Aerated concrete plate material circulation system and preparation process

A technology of aerated concrete and circulation system, which is applied to conveyor objects, cranes, walking bridge cranes, etc. It can solve the problems of low production efficiency and low degree of automation, so as to improve production efficiency, reduce labor intensity and improve circulation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

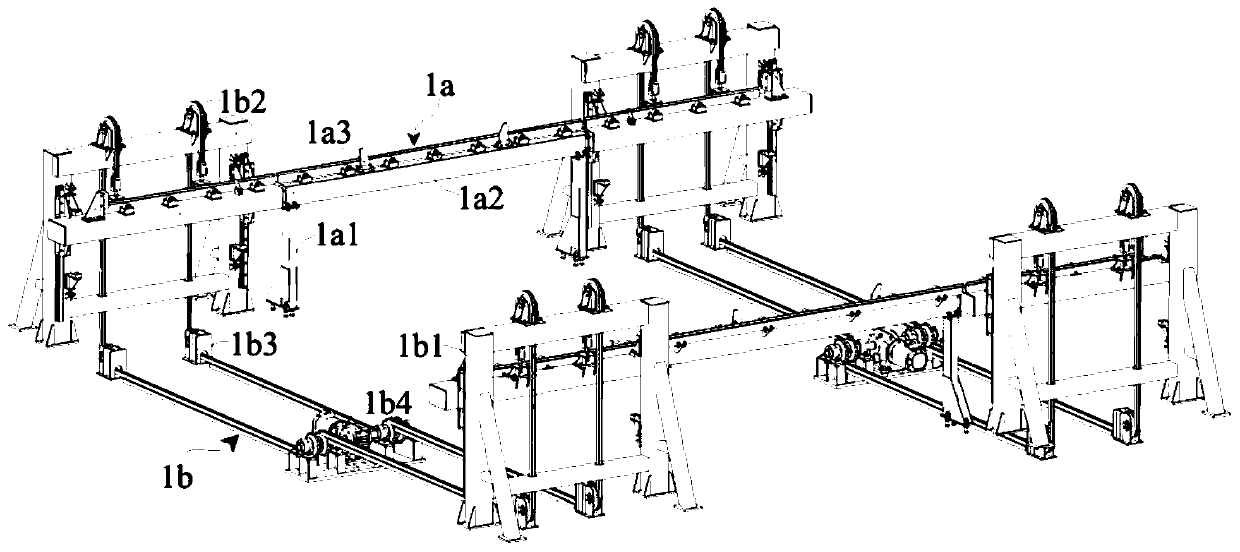

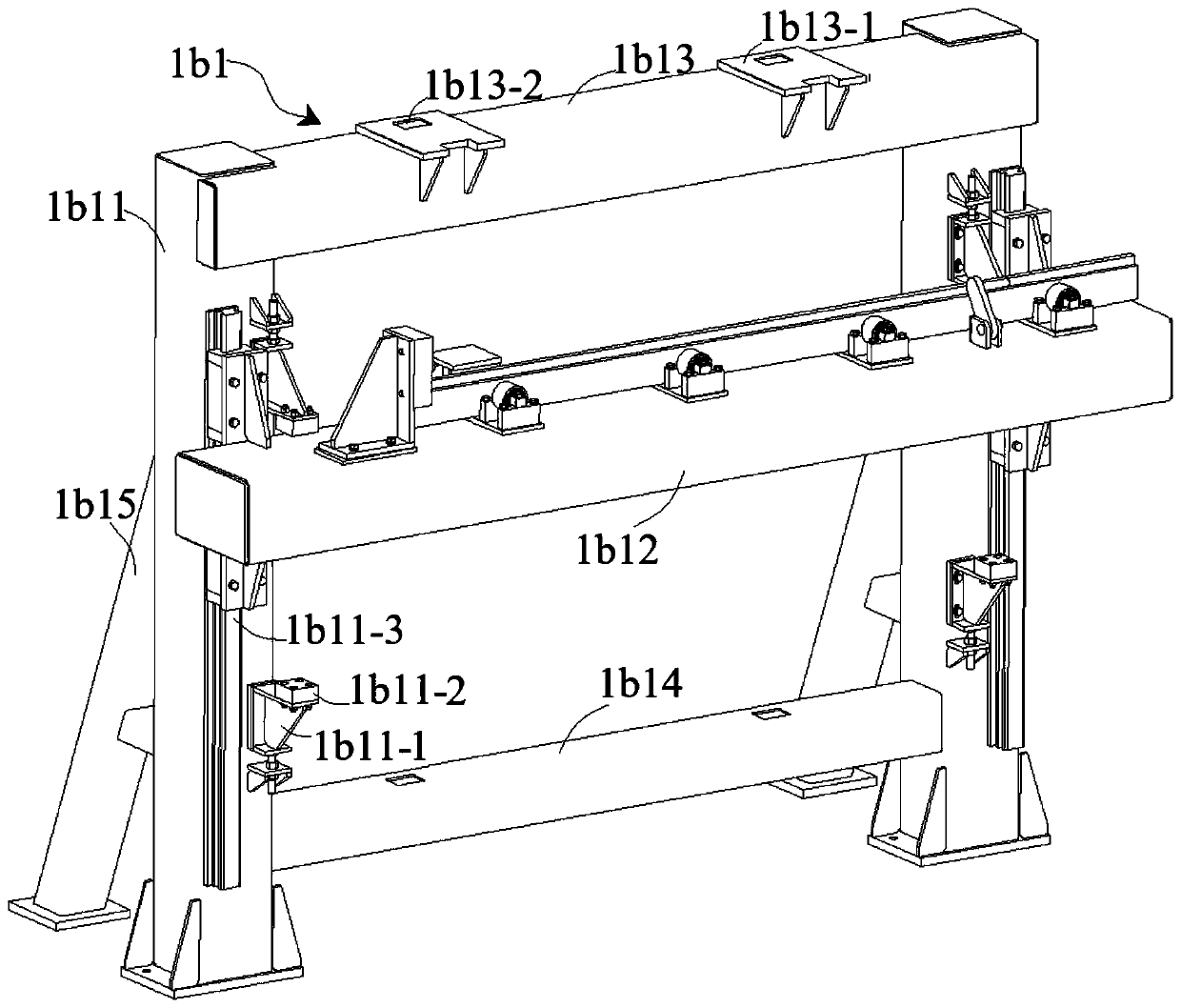

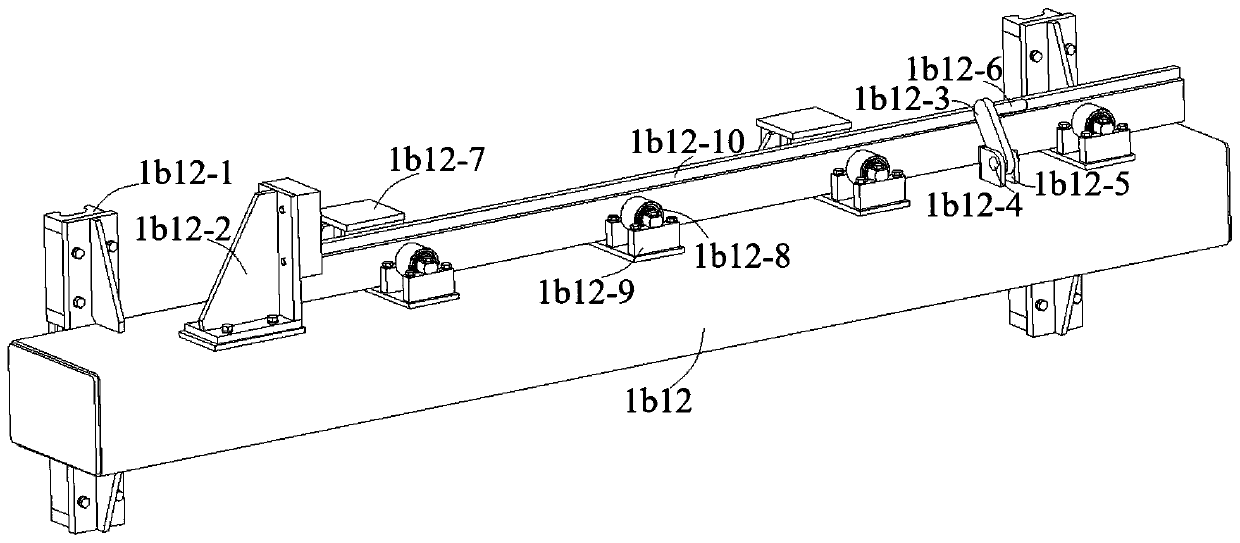

[0059] combine figure 1 with figure 2 , a height-adjustable aerated concrete slab reinforced mesh cage network frame in this embodiment includes a fixed unit 1a and a movable unit 1b, and two movable units 1b are arranged side by side with the fixed unit 1a, respectively located in the fixed unit Both sides of 1a. The movable unit 1b includes an adjustment assembly 1b1, a sprocket assembly one 1b2, a sprocket assembly two 1b3 and a drive assembly 1b4, the chain 1b45 of the drive assembly 1b4 bypasses the sprocket assembly two 1b3 and the sprocket assembly one 1b2, and is connected to the adjustment The movable beam 1b12 of the assembly 1b1 is driven by the drive assembly 1b4 to reciprocate in the vertical direction, and the saddle seat 12 reciprocates in the horizontal direction along the fixed beam 1a2 and the movable beam 1b12 of the fixed unit 1a.

[0060] The adjustment assembly 1b1 is provided with two, which are placed opposite to each other, and the distance between ...

Embodiment 2

