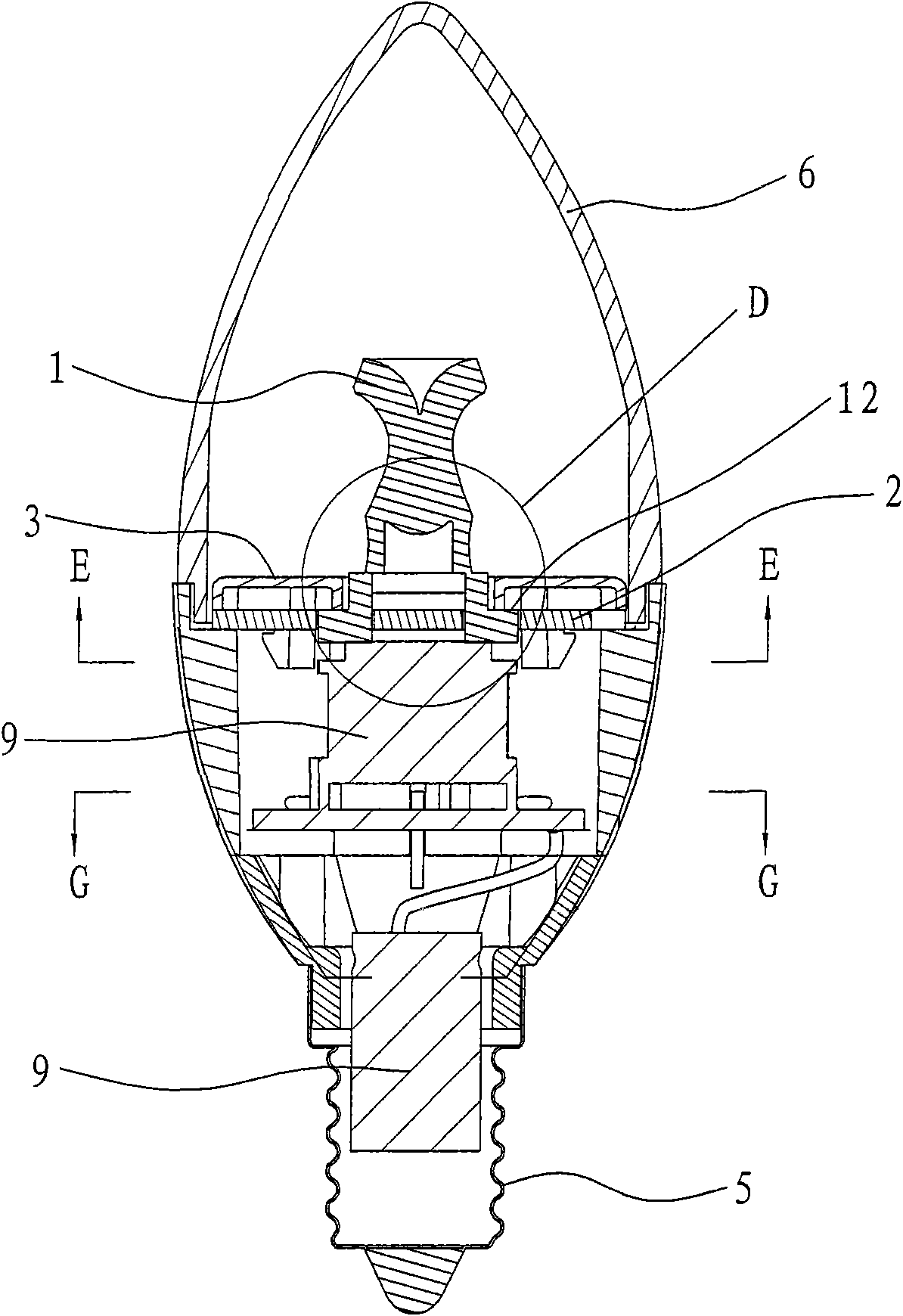

LED lamp structure

InactiveCN101922619APrevent movementWon't hurtPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses an LED lamp structure, which comprises a lens and an aluminium substrate. Two fixed blocks are formed under the lens; a space for accommodating an LED light source is formed between the two fixed blocks; and the fixed blocks are radially provided with flanges blocked by the aluminium substrate or a plastic cover buckled on the aluminium substrate. The structure has the advantages of convenient assembly and disassembly and simple structure; the LED light source is convenient to replace and maintain; the lens can be recycled, so that the cost of the production process is reduced, and the adverse loss of the LED light source in the production process is reduced.

