Patents

Literature

42results about How to "Less manpower and material resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

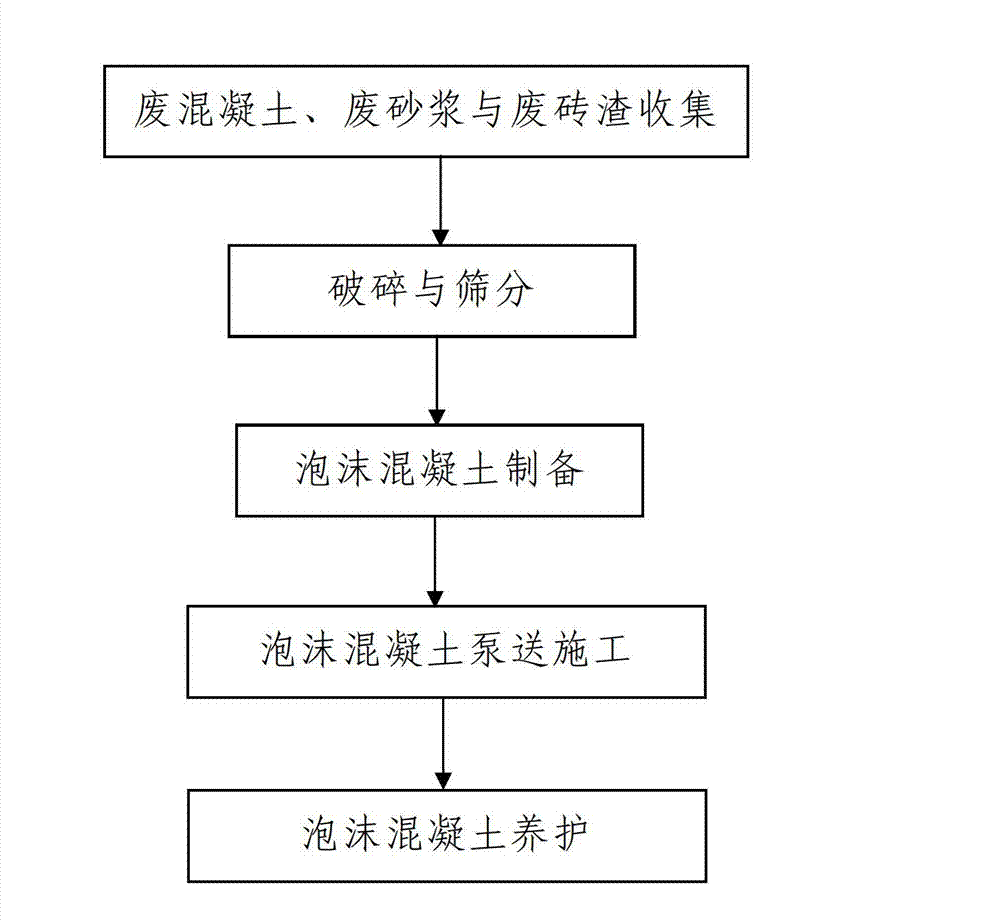

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

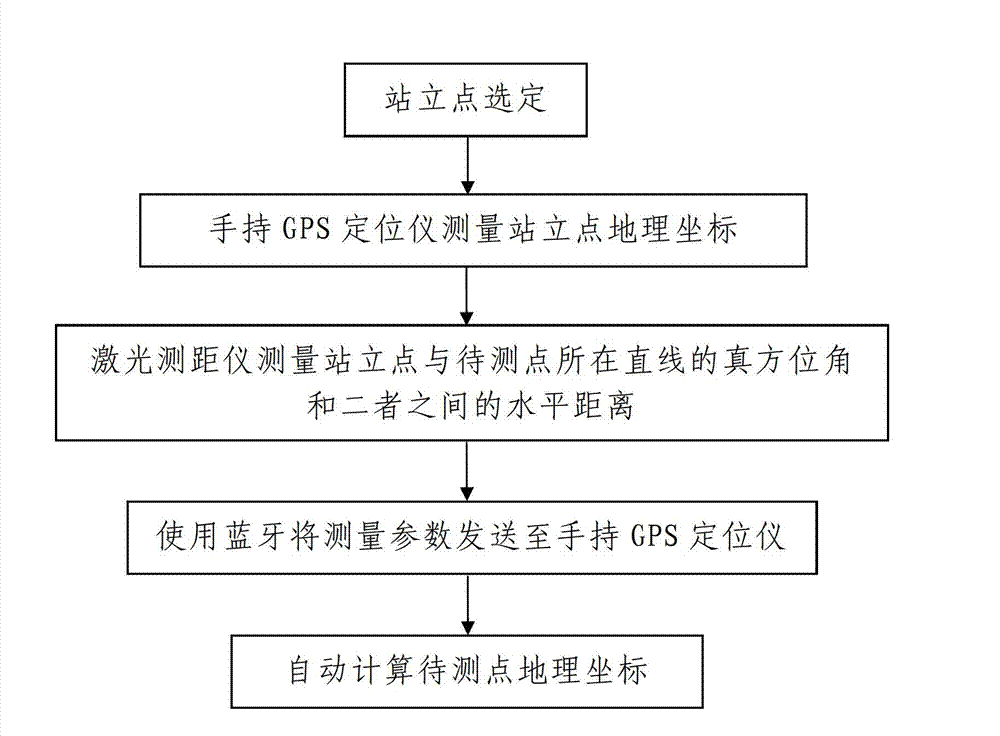

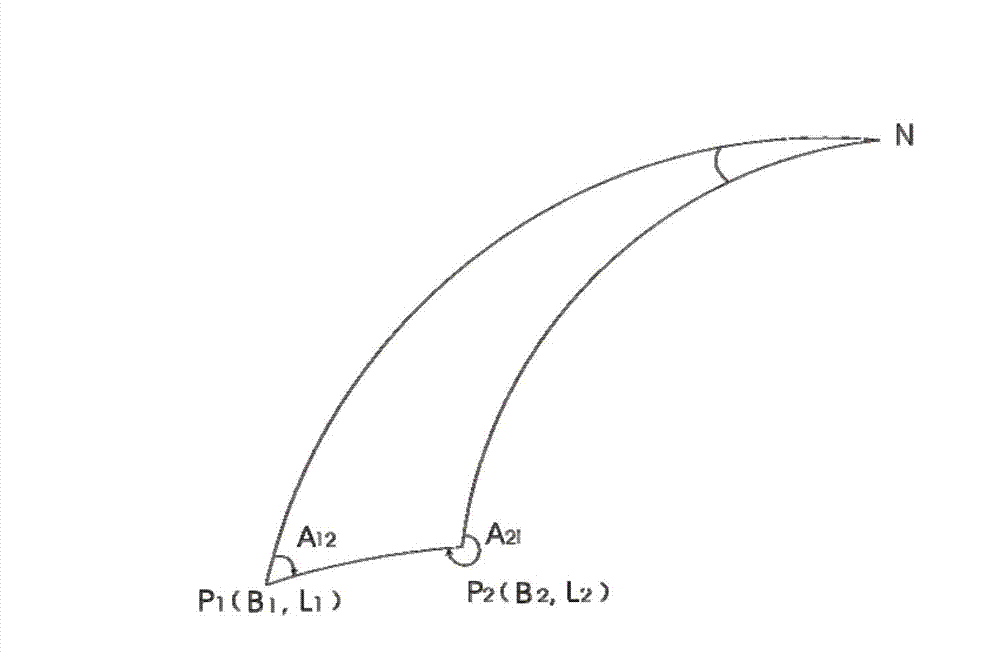

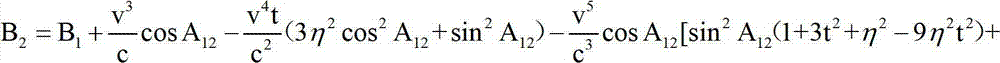

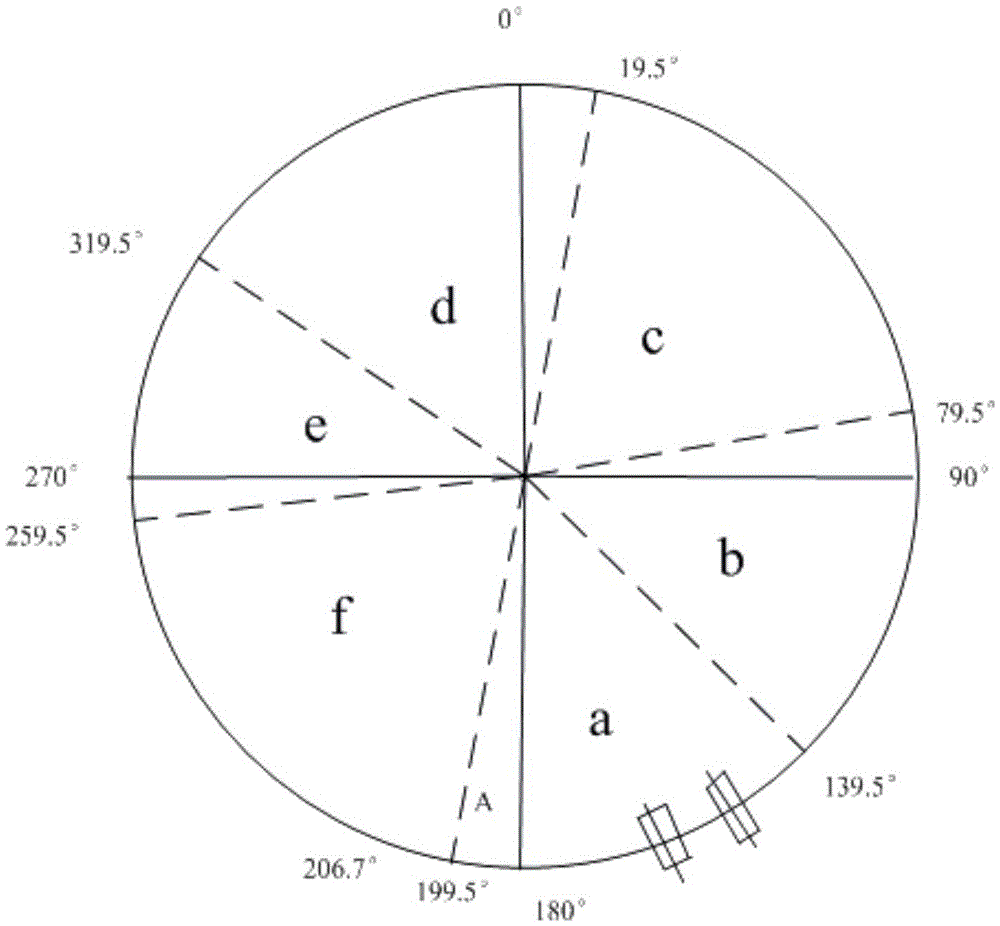

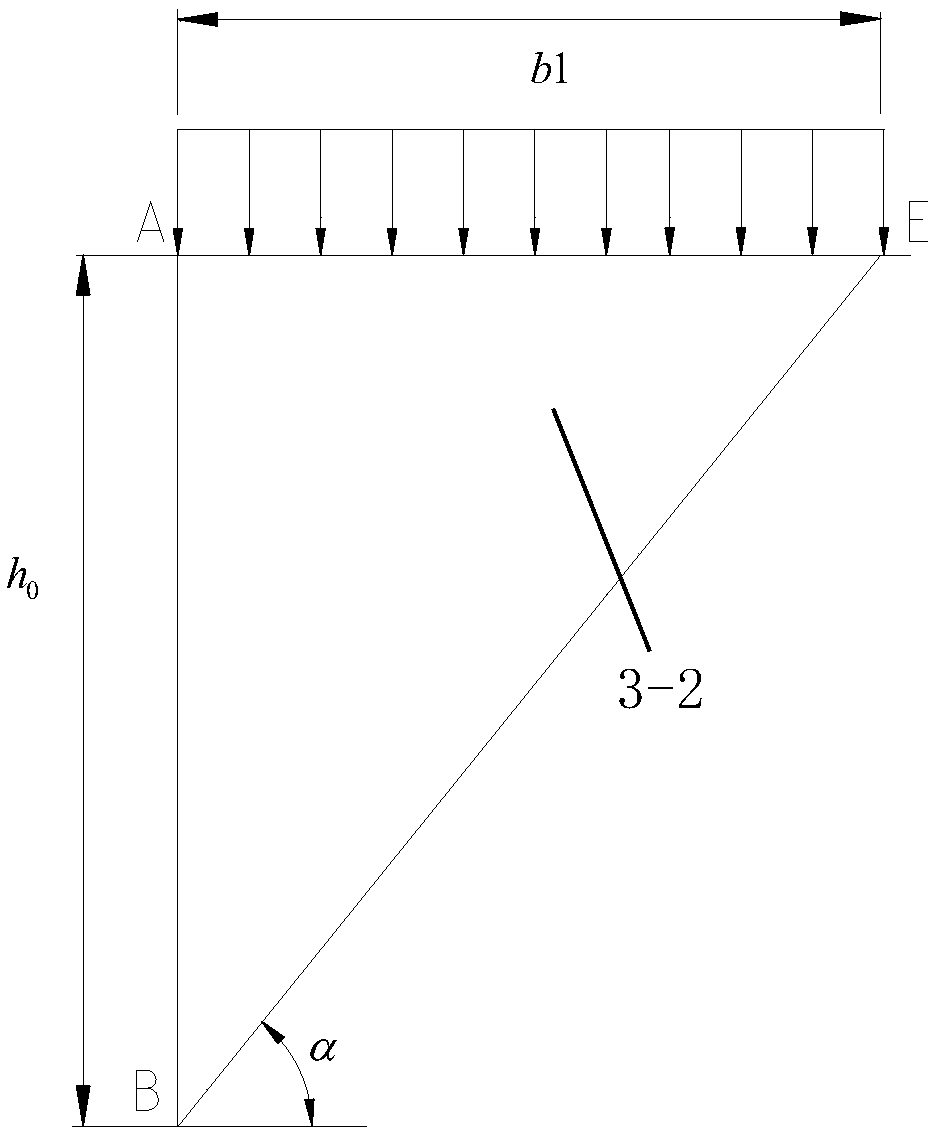

Quick measuring method based on laser ranging device

InactiveCN102829755ASimple stepsSimple and fast operationAngle measurementOptical rangefindersLaser rangingGps measurement

The invention discloses a quick measuring method based on a laser ranging device. The quick measuring method comprises the following steps of: 1, selecting a standing point, that is to say, selecting an observation point, which is beneficial for observation of a GPS (Global Positioning System), as a standing point P1 of a measuring worker; 2, measuring geographical coordinates of the standing point, that is to say, measuring geographical coordinates P1 (B1, L1) of the standing point P1 by utilizing a GPS measuring device; 3, measuring by the laser ranging device, that is to say, measuring horizontal distances s among a true azimuth angle A12 of a straight line of the standing point P1 and a point to be measured P2, the standing point P1 and the point to be measured P2 by utilizing the laser ranging device, wherein the laser ranging device is a laser ranging device provided with an electronic compass; and 4, converting the geographical coordinates of the point to be measured P2. The quick measuring method, provided by the invention, has the advantages of simple operation, convenience for implementation, quick measuring speed, high measuring precision, and capability of really realizing quick and accurate measurement of a detail point, and effectively solving the problems of slow measuring sped and difficulty in measurement of the conventional handheld GPS measuring method.

