Rebar net cage saddle circulating plate line and preparation technology

A steel mesh and saddle frame technology, which is applied in the direction of manufacturing tools, wire processing, wire mesh, etc., can solve the problems of using more manpower and low degree of automation, and achieve the goals of improving production efficiency, low labor intensity, and saving labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

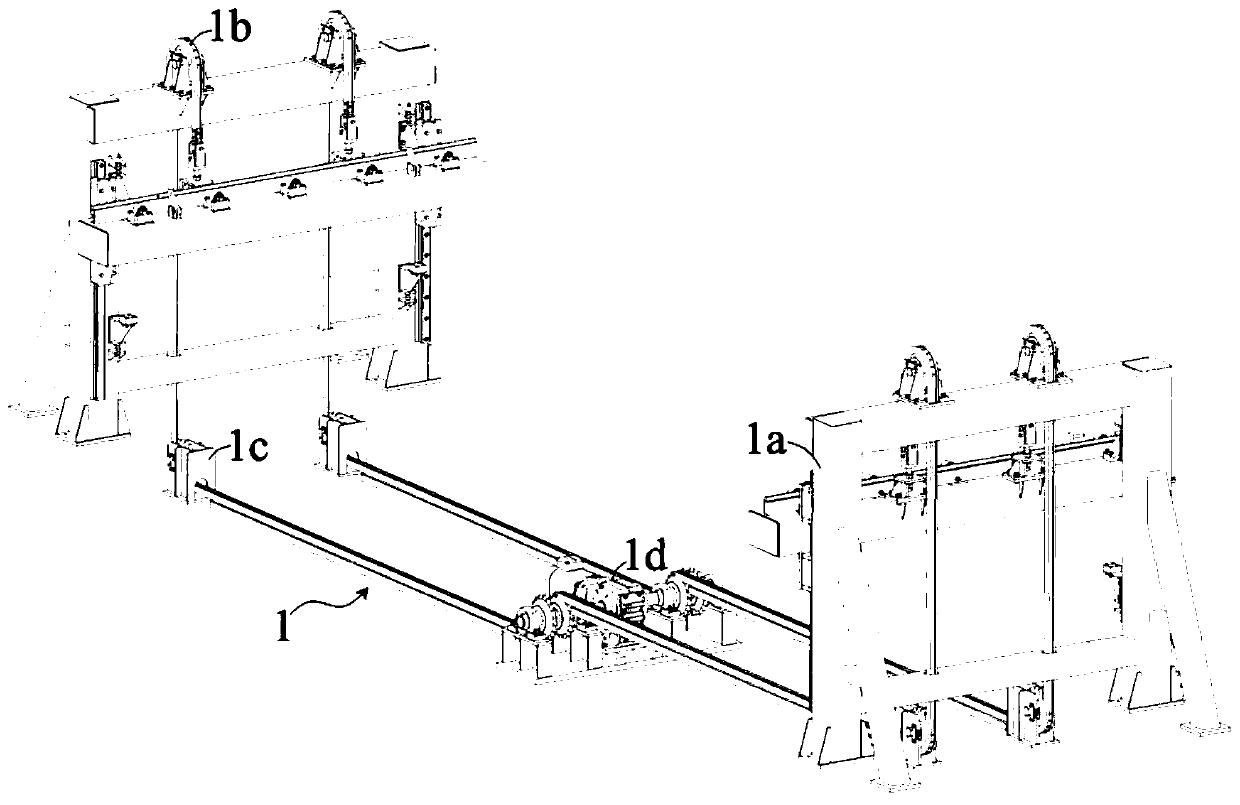

[0056] combine figure 1 with figure 2 , a height-adjustable aerated concrete slab reinforced mesh cage network frame of the present embodiment includes an adjustment assembly 1a, a sprocket assembly 1b, a sprocket assembly 2 1c and a drive assembly 1d, and the chain of the drive assembly 1d 1d5 bypasses the first sprocket assembly 1b and the second sprocket assembly 1c, and is connected to the movable beam 1a2 of the adjustment assembly 1a. Driven by the drive assembly 1d, the movable beam 1a2 reciprocates in the vertical direction and is placed on the movable beam 1a2 The saddle seat 14 can move in the horizontal direction along the movable beam 1a2.