Owner:XIAMEN TOPSTAR LIGHTING

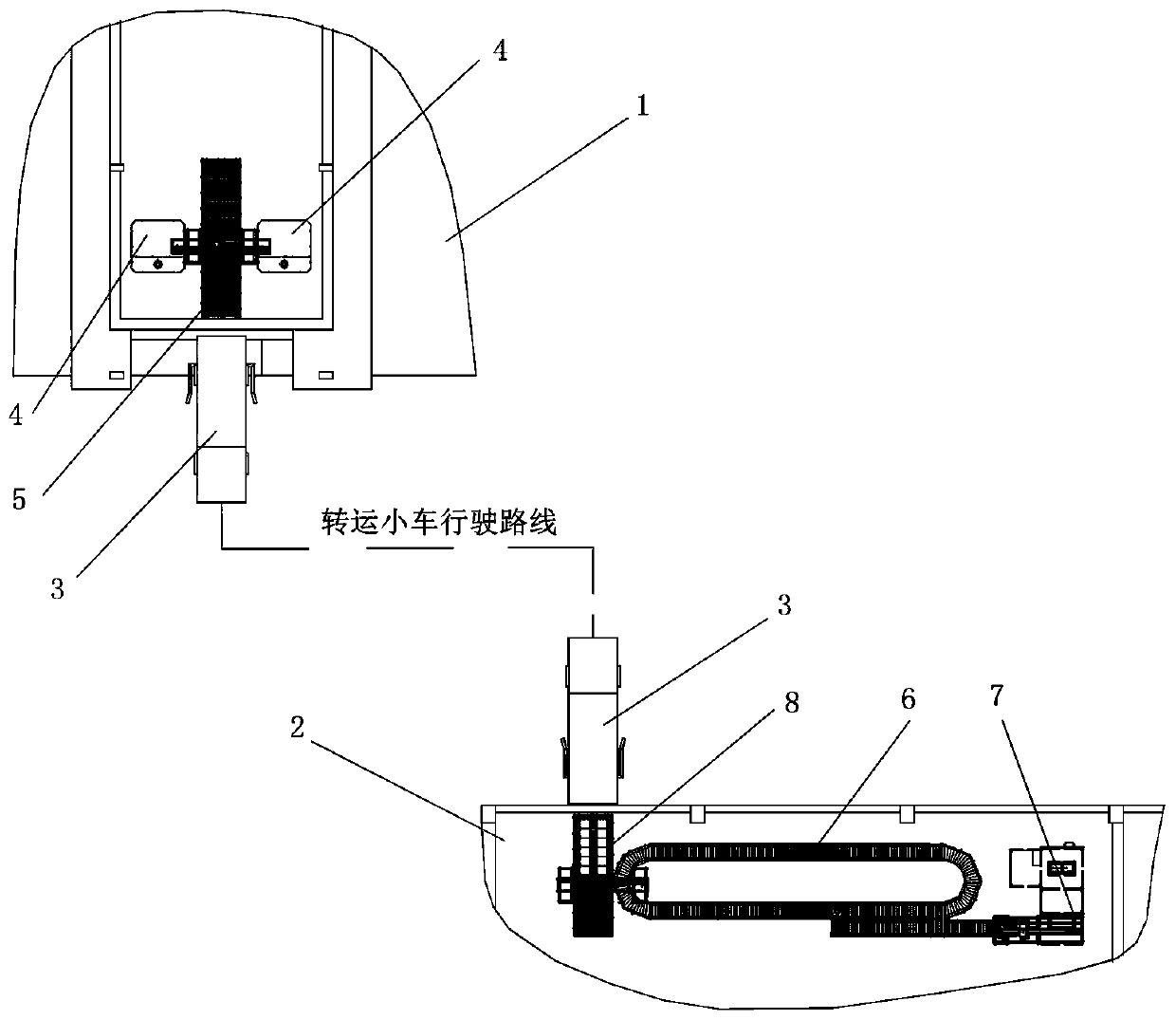

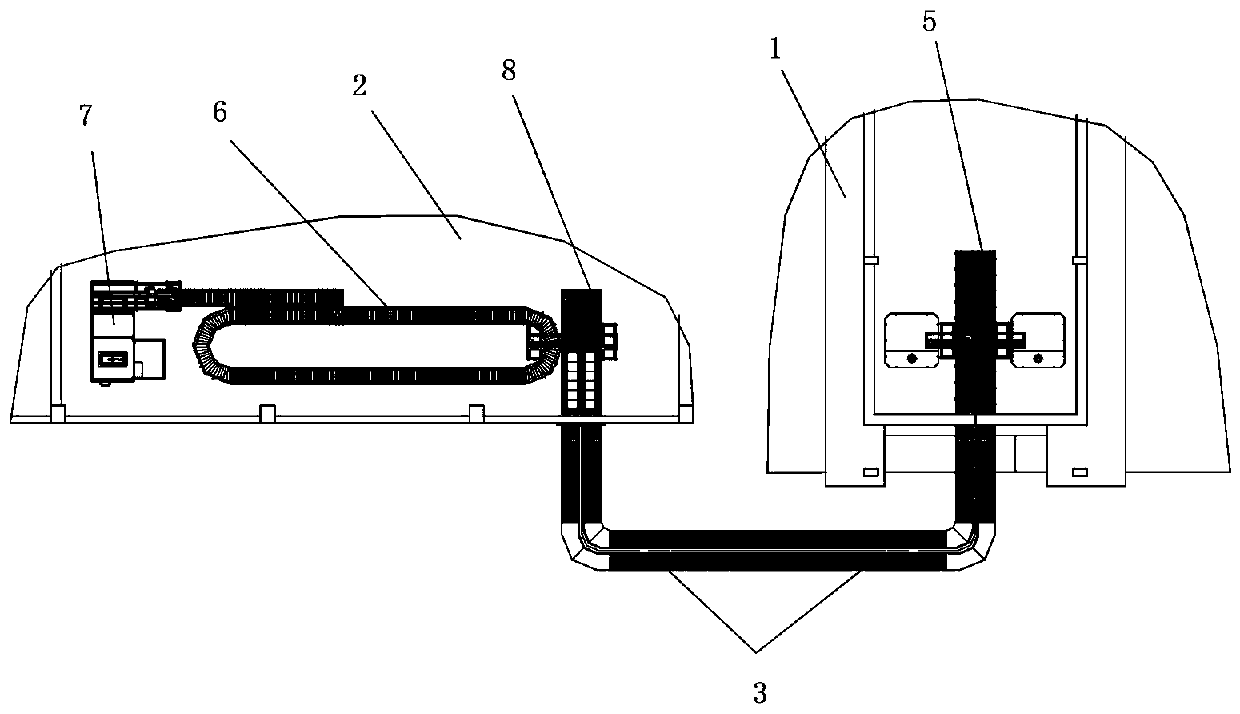

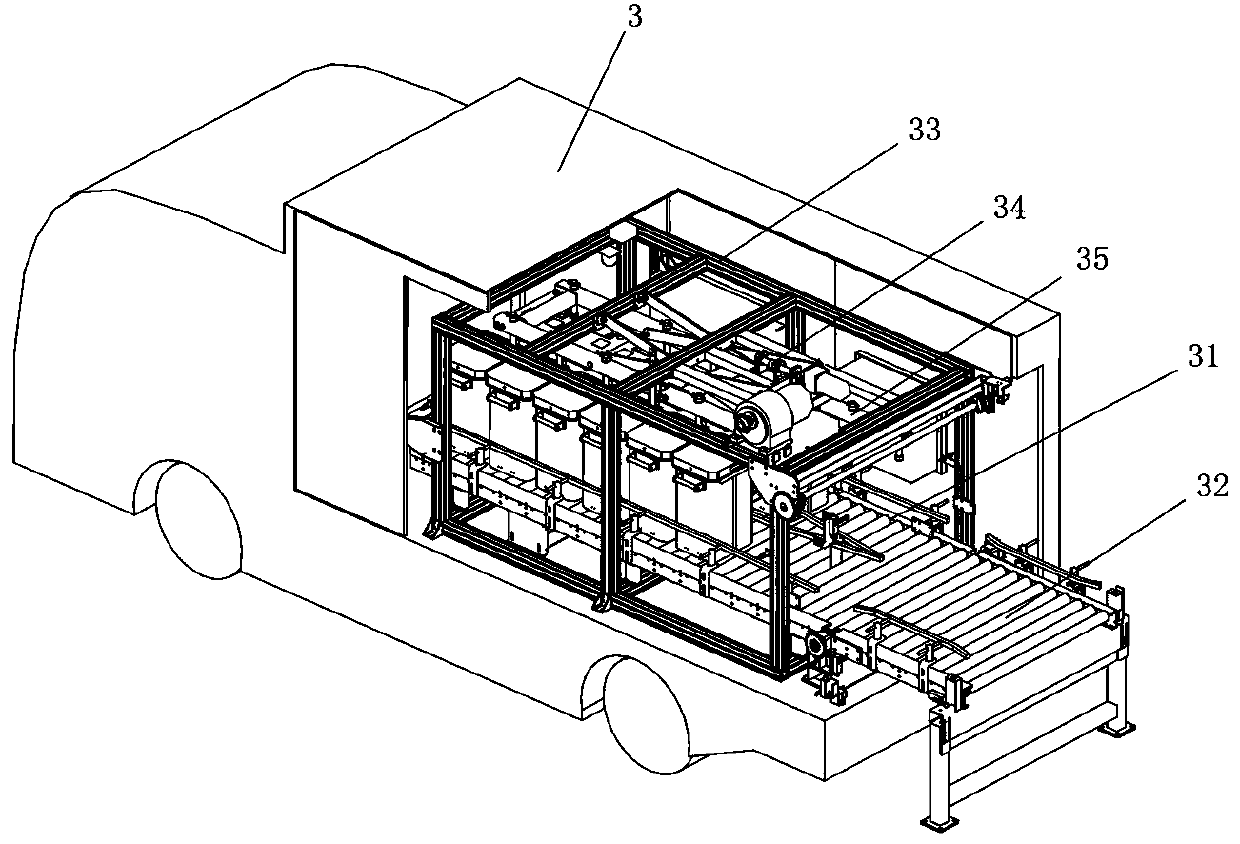

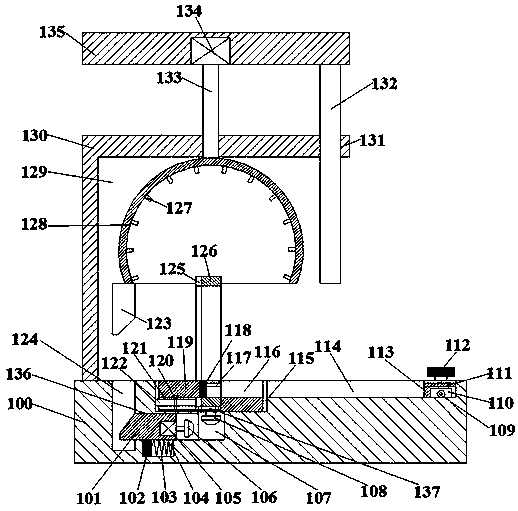

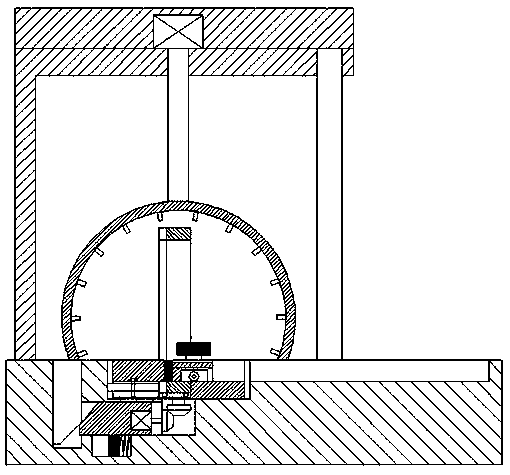

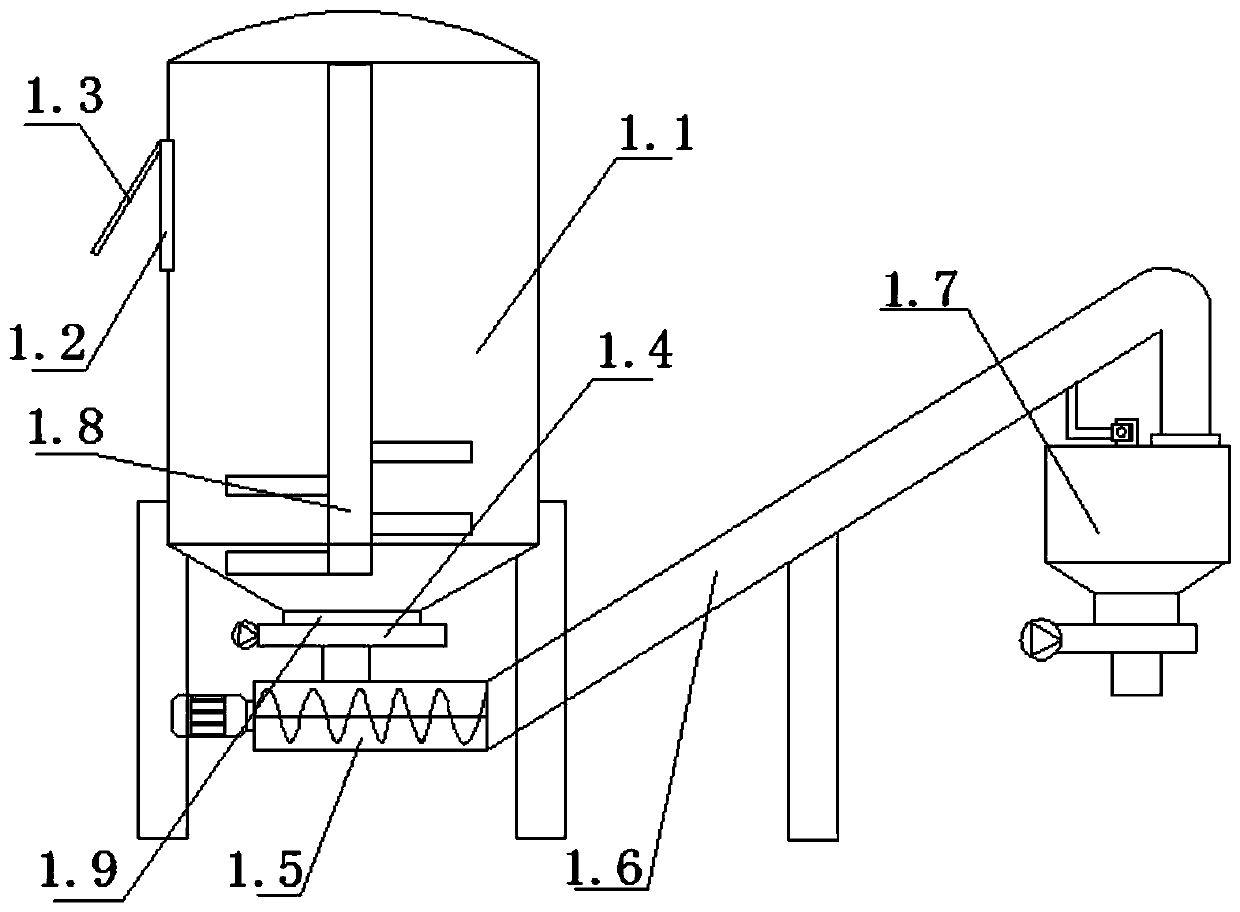

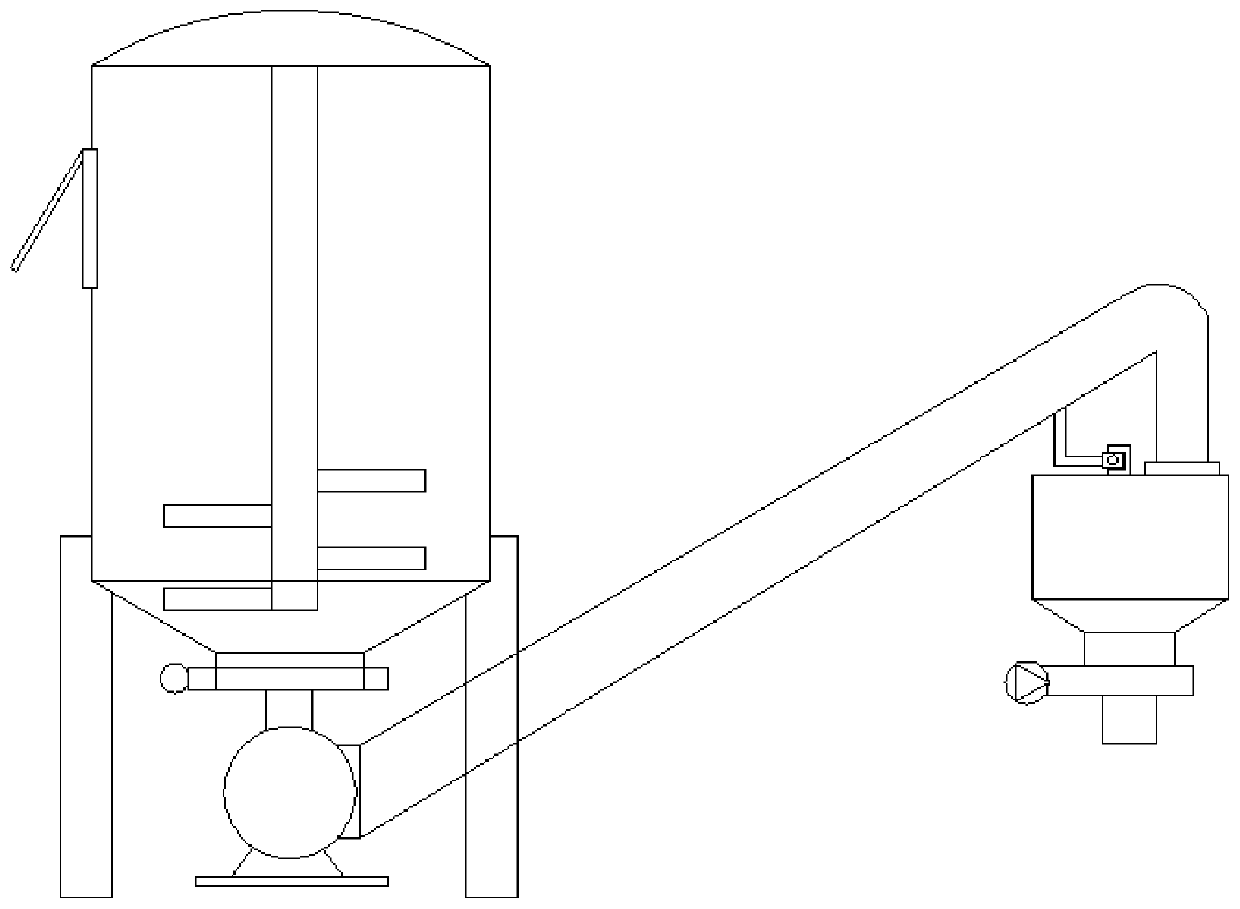

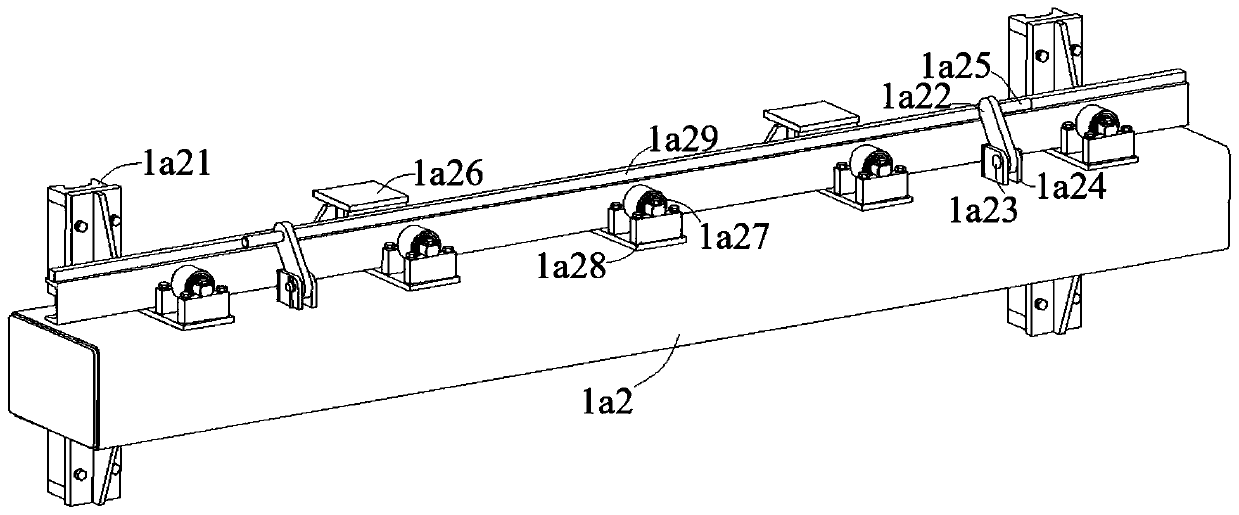

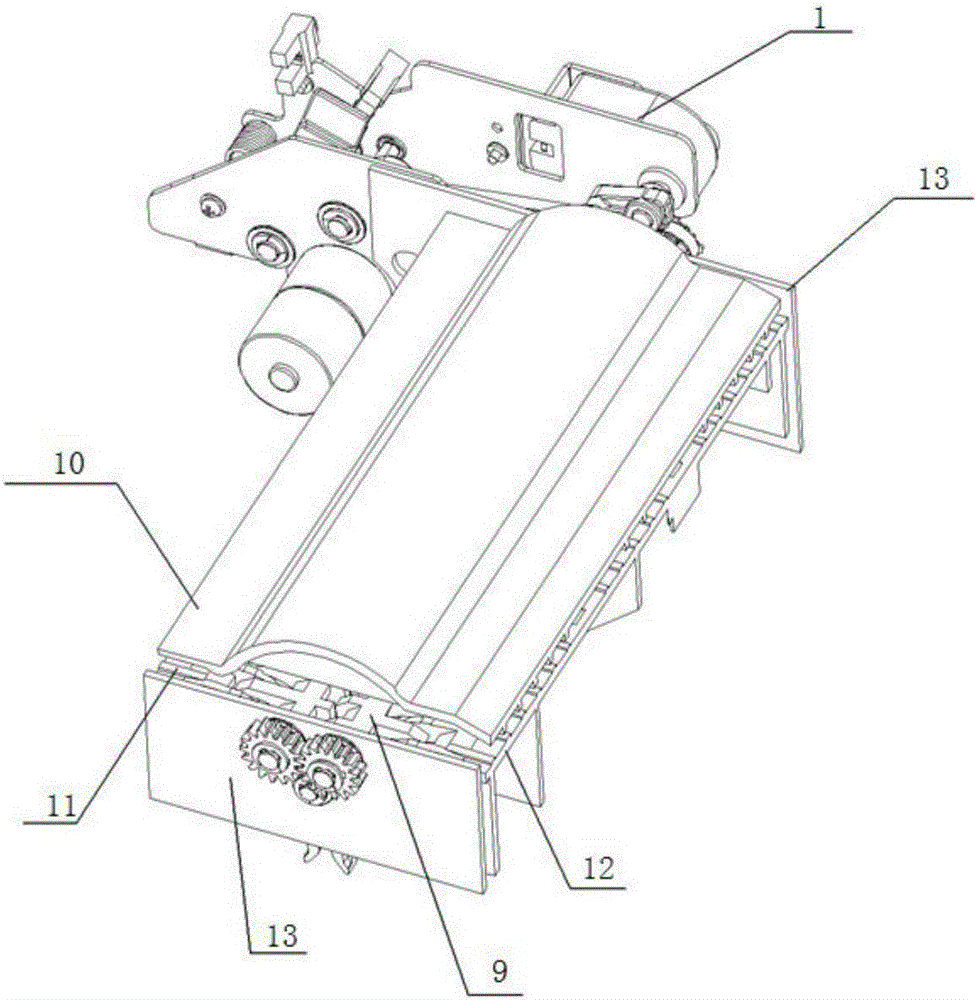

Sampling and sample preparation system used for samples

ActiveCN108045935AImprove automationImprove completenessWithdrawing sample devicesPreparing sample for investigationButt jointIn degree

The invention discloses a sampling and sample preparation system used for samples. The sampling and sample preparation system includes a sampling end and a sample preparation end. Butt joint conveyingis conducted between the sampling end and the sample preparation end through a butt joint conveying unit. The butt joint conveying unit is used for conveying a sample shipped sample barrel of the sampling end to the sample preparation end to conduct sample preparation, and conveying an empty sample barrel of the sample preparation end to the sampling end to conduct sample shipping. The sampling end is provided with an intelligent ore separator unit and a sampling end sampling barrel transshipment unit. The sample preparation end is provided with a sample batch unit, an automatic discharging unit, and a sampling end sampling barrel transshipment unit. The sampling and sample preparation system used for the samples has the advantages of being high in degree of automation and intelligence, high in security, capable of reducing manual labor intensity, and capable of keeping working continuity.

Owner:HUNAN SUNDY SCI & TECH DEV

Surface repairing device for electromechanical product

The invention discloses a surface repairing device for an electromechanical product. The device comprises a base, and a box body which is arranged on the end surface of the top part of the base, wherein a first cavity is formed in the box body; an inner toothed circular groove which communicates with the first cavity is formed in the end surface of the top part of the base; a second cavity communicates with the bottom part of the inner toothed circular groove; a first guide chute which is upwards open and is positioned at the left end of the inner toothed circular groove is arranged in the endsurface of the top part of the base; a second guide chute is arranged between the first guide chute and the second cavity in a communication manner; a turntable is connected into the inner toothed circular groove in a rotating fit manner; an arc-shaped chamber which is upwards open is formed in the turntable; a loading moving ring which is open in the left and right direction is connected into the arc-shaped chamber in a rolling fit manner; and a tooth shaped fixing ring is arranged on the left end surface of the loading moving ring. The device is simple in structure, convenient to operate, convenient to store, energy saving, environmentally friendly, uniform in repairing effect, and good in effect.

Owner:ZHUJI CITY JIMAILUO IMPORT & EXPORT CO LTD

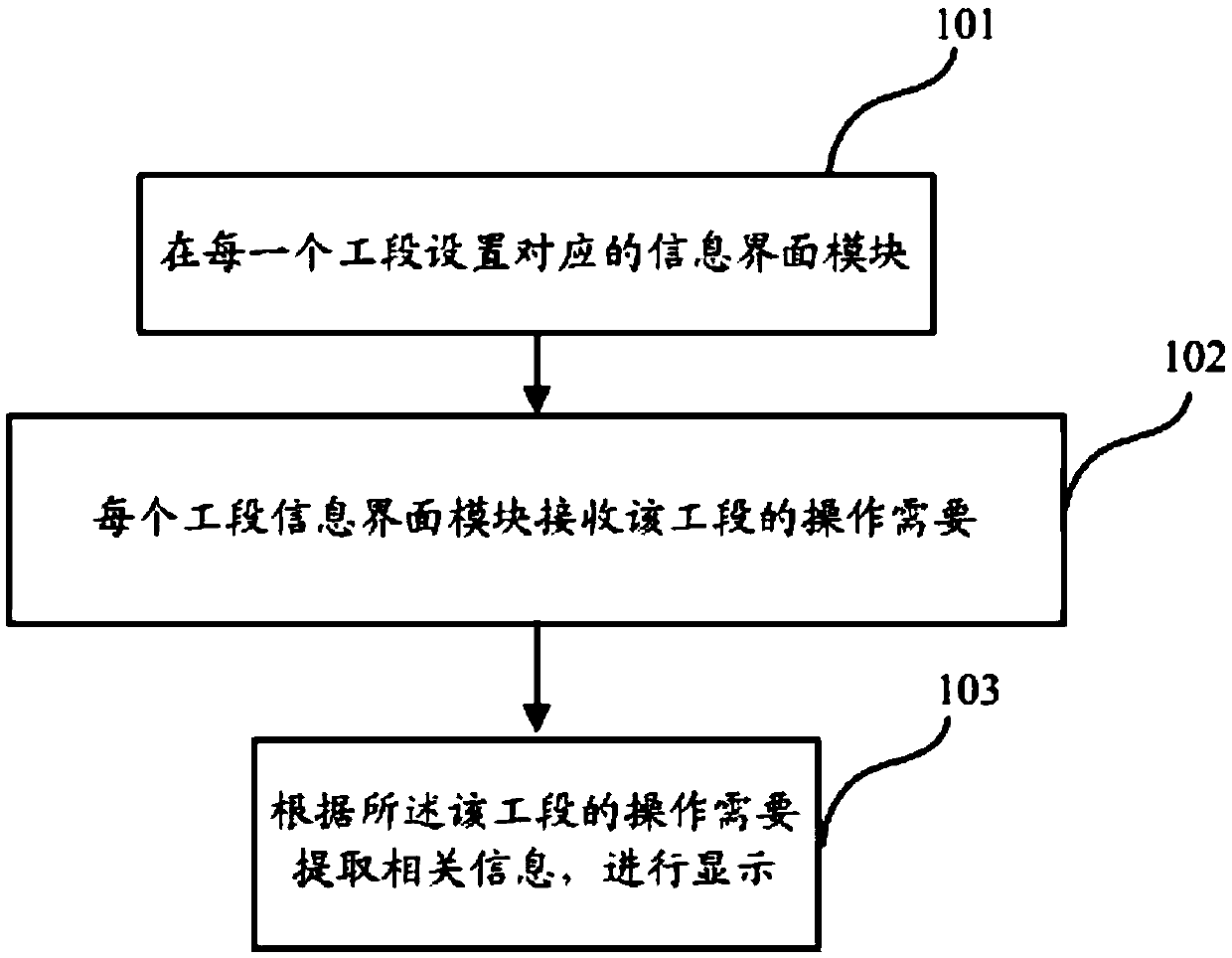

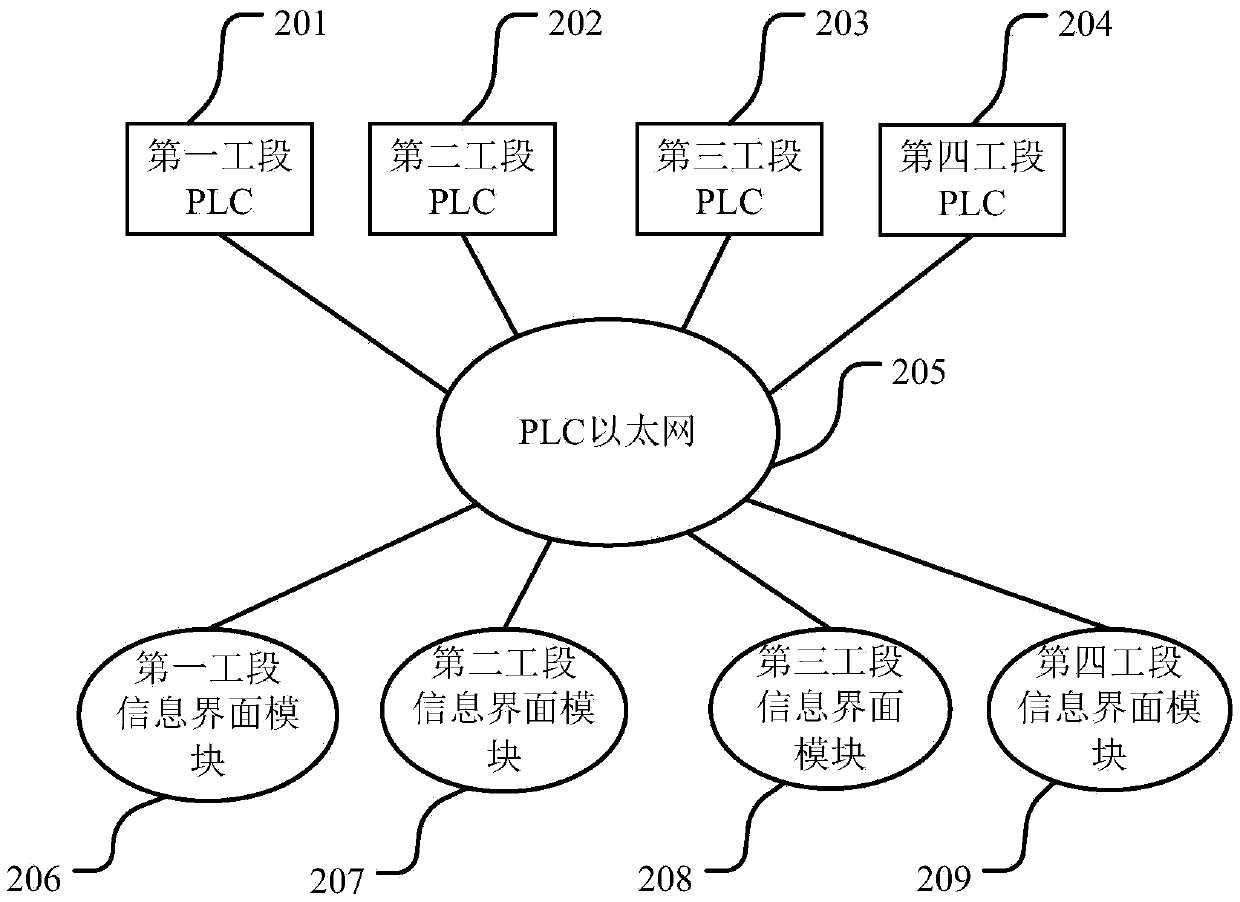

Gypsum board production information real-time interactive method and system

InactiveCN105373067AUnderstand comprehensivelyReal-time understandingData switching networksProgramme control in sequence/logic controllersRelevant informationComputer module

The invention provides a gypsum board production information real-time interactive method and system. The method comprises the steps that a corresponding information interface module is arranged at each workshop section; the information interface module of each workshop section receives operation needs of the workshop section; and relevant information is extracted according to the operation needs of the workshop section to be displayed. According to a set of information interactive method and system between all the workshop sections, data between all the workshop sections can be interactively displayed to each other and seamless communication can be realized, i.e. each workshop section can view the real-time key data of other workshop sections and perform transmission of the relevant information via the interactive interfaces so that all the workshop sections can effectively communicate and closely cooperate with each other via the system, and all the workshop sections are enabled to comprehensively understand production information relevant to the workshop sections in real time and perform information communication with other workshop sections timely.