Owner:XIAN MEIHANG INFORMATION IND

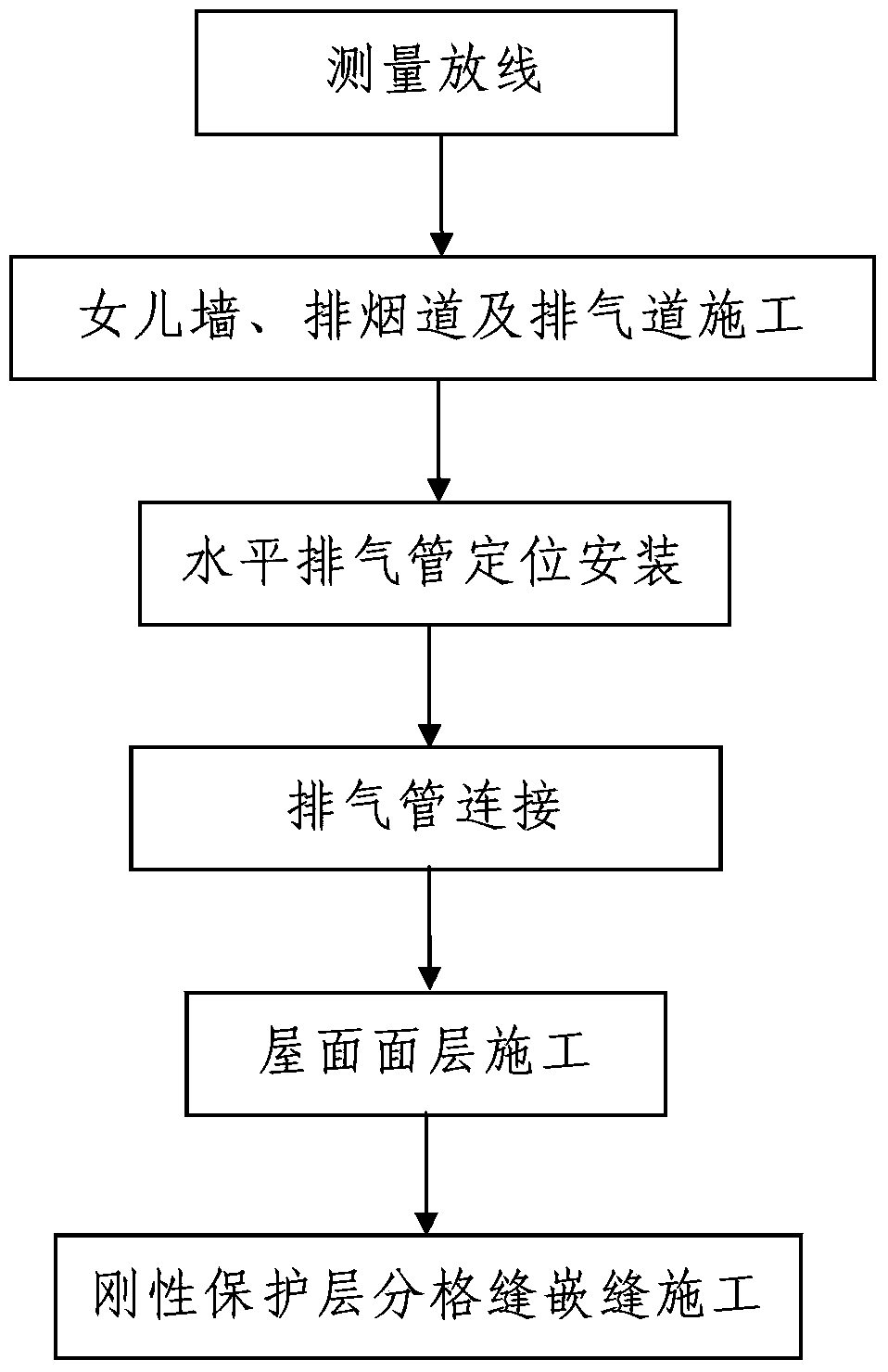

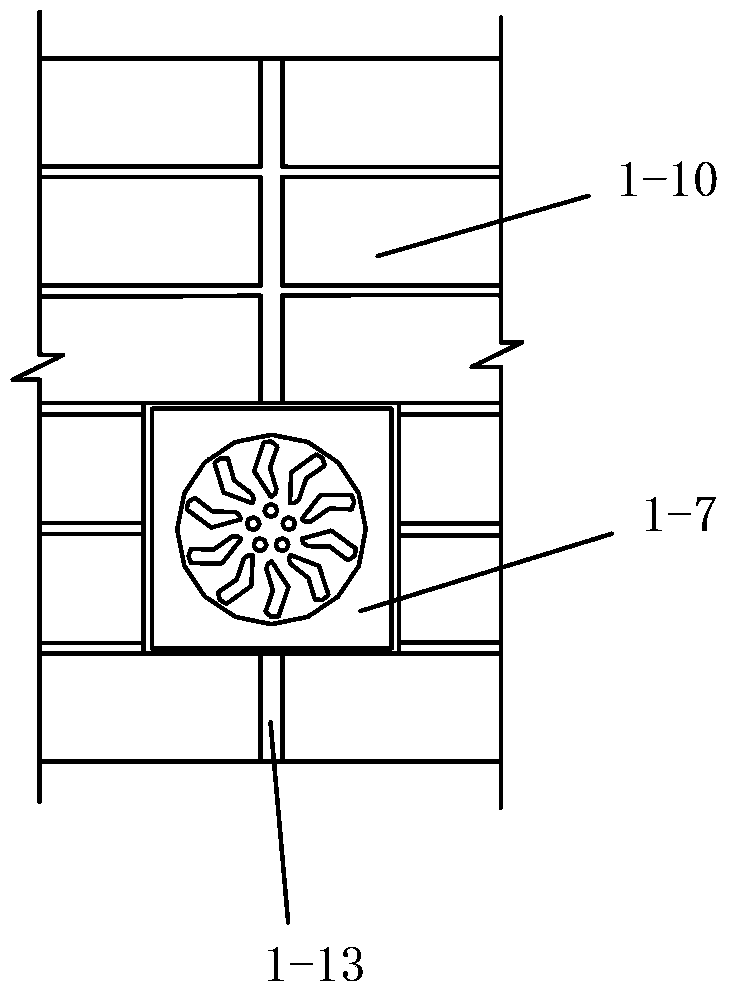

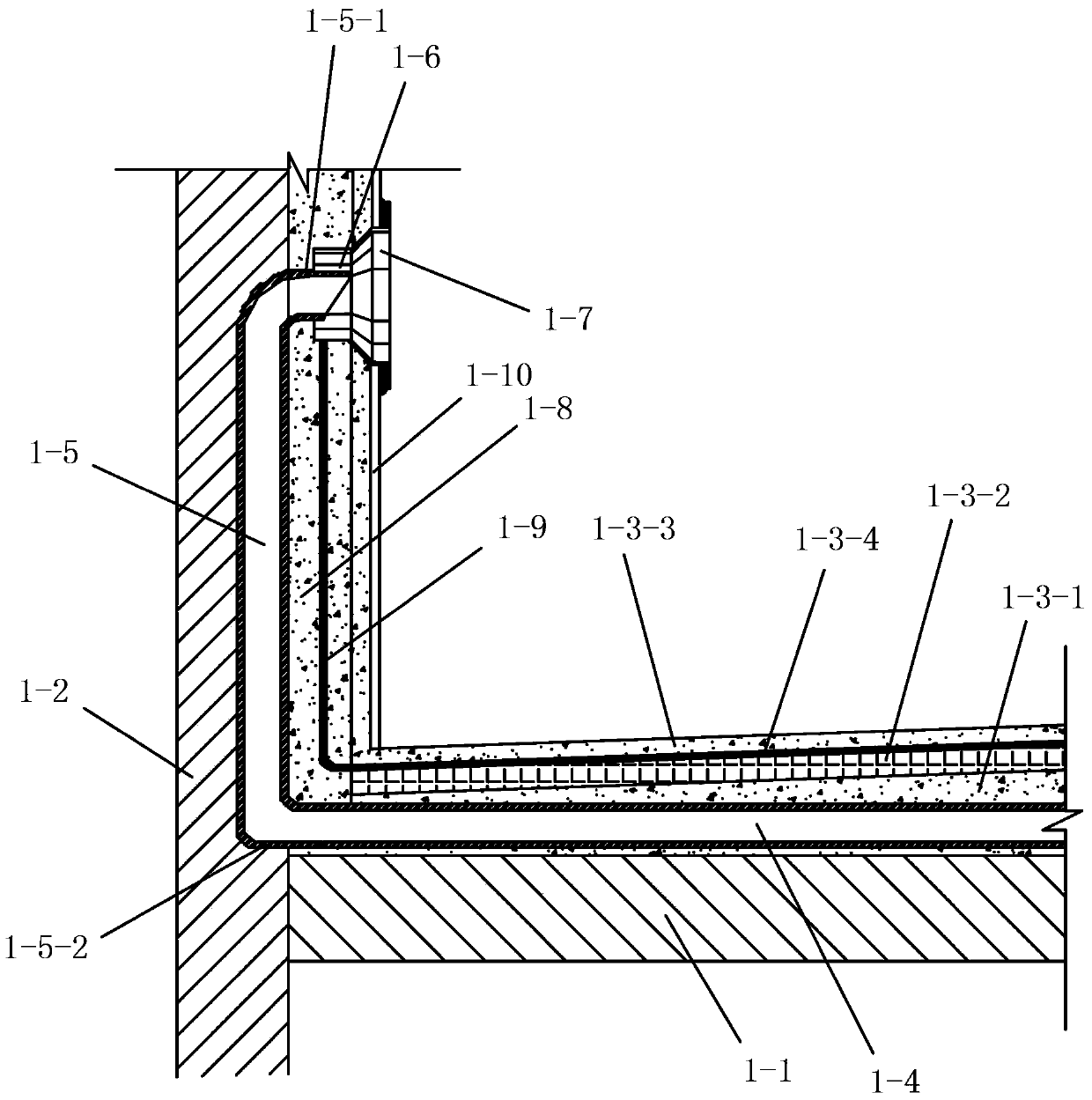

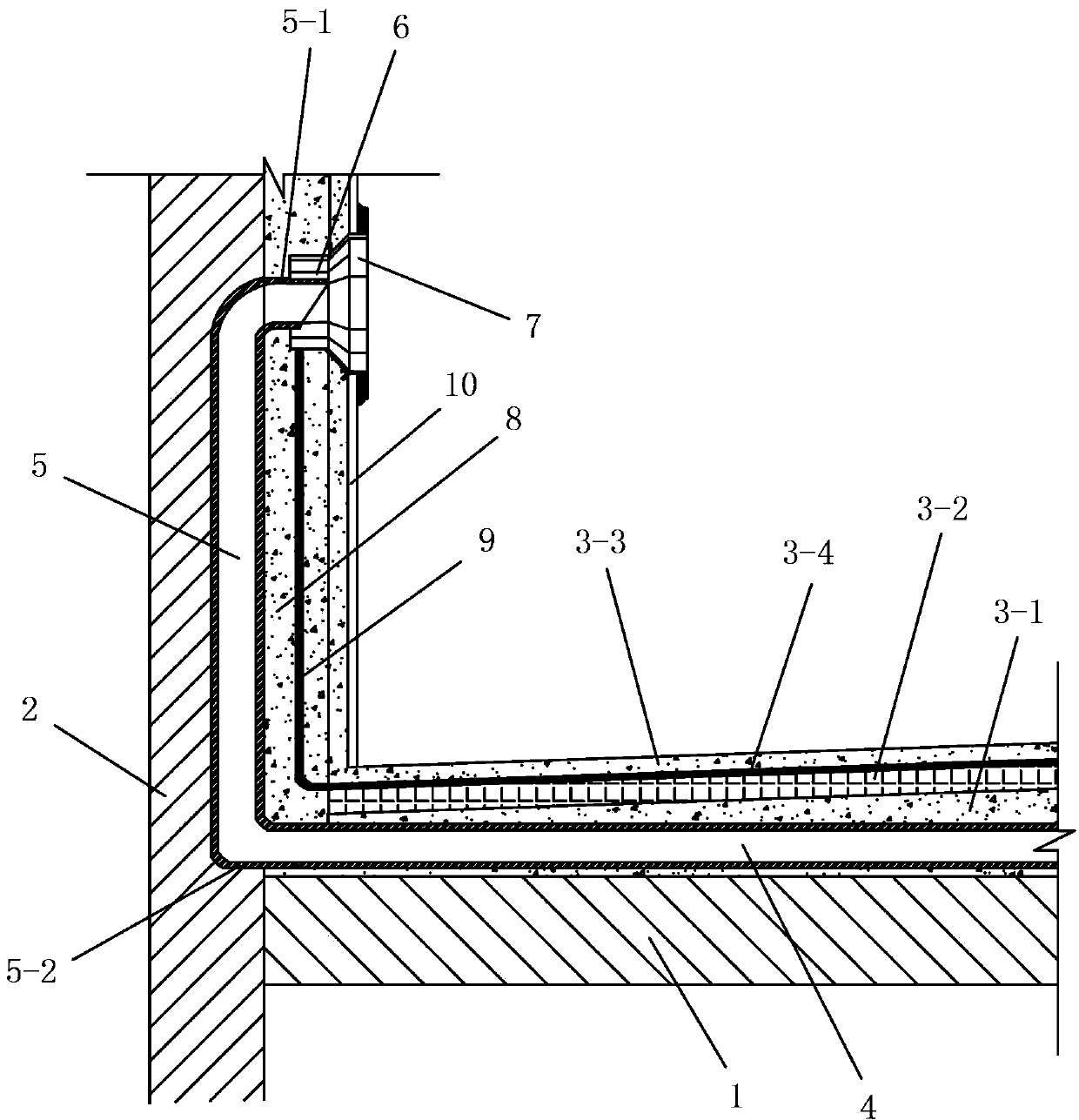

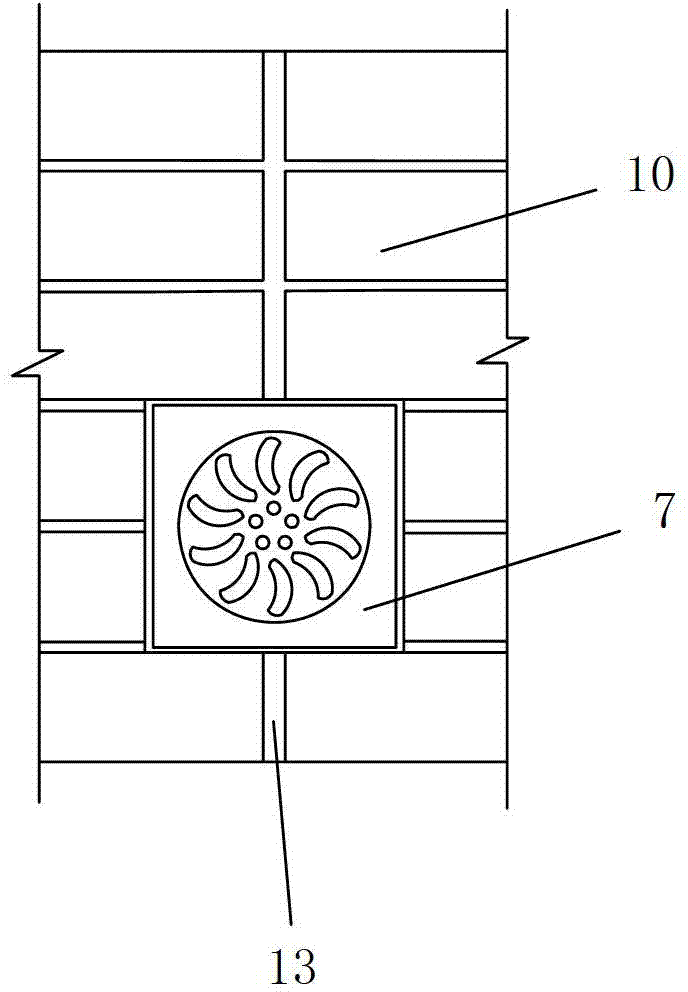

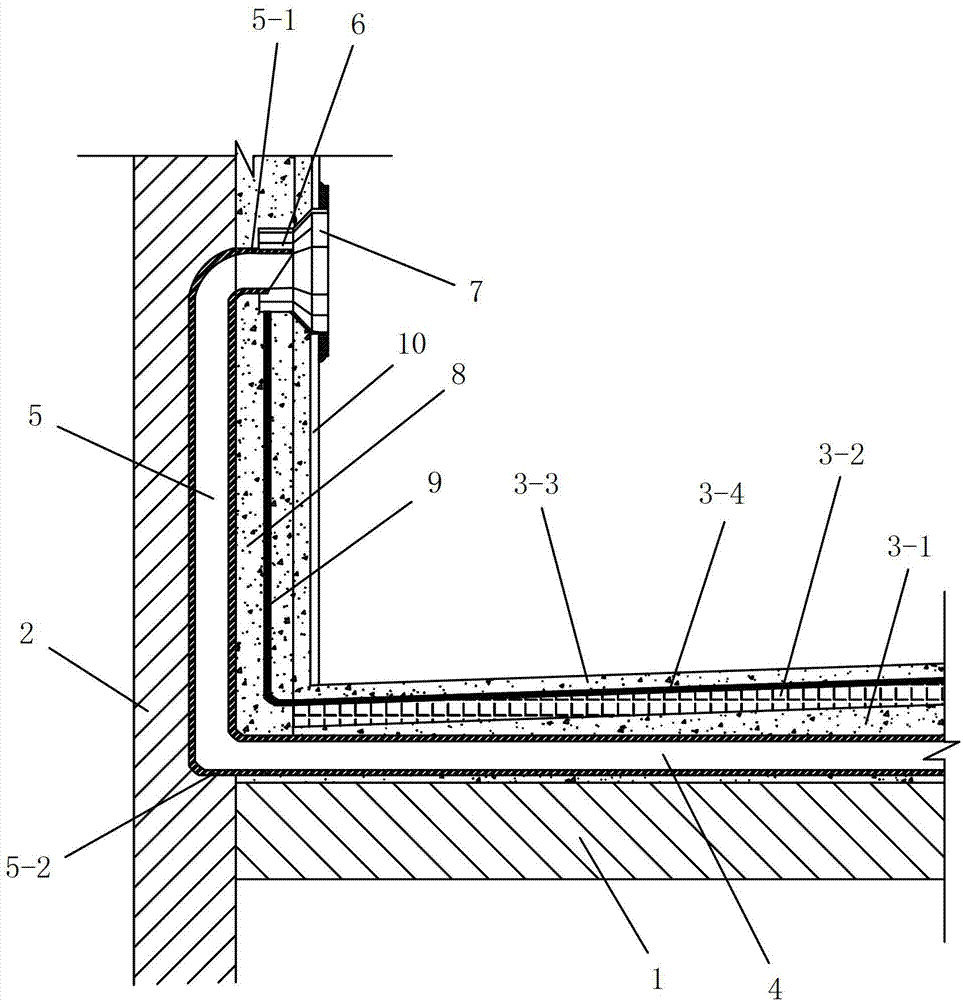

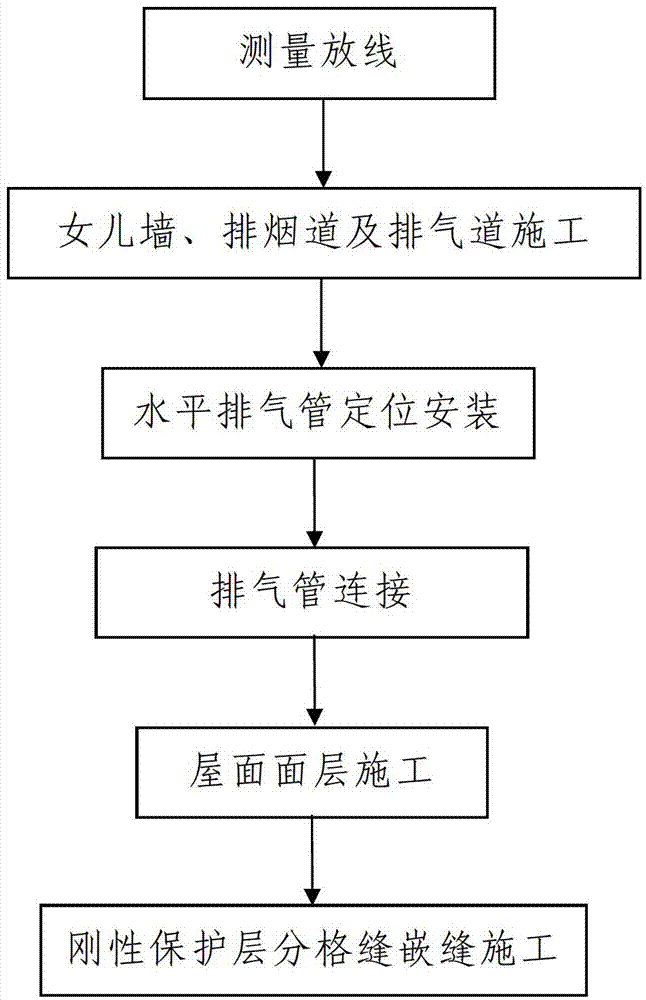

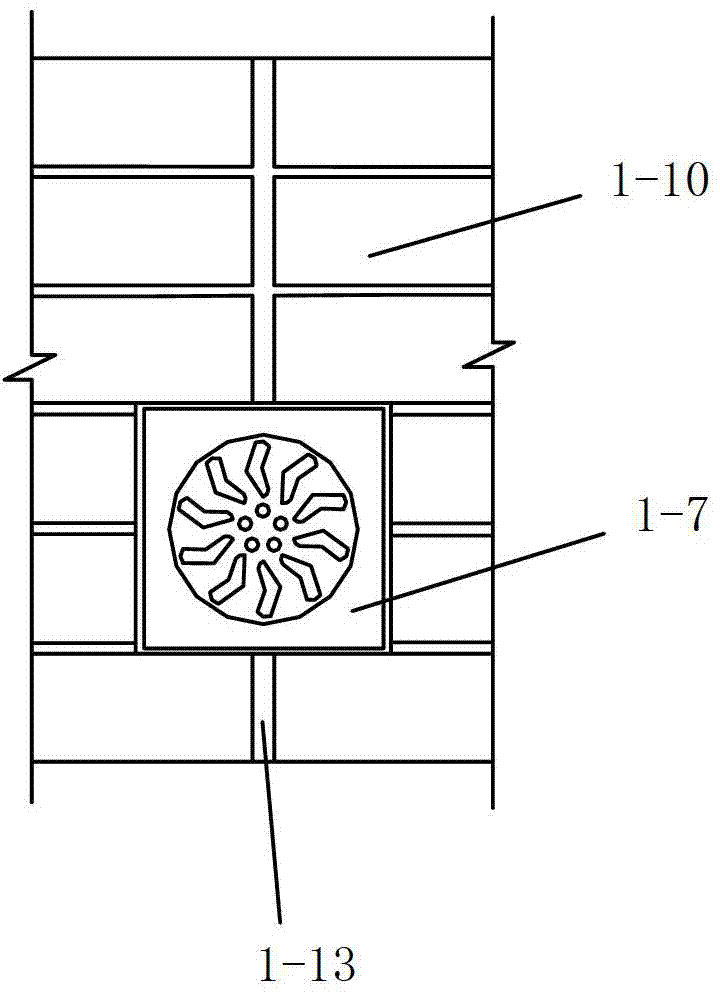

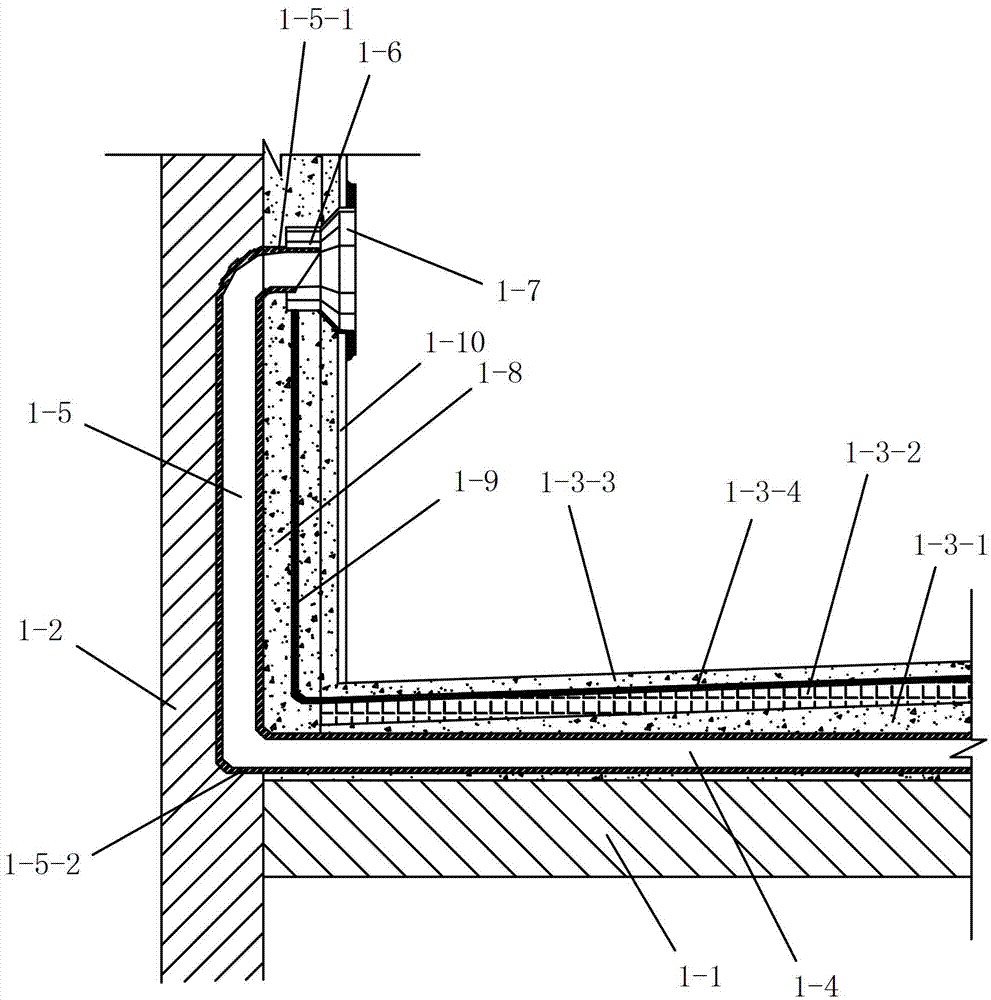

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

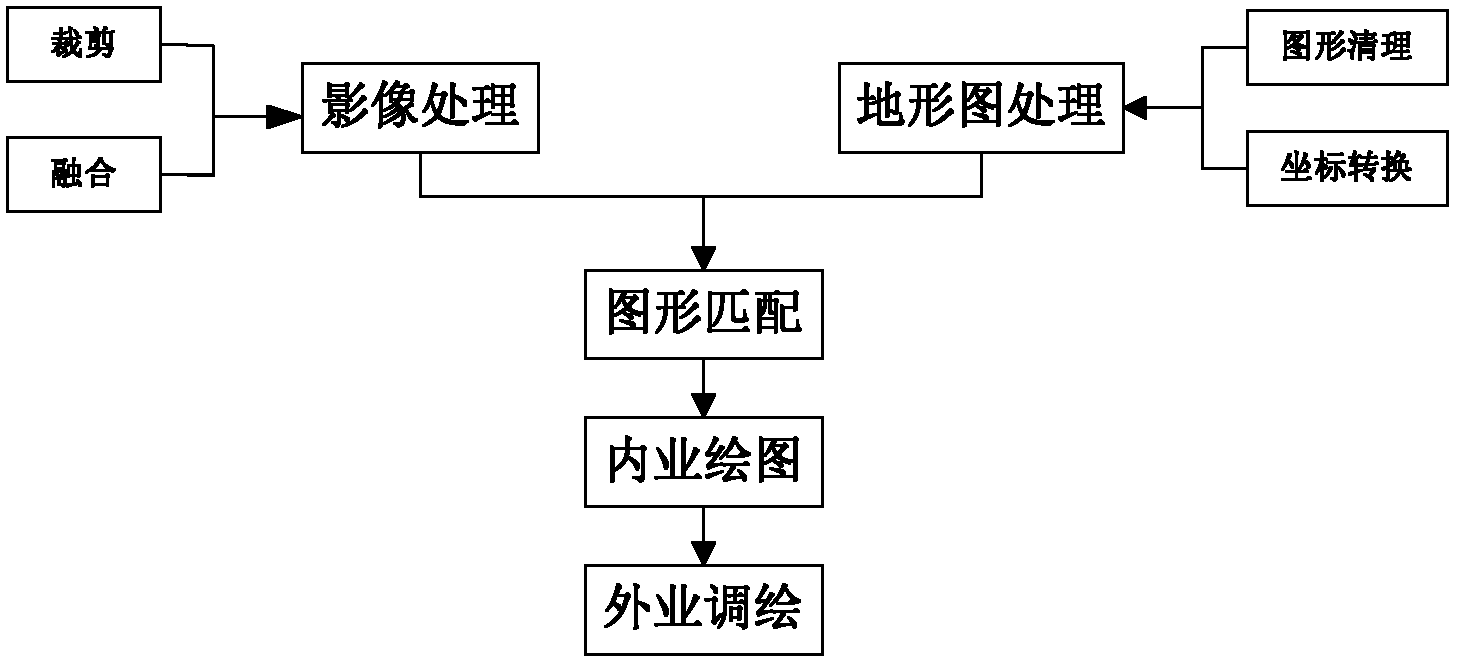

Traffic accident road base map information processing method based on topographic map and image

InactiveCN103136789AEasy to identifyImprove mapping accuracyMaps/plans/charts3D modellingInformation processingTraffic accident

The invention relates to a traffic accident road base map information processing method based on a topographic map and an image. The method comprises a first step of pre-processing topographic map data, a second step of pre-processing image data, a third step of matching the topographic map data processed by the first step and the second step with the image data, a fourth step of selecting various road information on the topographic map data and the image data according to set code requirements and automatically generating a road base map, and a fifth step of revising the road base map through field investigation and plotting. Compared with the prior art, the traffic accident road base map information processing method based on the topographic map and the image has the advantages of being high in mapping precision and full in data covering and the like. The data is easy to transfer and store, and traffic accident management time can be shortened.

