Light and environmentally-friendly type PVC artificial leather production technology

A production process and artificial leather technology, applied in the field of lightweight and environmentally friendly PVC artificial leather production process, can solve the problems of low efficiency of manufacturing equipment and process flow, low degree of automation, and personnel safety threats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

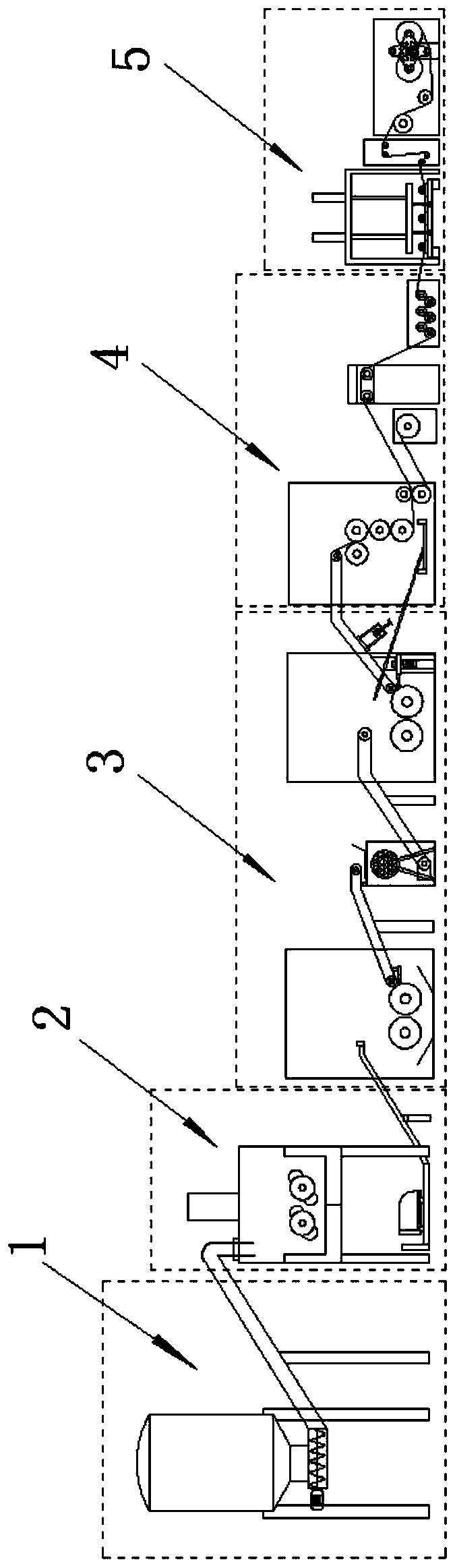

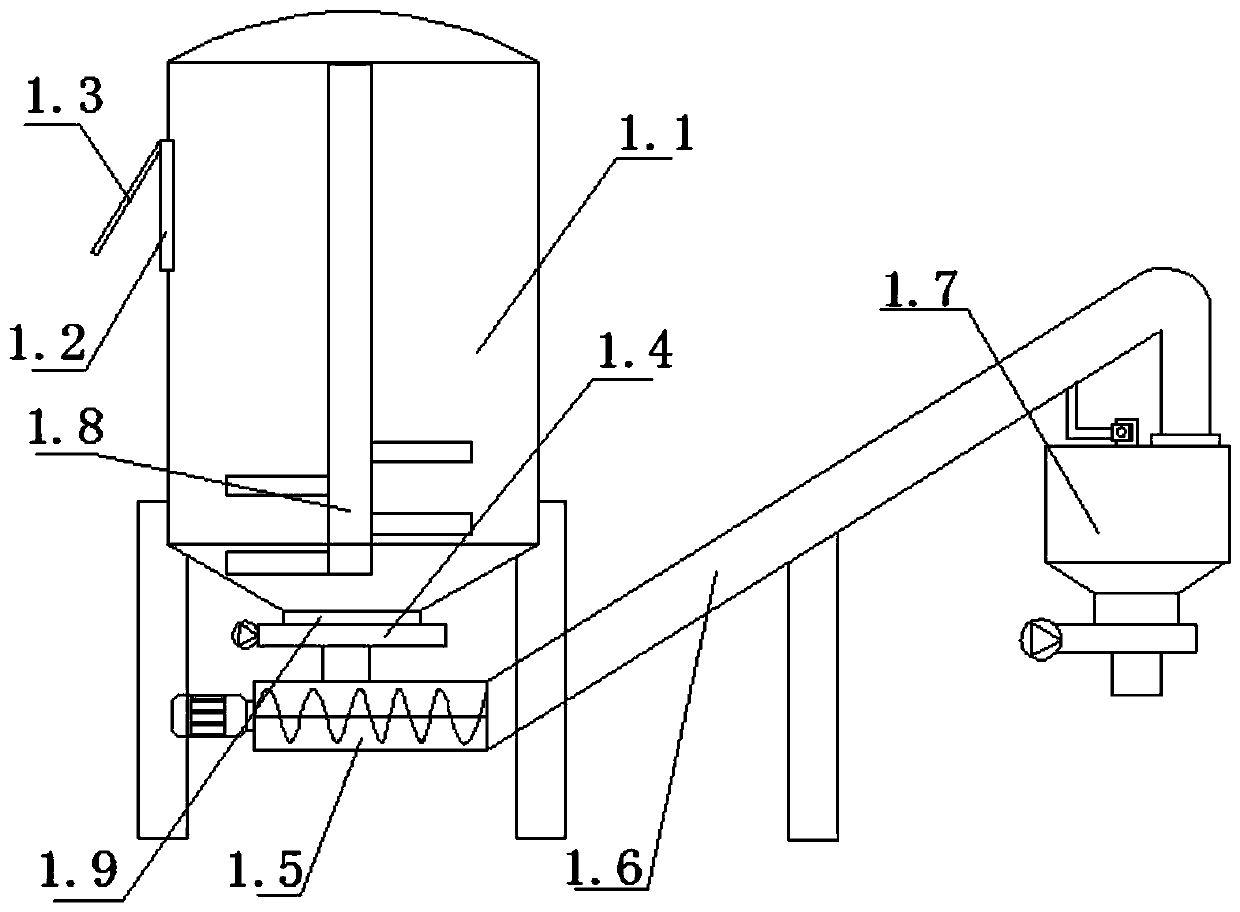

[0063] see Figure 1-19 , a kind of lightweight environment-friendly type PVC artificial leather production process that the present invention relates to, described process step is:

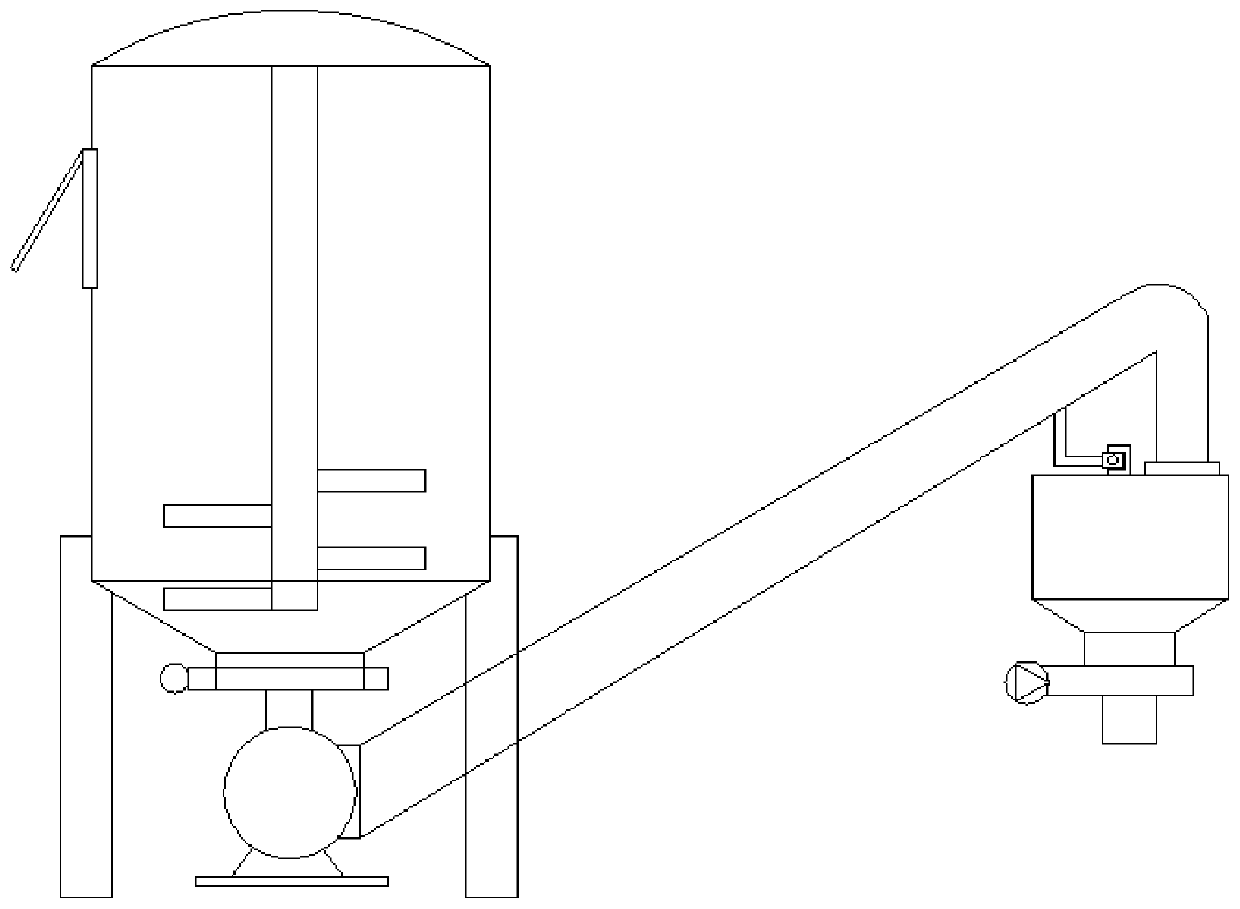

[0064] Step 1. Feeding: The three raw materials required for refining, including PVC granules, grease additives and calcium powder, are transported to the internal mixing mechanism 2 synchronously through the corresponding feeding mechanism 1 according to the proportion, and the PVC granules and calcium powder are conveyed to the feeding mechanism 1 of the extruder through the conveying device 1.5, and the grease additive is conveyed to the feeding mechanism 1 of the lift pump through the conveying device 1.5;

[0065] Step 2, internal mixing: the three raw materials are transported to the internal mixing mechanism 2, and the raw materials are squeezed and sheared by two relatively rotating rotors 2.4, and the various raw materials are fully mixed; after internal mixing, the gelatinous PVC The mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com