Owner:湖北北新建材有限公司

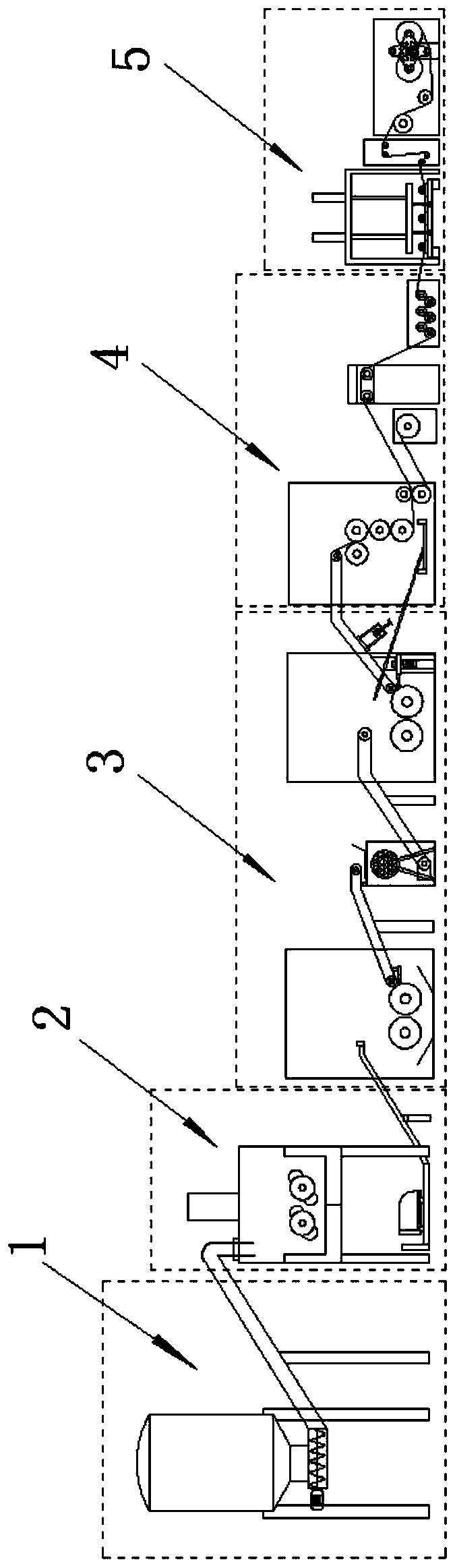

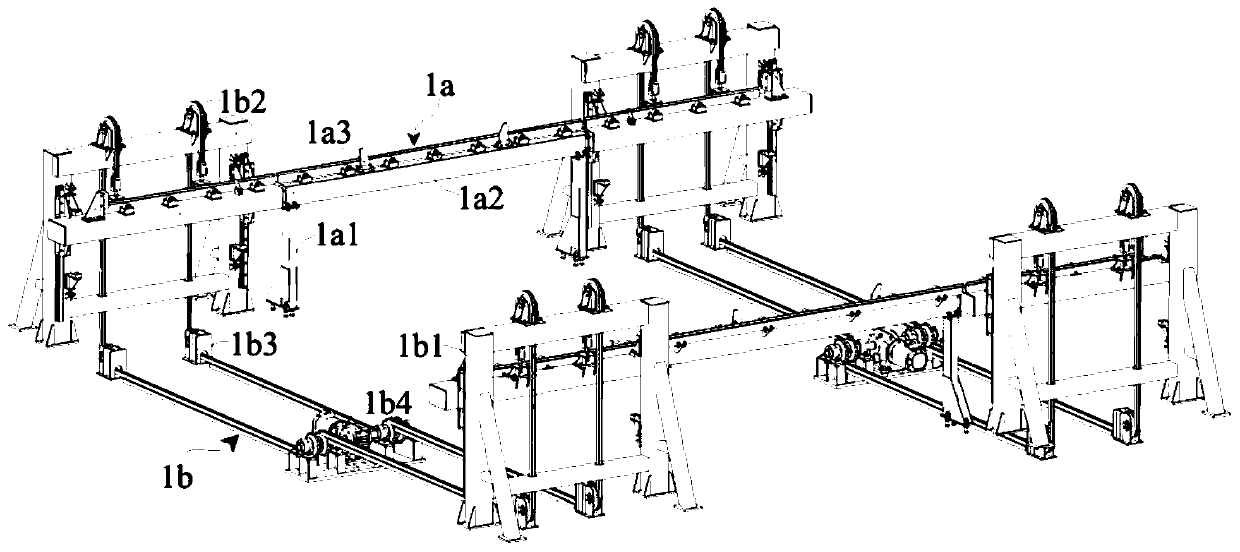

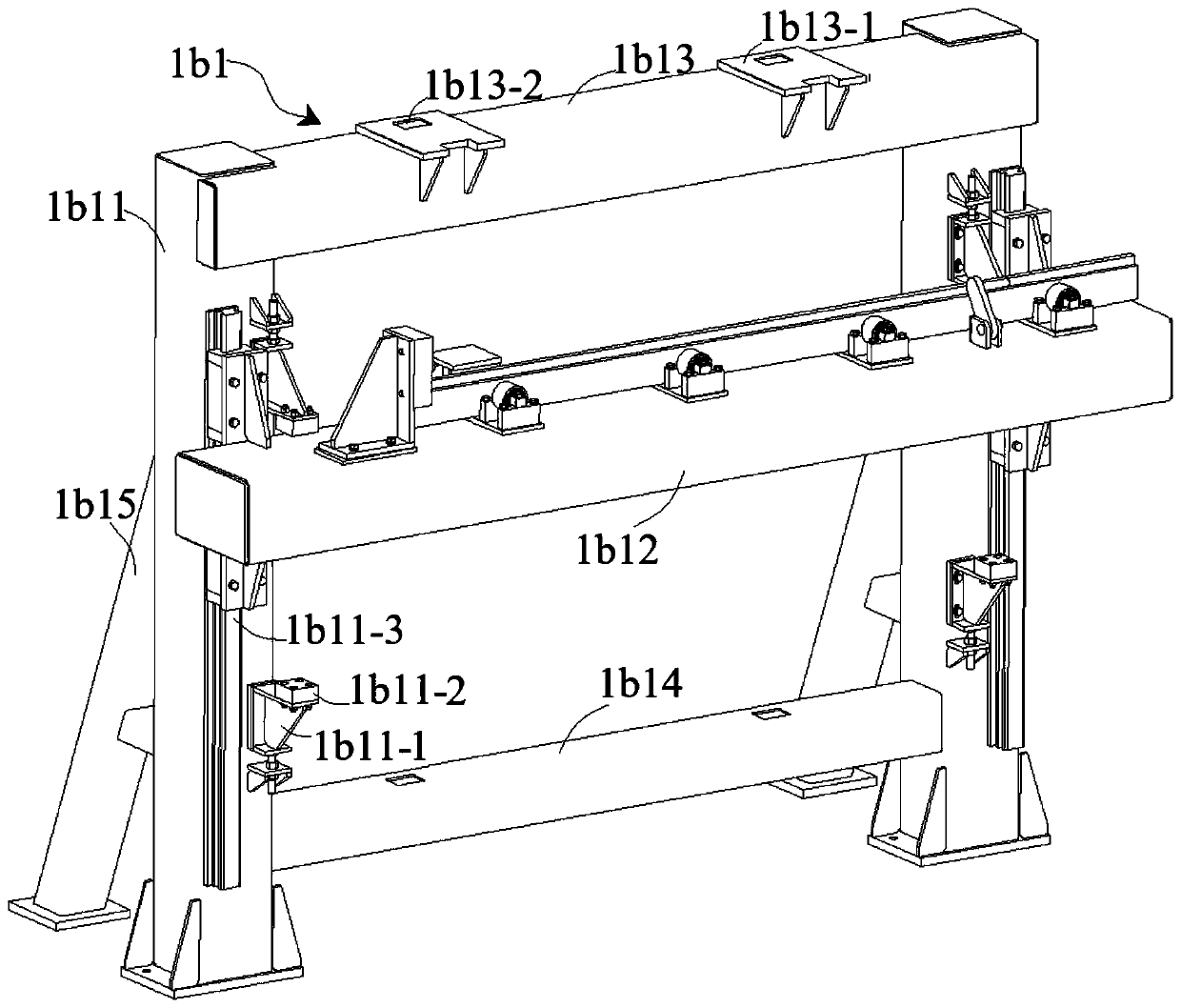

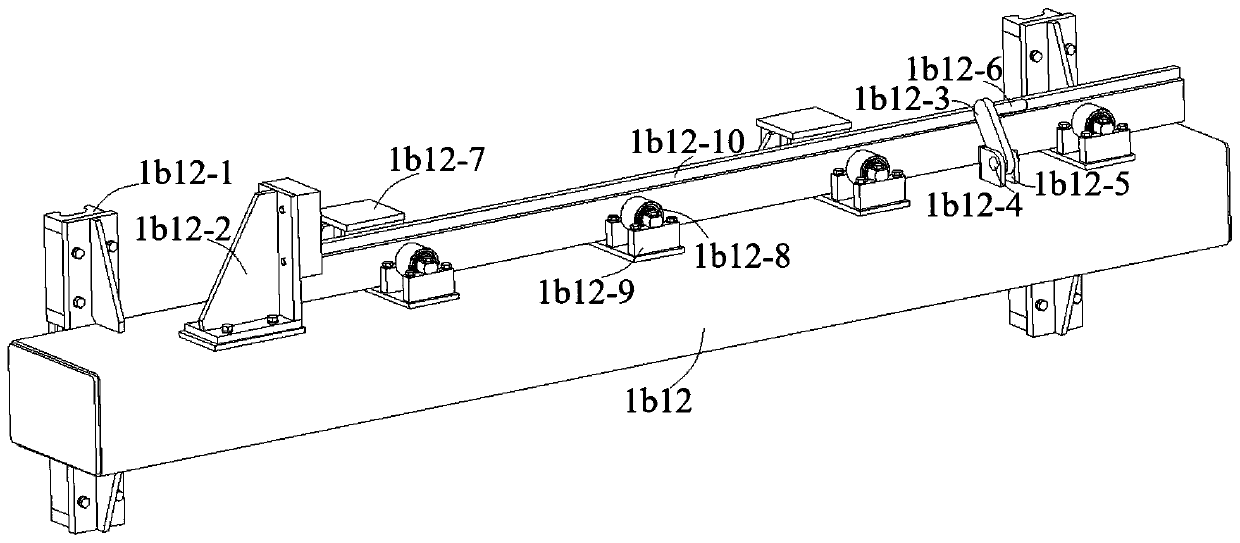

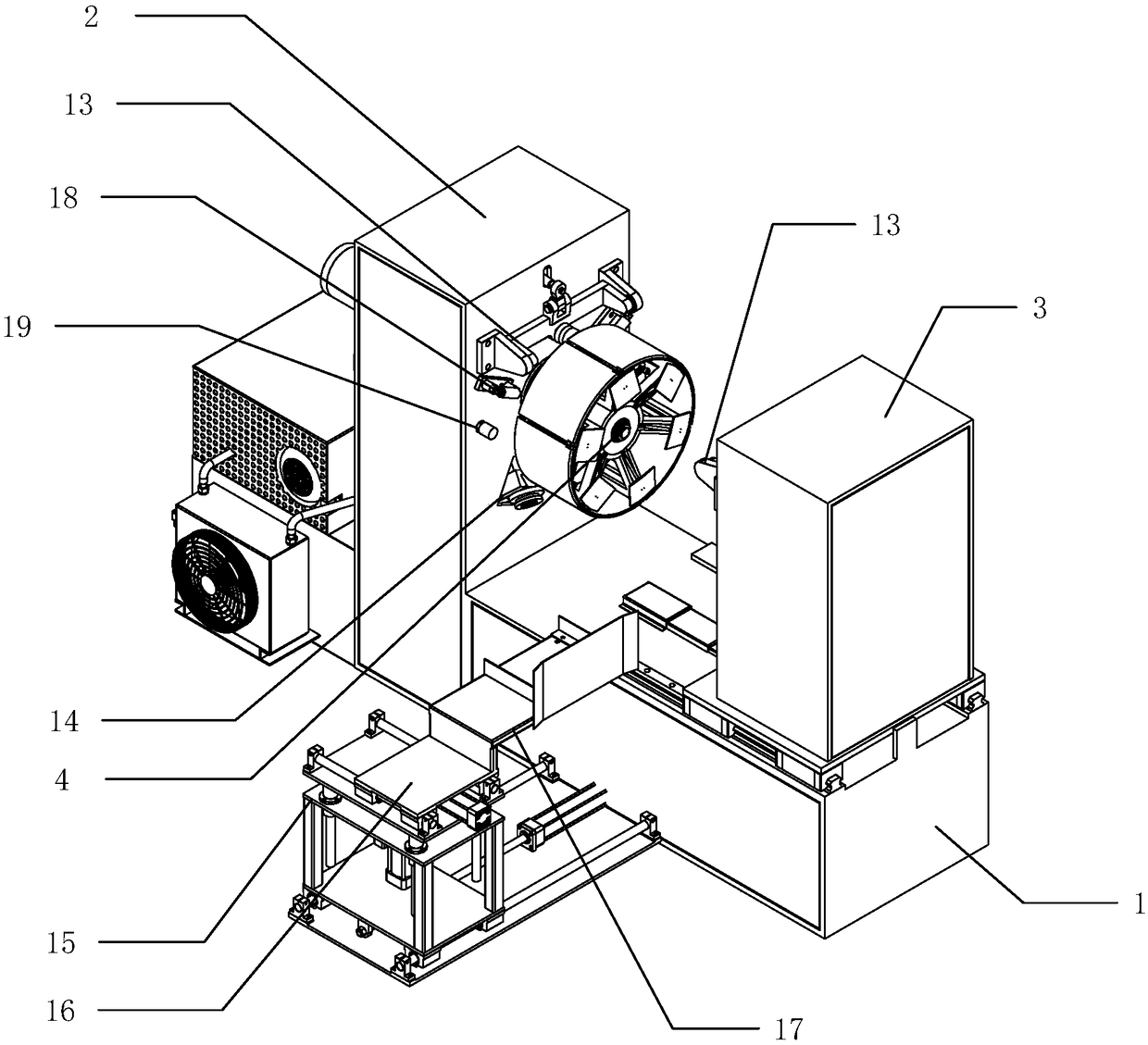

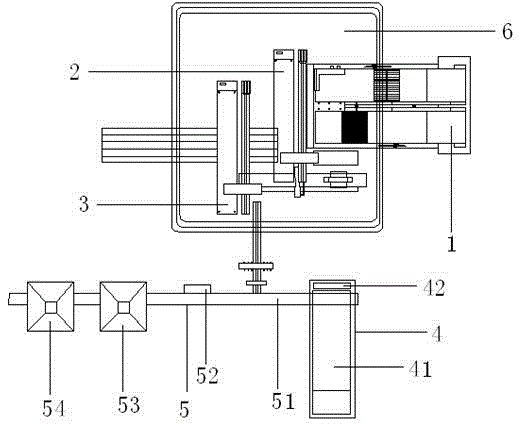

Light and environmentally-friendly type PVC artificial leather production technology

The invention relates to a light and environmentally-friendly type PVC artificial leather production technology which comprises the following process steps in sequence: feeding, banburying, primary open mill, filtering, secondary open mill, unwinding and calendering, cooling and winding. The production technology is realized based on a light and environmentally-friendly type PVC artificial leatherproduction line. The light and environmentally-friendly type PVC artificial leather production line is sequentially provided with a plurality feeding mechanisms (1), a banburying mechanism (2), an open mill mechanism (3), an unwinding and calendering mechanism (4) and a winding mechanism (5), wherein a guiding roller for transmitting PVC artificial leather is arranged on each of the unwinding andcalendering mechanism (4) and the winding mechanism (5); and the feeding mechanisms (1) are arranged according to the raw material demand. According to the light and environmentally-friendly type PVCartificial leather production technology, an integrated technological process is formed from raw material supply, banburying, open mill and calendering of a mixture to cooling and winding of a finished product to realize production automation, all working procedures are tightly matched through devices, the production efficiency and the product quality are improved, and the labor intensity is lowered.