Owner:TONGJI UNIV

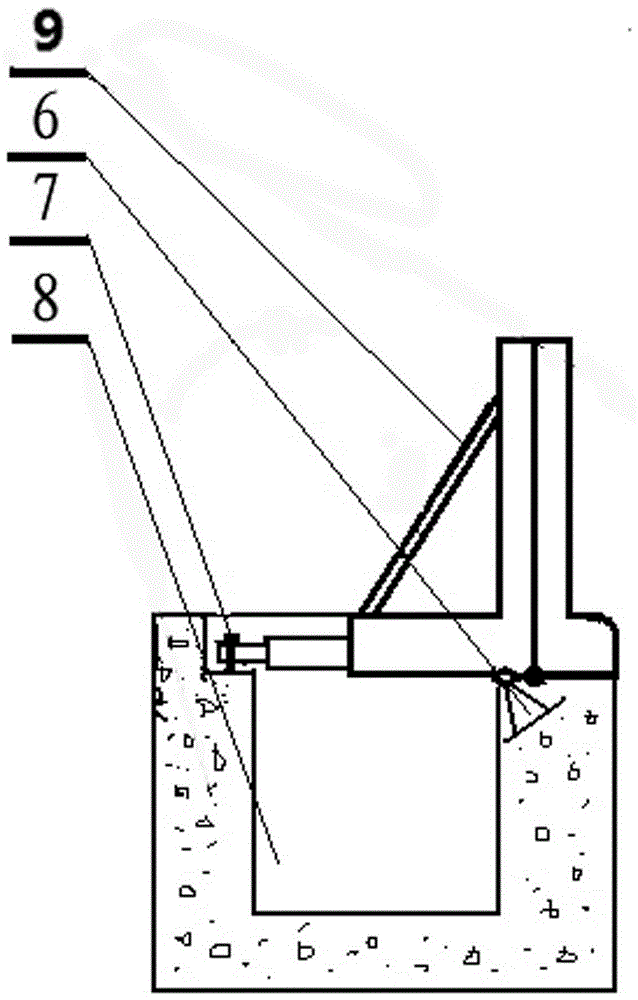

Hidden city flood prevention wall

InactiveCN106012962AGood strengthImprove integrityDamsClimate change adaptationWater blockEngineering

The invention discloses a hidden city flood prevention wall comprising a plurality of door bodies which are adjacently arranged, and the fracture surfaces of the door bodies are in the shape of inverted T; each door body comprises a water blocking door plate and wing plates located at the bottoms of the back side and the front side of the water blocking door plate; the wing plates are perpendicular to the water blocking door plates; the bottoms of the water blocking door plates are fixed to the top of one side of a water drainage ditch through a plurality of rotating supporting hinges; the water blocking door plates can rotate to the side of the water drainage ditch by 90 degrees from the erected state; when the water blocking door plates rotate to the side of the water drainage ditch by 90 degrees and are in a laid-down state, the water blocking door plates are flush with the municipal road ground; a plurality of telescopic supporting rods are connected in the wing plates of the bottoms of the back sides of the water blocking door plates and can be in lap joint with the top of the other side of the water drainage ditch after being pulled out, and therefore the water blocking door plates can be stabilized in the erected state; and the telescopic supporting rods are connected with the top of the other side of the water drainage ditch in a fastened manner through bolts. The flood prevention wall is safe, economical, convenient and fast to install and easy to store after being used, the city flood prevention requirement can be met, and it is guaranteed that the hidden city flood prevention wall, the urban landscape and roads are harmonious and unified.

Owner:田力

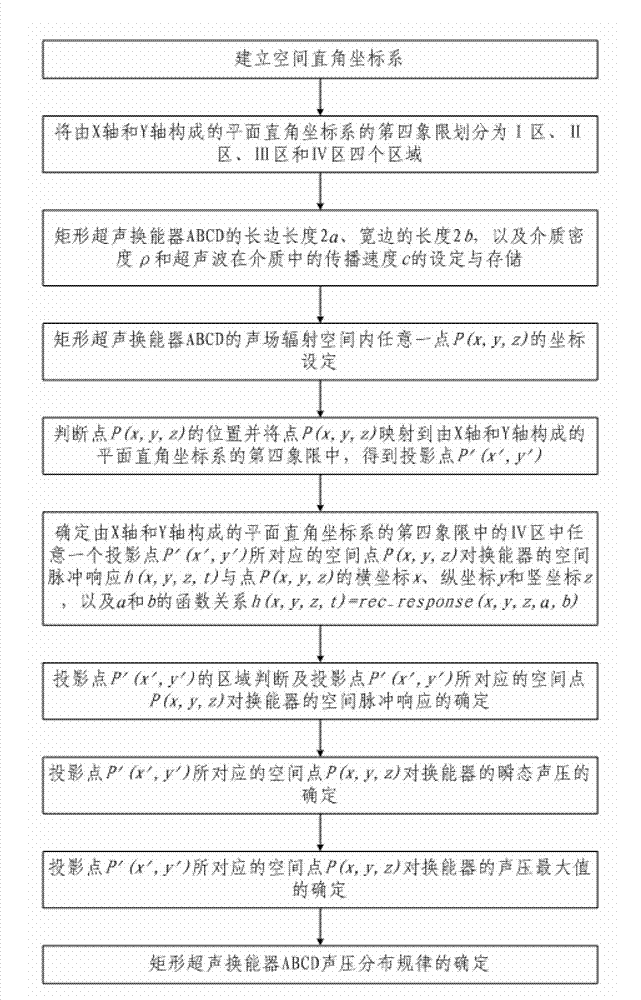

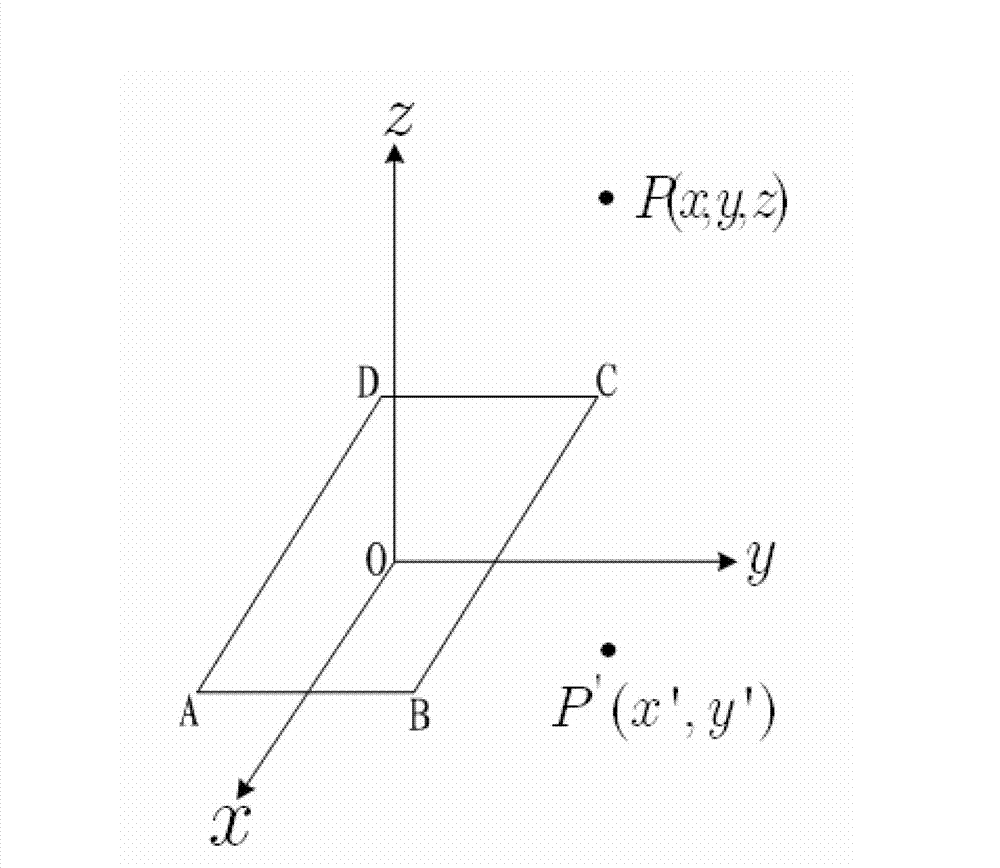

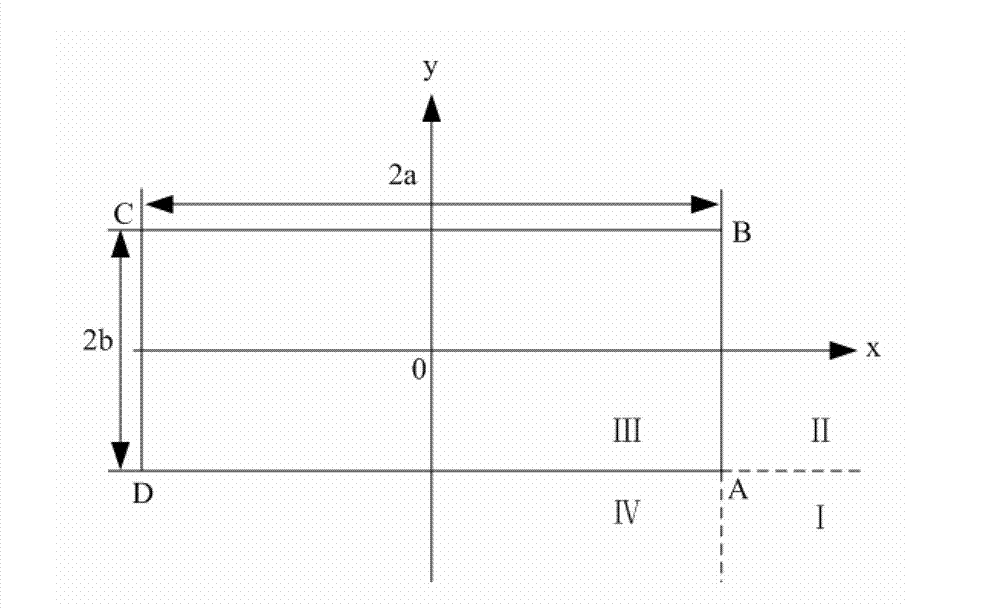

Simulation method for rectangular ultrasonic transducer sound field

ActiveCN102867099ANovel and reasonable designEasy to implementSpecial data processing applicationsUltrasonic sensorRectangular coordinates

The invention discloses a simulation method for a rectangular ultrasonic transducer sound field. The simulation method includes the following steps of 1, establishing a space rectangular coordinate system; 2, regionalizing a fourth quadrant; and 3, simulating a sound field of a rectangular ultrasonic transducer under a simulation software environment by a computer. Specifically, 301, setting and storing initial parameters; 302, setting a coordinate of an arbitrary point P (x,y,z) in sound field radiation space, 303, judging and mapping the position of the point P (x,y,z), 304, determining function relationship h (x,y,z,t)=rec_response (x,y,z,a,b), 305, determining space pulse response h (x,y,z,t) of the transducer by the space point P (x,y,z), 306, determining transient sound pressure p (x,y,z,t) of the transducer by the space point P (x,y,z), 307, determining sound pressure maximum pmax (x,y,z) of the transducer by the space point P (x,y,z), and 308, determining sound pressure distribution rule of the rectangular ultrasonic transducer. The simulation method for the rectangular ultrasonic transducer sound field is novel and reasonable in design, convenient to be realized, low in cost, high in simulation efficiency and high in accuracy, provides theoretical basis for optimizing the design of the rectangular transducer and making nondestructive testing process, and is high in practicability.