[0072] to combine Figure 9 with Figure 10 , a circulation system for aerated concrete slabs in this embodiment, including a network frame 1, a cage transfer crane 2, an anti-corrosion dipping tank 3, an electric saddle conveyor unit, a drying box 5, a brazing machine 6, and a mold car 7. Brazing machine 8 and wax dipping cylinder 9, the electric saddle conveyor unit includes electric saddle conveyor one 4, electric saddle conveyor two 10 and electric saddle conveyor three 11, electric saddle conveyor unit It has its own transmission device, which drives the chain to move through the sprocket, and then drives the saddle seat 12 placed on the chain to move, and the moving speed can be adjusted according to production requirements.

[0073] Among them, the electric saddle conveyor three 11 is connected end to end with the electric saddle conveyor two 10, and the brazing machine 8 moves on the walking beam 81 of the brazing machine, and its moving direction is parallel to the c...

Embodiment 3

[0079] A kind of air-entrained concrete slab cyclic preparation process of this embodiment utilizes the circulatory system described in Embodiment 2, and its steps are:

[0080] Step 1. Before the cycle starts, install the saddle frame 13 on the saddle frame seat 12, install the steel drill 14 on the saddle frame 13, place the assembled saddle frame seat 12 on the electric saddle frame conveyor 2 10 and the electric saddle frame Conveyor No. 3 11, under the action of its transmission device, it is transported to the bottom of cage transfer crane 2, and it is accurately positioned by electrical control;

[0081] Step 2: The cage transfer crane 2 lifts the saddle frame 12 from the electric saddle conveyor 3 11 to the network frame 1, and manually pushes the saddle frame 12 to the side where the steel mesh cage 15 is not installed Unit 1b, then push the saddle seat 12 that has installed the steel mesh cage 15 to the fixed unit 1a directly below the cage transfer crane 2, and accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com