Owner:江阴市兴恒塑胶有限公司

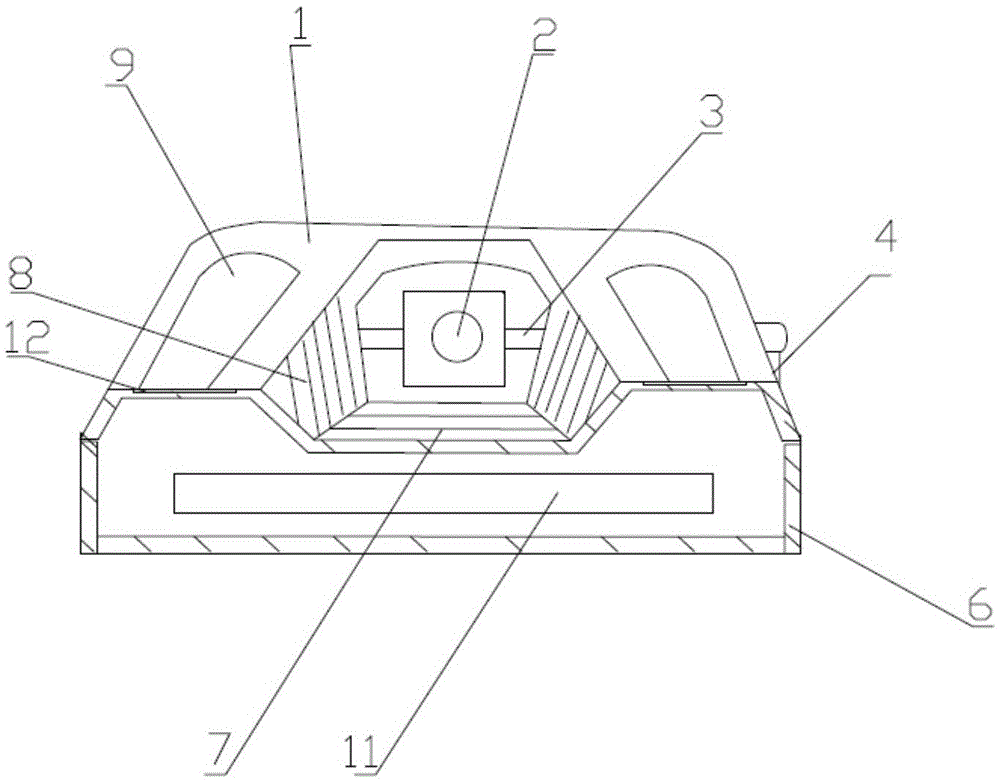

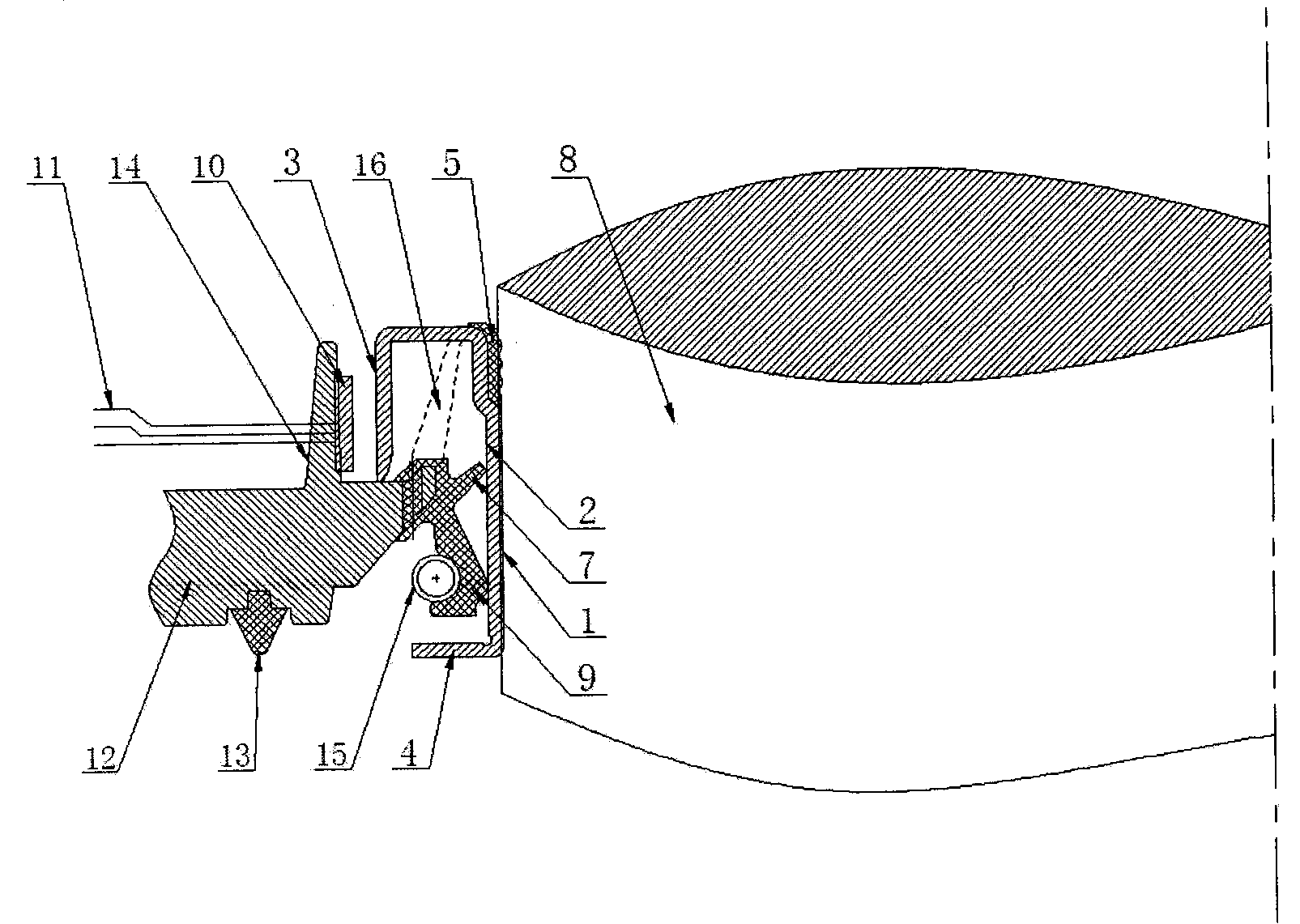

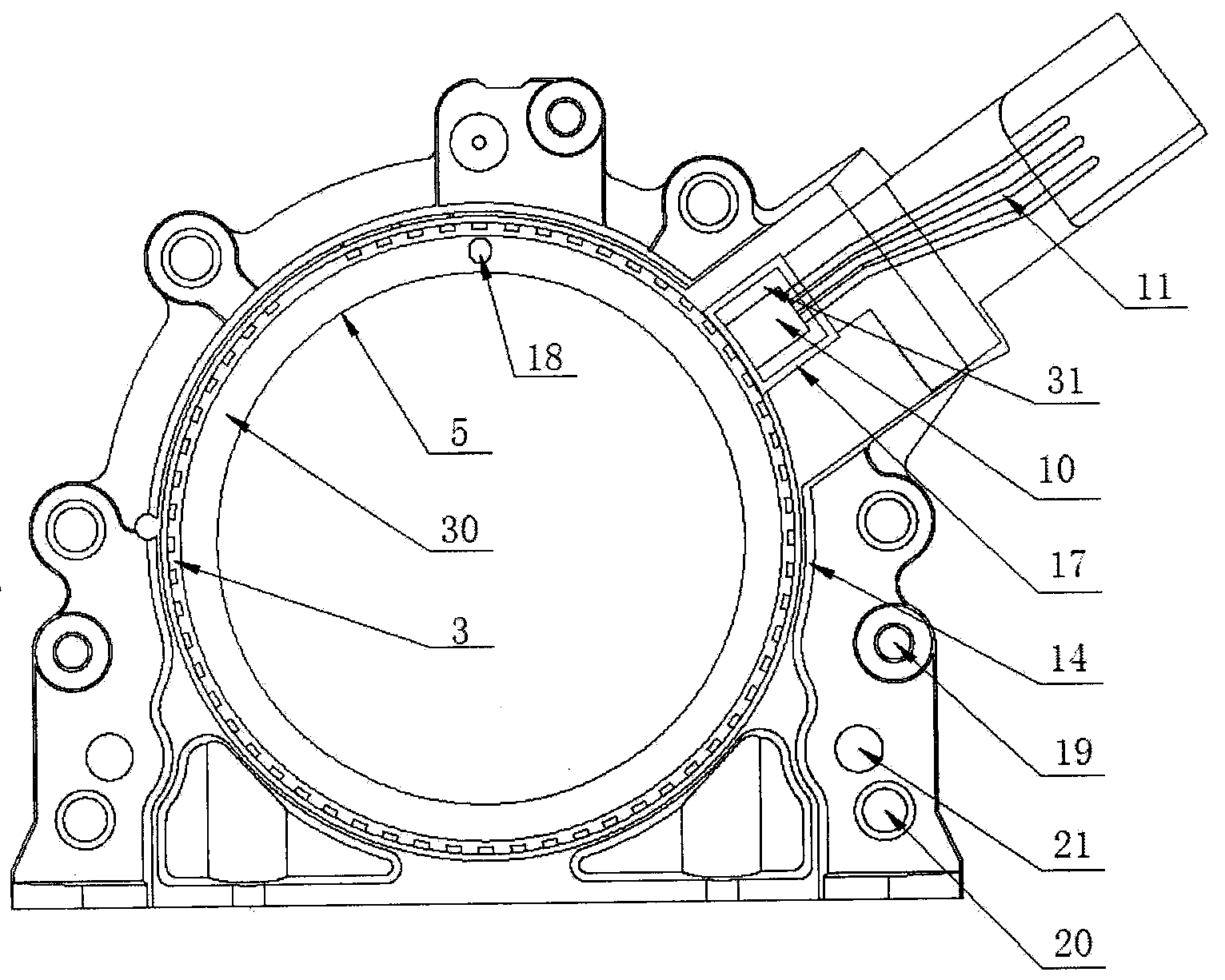

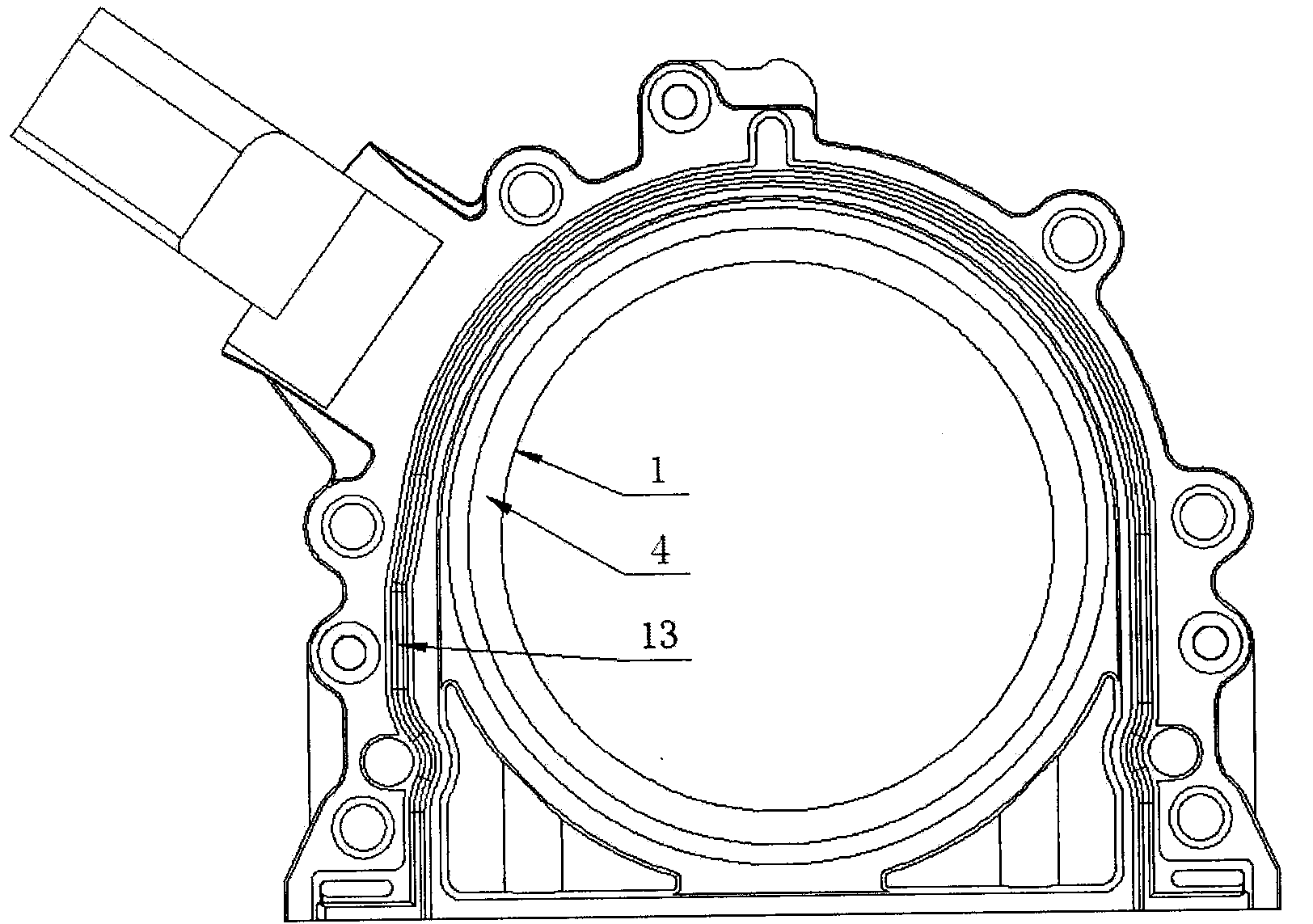

Assembly oil seal with sensing function

ActiveCN103821941AReduce mistakesReduce quality problemsEngine sealsDevices using optical meansCrankshaftInverted u

The invention provides an assembly oil seal with a sensing function. The assembly oil seal with the sensing function comprises a flange, an oil seal lip part matched with the inner ring of the flange, a coder and a sensor corresponding to the coder; the coder is an inverted U-shaped ring with one long end and one short end; the short end of the coder is a coder body arranged on the flange; the inner side of the long end of the coder is matched with the inner ring of the oil seal lip part. The assembly oil seal with the sensing function is durable, capable of accurately detecting the rotary speed of a crankshaft and integrated with the sensor.

Owner:董波 +1

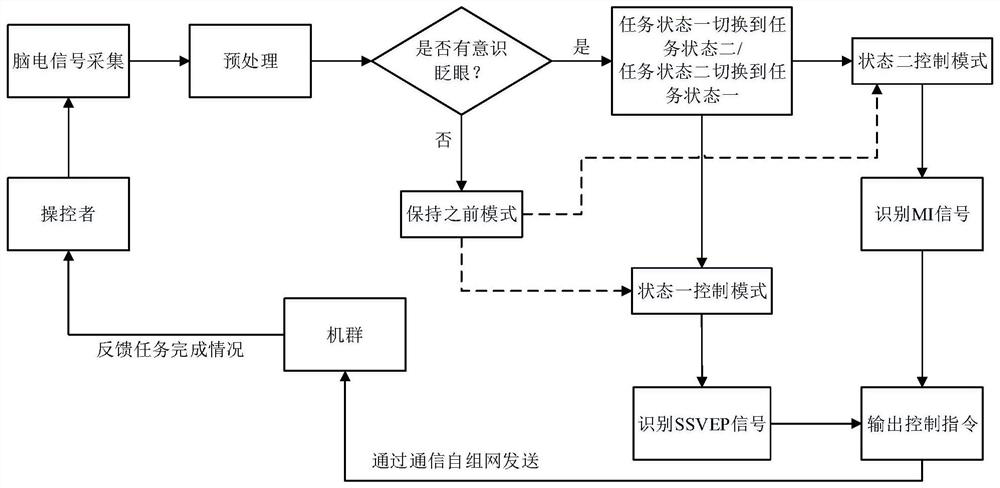

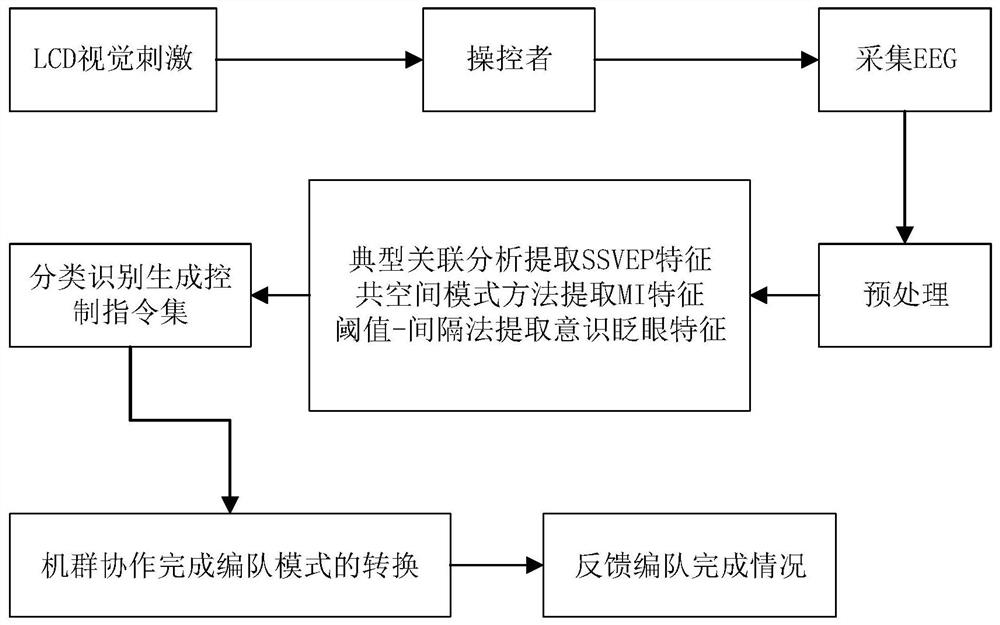

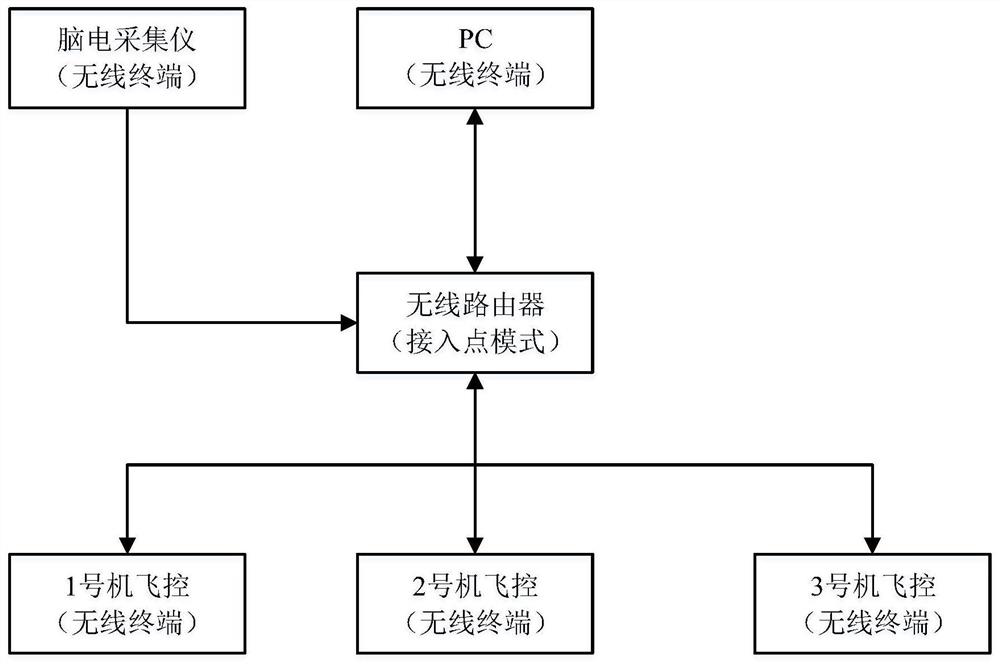

Novel unmanned aerial vehicle group brain-computer cooperative intelligent control method

PendingCN111638724ASolve the problem of poor interactivity and lack of ability to adapt to unknown environmentsReduce the burden onInput/output for user-computer interactionParticular environment based servicesSimulationUncrewed vehicle

The invention discloses a novel unmanned aerial vehicle group brain-computer cooperative intelligent control method. Specifically, task states are distinguished by collecting EEG of the brain when anoperator selects or decides, and a computer processes data to extract features and then provides a cluster control strategy to achieve brain-computer coordination. EEG is collected when an operator makes a decision or selects; data processing is carried out by the computer to extract features for classification and identification; an intelligent control strategy is provided in the form of an instruction to inform a fleet operator of the intention, the fleet autonomously cooperates to complete the conversion of the formation mode, the formation mode conversion does not need the operator to makea selection or decision, the burden of the brain is reduced, and the brain-computer division is clear, mutually cooperates and closely cooperates to complete the flight task. The invention aims to provide a new method capable of managing and interacting with the cluster, the defects in the prior art are effectively compensated, human brain intelligence is combined with artificial intelligence, and intelligent control of tasks such as flight formation mode conversion of the unmanned aerial vehicle cluster is realized through brain-computer cooperation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