Owner:云南保利天同水下装备科技有限公司

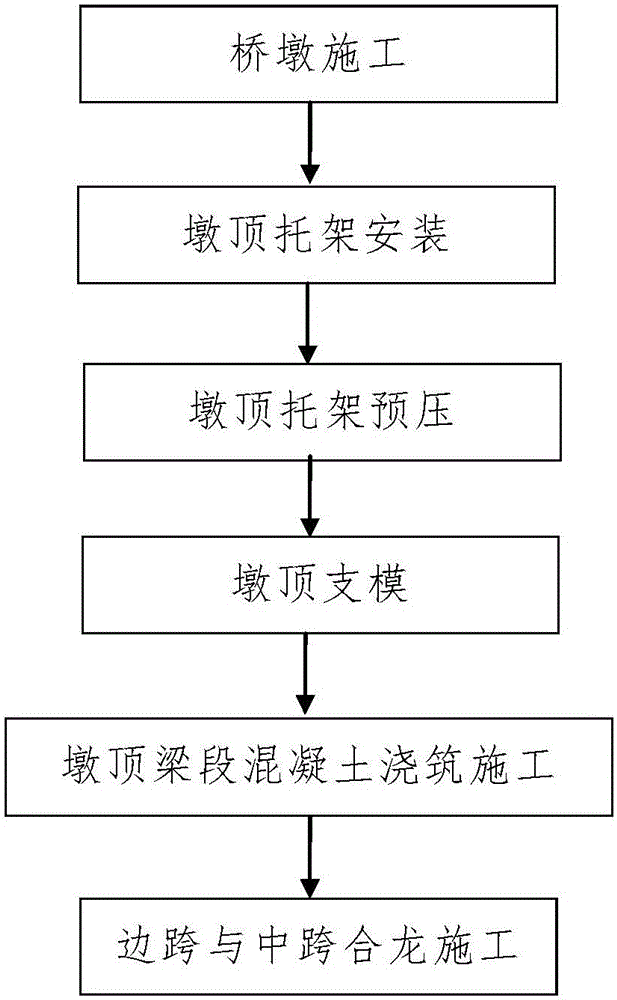

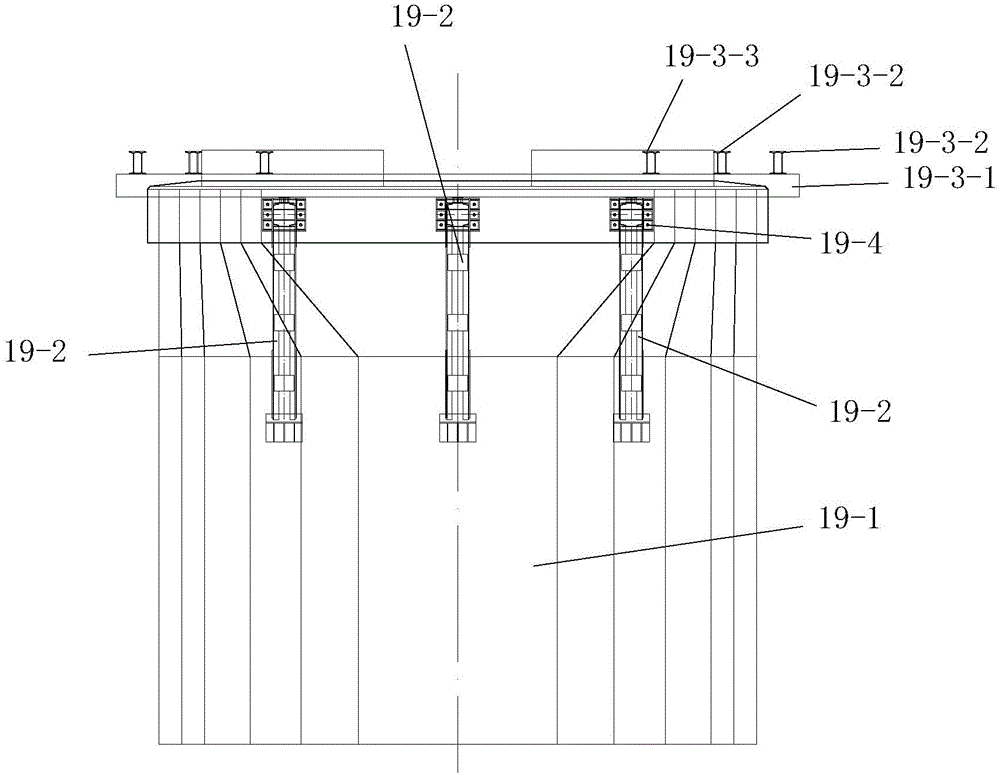

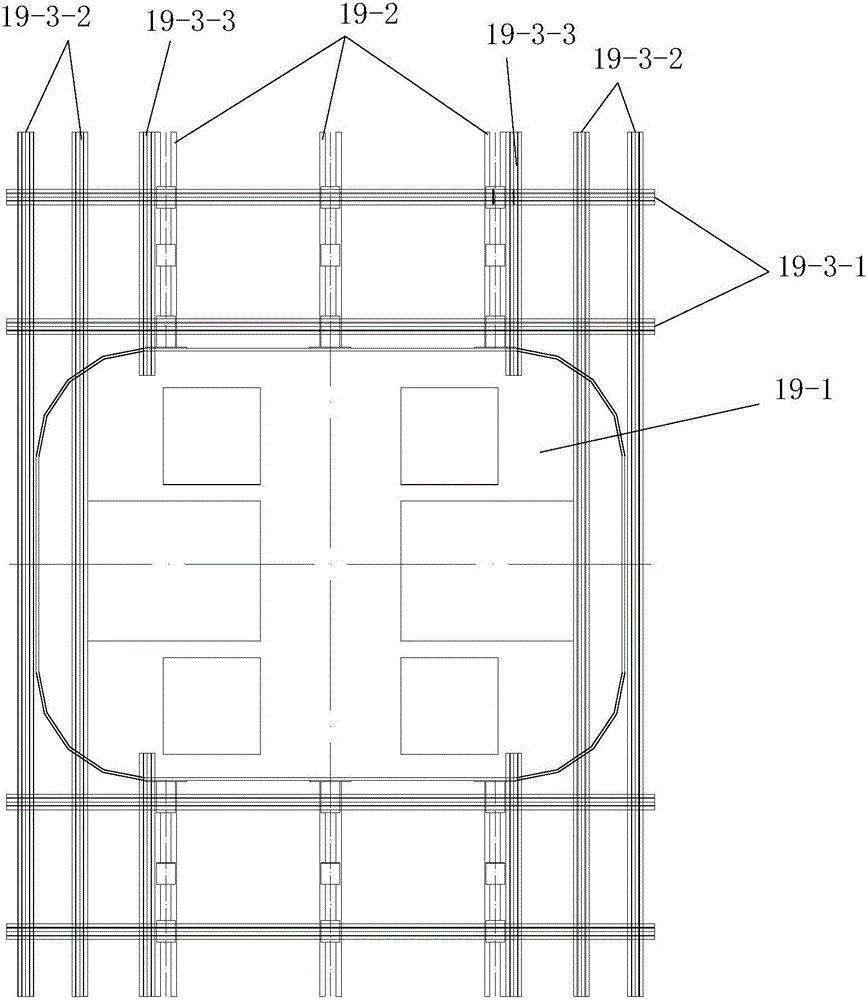

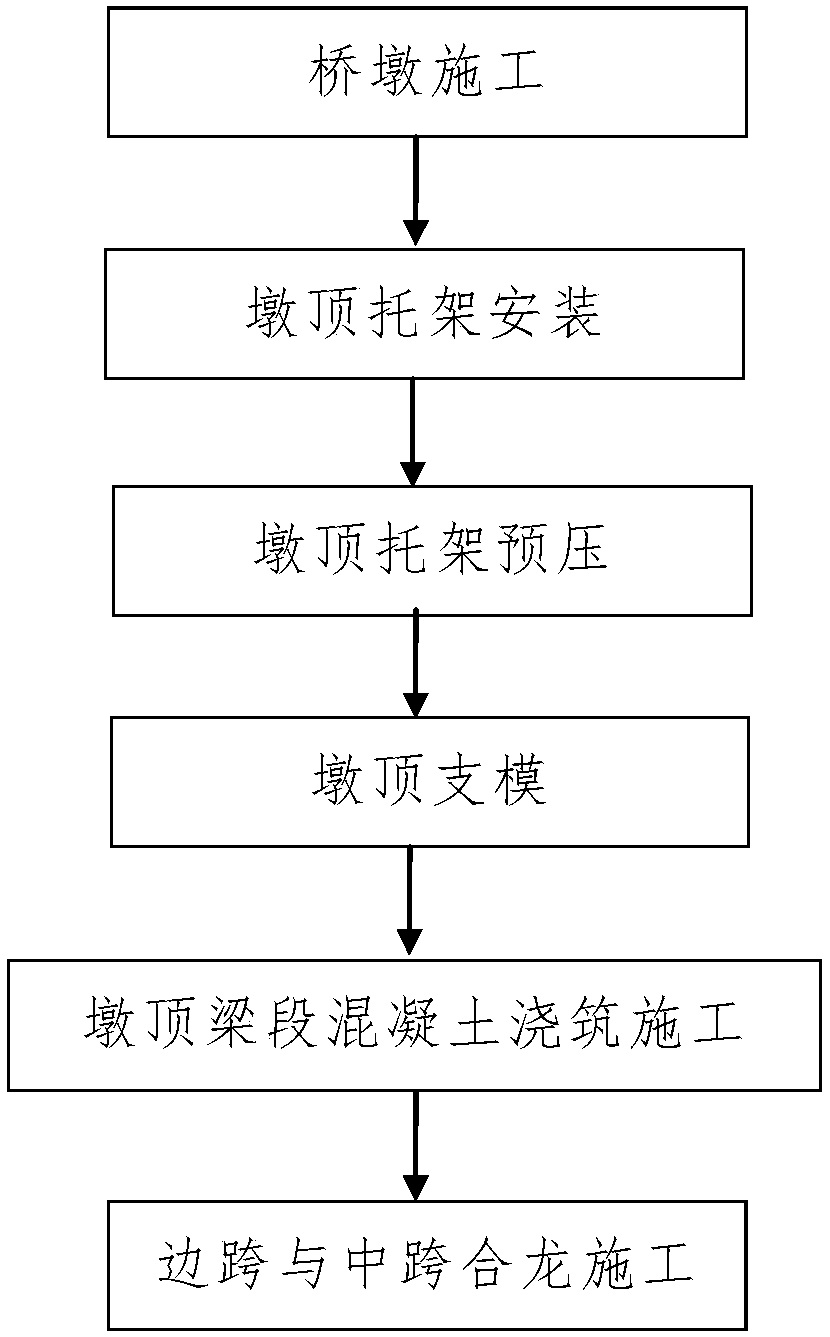

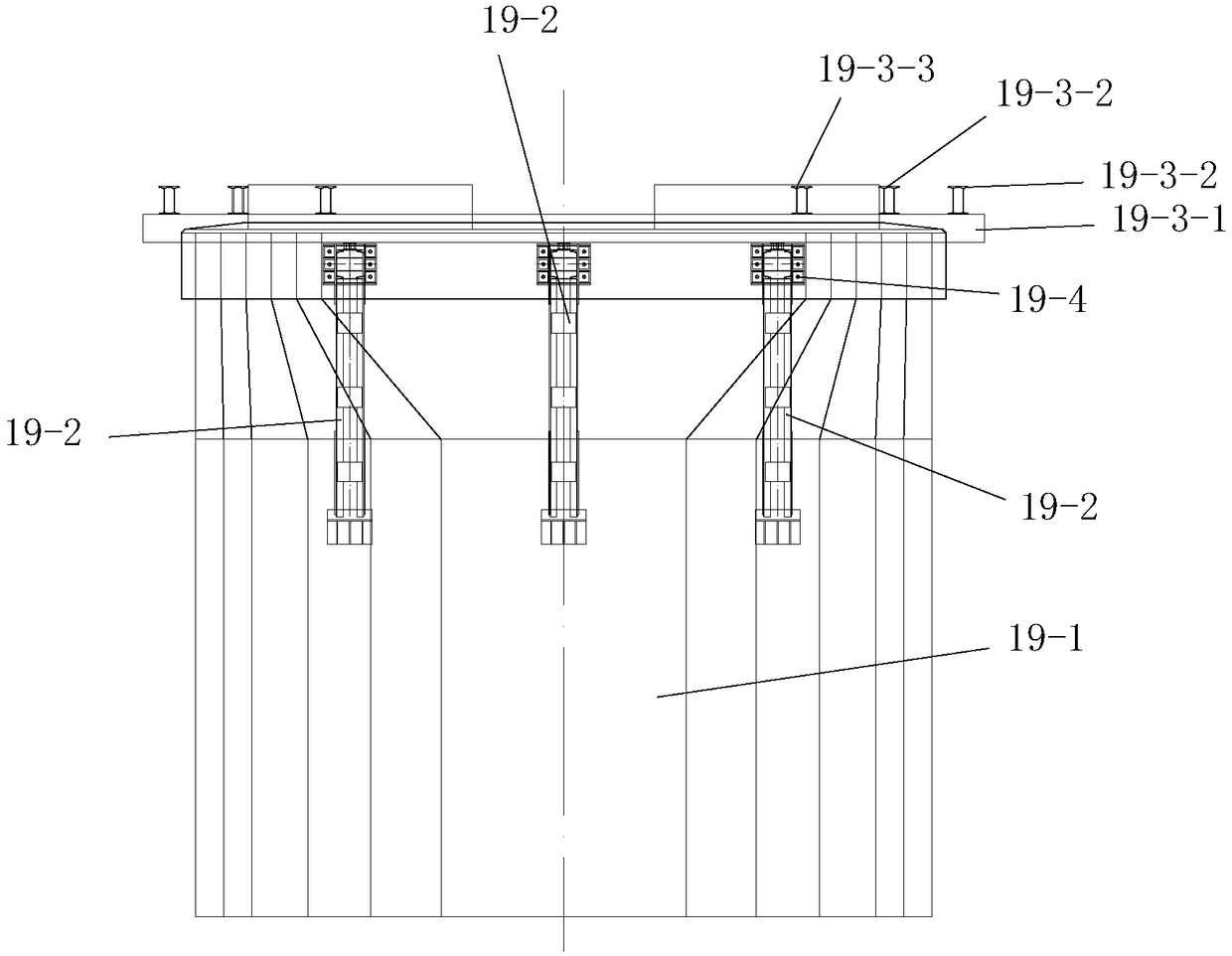

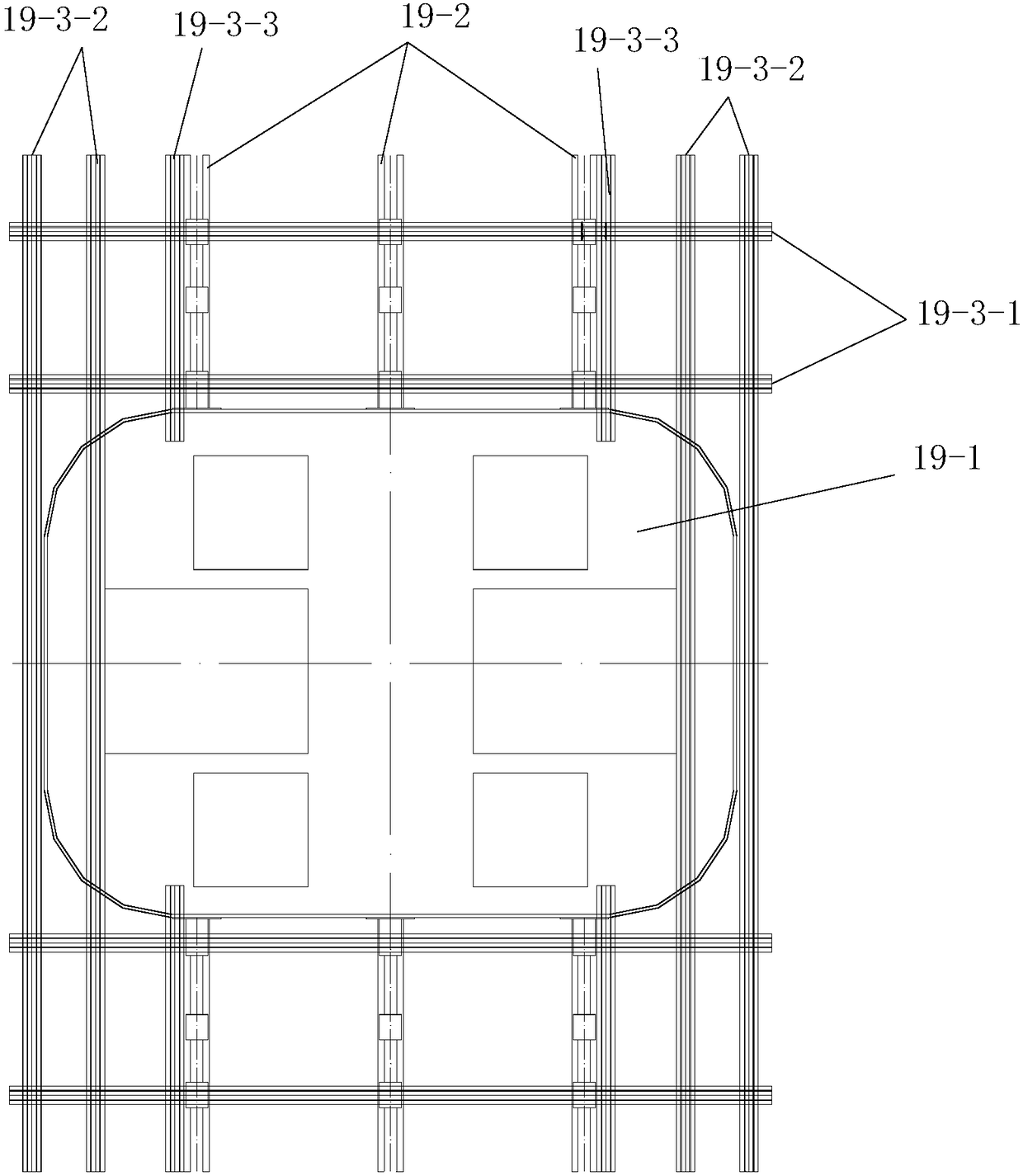

Construction method of large-span continuous beam closely next to existing line deep water foundation

ActiveCN106284085AThe method steps are simpleReasonable designBridge erection/assemblyContinuous beamRebar

The invention discloses a construction method of a large-span continuous beam closely next to an existing line deep water foundation. The large-span continuous beam to be constructed is a reinforced concrete box beam located on one side of an existing railway line, and is formed by splicing two side-span beam segments, a middle-span beam segment and two pier top beam segments. The construction method of the large-span continuous beam to be constructed comprises the steps that 1, bridge piers are constructed; 2, the pier top beam segments are constructed, specifically, pier top brackets are installed and pre-pressed, formworks are erected on the pier tops, and concrete is poured to the pier top beam segments; and 3, side-span and middle-span closure construction is carried out, specifically, after construction of the two pier top beam segments is completed, closure construction is carried out on the middle-span beam segment and the two side-span beam segments through a hanging basket. According to the method, the steps are simple, design is reasonable, construction is easy and convenient, the using effect is good, construction of the large-span continuous beam closely next to the existing line deep water foundation can be completed easily, conveniently and quickly, and the construction process is safe and reliable.

Owner:NO 1 ENG LIMITED OF CR20G

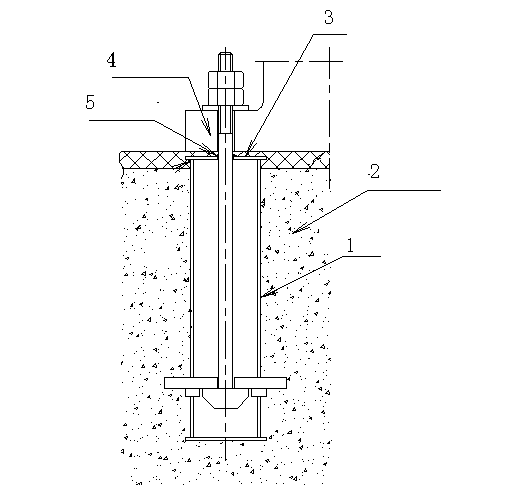

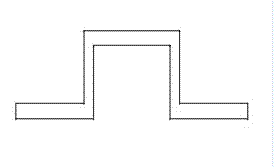

T-shaped foundation bolt hole plugging method

The invention relates to an installation method for a foundation bolt. A T-shaped foundation bolt hole plugging method comprises the steps that firstly, a foundation bolt sleeve is buried, and the upper surface of the sleeve is higher than an equipment foundation surface; secondly, during foundation retest, the upper surface of the foundation bolt sleeve is cut to be horizontal and polished; thirdly, a plugging steel plate is manufactured, wherein the square steel plate is manufactured by means of a thin steel plate, the side length of the plugging steel plate is 100mm greater than the diameter of a foundation bolt hole, a round hole is formed in the center of the plugging steel plate, and the diameter of the round hole is 1mm greater than that of the foundation bolt hole; fourthly, before equipment is installed, a foundation bolt is sleeved with the manufactured plugging steel plate, and a gap between the foundation bolt hole plugging steel plate and the foundation bolt is sealed though silica gel; fifthly, after the equipment is installed and adjustment and acceptance check are finished, the foundation bolt hole plugging steel plate and the foundation bolt sleeve are welded fixedly, and therefore the foundation bolt hole is plugged. The T-shaped foundation bolt hole plugging method is simple in operation, high in construction efficiency, little in investment of manpower and material resources, and little in environmental pollution.

Owner:CHINA MCC20 GRP CORP

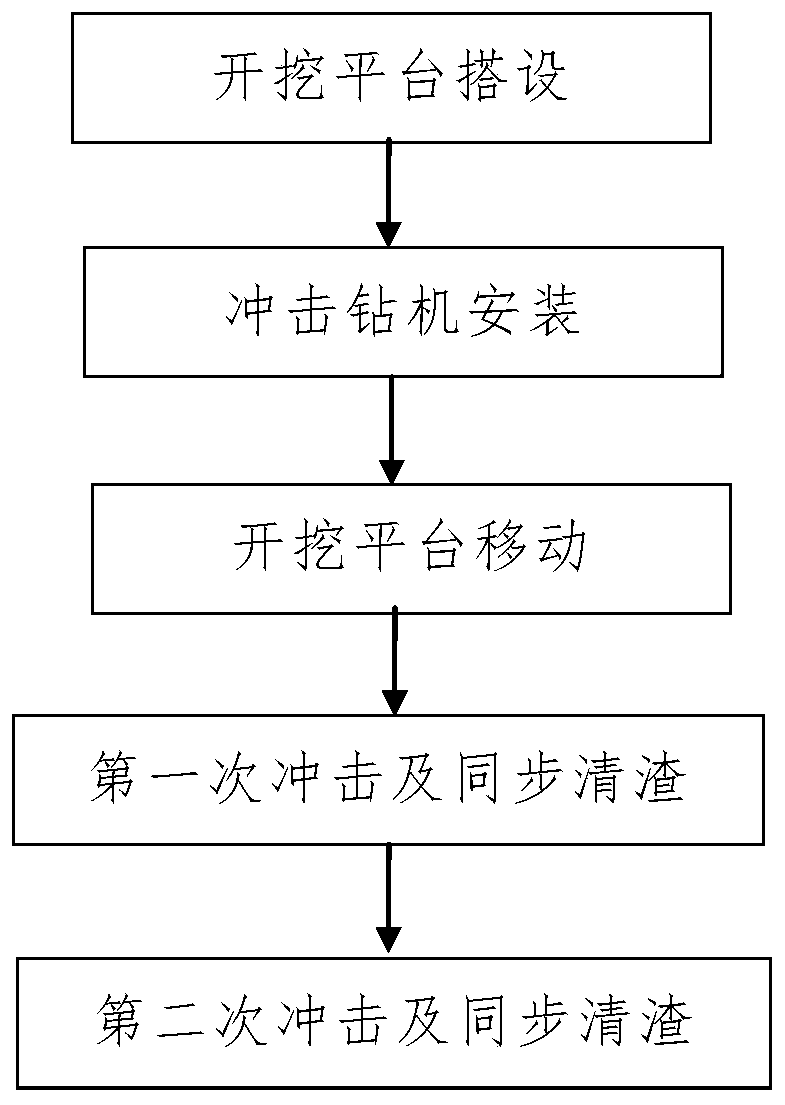

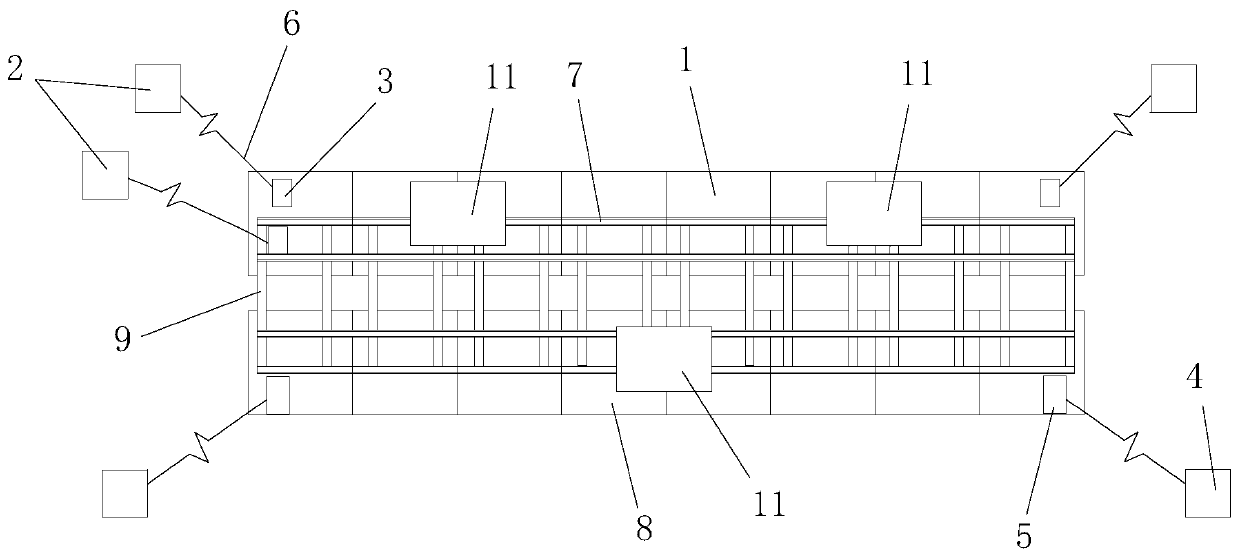

Excavation construction method for underwater foundation pits of deep water foundation adjacent to existing line large-span continuous beam

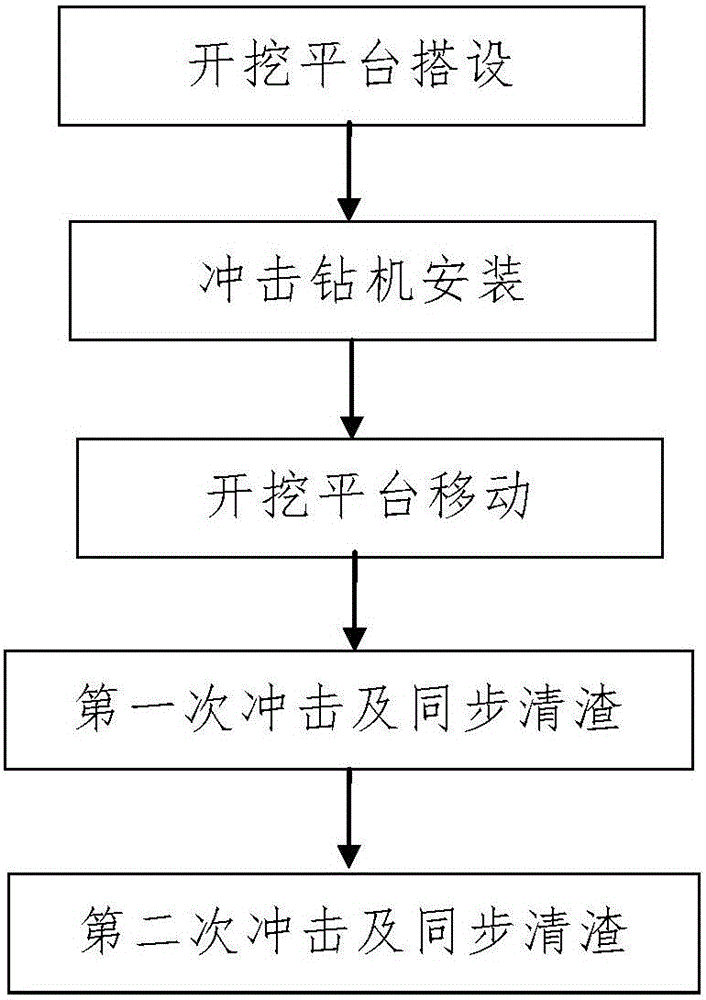

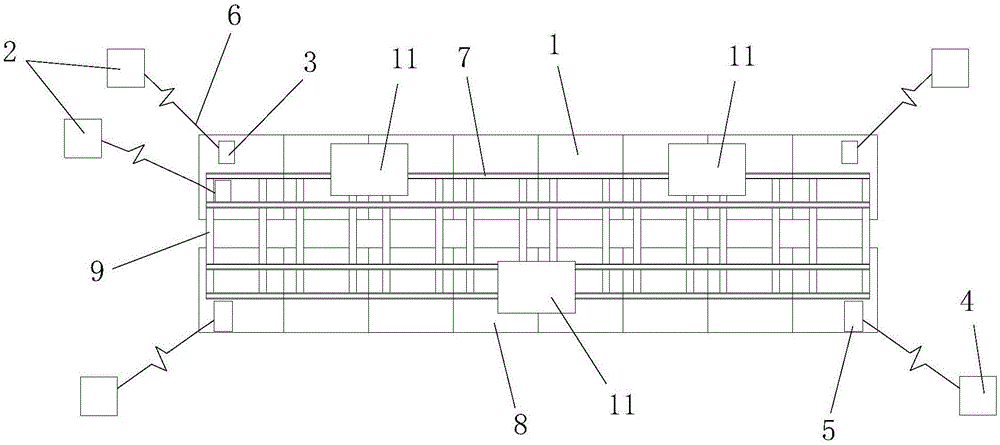

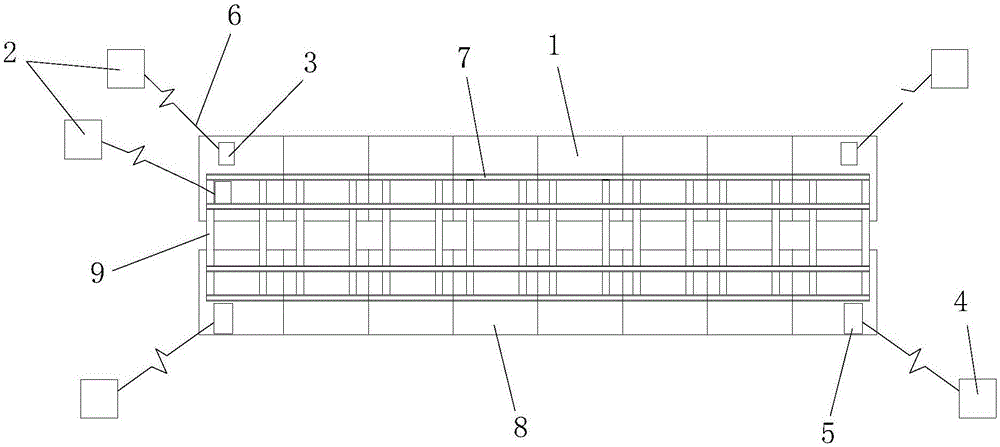

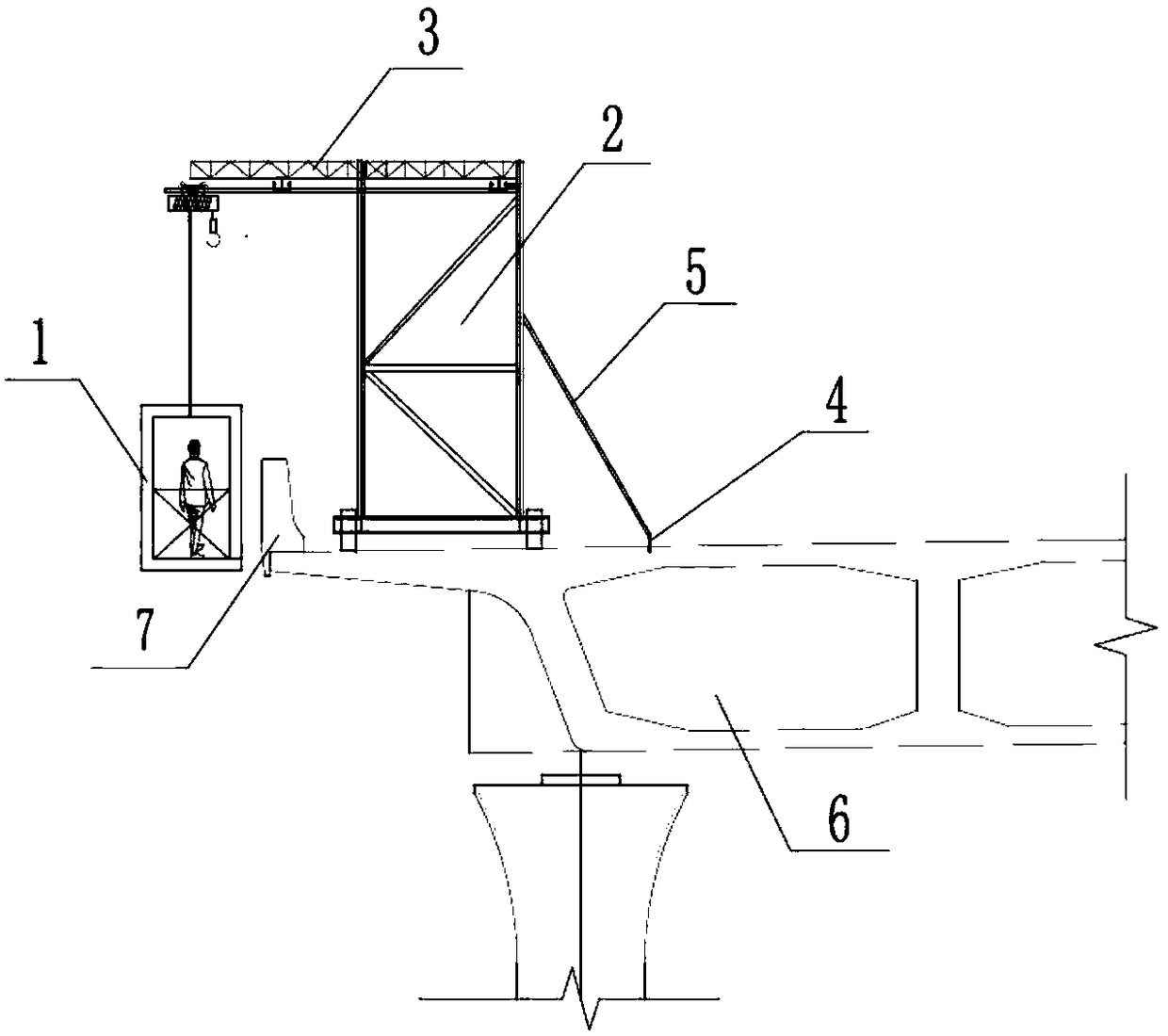

InactiveCN106120802AThe method steps are simpleReasonable designBridge erection/assemblyExcavationsSlagUnderwater

The invention discloses an excavation construction method for underwater foundation pits of a deep water foundation adjacent to an existing line large-span continuous beam. The excavation construction method comprises the following steps: I, erecting an excavation platform which comprises an assembly type floating body and a floating body position regulating device; II, mounting impact drilling machines: mounting the plurality of impact drilling machines on the excavation platform, wherein the plurality of the impact drilling machines form impact crushing equipment; III, moving the excavation platform; IV, impacting for a first time and synchronously removing slag: carrying out impact crushing on integral underwater base rocks in a construction area where an underwater abutment lies and moving away rock blocks by adopting a long-arm excavator; and V, impacting for a second time and synchronously removing slag: carrying out impact crushing on underwater rocks at bottom mounting positions of a cofferdam, and moving away rock blocks by adopting the long-arm excavator. The excavation construction method disclosed by the invention is simple in step, is reasonable in design, is simple and convenient to construct, is good in using effect, and can simply, quickly and quickly complete an excavation construction process for the underwater foundation pits of the deep water foundation; and the excavation construction process is safe and reliable, and has relatively small influences on the outside world.

