Integrated wheel and electric vehicle with integrated wheel

A technology for electric bicycles and hubs, which is applied in the directions of hubs, vehicle components, and rider drives, etc. It can solve problems such as installation and appearance angles that are not simple and beautiful, increase the size and weight of electric vehicles, and do not consider battery charging issues, etc., to achieve effective Conducive to conduction heat dissipation, convenient charging, convenient and easy threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

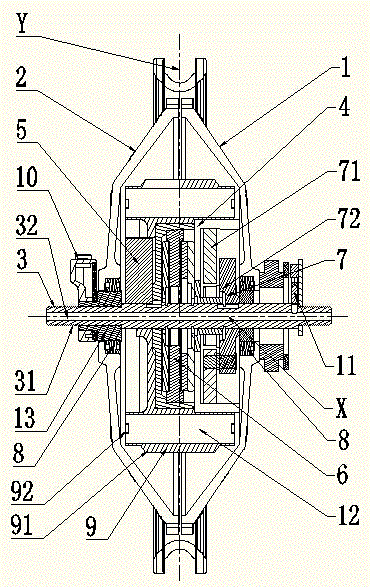

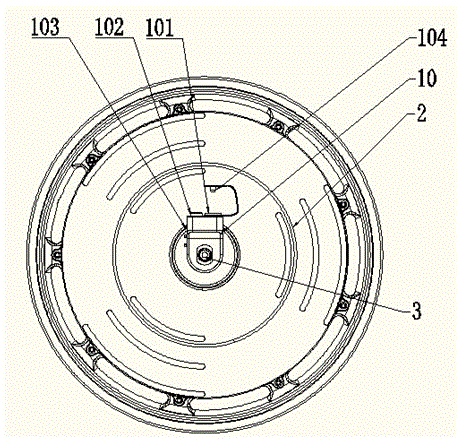

[0027] An integrated wheel disclosed by the present invention, as attached figure 1 As shown, it includes a wheel hub 1 and a wheel cover 2 matched with the wheel hub 1. The outlines of the wheel hub 1 and the wheel cover 2 are approximately shield-shaped or pot-shaped, and they take the Y axis as the axis of symmetry. The wheel hub 1 and the The wheel cover 2 is connected by several bolts and they are connected into one body to form a hollow cavity, and the center position of the wheel hub 1 and the wheel cover 2 is provided with a central hole.

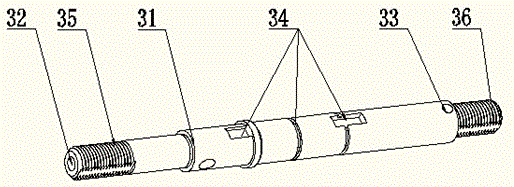

[0028] The hub 1 is provided with a coaxial shaft center 3 and an outer ring gear 4, as attached figure 2 As shown, the shaft center 3 includes a body 31, and the body 31 is provided with a through hole 32 along the X-axis direction, a wire hole 33, and a plurality of installation grooves 34, and external threads are also provided on the outer walls at both ends, so that The diameter of the through hole 32 is reasonably designed, ...

Embodiment 2

[0042] Further, the present invention also discloses an electric vehicle, the rear wheel or front wheel of the electric vehicle is the integrated wheel described in Embodiment 1, and in this embodiment, the rear wheel is preferably the integrated wheel , the front wheel is an ordinary wheel, and the electric vehicle includes a vehicle frame, which can be any one of a known ordinary bicycle or a folding bicycle or an electric vehicle frame, preferably a folding bicycle frame, and the A common front wheel is installed on the vehicle frame, the integrated wheel is installed on the vehicle frame through a quick change mechanism, and the ratchet assembly 11 on the integrated wheel is connected with the crank chainring on the bicycle through a chain.

[0043] When using this electric vehicle, the process of its remote control is the same as that described in Embodiment 1, and will not be repeated here; The crank toothed plate rotates, and the crank toothed plate drives the chain to ...

Embodiment 3

[0046] This embodiment further discloses an electric vehicle. Compared with Embodiment 2, the overall structure of this embodiment is similar to that of Embodiment 2, and the difference is that the rear wheels and front wheels of the electric vehicle are both Of course, the integrated wheel as the front wheel can omit the ratchet assembly 11, and the two integrated wheels are connected to the frame through a quick change mechanism.

[0047] When working, its control process is similar to that of Embodiments 1 and 2, the difference is that: the user can first control one of the front wheels or the rear wheels; Work is carried out, so that the battery life of the electric vehicle can be greatly increased without adding additional electric vehicle components and without changing the original structure of the electric vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com