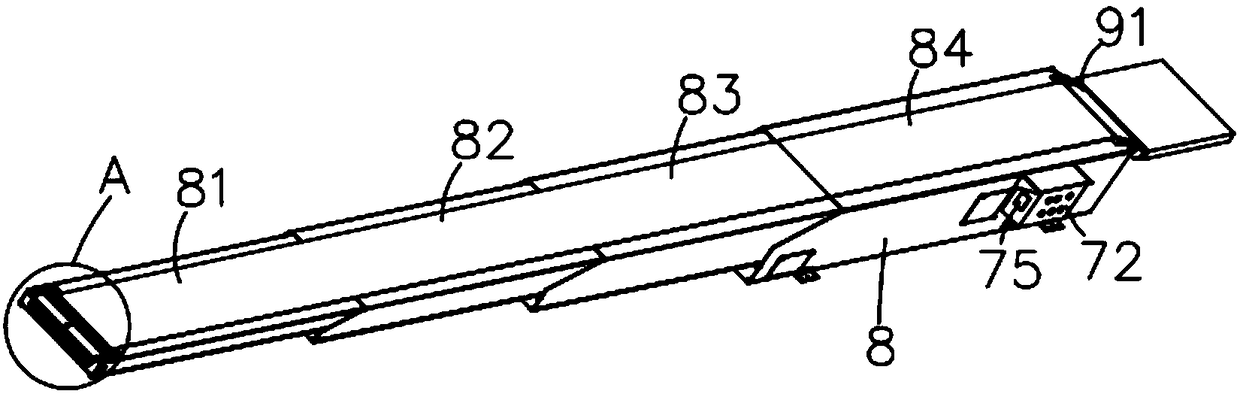

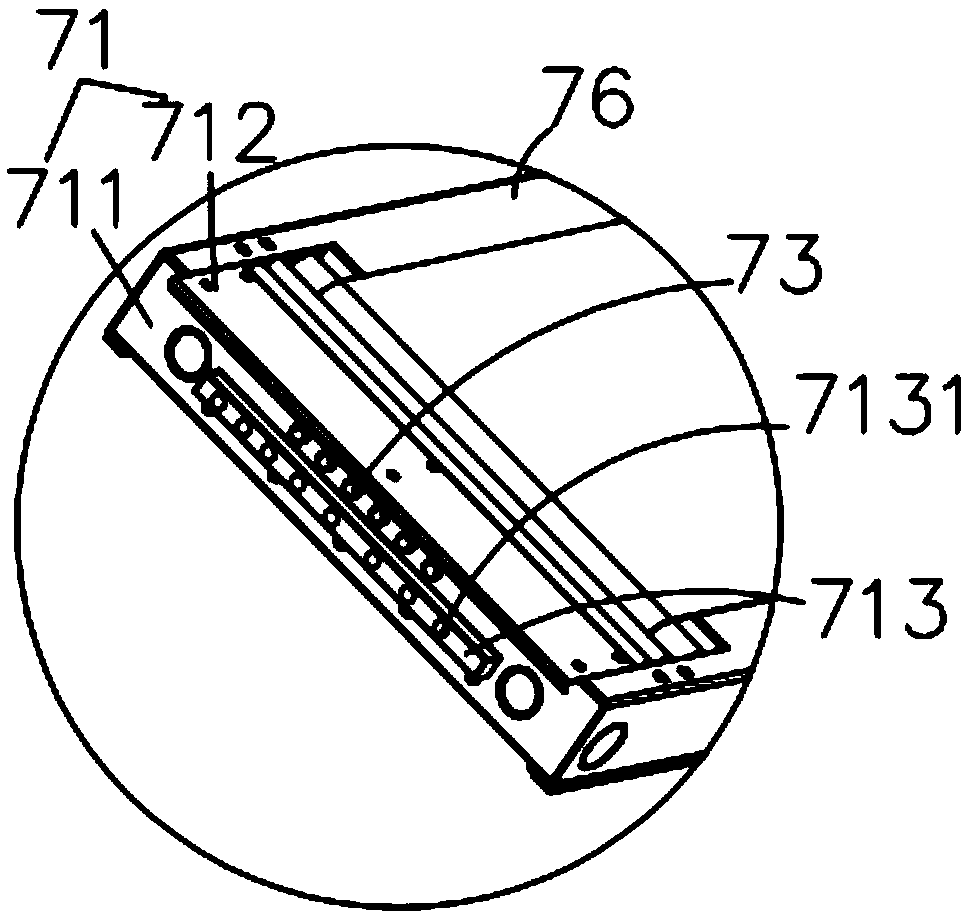

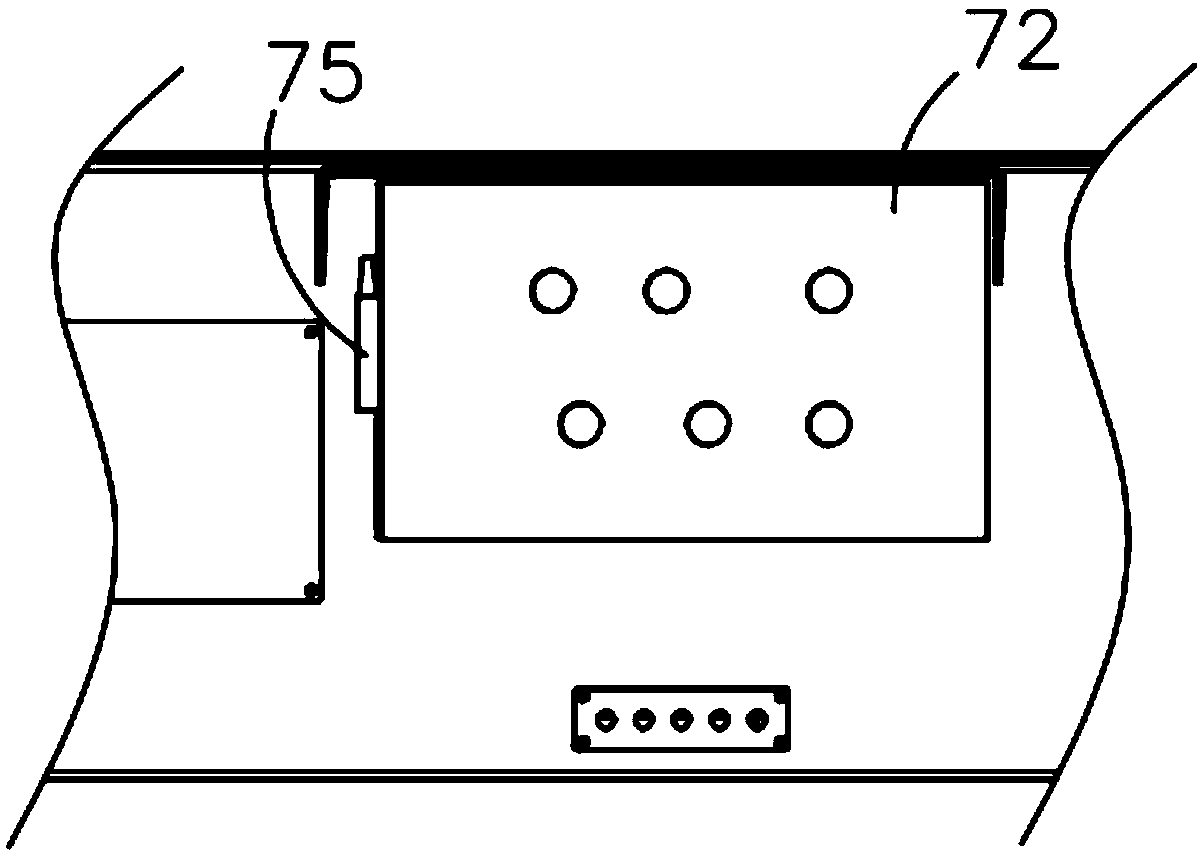

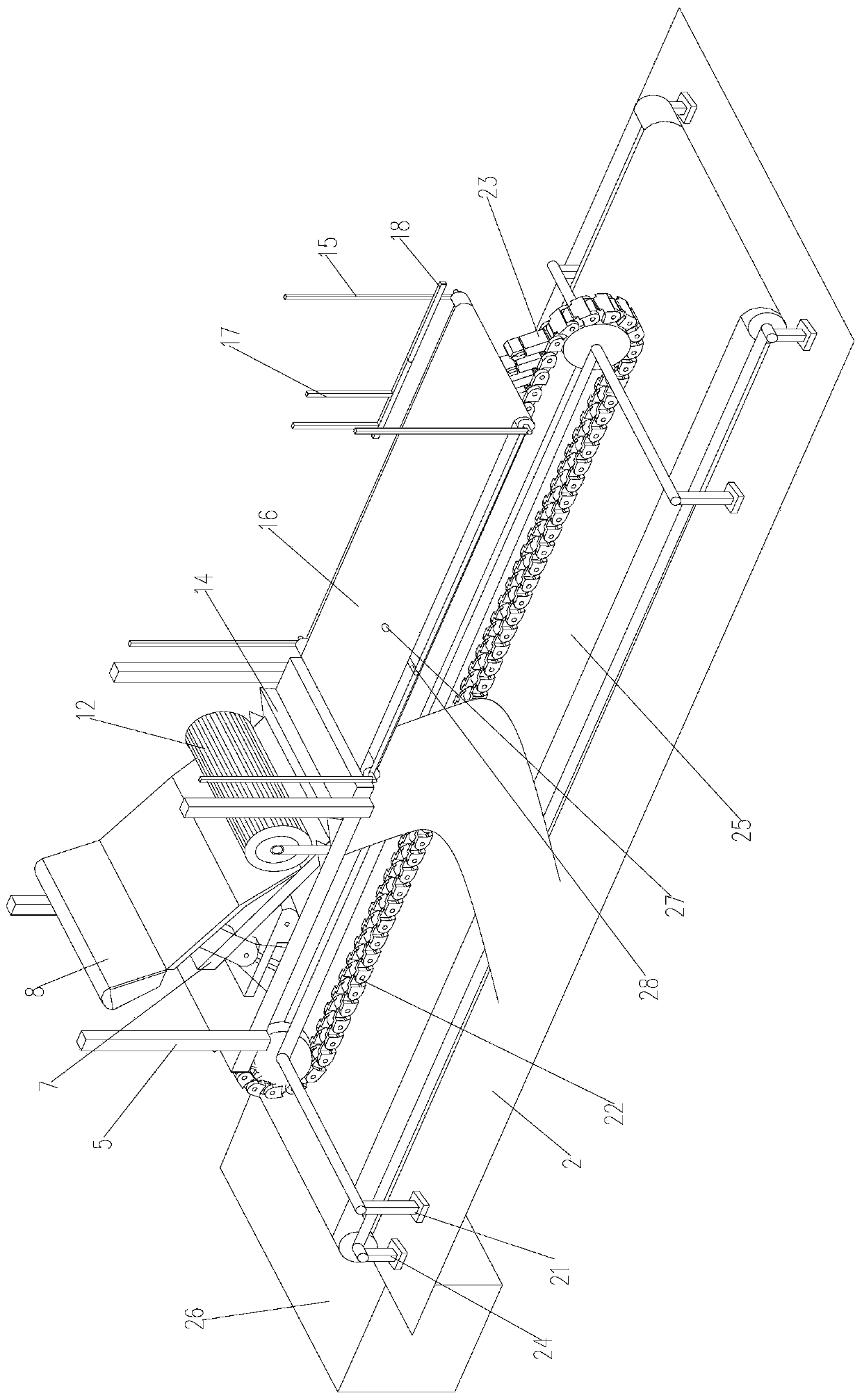

Novel telescoping machine for logistics transportation

ActiveCN108609352AImprove structural stabilityImprove operational convenienceConveyorsLogistics managementEngineering

The invention discloses a novel telescoping machine for logistics transportation. The novel telescoping machine for logistics transportation comprises a telescoping machine body, a distance control assembly, a connecting assembly and a climbing assembly, wherein the distance control assembly, the connecting assembly and the climbing assembly are arranged on the telescoping machine body. The climbing assembly is arranged at the rear end of the telescoping machine body. The telescoping machine body comprises a plurality of sections, wherein the sections are connected in sequence. The section, atthe front position, of every two adjacent sections in the sections is named a telescoping machine front stage, the section, at the rear position, of every two adjacent sections in the sections is named a telescoping machine rear stage, and the telescoping machine front stages and the telescoping machine rear stages are connected through the connecting assembly. Compared with the prior art, the novel telescoping machine for logistics transportation has the advantages that the distance control assembly, the connecting assembly and the climbing assembly are arranged on the telescoping machine body, the assemblies are matched with each other, and therefore the structural stability, the operating convenience, the working safety and other performance of the telescoping machine are greatly improved.

Owner:长沙六竹机电科技有限公司

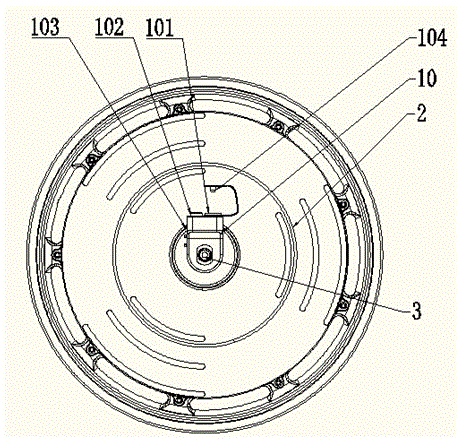

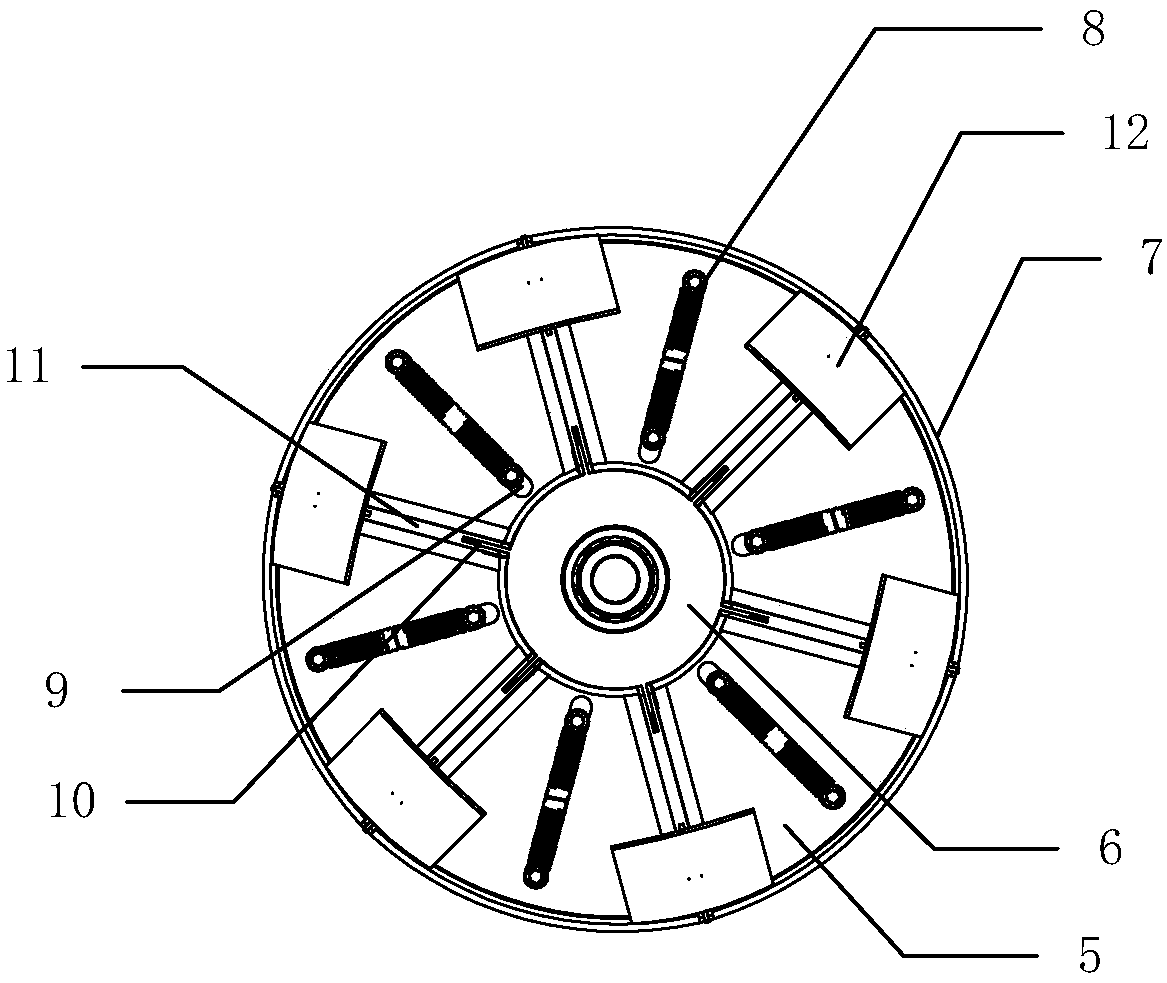

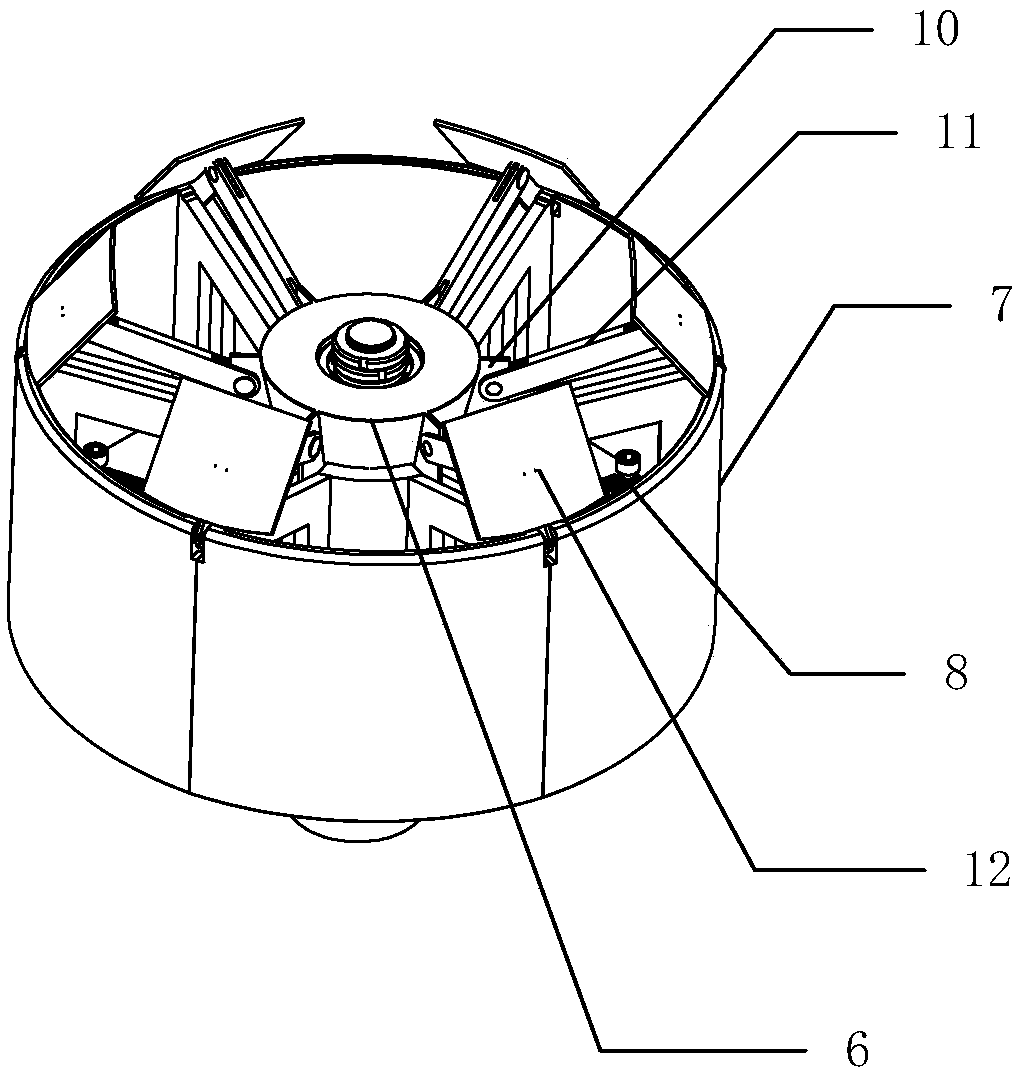

Integrated wheel and electric vehicle with integrated wheel

InactiveCN105059463ACooperate closelyPerfect Collection GuaranteedHubsMechanical energy handlingElectric vehicleMechanical engineering