Owner:NO 1 ENG LIMITED OF CR20G

Safety construction method of cast-in-place reinforced concrete crash barrier

InactiveCN108797339AImprove anti-overturn performanceEnsure construction safetyBridge structural detailsBridge erection/assemblyReinforced concreteHanging basket

The invention discloses a safety construction method of a cast-in-place reinforced concrete crash barrier. The method includes the following steps that when top plate reinforcing steel bars are arranged on a cast-in-place concrete box girder, lifting-lug-shaped embedded reinforcing steel bars are installed in the position of a box girder web in the bridge direction; after a box girder top plate ispoured, the embedded reinforcing steel bars are tightly combined with concrete, and the portions, higher than the concrete, of the embedded reinforcing steel bars are each in a lifting lug shape; a hanging basket is connected with a self-propelled trolley through a cantilever beam; the self-propelled trolley moves in the bridge direction, and after the self-propelled trolley walks to a preset construction position, a steel rope on a trolley tail of the self-propelled trolley is connected with the embedded reinforcing steel bar closest to the self-propelled trolley and fixed through an anti-separation clamp; and a worker enters the hanging basket to conduct construction operation. The overturning risk of the hanging basket can be reduced when a formwork on the outer side of the crash barrier is installed and detached.

Owner:WISDRI ENG & RES INC LTD +1

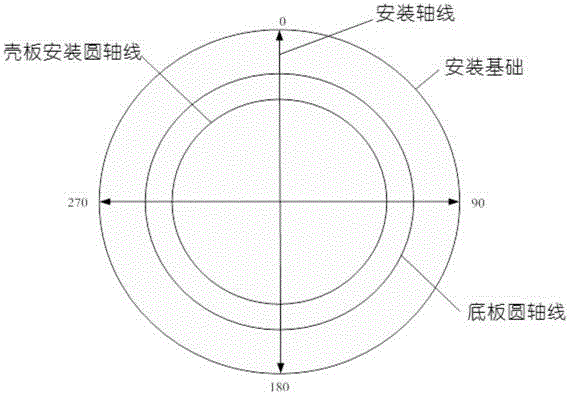

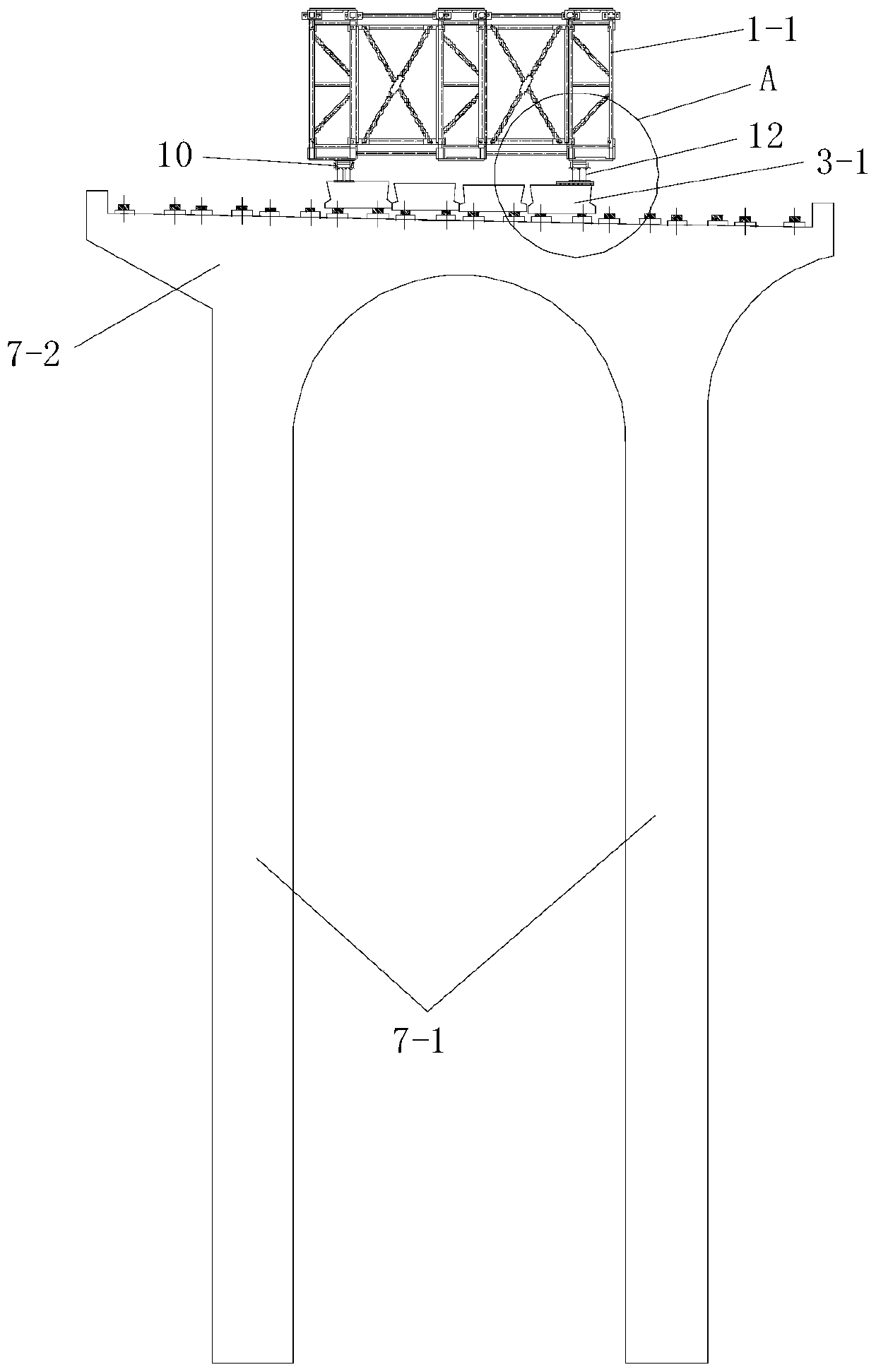

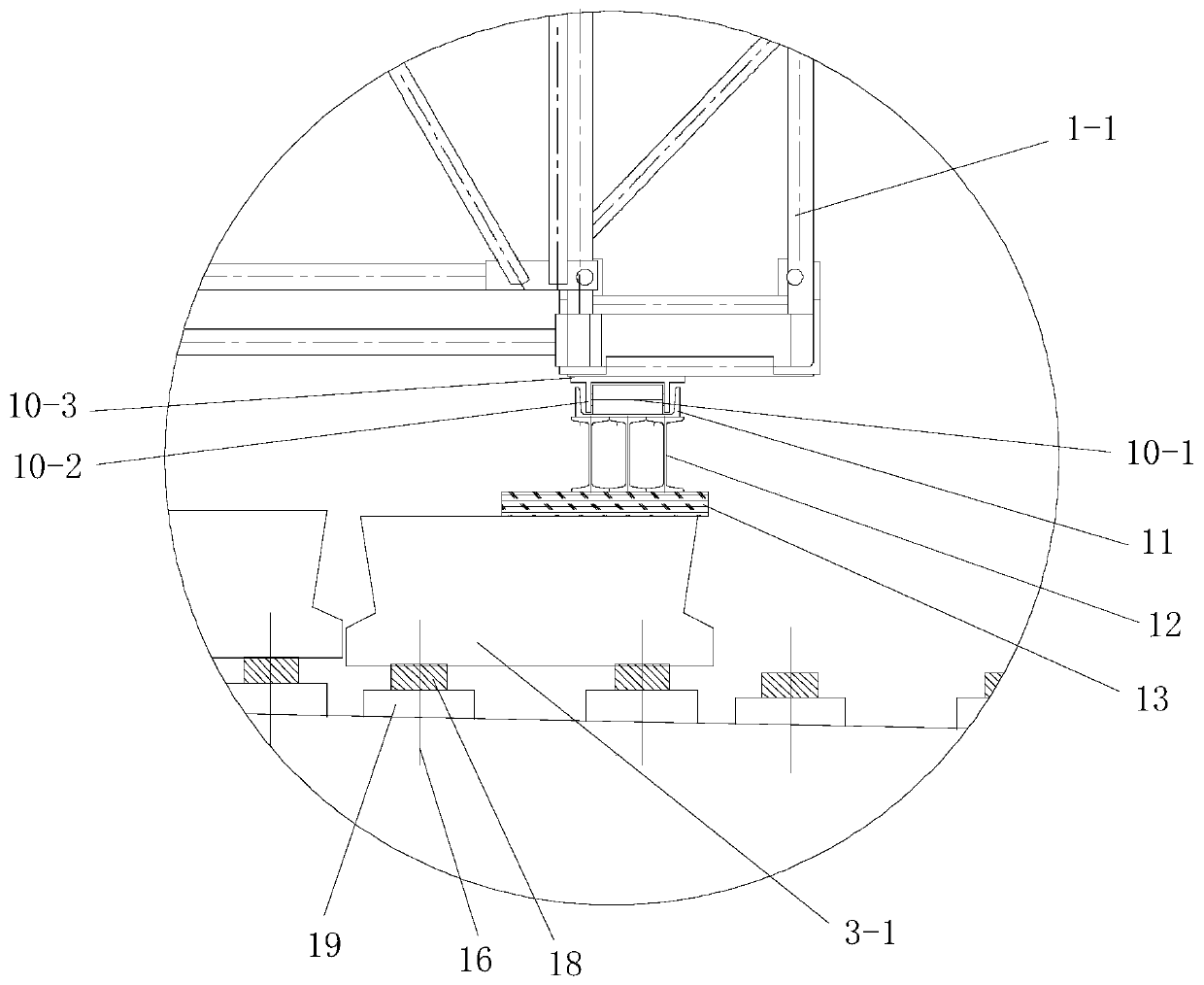

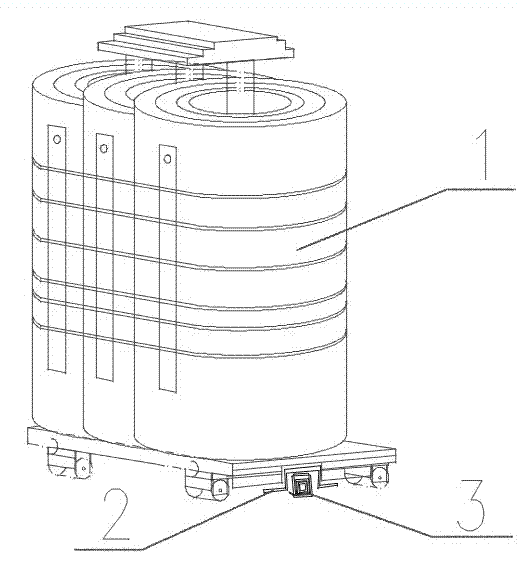

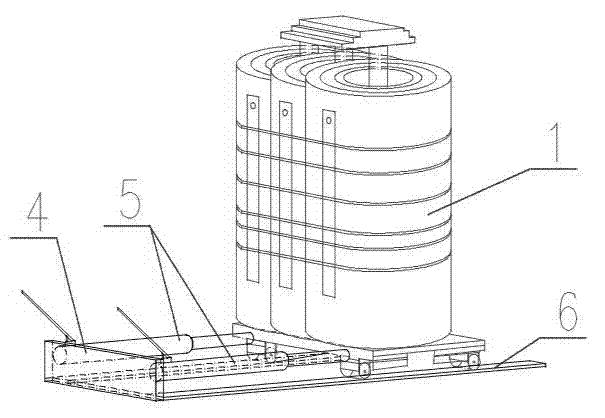

Method for manufacturing and mounting nuclear power desalting water tank

InactiveCN105569412ASmall amount of deformationExtended service lifeBulk storage containerNuclear powerEngineering

The invention discloses a method for manufacturing and mounting a nuclear power desalting water tank. A method for assembling and forming the nuclear power desalting water tank comprises the following steps: assembling a part of top plates, and reserving unassembled top plate limbs so as to form a space in which an embracing bar lifting system is erected; erecting the embracing bar lifting system; welding, wherein a product can be lifted by the embracing bar lifting system; welding an N-1st layer of wall plates to form an N-1st layer of shell plates, performing full-length welding on the N-1st layer of shell plates with an Nth layer of shell plates, welding an N-2nd layer of wall plates to form an N-2n layer of shell plates, performing full-length welding on the N-2nd layer of shell plates with the N-1st layer of shell plates, repeating the operation, performing full-length welding from top to bottom in sequence till full-length welding of an N / 2+1st layer of shell plates and a former layer of shell plates is completed. A buttress support method is adopted to mount the wall plates of the desalting water tank; operators can enter and go outside under the desalting water tank freely; by adoption of the method, no scaffold is needed in the mounting field, so that labor and materials for erecting the scaffold can be reduced, and the safety coefficient can be increased as operators can enter and go outside under the desalting water tank freely.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

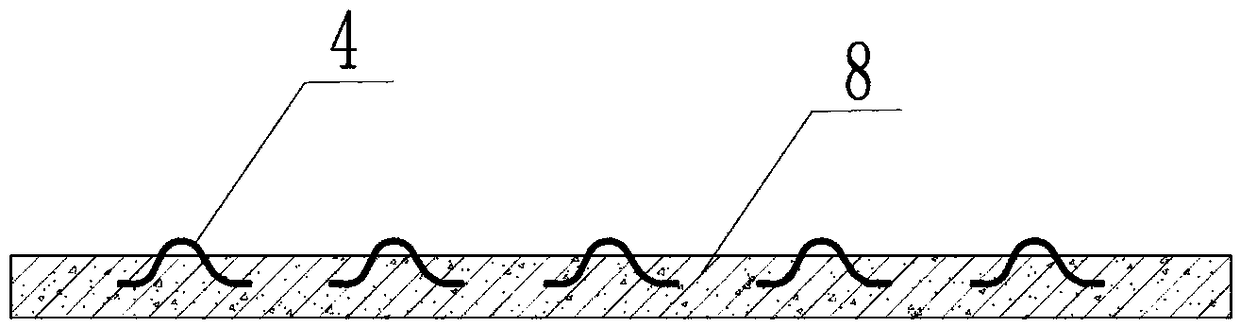

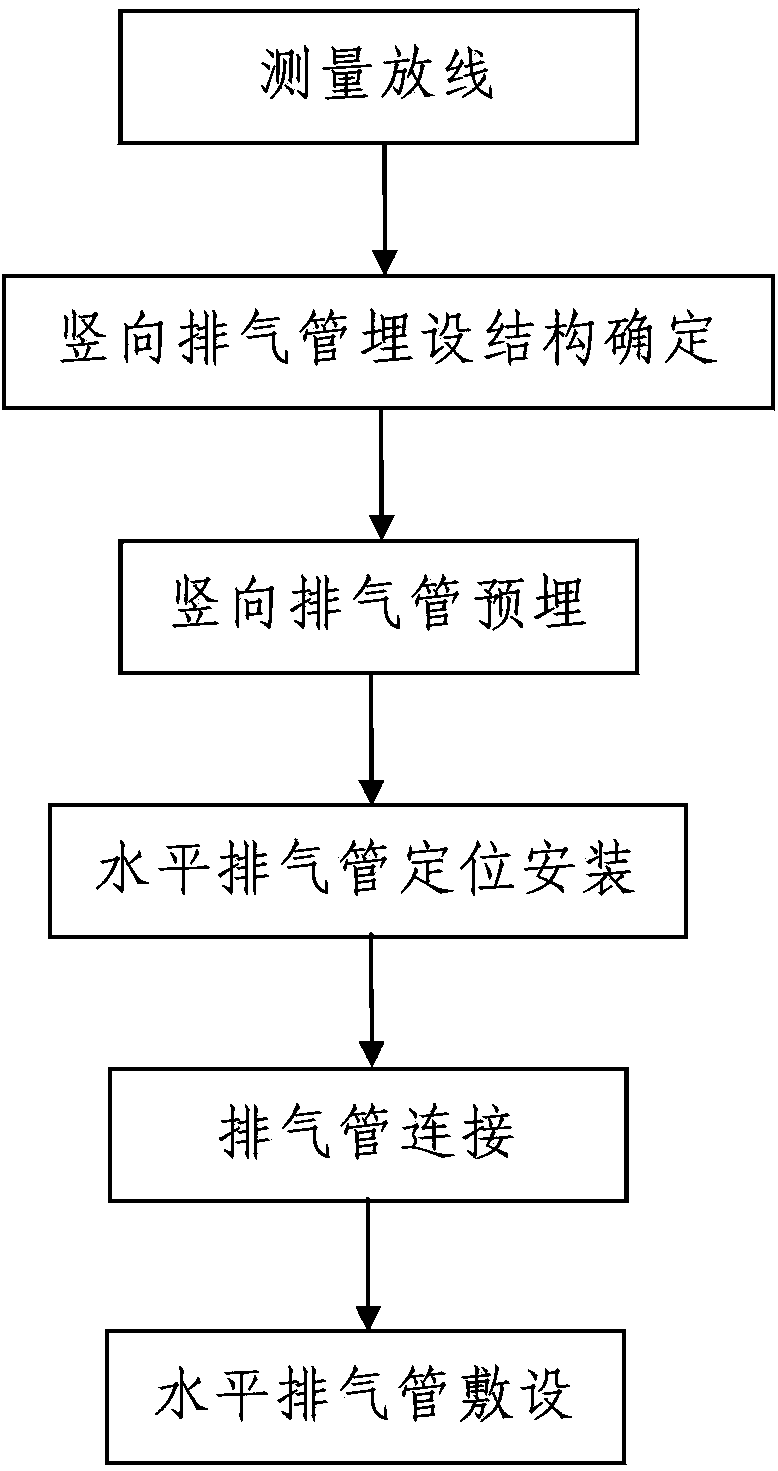

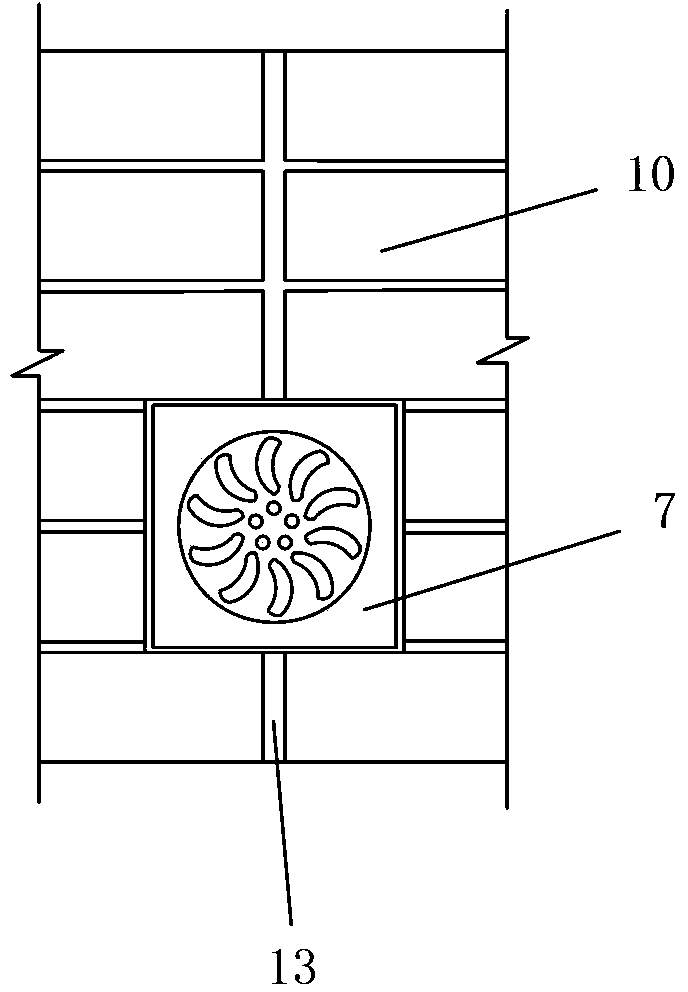

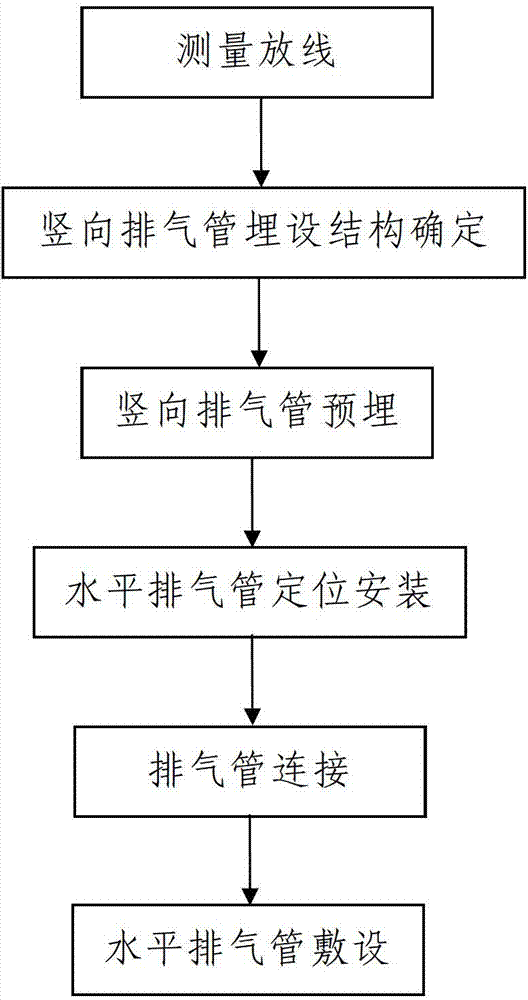

Construction process of concealed roofing exhaust hole

InactiveCN103362257AGuarantee the construction qualityConstruction quality is easy to controlLighting and heating apparatusRoof covering ventilationsReinforced concreteRebar

The invention discloses a construction process of concealed roofing exhaust holes, wherein a roofing exhaust system is arranged on a constructed roofing, the roofing exhaust system comprises sloping layers which are uniformly laid in a roofing layer or a plurality of first horizontal exhaust pipes which are uniformly laid in a heat-insulating layer; both ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe; and the vertical exhaust pipe is buried into a parapet, the lateral wall of a discharge flue or the lateral wall of an exhaust passage, and the parapet, the discharge flue and the exhaust passage are all of reinforced-concrete structures. The construction process of the concealed exhaust holes comprises the following steps of 1, measuring and releasing lines; 2, determining the buried structures of the vertical exhaust pipes; 3, pre-burying the vertical exhaust pipes; 4, positioning and installing the horizontal exhaust pipes; 5, connecting the exhaust pipes; and 6, laying the horizontal exhaust pipes. The construction process of the concealed roofing exhaust holes has the advantages of simple process step and reasonable design, the using effect of the molded roofing exhaust system through construction is good, and the problems of easy blockage, easy damage, unsmooth exhaust, poorer exhaust effect and the like existing in the existing exposed mode of the exhaust holes can be solved.