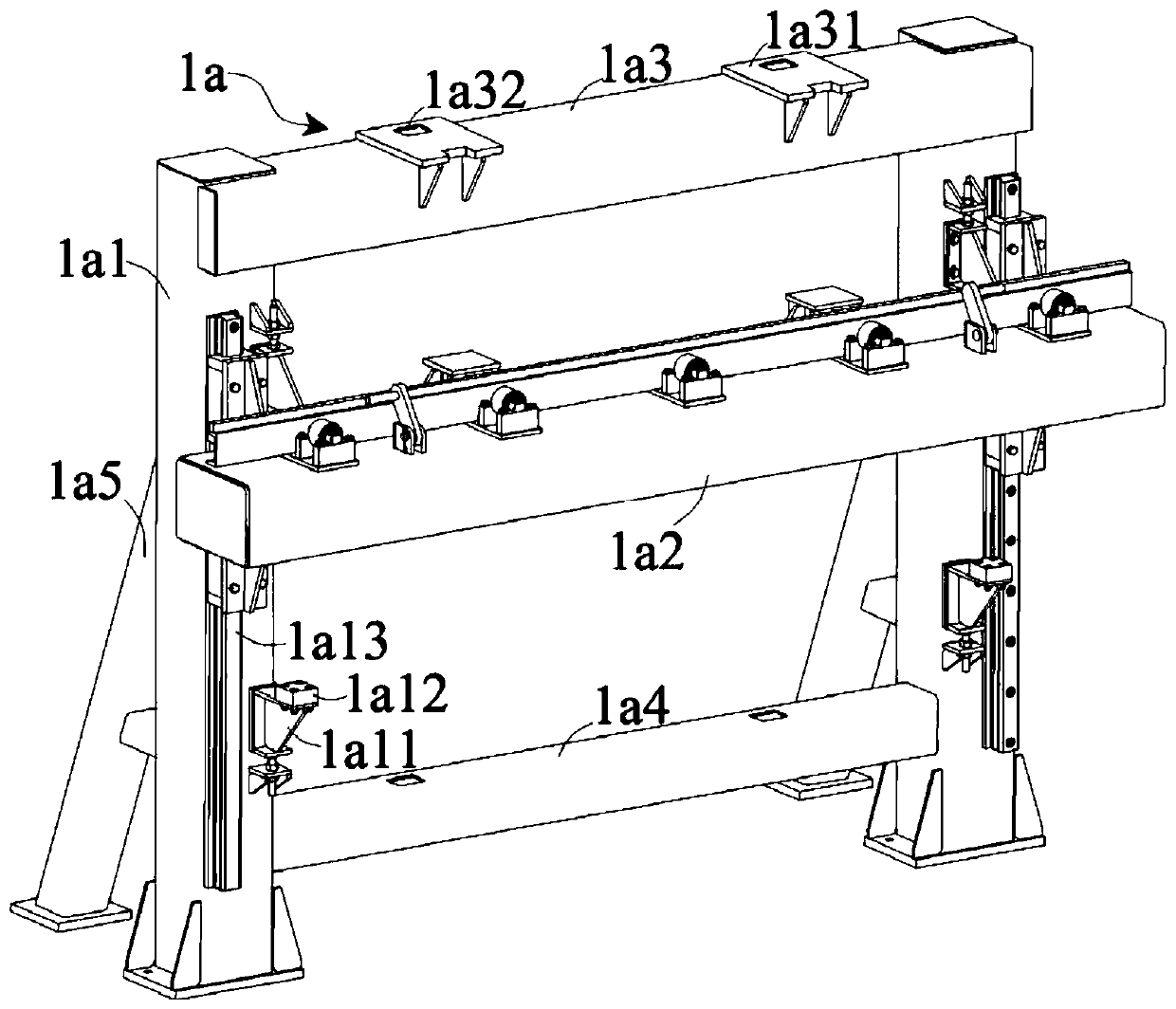

[0057] The adjustment assembly 1a is provided with two, which are placed opposite to each other, and the distance between them matches the length of the saddle seat 14. The adjustment assembly 1a also includes a column 1a1, a top beam 1a3 and a crossbeam 1a4, and there are two columns 1a1, Installed on the embedded board on ...