The invention discloses an integrated wheel and a corresponding electric vehicle. The integrated wheel comprises a hub and a wheel cover, wherein a shaft core and an external tooth ring are arranged on the hub, and a controller, a motor, a power transmission mechanism, a pair of bearings, a fixing frame, a charging assembly and a ratchet wheel assembly are arranged on the shaft core; the controller is connected with the motor, the charging assembly and the ratchet wheel assembly; the motor is connected with the power transmission mechanism; the power transmission mechanism is connected with the external tooth ring, and the hub and the wheel cover are respectively connected with one bearing; a battery assembly is arranged on the fixing frame and connected with the controller and the motor. The integrated wheel disclosed by the invention is exquisite in design, simple to operate, balanced and stable in power transmission and high in efficiency; all electric components are convenient and easy to wire and thread, so that interference caused by rotation on wiring is avoided, and the operating efficiency and the stability of connection among all the components are greatly improved; the integrated wheel is convenient to charge, and besides the hollow shaft core is also favorable for heat conduction and heat dissipation, so that the heat dissipating efficiency is improved. The integrated wheel disclosed by the invention can be suitable for various types of bicycles and various types of electric vehicles and is good in adaptability and wide in application range.

Owner:苏州速蝶科技有限公司

Aerated concrete plate material circulation system and preparation process

ActiveCN111573232AReduce manual labor intensityReduce labor costsTravelling cranesConveyor partsRebarCorrosion prevention

The invention discloses an aerated concrete plate material circulation system and a preparation process, and belongs to the field of a saddle frame steel mesh cage circulation transportation line. Thesystem includes a grid-forming frame, a mesh cage transport crane, an anti-corrosion impregnating tank, an electric saddle conveyor I, a drying box, a drill rod inserting machine, a drill rod pullingmachine, a wax dipping cylinder, an electric saddle conveyor II, and an electric saddle conveyor III; the drill rod pulling machine, the wax dipping cylinder, the electric saddle conveyor II, and theelectric saddle conveyor III are disposed in order; the electric saddle conveyor I and the drill rod inserting machine are disposed in order to form two parallel conveying paths; and the grid-formingframe, an end head of one conveying path, the anti-corrosion impregnating tank and the end head of the other conveying path are disposed below the mesh cage transport crane in order to form an automated circulation path. The circulation system enables the production efficiency to be improved through cooperation between the grid-forming frame with adjustable height and the electric saddle frame conveyors with adjustable speed, and enables the service life of steel drill rods and the quality of a steel bar cage through wax dipping, anti-corrosion and drying and does not affect production efficiency.

Owner:ANHUI KEDA IND CO LTD

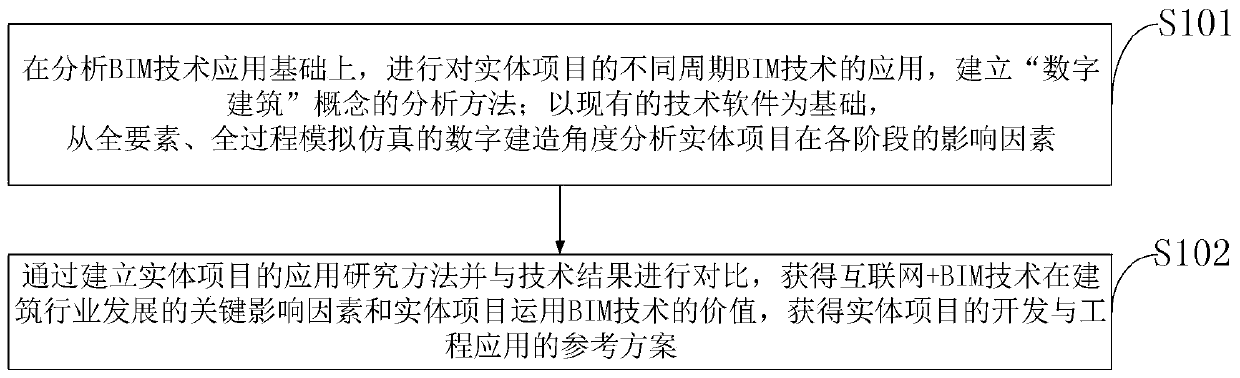

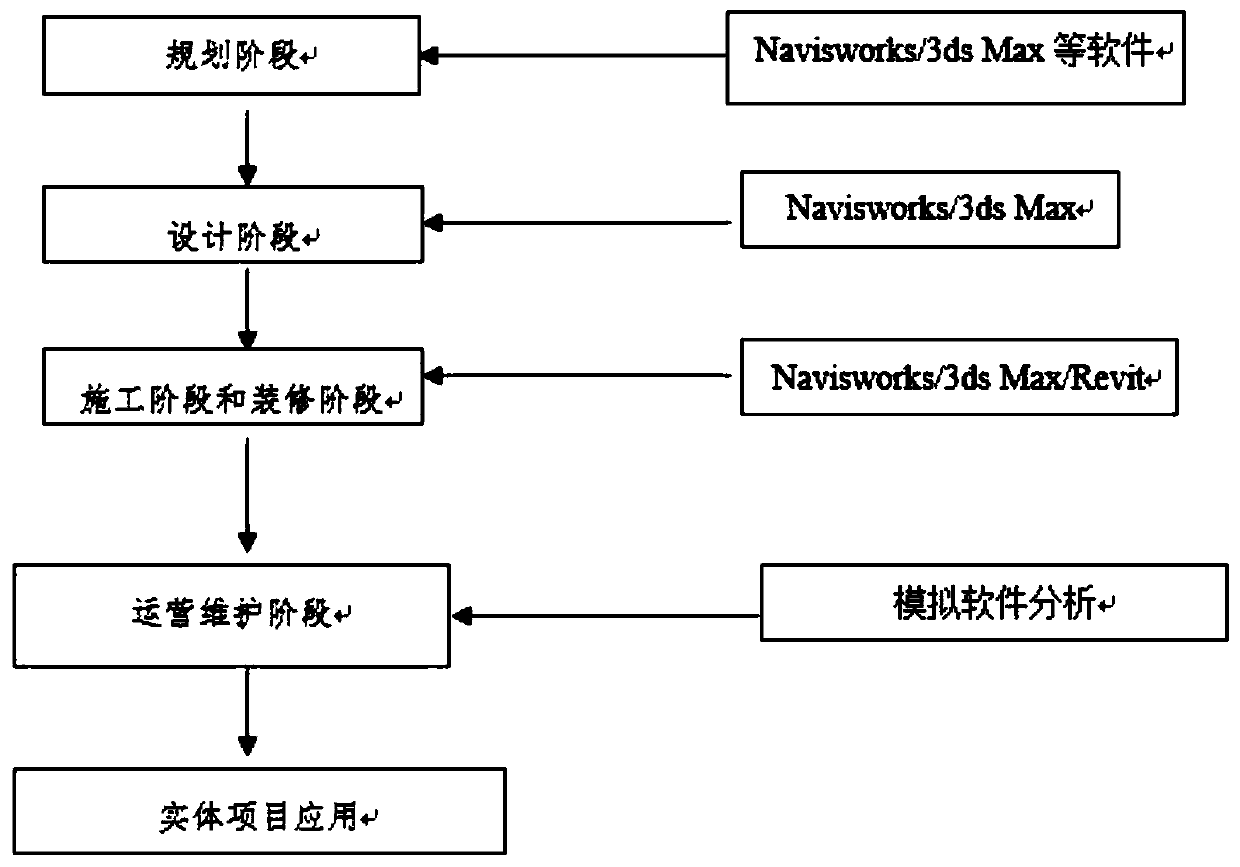

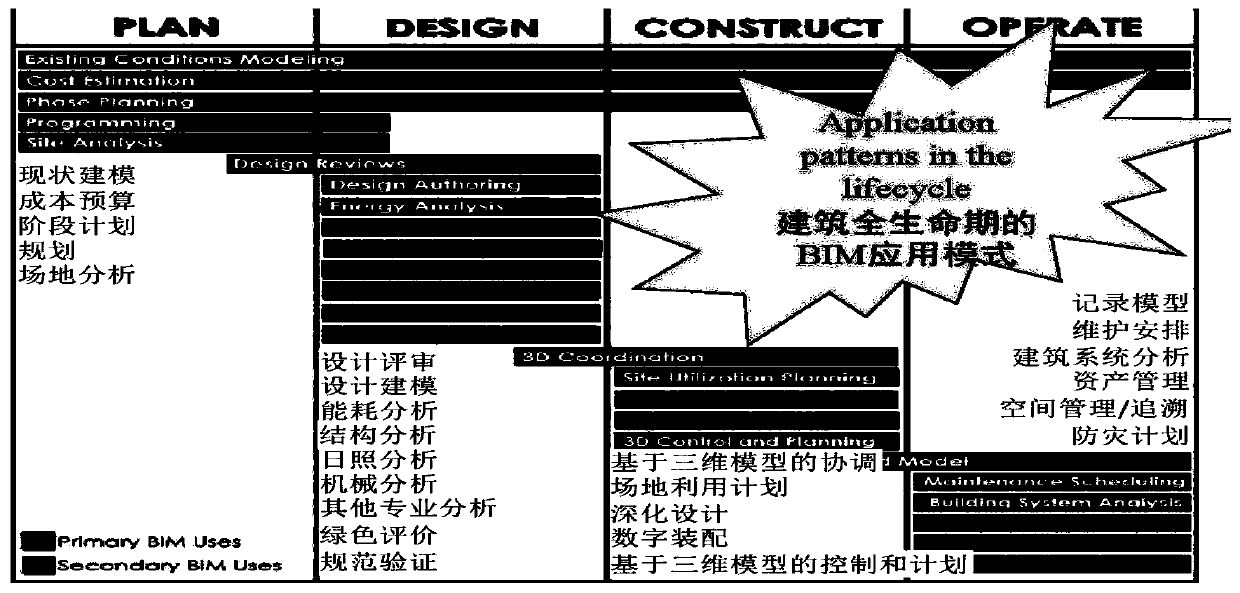

Residential building entity full life cycle analysis method based on Internet and BIM

PendingCN110276555AReasonable site analysisReasonable choiceGeometric CADDesign optimisation/simulationFull life cycleThe Internet

The invention belongs to the technical field of residential building entity full life cycle prediction, and discloses a residential building entity full life cycle analysis method based on the Internet and BIM. The method includes: establishing an analysis method for a digital building concept; analyzing influence factors of the entity project in each stage from the perspective of full-factor and whole-process analog simulation; by establishing an application method of an entity project and comparing the application method with a technical result, obtaining key influence factors of the Internet + BIM technology in the development of the building industry and the value of the entity project using the BIM technology, and obtaining a reference scheme of the development of the entity project and engineering application. By establishing the application method of the entity project and comparing the application method with the technical result, the key influence factors of the Internet + BIM technology in the development of the construction industry and the value of the entity project using the BIM technology are obtained, and the reference scheme of the development of the entity project and the engineering application is obtained.

Owner:WUCHANG INST OF TECH

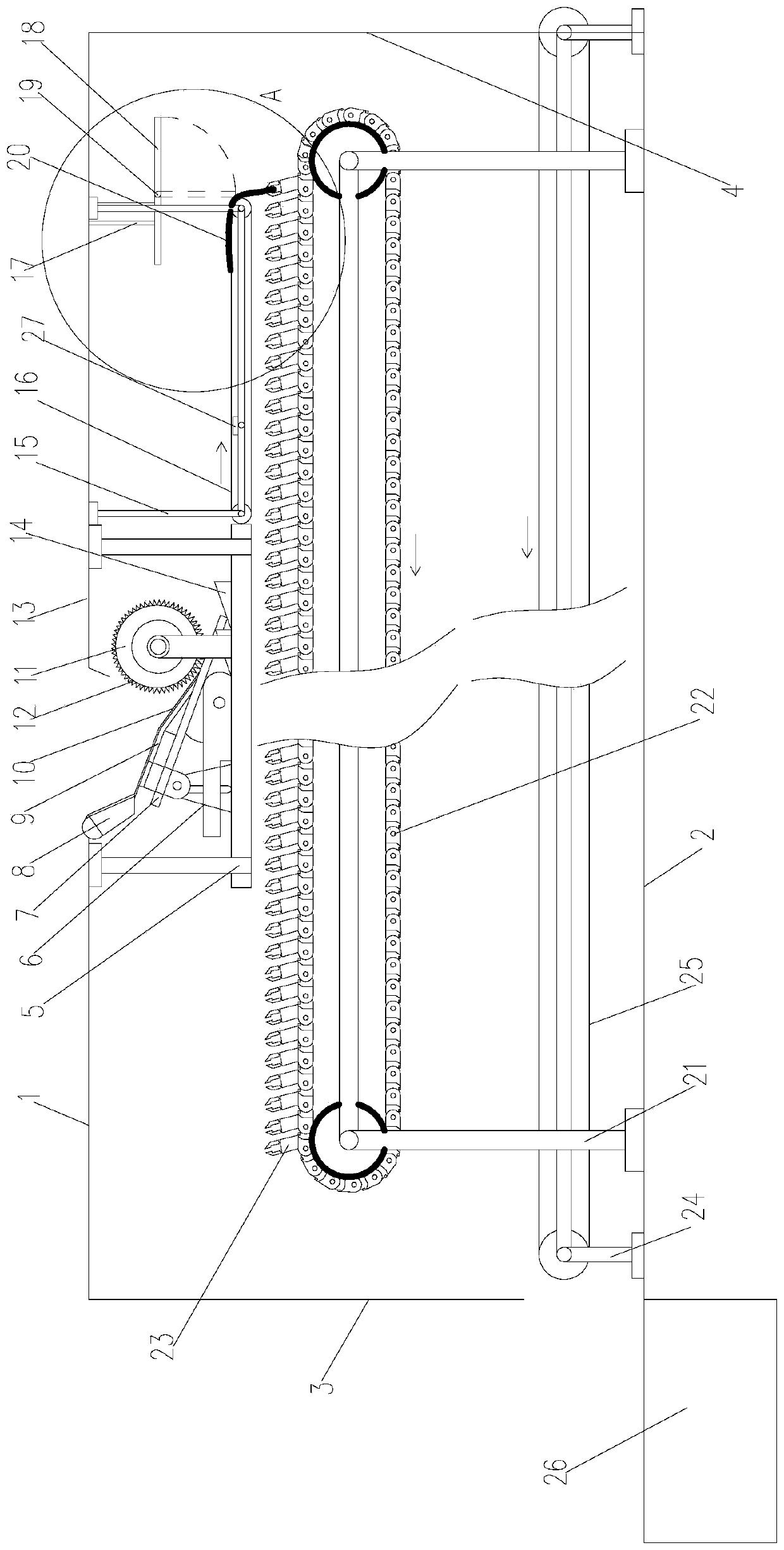

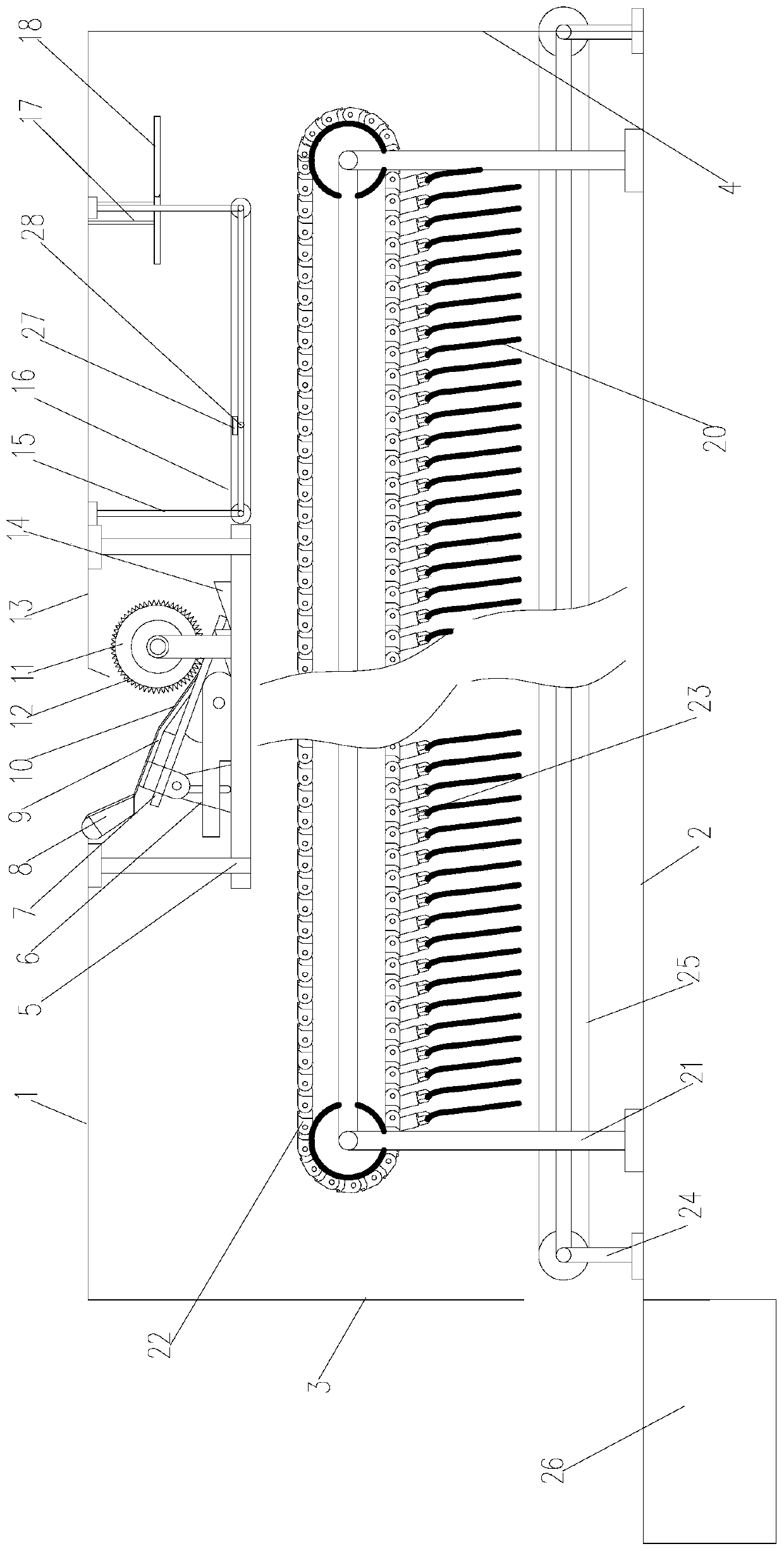

Automatic sorting and finishing machine for accounting documents

ActiveCN110451305AGood effectAvoid paper jamsArticle feedersArticle deliveryInfrared emitterEngineering

The invention discloses an automatic sorting and finishing machine for accounting documents. The automatic sorting and finishing machine includes a machine box and a storage box, the machine box is internally provided with a sorting machine, a finishing machine, a terminal transmission machine and automatic paper blocking rod, a document sorting machine is arranged at the conveying front end of the sorting machine, the sorting machine includes a sorting machine electric drum, a transparent sorting belt and a high-definition camera, the finishing machine includes a finishing machine drum, a chain transmission belt and N electric clamping jaws, and the electric clamping jaws are internally provided with infrared emitters, infrared receivers and electric clamping jaws control modules which communicate with a main controller. According to the automatic sorting and finishing machine, the stacked accounting documents are staggered through the document sorting machine, the sorting machine isused for sorting the accounting documents of bill numbers to be selected, the accounting documents of the bill numbers to be selected and the automatic paper blocking rod are matched and clamped by the electric clamping jaws on the finishing machine, the accounting documents of unselected bill number fall into a terminal transmission belt and are output, then the bill numbers to be selected are sorted, the electric clamping jaws release the sorted accounting documents in turn and the accounting documents are output through the terminal transmission belt, and automatic sorting and finishing ofthe accounting documents are realized.