Owner:陕西建工集团有限公司 +1

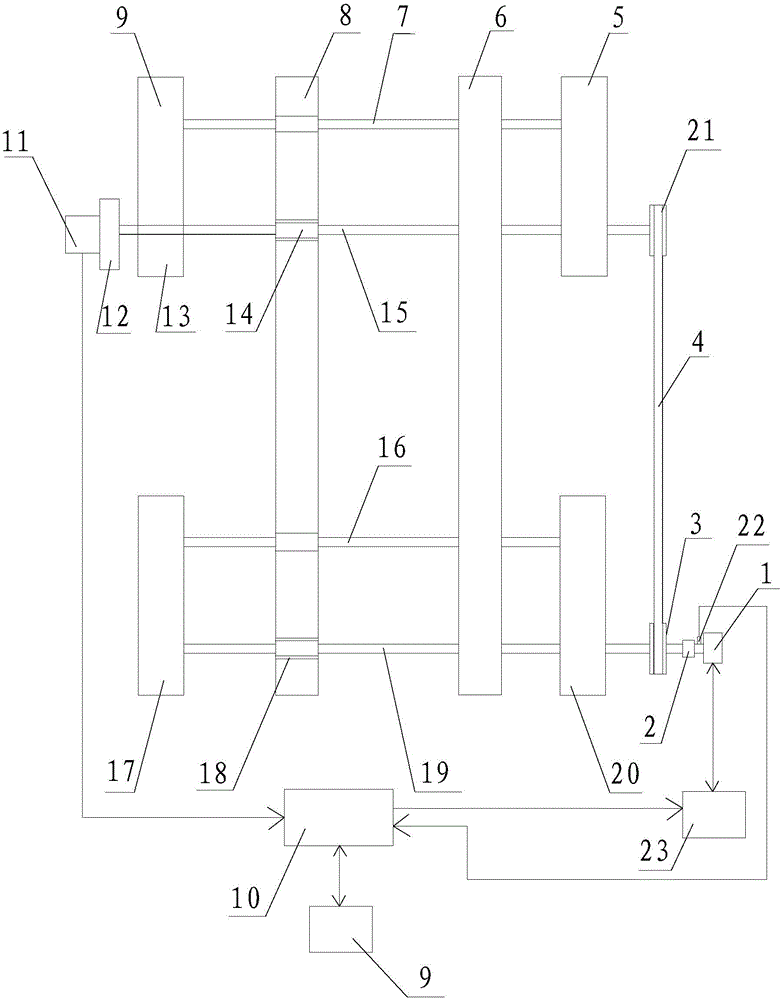

Crest welder guide rail width closed-loop control system

InactiveCN105657986ASimple structureNovel and reasonable designPrinted circuit assemblingFrequency changerLiquid-crystal display

The invention discloses a crest welder guide rail width closed-loop control system comprising a guide rail width regulating mechanism, an electric regulating assembly, a guide rail width measuring assembly, a programmable logic controller and a touch liquid crystal display screen. The guide rail width regulating mechanism comprises a first fixed block, a second fixed block, a third fixed block, a fourth fixed block, a fixed guide rail, a movable guide rail, a first polished rod, a first regulating screw, a second polished rod and a second regulating screw. The first regulating screw is in threaded connection with a first screw nut, and the second regulating screw is in threaded connection with a second screw nut. The electric regulating assembly comprises a first synchronous pulley, a second synchronous pulley, a variable-frequency and variable-speed motor and a frequency converter. A synchronous belt is connected across the first synchronous pulley and the second synchronous pulley. The guide rail width measuring assembly comprises an encoder and a reduction gear, and the reduction gear is connected with a multi-turn potentiometer. The crest welder guide rail width closed-loop control system is convenient to operate, is conductive to the increase of welding efficiency, and effectively improves the precision of crest welder guide rail width detection and control.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

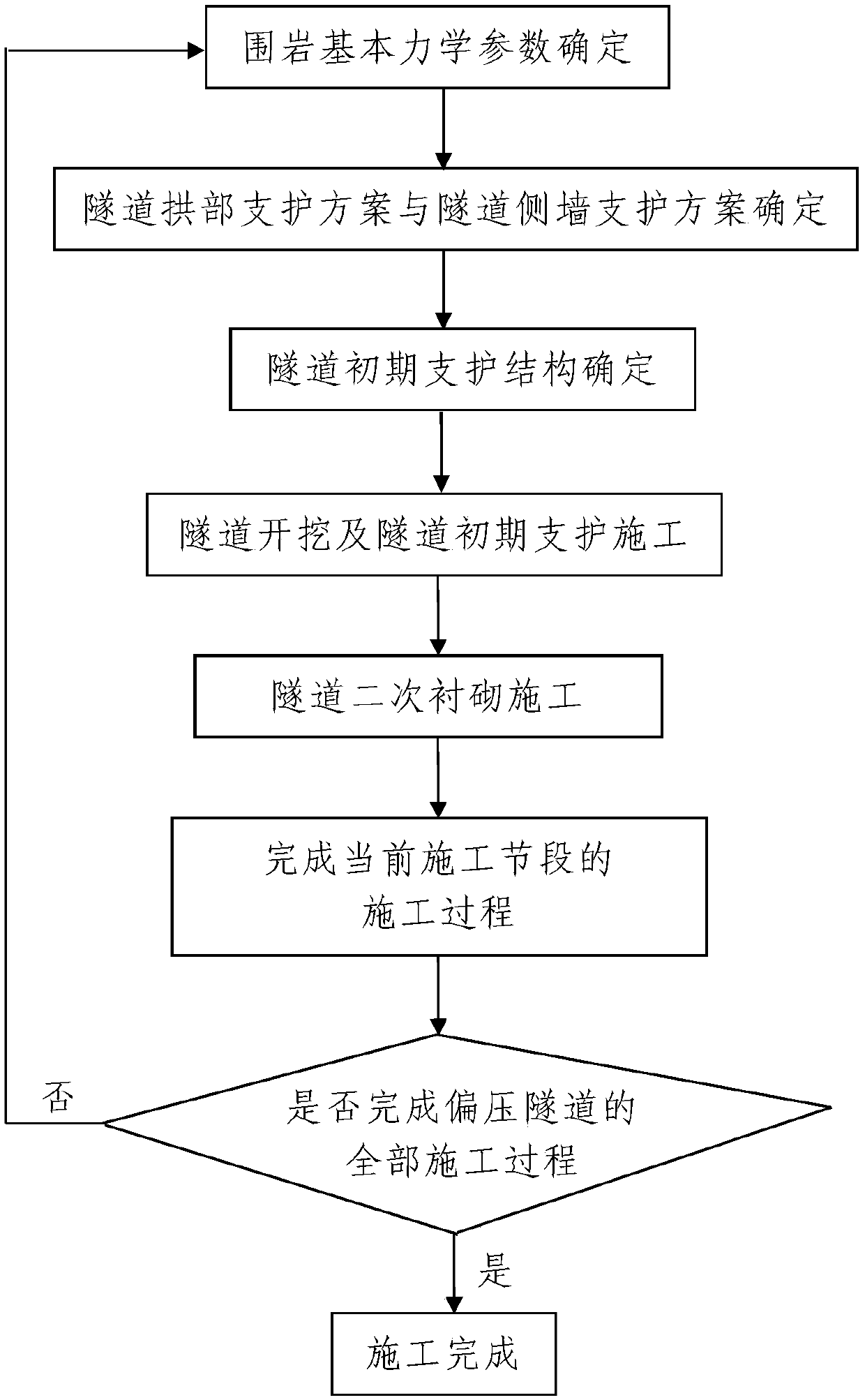

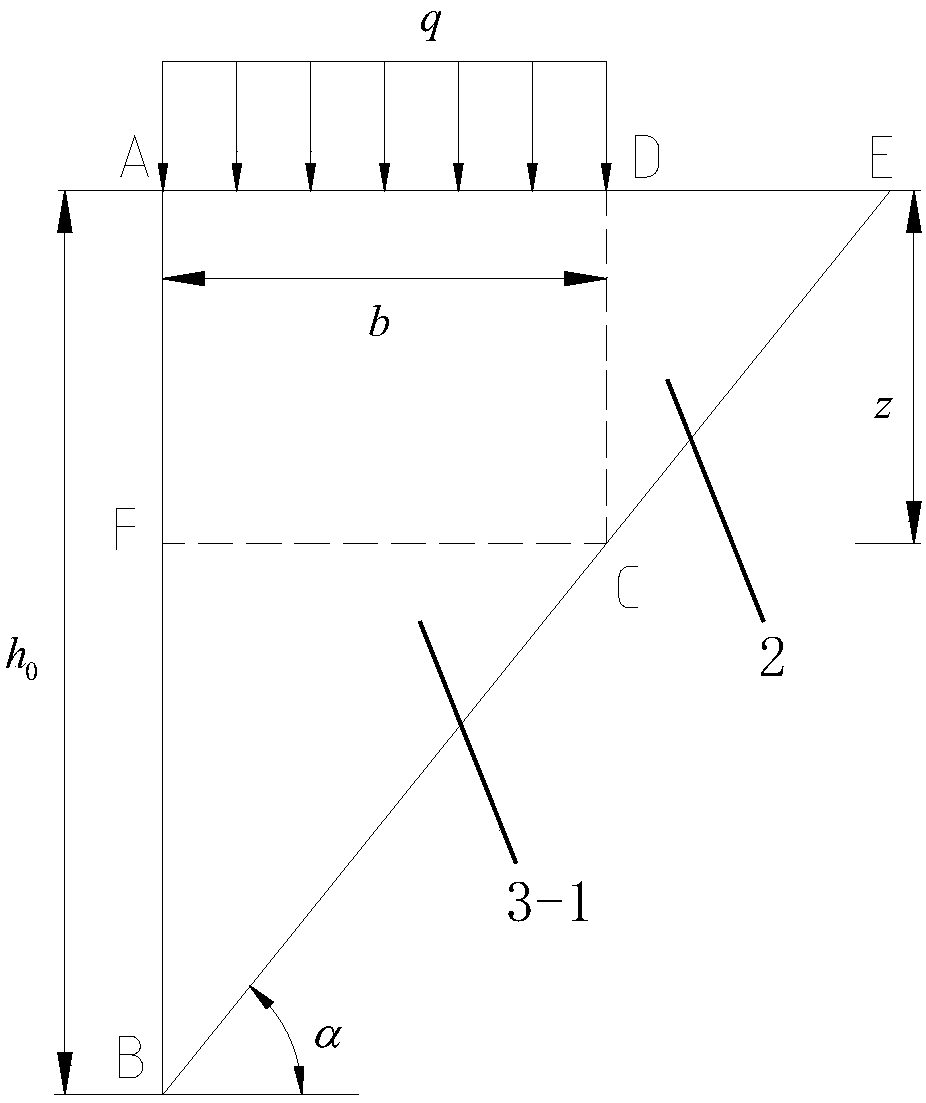

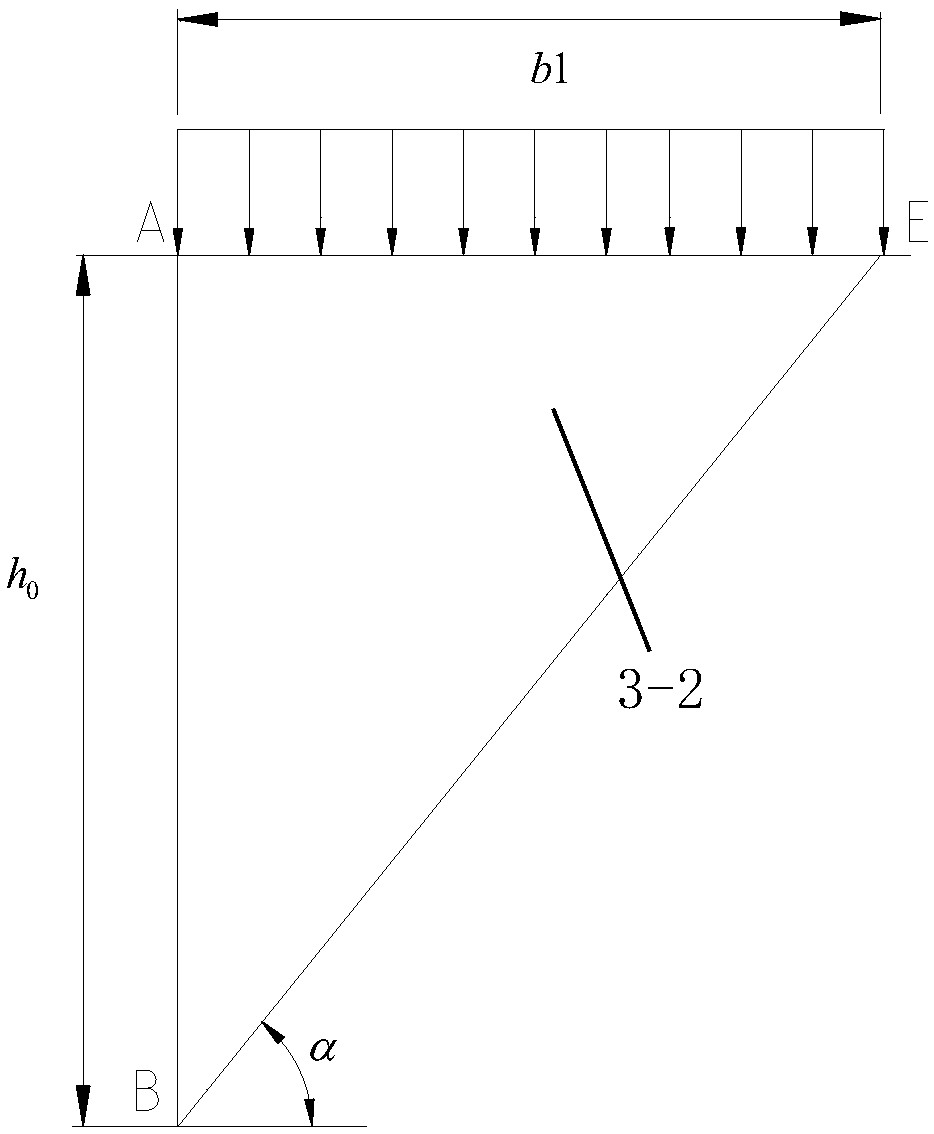

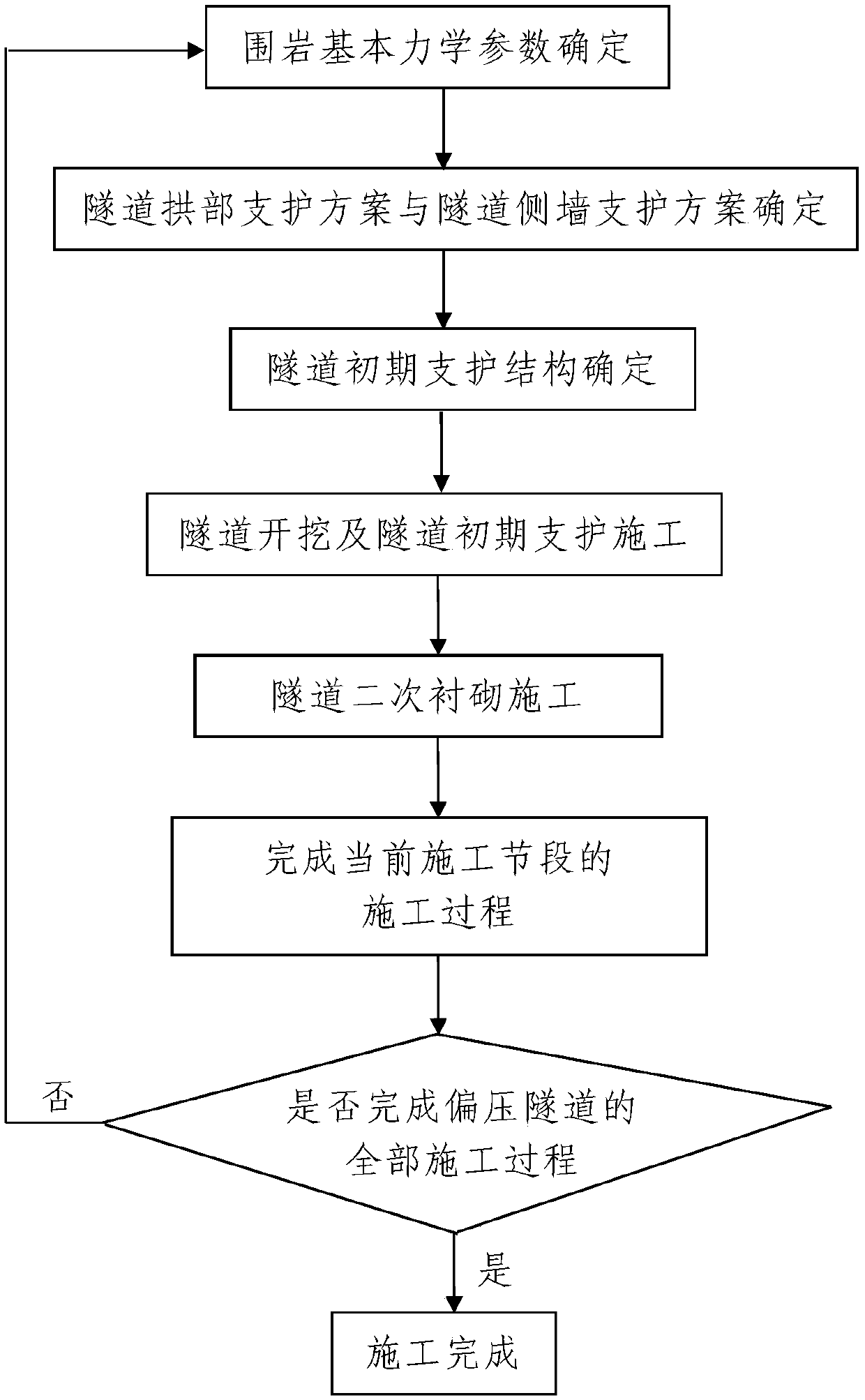

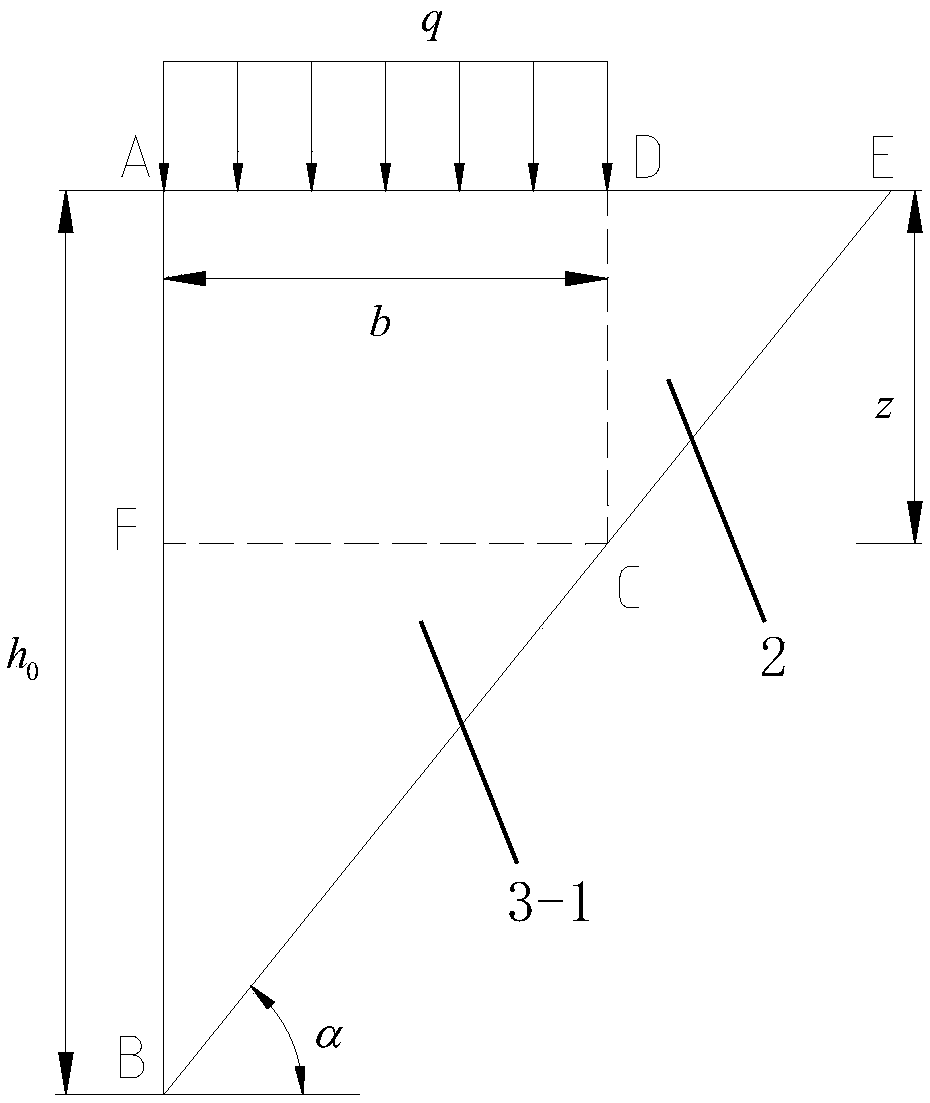

Unsymmetrically loading tunnel construction method

ActiveCN108086983ASimple stepsEasy to implementUnderground chambersTunnel liningSupporting systemStable state

The invention discloses an unsymmetrically loading tunnel construction method. The method comprises the steps of 1, determining basic mechanical parameters of surrounding rocks; 2, determining a supporting scheme of arch parts of a tunnel and a supporting scheme of side walls of the tunnel; 3, determining an initial supporting structure of the tunnel; 4, conducting tunnel excavation and initial supporting construction on the tunnel; 5, conducting secondary lining construction on the tunnel; 6, conducting construction on the next section: executing the steps 1-5 again, and conducting construction on the next section; repeatedly executing the step 6 until the entire construction process of the unsymmetrically loading tunnel is completed. The method has the advantages of being simple in process, convenient to implement and good in use effect. The supporting structure adopted for a tunnel anchorage supporting system is designed according to the judgment of instability of the side walls ofthe tunnel, deformation and destruction of the surrounding rocks of the side walls of the unsymmetrically loading tunnel can be effectively controlled, a tunnel arch part supporting system is determined according to the height of the roof caving arch camber when the side wall of the tunnel is in a stable state, requirements of stable supporting of the tunnel are satisfied, and construction costs are low.

Owner:沭阳建潼桥梁钢构制造有限公司

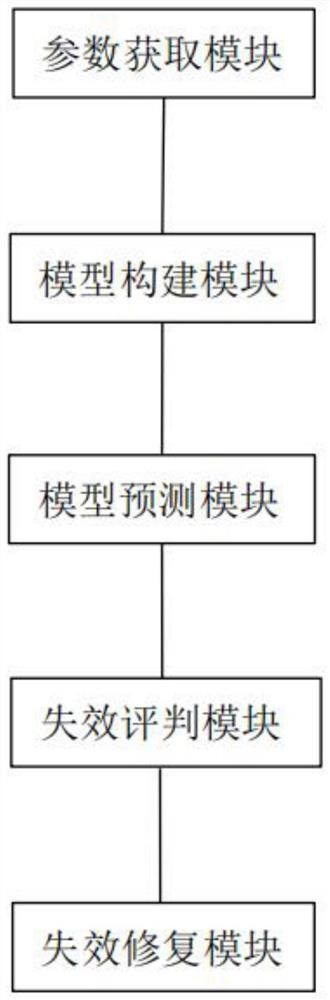

Coal mine underground gas extraction drilling failure evaluation system

PendingCN114837657AImprove the extraction effectAccurate samplingSurveyConstructionsEvaluation resultMining engineering

The invention discloses a coal mine underground gas extraction drilling failure evaluation system, which comprises a parameter acquisition module used for acquiring geological parameters of a to-be-researched coal seam; the model construction module is used for constructing a gas extraction drilling prediction model; the model prediction module is used for inputting the geological parameter data into a gas extraction drilling prediction model and predicting and judging the drilling operation state according to the judgment indexes; the failure evaluation module is used for performing drilling failure type division according to an evaluation result to obtain a failure type result of each drilling hole; and the failure repairing module is used for repairing the drill holes according to the failure types of all the drill holes, and real-time operation of gas drill hole extraction is guaranteed. The method is reasonable in design, coal seam gas extraction can be guaranteed to reach the standard on the premise that the gas extraction effect is improved and the construction cost is reduced, accurate coal seam gas extraction is achieved, and a theoretical basis and technical guidance are provided for on-site extraction drill hole arrangement.