Embodiment 2

[0067] combine Figure 7 with Figure 8 , a kind of reinforced mesh cage saddle frame circulating plate line of the present embodiment, comprising a network frame 1, a saddle frame ferry car-2, an anti-corrosion drying crane 3, an anti-corrosion dipping tank 4, a drying conveyor chain 5, and a drying box 6. Brazing machine 7, mold car 8, saddle ferry car 2 9, brazing machine 10, wax dipping cylinder 11, electric saddle conveyor 12 and transfer saddle conveyor 13.

[0068]Network frame 1 is provided with a plurality of side by side, and its spacing is less than the width of saddle frame seat 14, and the spacing between the network frame frame 1 that is close to each other and electric saddle frame conveyor 12 is less than the width of saddle frame seat 14, makes saddle frame seat 14 can be transported along the rails of a plurality of network frames 1 and electric saddle conveyors 12, and the brazing machine 10 walks on the walking beam 101 of the brazing machine, and the heig...

Embodiment 3

[0076] A kind of sheet material preparation process of reinforced mesh cage saddle frame circulation of the present embodiment, utilizes the sheet material line described in embodiment 2, and its steps are:

[0077] Step 1. Before the cycle starts, install the saddle frame 15 on the saddle frame seat 14, install the steel braze on the saddle frame 15, and place the assembled saddle frame seat 14 on the electric saddle frame conveyor 12;

[0078] Step 2, under the action of its transmission device, transport to the network frame 1, and manually form the network on the manual saddle conveyor 18, and push the saddle seat 14 with the steel mesh cage installed on the saddle ferry car-2 ;

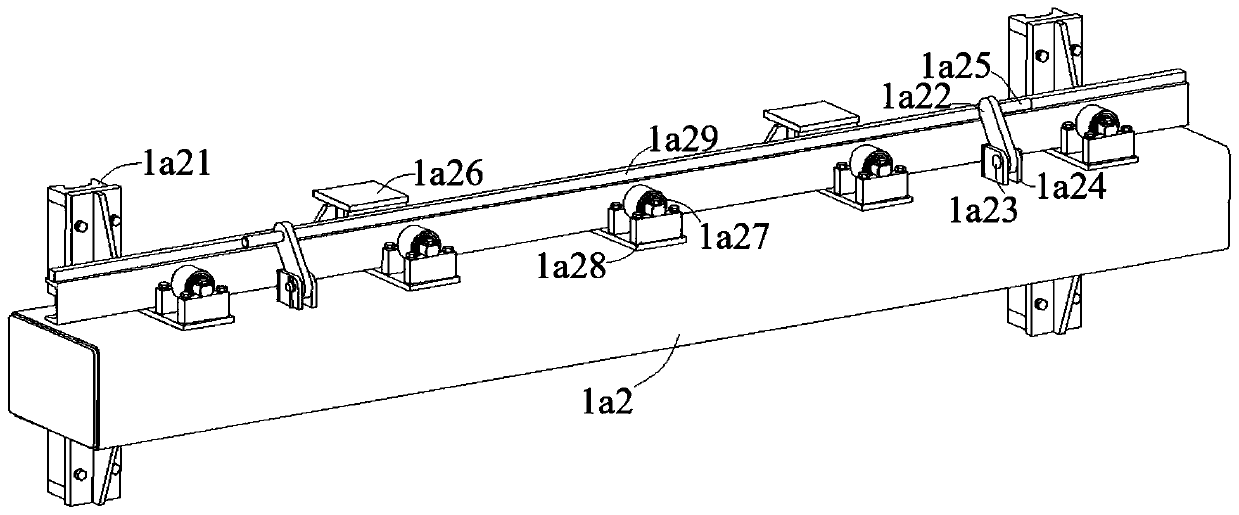

[0079] Specifically, first the movable beam 1a2 of the network frame 1 is adjusted to the height consistent with the electric saddle conveyor 12, and the baffle plate 1a22 on the movable beam 1a2 is adjusted to the state that can not hinder the saddle seat 14;

[0080] Wait for the electric sadd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com