Owner:XIAN UNIV OF SCI & TECH

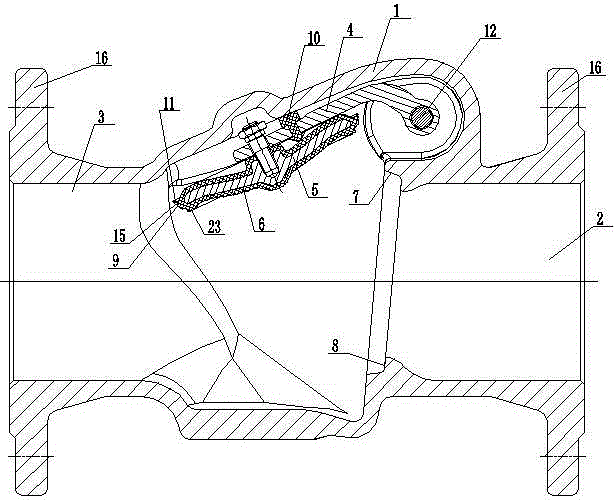

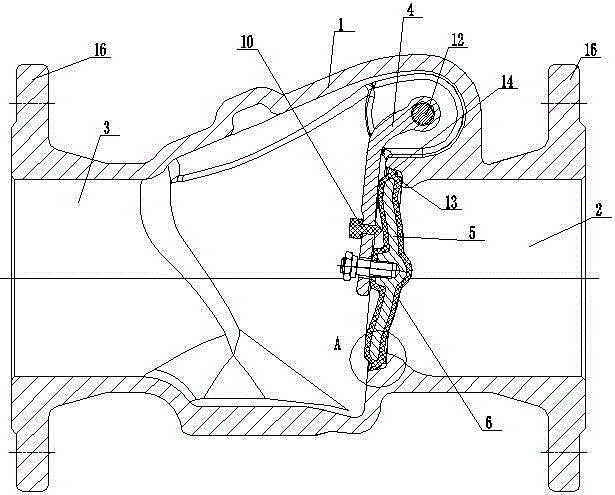

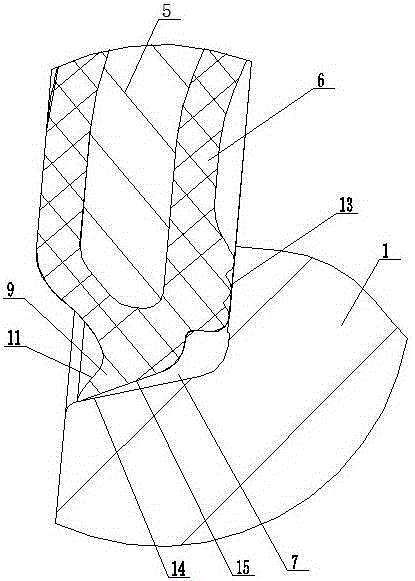

Self-sealing swing flexible-sealing check valve

The invention discloses a self-sealing swing flexible-sealing check valve which comprises a valve body. A liquid inflow cavity and a liquid outflow cavity which are communicated with each other are formed in the valve body. A rocking bar is hinged into the valve body and connected with a valve plate capable of blocking the liquid inflow cavity and the liquid outflow cavity. The outer surface of the valve plate is coated with an elastic sealing layer. One end face of the valve plate is a connecting end face used for being connected with the rocking bar and the other end face of the valve plate is a sealing end face. A counter-bored hole is formed in the inner end face of the cavity wall of the liquid inflow cavity, so that a transitional step is formed between the liquid inflow cavity and the counter-bored hole. After the elastic sealing layer on the sealing end face of the valve plate makes contact and is matched with the transitional step, an axial sealing pair for achieving the axial sealing purpose can be formed. After the elastic sealing layer on the outer circumferential face of the valve plate makes contact and is matched with the hole wall of the counter-bored hole, a radial sealing pair for achieving the radial sealing purpose can be formed. The check valve is simple in structure and has the double effects of axial sealing and radial sealing, and seepage or leakage is unlikely to happen even when the fluid pressure is low.

Owner:AQUA CASTING INC

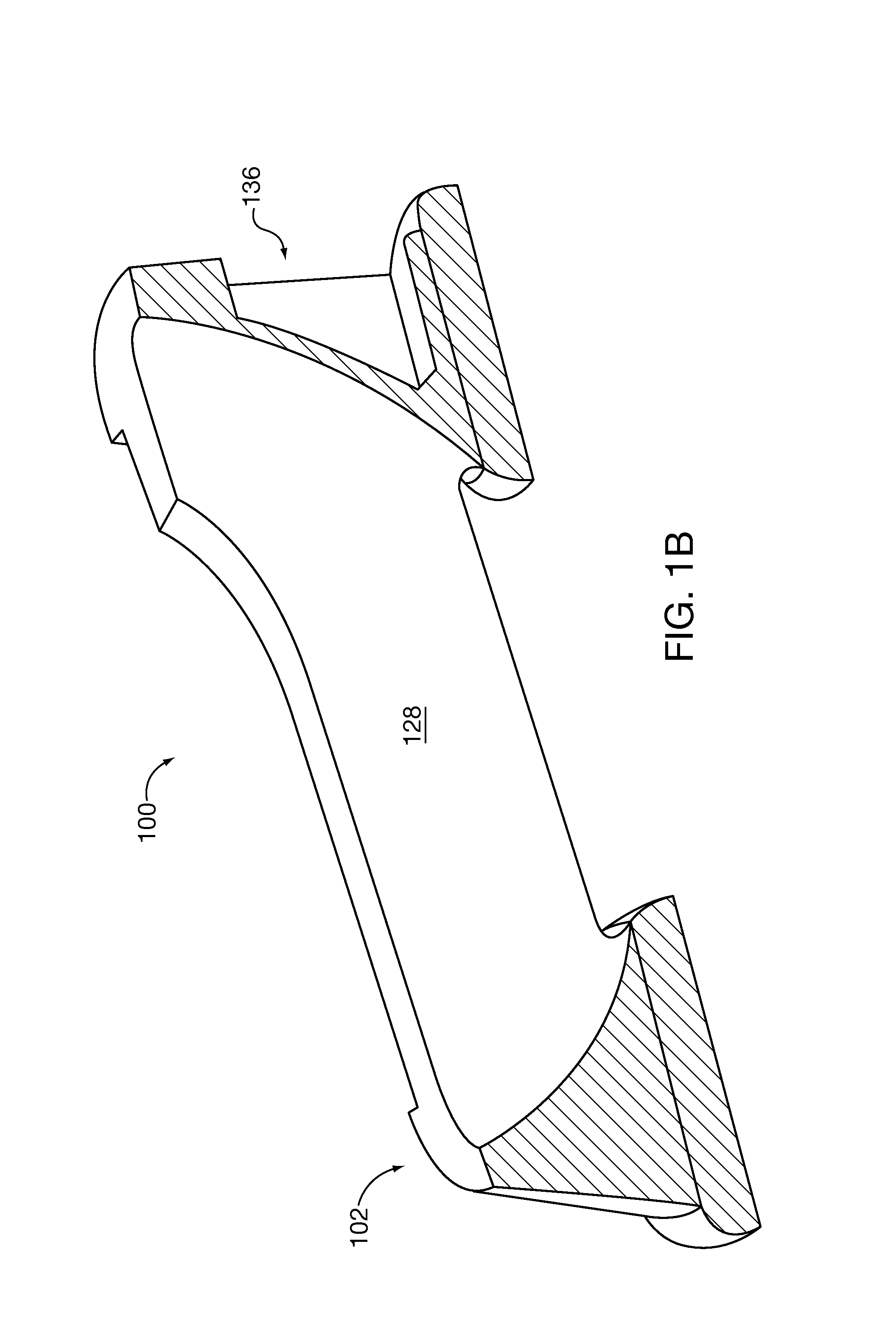

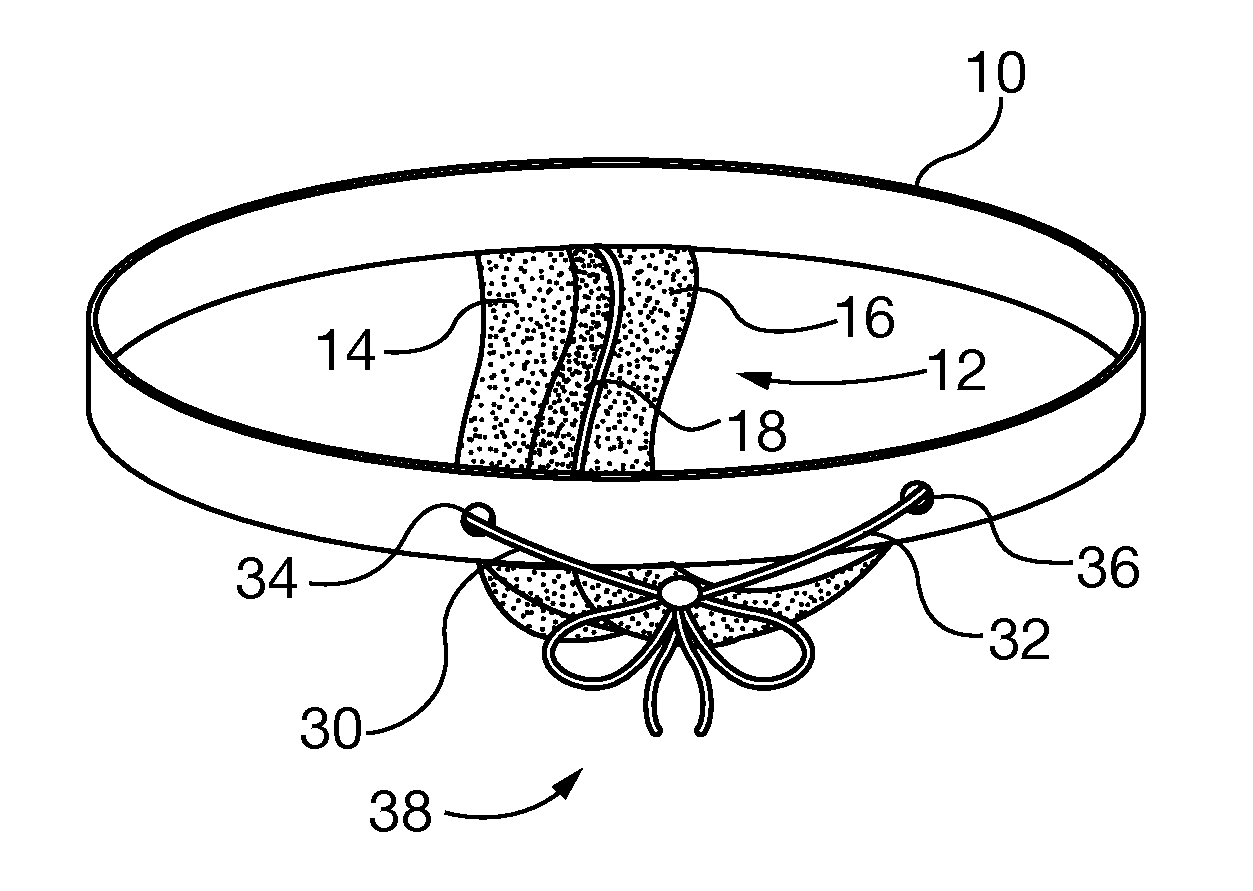

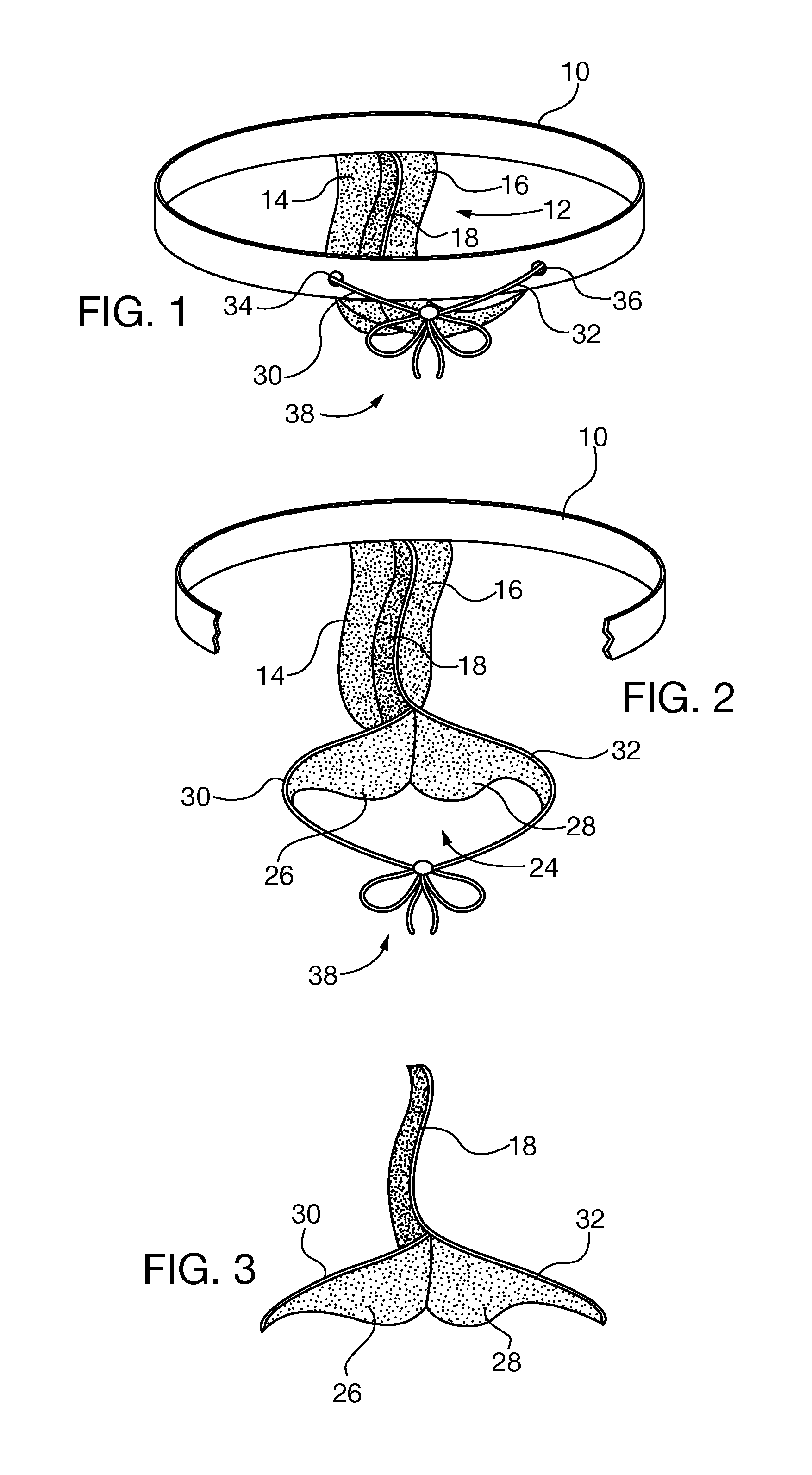

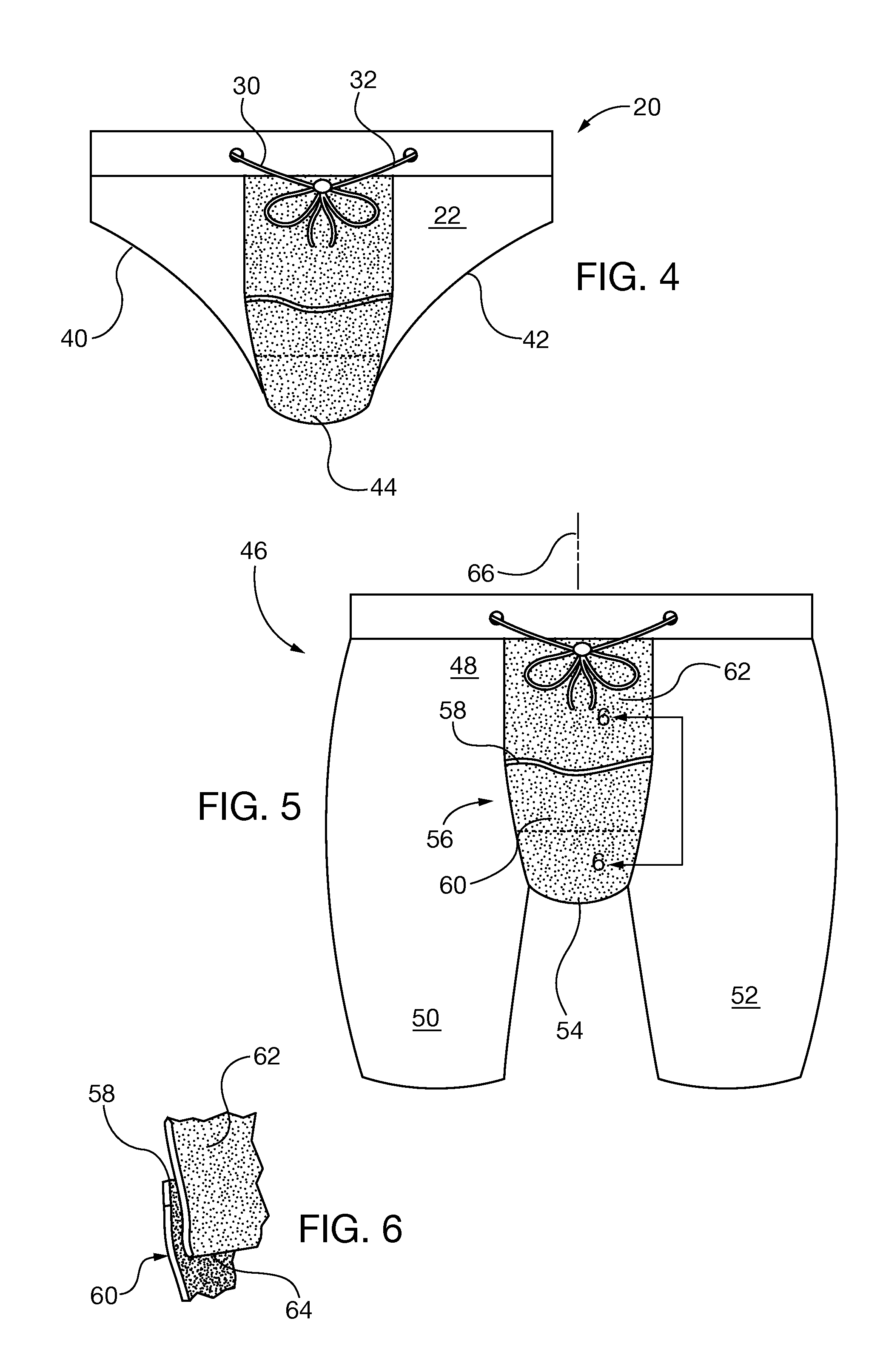

Underwear

ActiveUS20140237704A1Improve hygienePrevent buttock-to-buttock chafingAbsorbent padsUndergarmentsPenisThigh