Owner:GUIZHOU UNIV +1

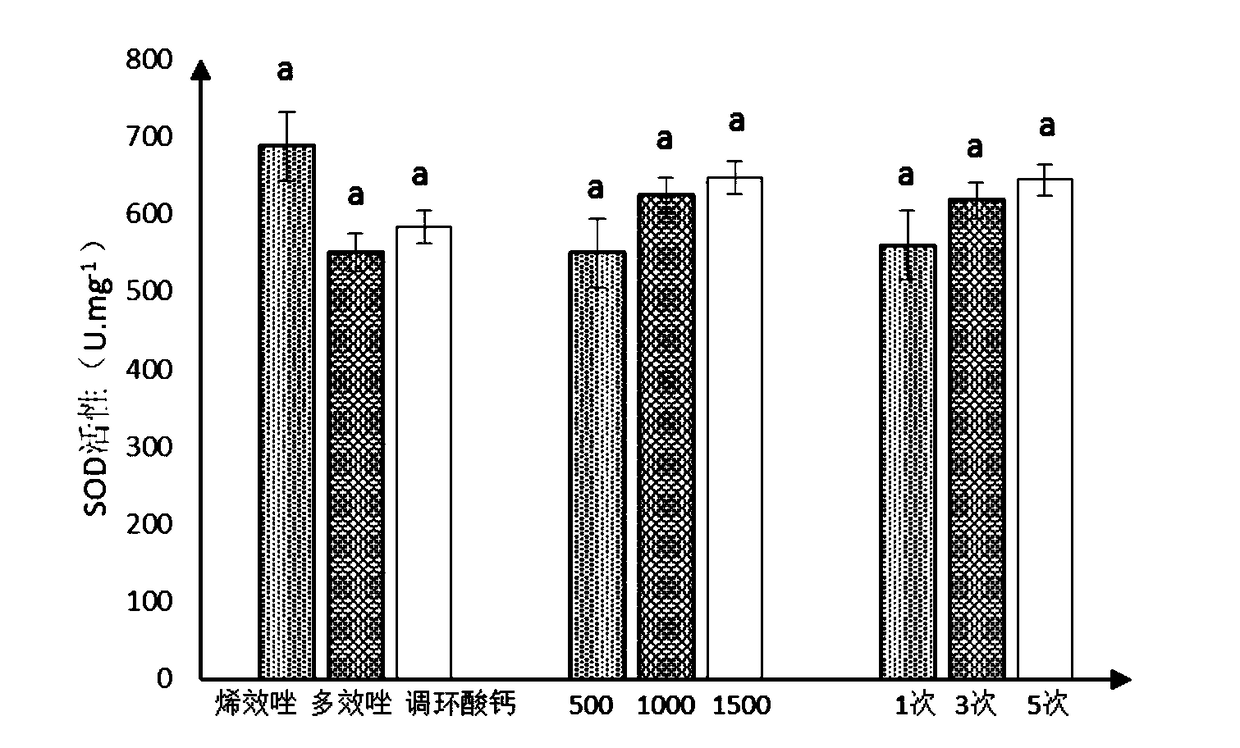

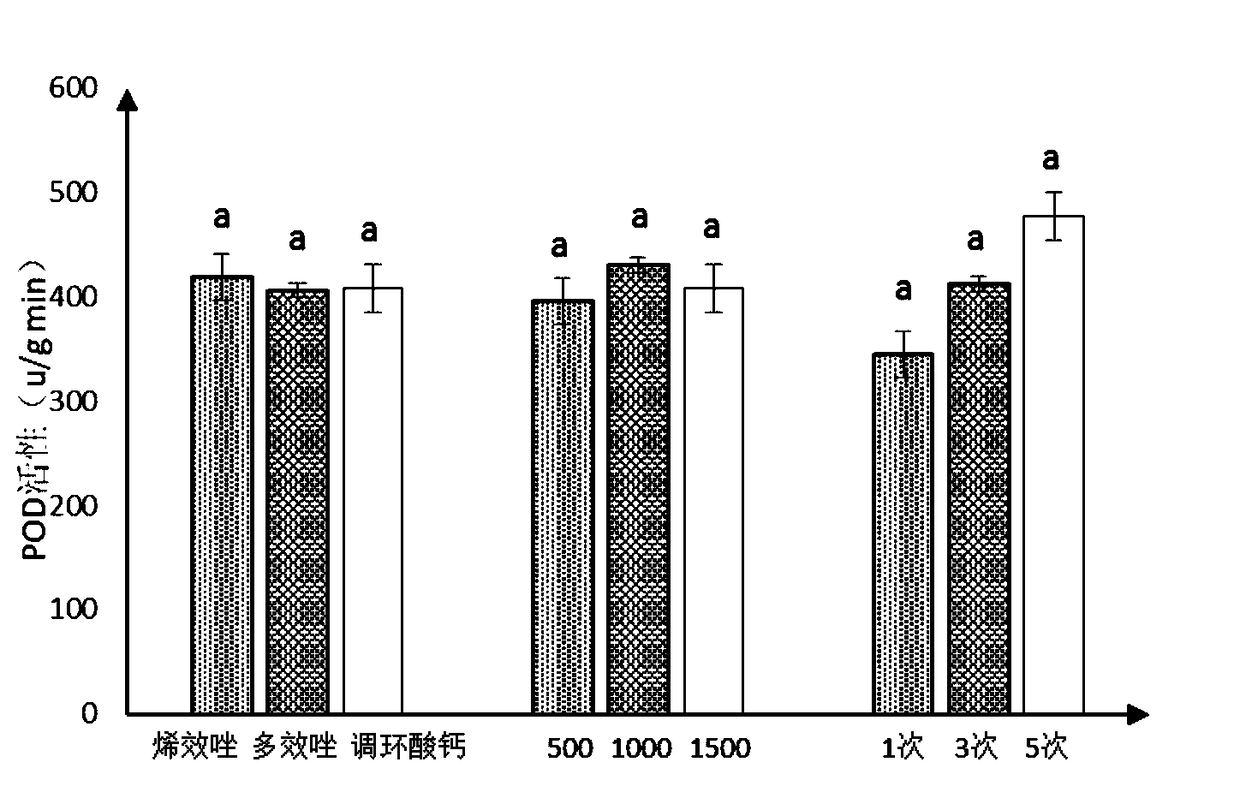

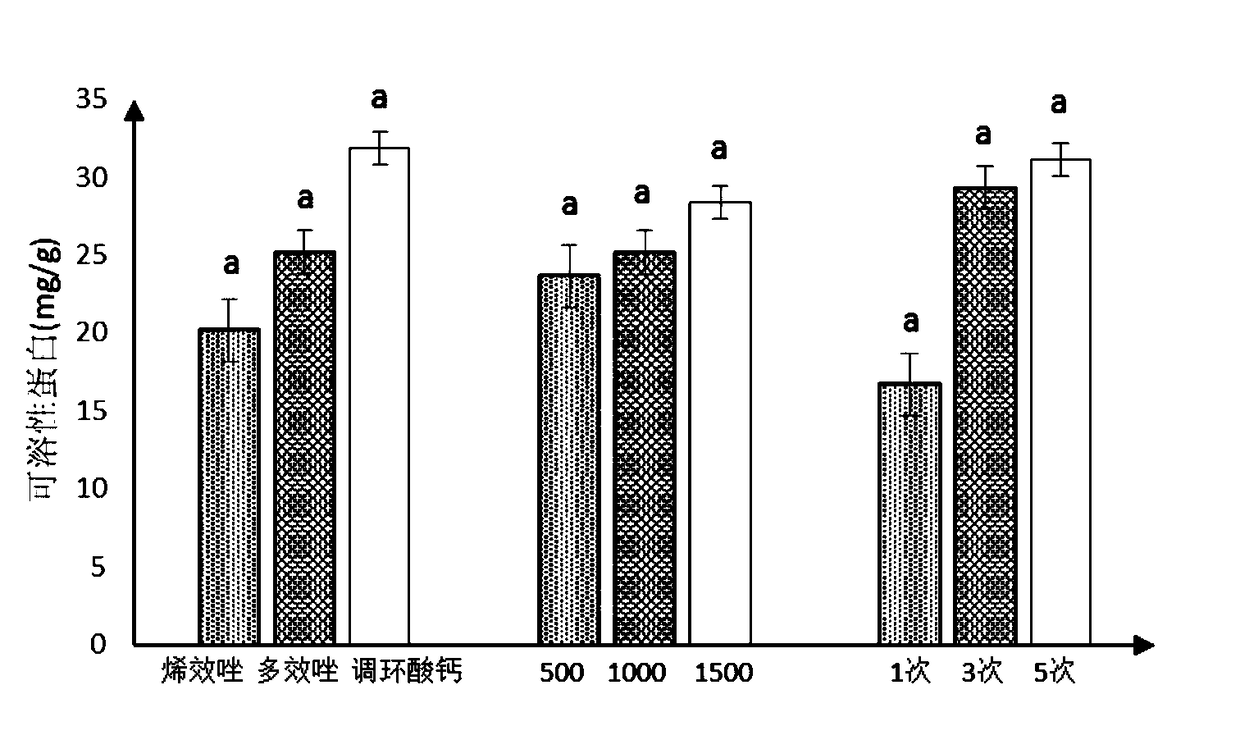

Dwarf culture method for magnolia wufengensis by using uniconazole

The invention discloses a dwarf culture method for magnolia wufengensis by using uniconazole. Magnolia wufengensis grafted seedlings are used as materials, a plant growth retardant is sprayed to the grafted seedlings before the grafted seedlings which survive after grafting grow rapidly, the plant growth retardant is 5% wettable powder of the uniconazole, the useconcentration is 1500 mg / L, and theplant growth retardant is sprayed five times in one growing season. The spraying method adopts foliar spraying, the front and back faces of all leaves of plants are sprayed until waterdripsfrom the leaveseach time, and the spraying interval is 10 days. The methodhas a remarkable dwarfing effect, easy operation and low cost, and provides ideas forsubsequent dwarfingof the magnolia wufengensis grafted seedlings, and the method has an important significance in greening and ornamental value of the magnolia wufengensis.

Owner:BEIJING FORESTRY UNIVERSITY

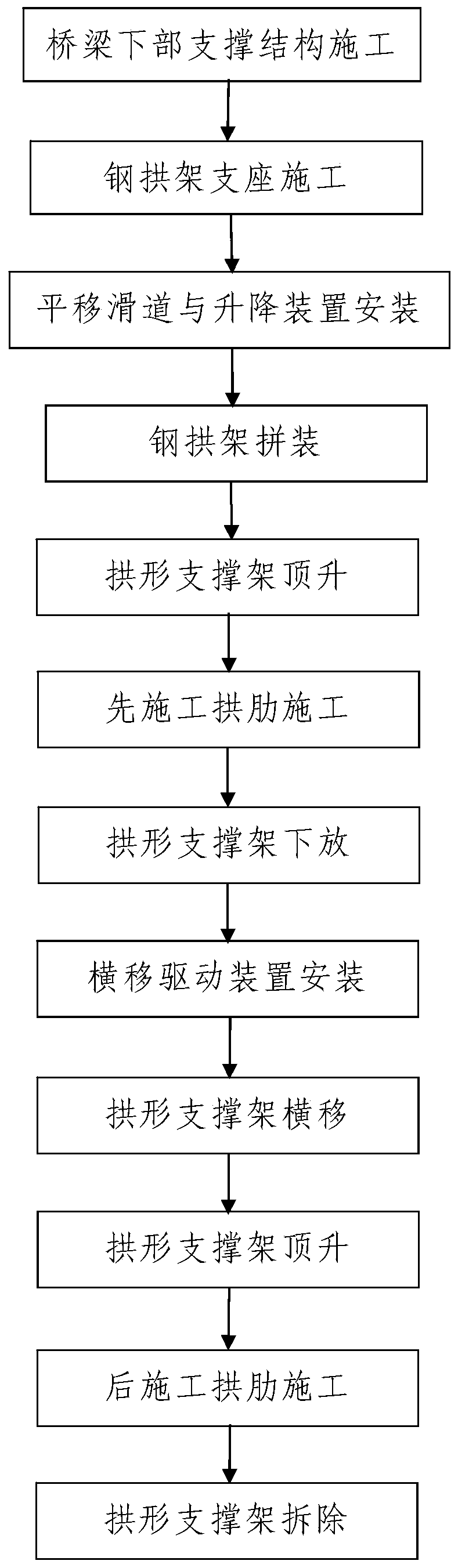

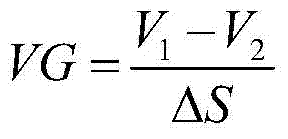

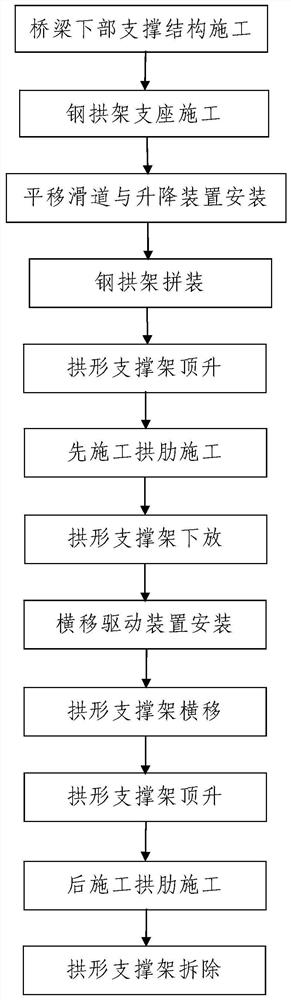

Construction method of arch ribs of deck type box arch bridge

ActiveCN110438906AImprove construction efficiencyThe method steps are well designedBridge erection/assemblyStructural engineeringArch bridge

The invention discloses a construction method of arch ribs of a deck type box arch bridge. The constructed deck type arch bridge comprises the two arch ribs which are symmetrically arranged on the left and right sides. During the construction of the arch ribs of the deck type arch bridge, the construction method comprises the following steps: (1) performing the construction of a lower supporting structure of the bridge; (2) performing the construction of the arch ribs. The process of the construction of the arch ribs comprises the steps of performing the construction of steel arch supports, mounting translation slideways and lifting devices, assembling a steel arch, lifting up an arched support frame, performing the construction of the earlier-construction arch rib, laying the arched support frame downward, mounting transverse-movement driving devices, transversely moving the arched support frame, lifting up the arched support frame, performing the construction of the later-construction arch rib, and removing the arched support frame. The construction method of the arch ribs of the deck type box arch bridge is reasonable in design, simple in construction and good in application effect. The two arch ribs are constructed one after the other by virtue of the steel arch, and the steel arch is supported and transversely moved by virtue of an arch supporting and transverse-movement device, so that the construction process of the two arch ribs can be completed simply and quickly. The construction process is safe and reliable. The construction efficiency of the deck type arch bridge can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

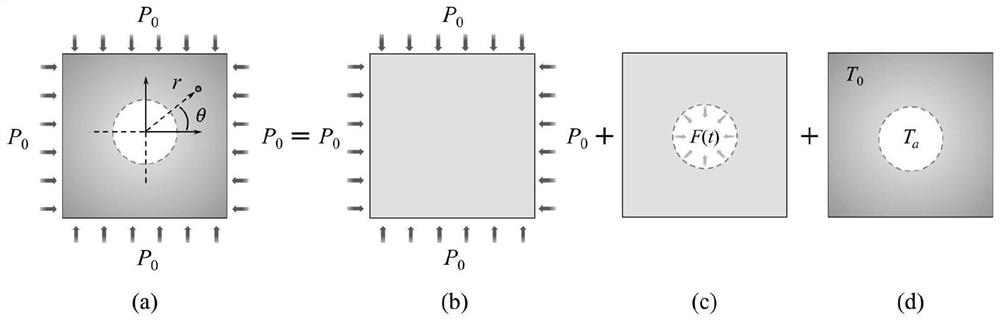

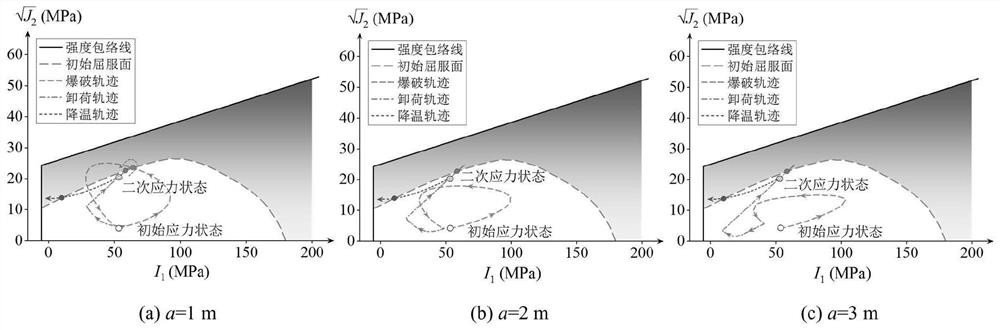

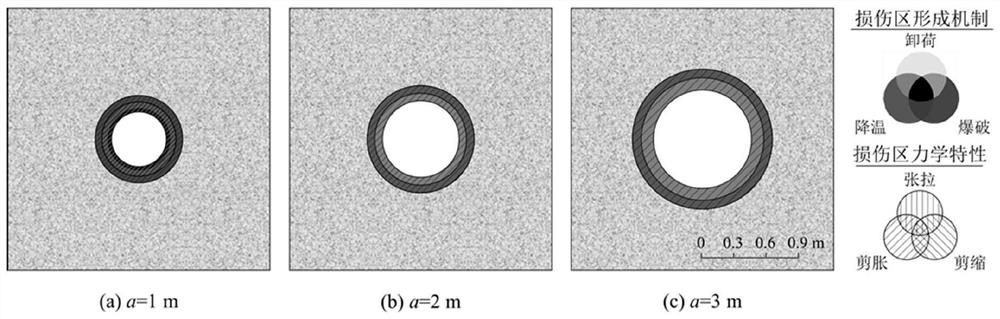

Surrounding rock excavation damage analysis method under thermal-mechanical coupling condition and application thereof

ActiveCN113326551AAccurate analysisAccurately assess the programGeometric CADSpecial data processing applicationsThermal forceClassical mechanics

The invention discloses a surrounding rock excavation damage analysis method under a thermal-mechanical coupling condition and application thereof, and the analysis method comprises the steps: building an excavation blasting-unloading-cooling whole-process model of a tunnel, and solving a process control equation comprising thermal stress, dynamic stress and ground stress superposition coupling; therefore, rock heat-force coupling responses of the model under different geological conditions and excavation modes are obtained. The distribution range of the excavation damage area can be determined, the formation stage and the formation reason of rock mass damage can be disclosed, meanwhile, the analysis method has the advantages of being high in calculation efficiency, short in needed time, small in consumed manpower and material resources and the like, and prediction and guidance can be provided for adaptive excavation design of the chamber under the high-temperature and high-pressure conditions.

Owner:SICHUAN UNIV

Method of positioning transformer in frequency converter cabinet

InactiveCN102868112AAvoid unsafe hazardsSmall lifting heightTransformers/reacts mounting/support/suspensionSwitchgearType frequencyTransformer

The invention discloses a method of positioning a transformer in a large frequency converter cabinet and provides a novel method of efficiently solving the problem that the transformer is positioned in the cabinet type frequency converter for enterprises of metallurgy and electric power. Under the condition that a cabinet body or an architectural structure is not damaged, the transformer is smoothly conveyed onto the base of the cabinet, thereby avoiding trivial procedures of manufacturing a door frame and removing the top of the cabinet; and the method can be applied only by processing a few necessary instruments, a lifting bracket in the shape of Omega, paving tracks and the like. The method of positioning the transformer in the large frequency converter cabinet has the advantages of simplicity and convenience in operation, high working performance, small lifting height and steady and reliable positioning process, and has the advantages of avoiding the unpredictable hidden dangers left by damaging the cabinet body or the architectural structure of an electric room, the usages of manpower and material resources are fewer, the positioning efficiency is high, and the installing cost is greatly reduced.

Owner:CHINA MCC17 GRP

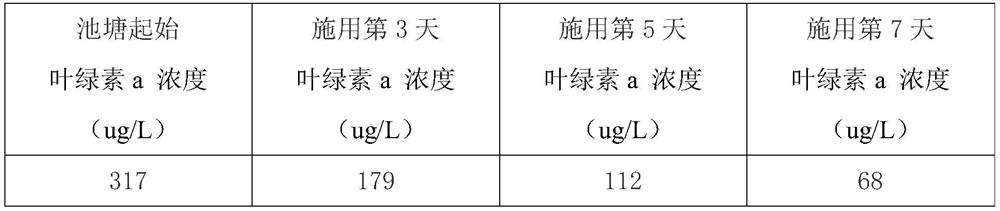

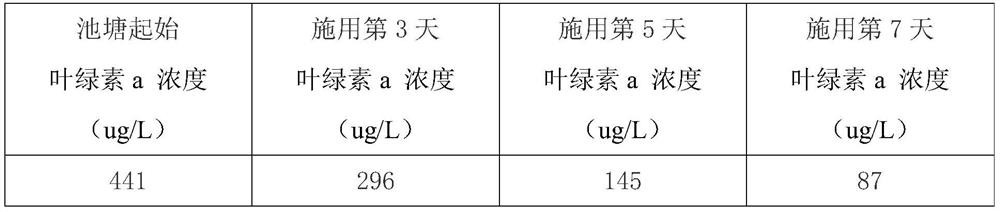

Composite ecological treatment agent for treating blue-green algae as well as preparation method and application thereof

ActiveCN112723557ARaw materials are easy to getEasy to manufactureTreatment using aerobic processesWater contaminantsVitamin CNutrition

The invention discloses a composite ecological treatment agent for treating blue-green algae as well as a preparation method and application thereof, and relates to the technical field of aquaculture. The composite ecological treatment agent is composed of composite bacillus, zeolite powder, water-sprinkling detoxification vitamin C and granular oxygen according to a weight ratio of (0.9-1.4):(9-11):(0.4-1):1. The composite ecological treatment agent for treating blue-green algae is prepared by crushing the granular oxygen and then mixing the crushed granular oxygen with a mixture of the composite bacillus, the zeolite powder and the water-sprinkling detoxification vitamin C; the composite ecological treatment agent is sprayed into an aquaculture pond where blue-green algae burst, blue-green algae can be prevented and controlled through nutrition competition and an ecological method, pond aquaculture water oxygen deficit caused by algae death after blue-green algae treatment is avoided, and good conditions are created for survival and growth of river crabs and crayfishes.