Underwear adapted to add an inner structure to a traditional covering comprising waistband and fabric panels conventionally covering the buttocks, hips, and genital areas. The inner structure may include a fabric panel bearing a ridge intended to occupy the cleft separating the buttocks, with the fabric panel adhering closely to the buttocks. The inner structure may also or instead include a fabric scrotum guard which covers the rear of the scrotum and which separates the scrotum from the inner thighs and separates the right and left perineal folds where inner thighs meet the lowermost trunk. The scrotum guard may include adjustment structure for adjusting tightness of the fit with the Y formed at the scrotum and the entire perineum. The front of the traditional covering may have an opening for retrieving the penis which opening is arranged horizontally rather than in the traditional generally vertical orientation.

Owner:MEHRABIAN HAMLET

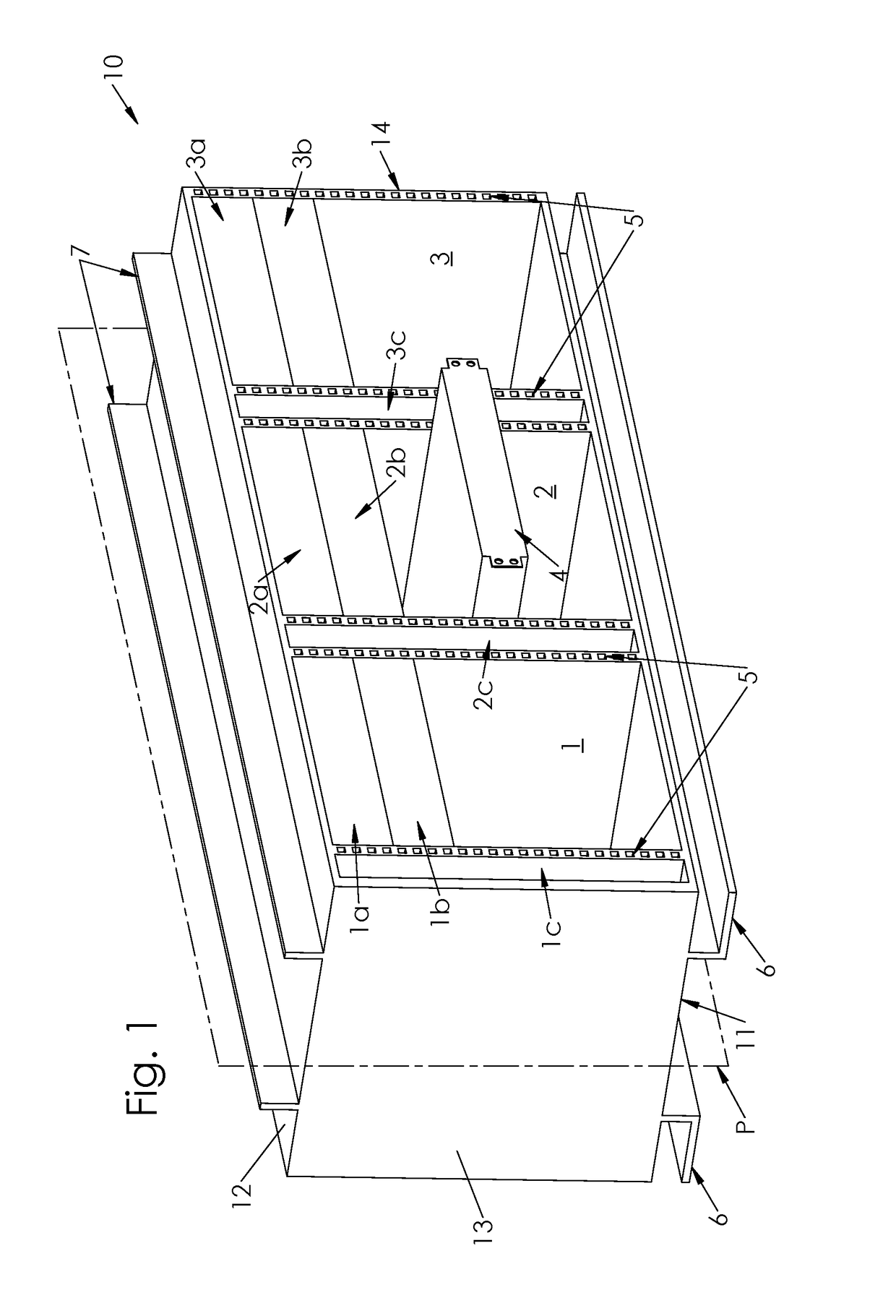

Transportable and stackable server racks

ActiveUS10219400B2Transportation safetyCooperate closelySide-by-side/stacked arrangementsServersWaste management

A server rack including a bottom panel, a top panel opposite to said bottom panel, a plurality of housing units configured for receiving rack-mountable equipment, the plurality of housing units being horizontally side-by-side arranged between the top panel and the bottom panel, the bottom panel comprising two support rails for supporting the server rack.

Owner:OVH

Rebar net cage saddle circulating plate line and preparation technology

ActiveCN111558996ARealize automatic controlCooperate closelyLiquid surface applicatorsCeramic shaping plantsProduction lineStructural engineering

The invention discloses a rebar net cage saddle circulating plate line and a preparation technology and belongs to the field of saddle rebar net cage circulating transportation lines. The rebar net cage saddle circulating plate line comprises a plurality of networking frames, a first saddle ferry bus, an anticorrosion drying crane, a drying conveying chain, a drill rod inserting machine, a secondsaddle ferry bus, a drilling rod pulling machine and an electric saddle conveyor; the networking frames are placed side by side; the networking frames, the electric saddle conveyor and the drilling rod pulling machine form a conveying path; the anticorrosion drying crane and the drill rod inserting machine are arranged above the two ends of the drying conveying chain separately to form another conveying path; the first saddle ferry bus and the second saddle ferry bus are connected with the ends of the two conveying paths separately to form a closed loop circulating path; a transferring saddleconveyor and net cages desiderating to be transferred are arranged in the closed loop circulating path; and the networking frames and the transferring speeds of other devices are cooperated, so that the circulating process is ensured to be efficient and in order; and in addition, a waxing cylinder is arranged in the rebar net cage saddle circulating plate line to prolong the service life of steeldrill rod; high-temperature steam of an autoclave in a production line is utilized, and energy consumption is reduced through wax melting due to heat exchange.

Owner:ANHUI KEDA IND CO LTD

Hair dryer flanging roll round machine

PendingCN109396234AIncrease radial sizeReduce stepsMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a hair dryer flanging roll round machine. The hair dryer flanging roll round machine comprises a machine frame, a fixed end is arranged on one side of the machine frame, and amovable end is connected to the other side of the machine frame in a transmission mode through a linear guide. The movable end moves back and forth in the direction which is close to the fixed end, afeeding mechanism is arranged on one side of the fixed end, an expansion container is arranged on the side surface, close to the movable end, of the fixed end, a first flanging roll round mechanism isarranged on one side of the expansion container, a second flanging roll round mechanism is arranged on the side surface, close to the fixed end, of the movable end, and the expansion container is intransmission connection with the fixed end through a drive mechanism. According to the hair dryer flanging roll round machine, automatic machining and production of the flanging and roll round of a hair dryer is realized, positioning and clamping of the hair dryer is more convenient, two ends of the hair dryer are machined simultaneously, and the machining efficiency is further improved.

Owner:FOSHAN CITY NANHAI POPULA FAN

Automatic gear shaft machining and detecting device

ActiveCN104858702AReasonable layoutCooperate closelyMeasurement/indication equipmentsCleaning using gasesGear wheelEngineering

The invention discloses an automatic gear shaft machining and detecting device. The automatic gear shaft machining and detecting device comprises an automatic machining device, an automatic detecting device, an automatic feeding device, an automatic oil immersing device and an automatic discharging conveying device. Workpieces which pass machining detection sequentially pass through the automatic feeding device, the automatic machining device, the automatic detecting device, the automatic oil immersing device and the automatic discharging conveying device. Workpieces which do not pass machining detection sequentially pass through the automatic feeding device, the automatic machining device and the automatic detecting device. The automatic gear shaft machining and detecting device is reasonable in layout, all the devices closely work together, the processes of gear shaft machining and detecting are combined effectively, and the automation degree and the production efficiency are greatly improved.

Owner:TATUNG GEAR KUNSHAN

Guider for flaky object conveying

ActiveCN106097567ASimple structureSimple structural designCoin/currency accepting devicesArticle feedersEngineeringElectromagnet

The invention discloses a guider for flaky object conveying, comprising a reversing blade assembly, a power drive assembly matching the reversing blade assembly, and a channel arranged outside the reversing blade assembly. The power drive assembly comprises a power drive assembly frame, a two-way electromagnet assembly and a power motor assembly. The two-way electromagnet assembly and the power motor assembly are arranged on the power drive assembly frame. The two-way electromagnet assembly and the power motor assembly drive the power drive assembly to rotate and reverse. The reversing blade assembly and the channel form a conveying channel when the reversing blade assembly rotates and reverses. The guider for flaky object conveying has the advantages of reasonable and simple structure design, low production cost, easy-to-control precision, and easy operation.

Owner:广州智清电子科技有限公司

Portable Bicycle Stand

A stand for a bicycle having a wheel, which stand holds the bicycle in an upright position of use on a horizontal surface. The stand comprises a trough having an upwardly open receptacle which is dimensioned and configured to receive the wheel in close cooperation therewith. One or more feet may be manually coupled to the trough to project laterally therefrom to steady the trough on the horizontal surface. The feet may slide fit to the trough, fasten by threaded fasteners, or may fold for stowage within the trough and swing out into a deployed position. The trough may include a storage compartment for bicycle tools and repair materials.

Owner:PARKINS HOWARD

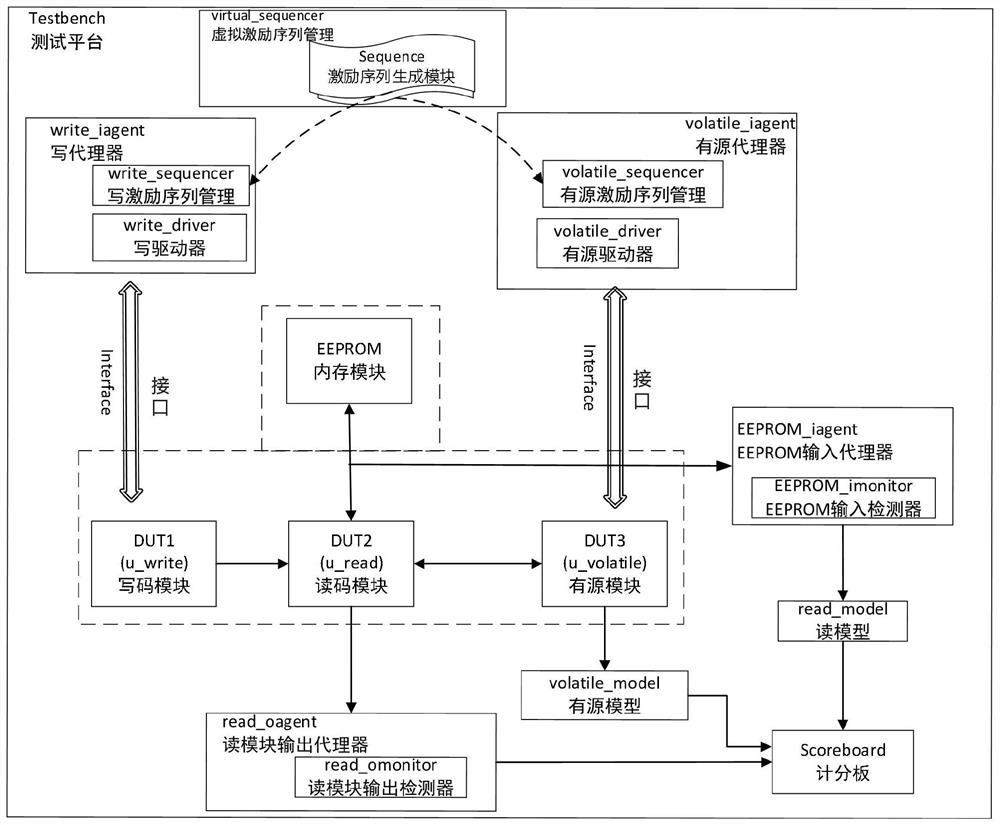

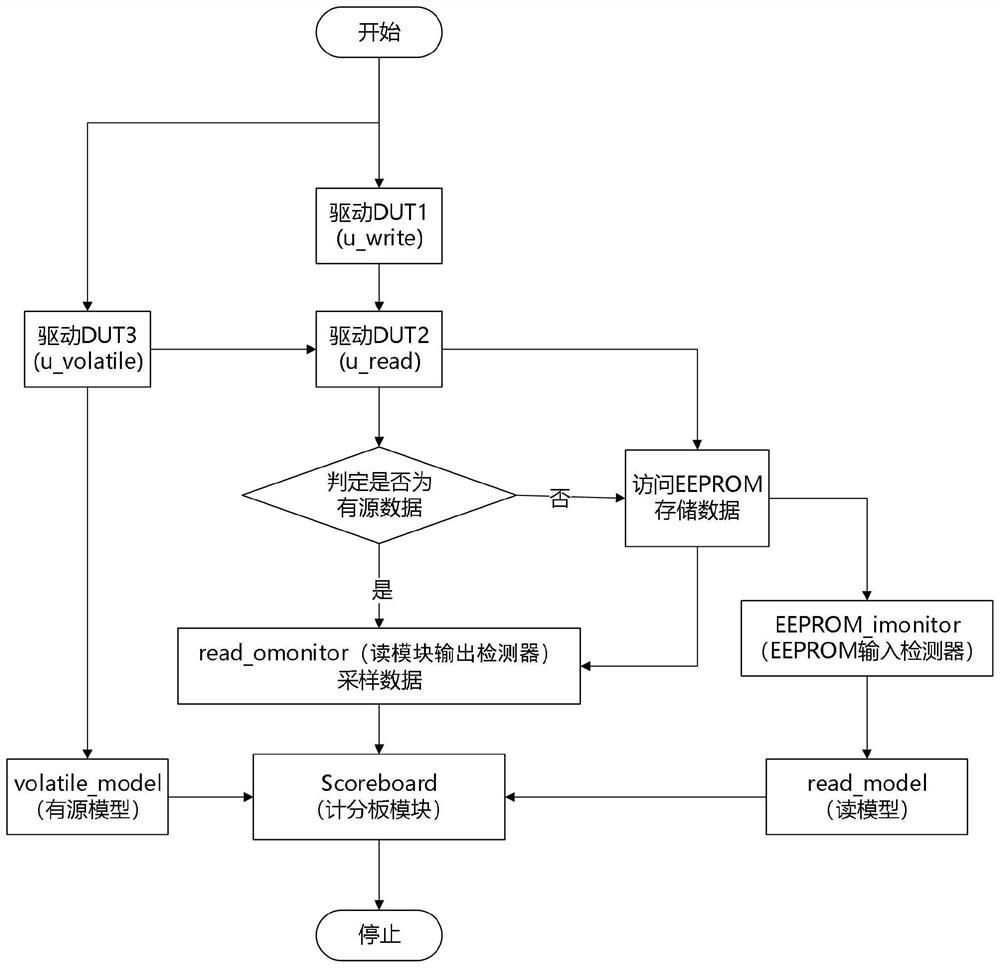

UVM-based transponder chip multi-module synchronous verification platform and verification method

PendingCN114036013AImprove verification efficiencyVerify closeFunctional testingTransmissionTest designComputer architecture

The invention discloses a UVM-based transponder chip multi-module synchronous verification platform and verification method. Linkage among a plurality of modules in the working process of the transponder chip is considered; a code writing module, a code reading module and an active module of the transponder chip are simultaneously instantiated into a to-be-tested design DUT for simulation verification; the mutual cooperation operation relation between modules of the transponder chip is better met, and simulation closer to the actual environment can be achieved. The three modules are verified as a whole; compared with verification by a single module, part of external interfaces are changed into internal interface signals, and the number of interface excitation needing to be applied is reduced; meanwhile, signal matching between the modules is closer, and matching output of one module to the other module is needed; during debugging, signals need to be observed in a combined manner, and the coordination and consistent work of the three modules of the transponder is embodied. Functional modules in a plurality of transponder chips can be verified at the same time, and the verification efficiency of the transponder chips can be improved.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com