Owner:HUAIYIN TEACHERS COLLEGE

Construction process of concealed roofing exhaust hole

InactiveCN103362257BGuarantee the construction qualityConstruction quality is easy to controlLighting and heating apparatusRoof covering ventilationsReinforced concreteRebar

The invention discloses a construction process of concealed roofing exhaust holes, wherein a roofing exhaust system is arranged on a constructed roofing, the roofing exhaust system comprises sloping layers which are uniformly laid in a roofing layer or a plurality of first horizontal exhaust pipes which are uniformly laid in a heat-insulating layer; both ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe; and the vertical exhaust pipe is buried into a parapet, the lateral wall of a discharge flue or the lateral wall of an exhaust passage, and the parapet, the discharge flue and the exhaust passage are all of reinforced-concrete structures. The construction process of the concealed exhaust holes comprises the following steps of 1, measuring and releasing lines; 2, determining the buried structures of the vertical exhaust pipes; 3, pre-burying the vertical exhaust pipes; 4, positioning and installing the horizontal exhaust pipes; 5, connecting the exhaust pipes; and 6, laying the horizontal exhaust pipes. The construction process of the concealed roofing exhaust holes has the advantages of simple process step and reasonable design, the using effect of the molded roofing exhaust system through construction is good, and the problems of easy blockage, easy damage, unsmooth exhaust, poorer exhaust effect and the like existing in the existing exposed mode of the exhaust holes can be solved.

Owner:陕西建工集团有限公司 +1

A kind of bias tunnel construction method

ActiveCN108086983BSimple stepsEasy to implementUnderground chambersTunnel liningSupporting systemStable state

The invention discloses an unsymmetrically loading tunnel construction method. The method comprises the steps of 1, determining basic mechanical parameters of surrounding rocks; 2, determining a supporting scheme of arch parts of a tunnel and a supporting scheme of side walls of the tunnel; 3, determining an initial supporting structure of the tunnel; 4, conducting tunnel excavation and initial supporting construction on the tunnel; 5, conducting secondary lining construction on the tunnel; 6, conducting construction on the next section: executing the steps 1-5 again, and conducting construction on the next section; repeatedly executing the step 6 until the entire construction process of the unsymmetrically loading tunnel is completed. The method has the advantages of being simple in process, convenient to implement and good in use effect. The supporting structure adopted for a tunnel anchorage supporting system is designed according to the judgment of instability of the side walls ofthe tunnel, deformation and destruction of the surrounding rocks of the side walls of the unsymmetrically loading tunnel can be effectively controlled, a tunnel arch part supporting system is determined according to the height of the roof caving arch camber when the side wall of the tunnel is in a stable state, requirements of stable supporting of the tunnel are satisfied, and construction costs are low.

Owner:沭阳建潼桥梁钢构制造有限公司

Construction method of large-span continuous beams adjacent to existing deep-water foundations

ActiveCN106284085BThe method steps are simpleReasonable designBridge erection/assemblyReinforced concreteContinuous beam

Owner:NO 1 ENG LIMITED OF CR20G

Building roof construction process

InactiveCN103362254BSimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

Owner:陕西建工集团有限公司 +1

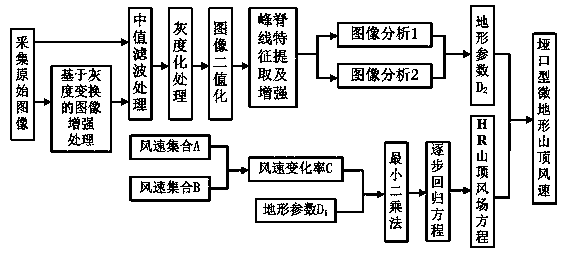

Bealock type microtopography mountain top wind speed intelligent measurement method

PendingCN110765408AAvoid limitationsLess manpower and material resourcesImage enhancementData processing applicationsEngineeringAtmospheric sciences

The invention discloses a bealock type microtopography mountain top wind speed intelligent measurement method comprising the following steps: collecting an original image of a bealock type microtopography with a pre-measured wind speed, and carrying out intelligent image identification processing so as to obtain topographic parameters of the bealock type microtopography; combining the existing wind speed value data of the bealock type microtopography area with topographic parameters of the bealock type microtopography where the power transmission line is located, and fitting an H / R mountain top wind field equation; and combining the topographic parameters obtained through image recognition with a bealock type micro-topography mountain top wind field equation to obtain the bealock type micro-topography mountain top wind speed for establishing the power transmission line. The method is convenient to use and low in cost, necessary data can be provided for safety design when the power transmission line passes through the bealock type microtopography, and safe and stable operation of the power transmission line is effectively guaranteed.

Owner:国网宁夏电力有限公司经济技术研究院 +1

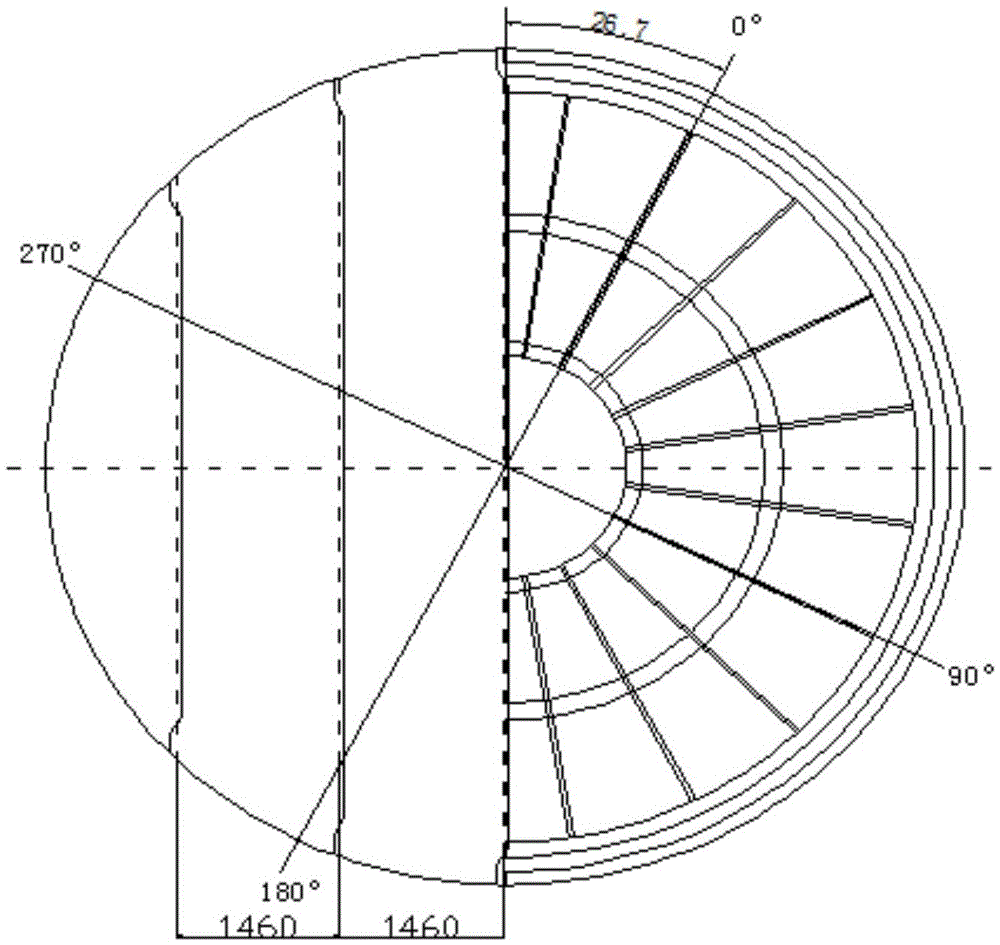

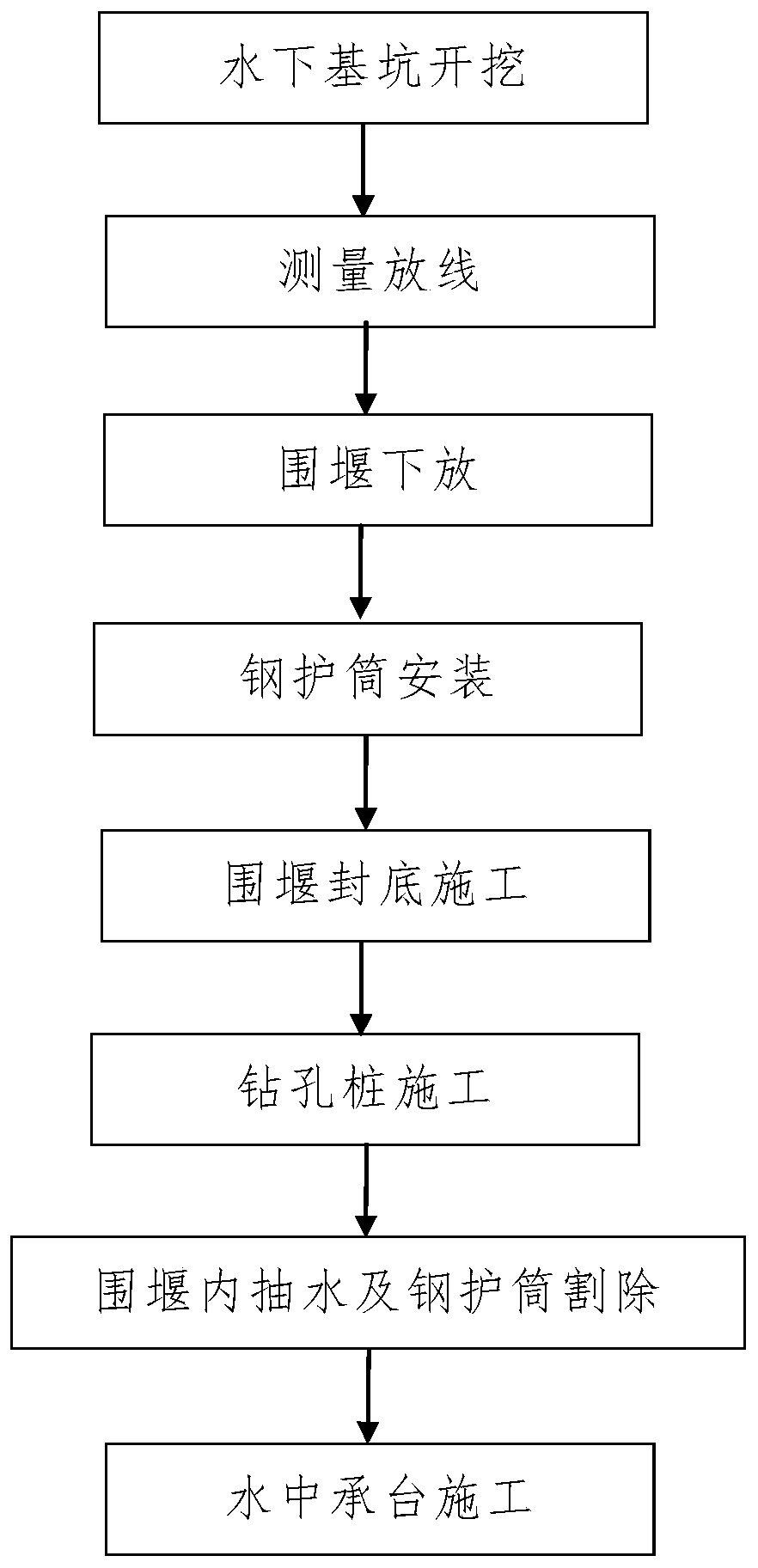

Construction method of deep-water foundation with long-span continuous beam adjacent to existing line

ActiveCN106351241BThe method steps are simpleReasonable designBulkheads/pilesSlagArchitectural engineering

The invention discloses a deep-water foundation construction method for a large-span continuous beam adjacent to an existing railway line. A deep-water foundation for construction comprises an underwater abutment and a plurality of drilled piles, wherein the underwater abutment is positioned on an underwater base rock on one side of the existing operating railway line, and the drilled piles are used for supporting the underwater abutment. The deep-water foundation construction method includes the steps: firstly, excavating an underwater foundation pit mounted at the bottom of a cofferdam by setting up an excavation platform, mounting an impact drill, moving the excavation platform and performing first impact, synchronous slag removal, second impact and synchronous slag removal; secondly, constructing the drilled piles and the underwater abutment by surveying and setting out, lowering a cofferdam, mounting a steel casing, sealing the bottom of the cofferdam, constructing the drilled piles, drawing water in the cofferdam, cutting off the steel casing and constructing the abutment. The steps are simple, the method is reasonable in design, simple and convenient in construction, good in use effect, safe and reliable in construction process and less in external influence, and the deep-water foundation construction process can be simply, conveniently and rapidly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD

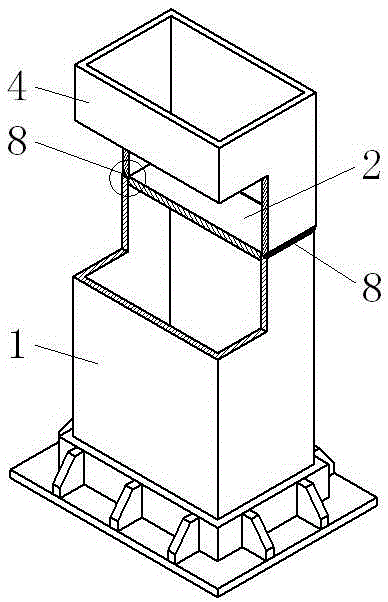

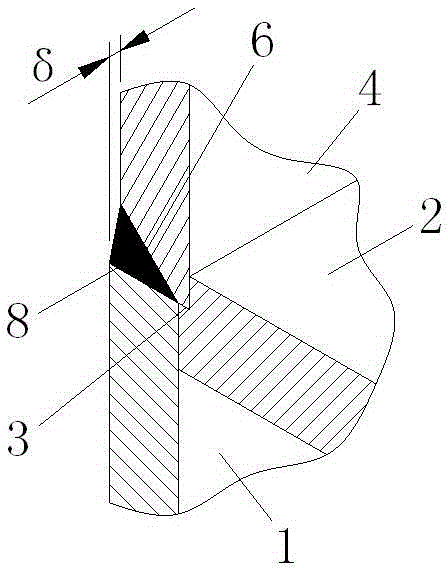

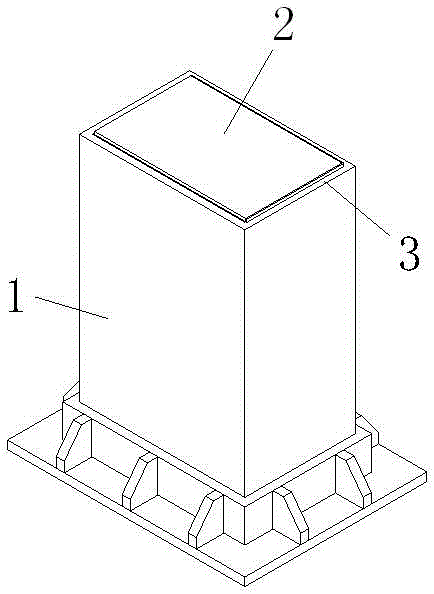

Correction method and structure of honeycomb grid column steel frame building foundation steel column

InactiveCN102889002BSolve deviationLess manpower and material resourcesStrutsBuilding repairsMetallurgyHoneycomb

Owner:CHINA CONSTR FOURTH ENG DIV

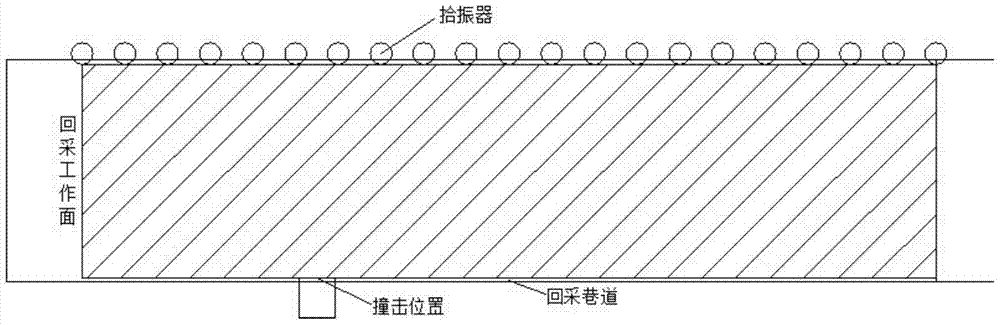

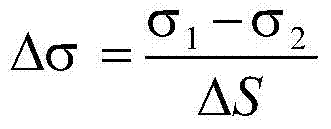

A Multi-information Coupling Prediction Method for In-situ Stress Type Rockburst Hazard

InactiveCN105045969BReal-time forecastImprove accuracySpecial data processing applicationsStress distributionTomography

The invention discloses a multi-information coupling prediction method for ground stress type rock burst risk. One side of the coal is blasted or hits the coal wall, and it is received by the pickup on the other side, and then CT tomography is used to obtain the distribution of the wave velocity gradient; (3) due to the coupling between the stress gradient and the wave velocity gradient, By determining the critical value of the stress gradient of the rock burst in the coal body, the critical value of the wave velocity gradient VGm is obtained; (4) In the process of coal mining, the wave velocity gradient VG in the coal body is obtained in real time through the formula; (5) The real-time The detected wave velocity gradient VG is compared with the wave velocity gradient critical value VGm. If VG is less than VGm, the prediction result is safe; if VG is greater than VGm, the prediction result is dangerous. It can predict the risk of rock burst in real time, and fully obtain the information of the outburst risk of rock burst.

Owner:CHINA UNIV OF MINING & TECH

A Construction Method for Arch Ribs of an Overhead Box Arch Bridge

ActiveCN110438906BImprove construction efficiencyThe method steps are well designedBridge erection/assemblyArchitectural engineeringRib first

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD

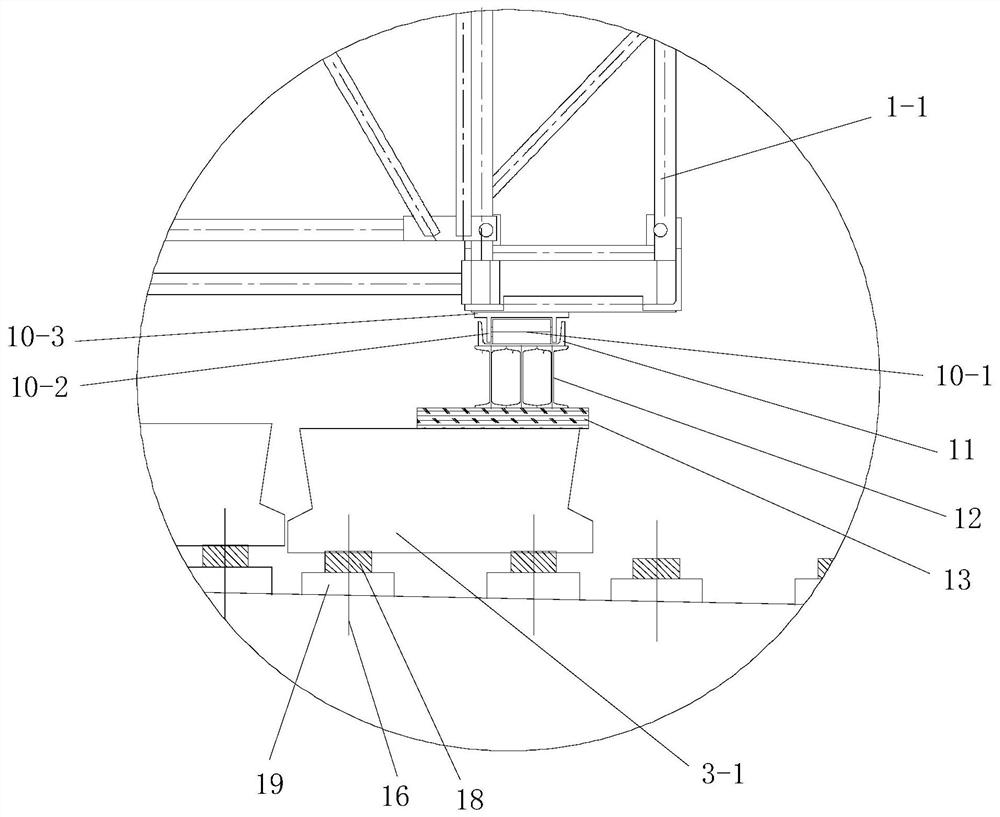

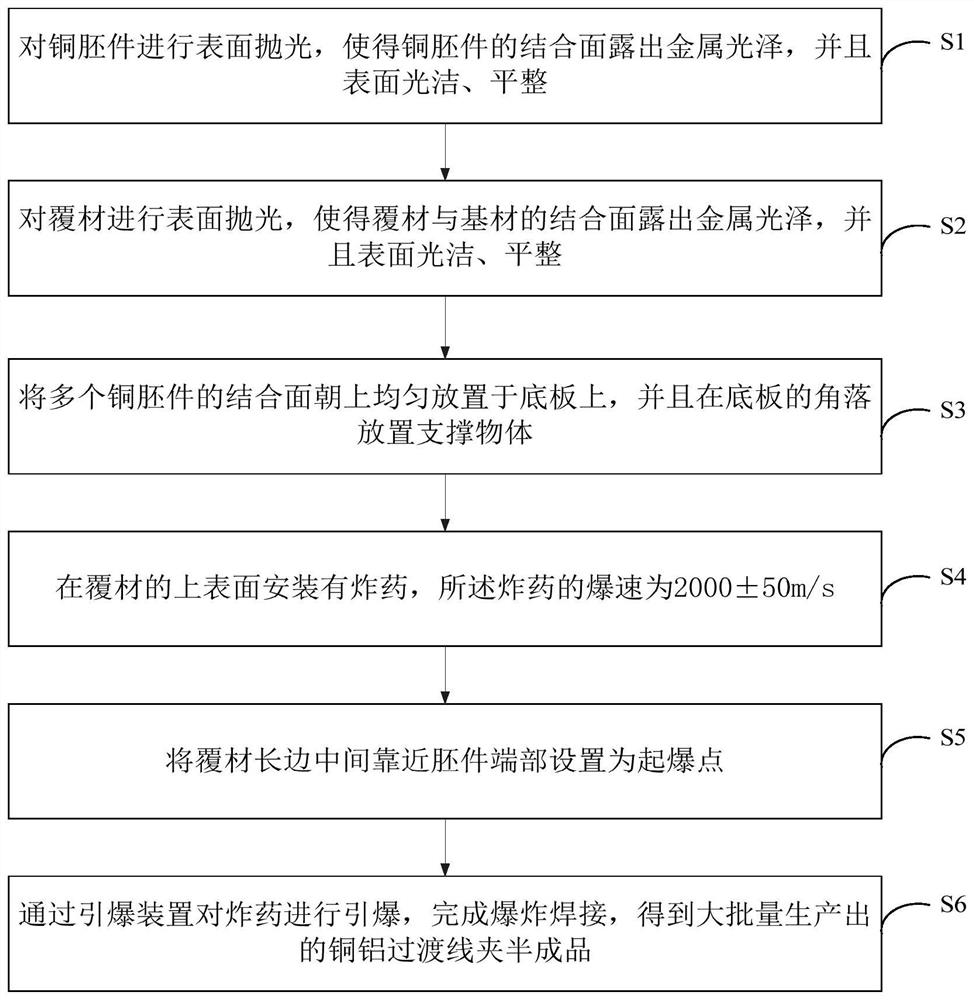

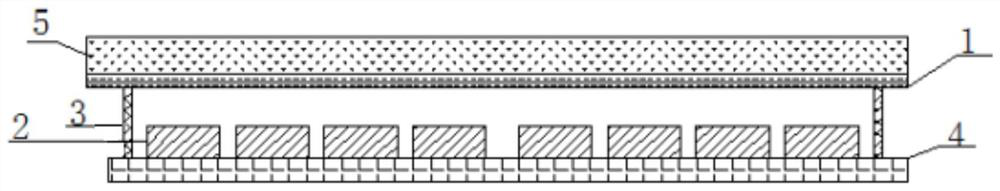

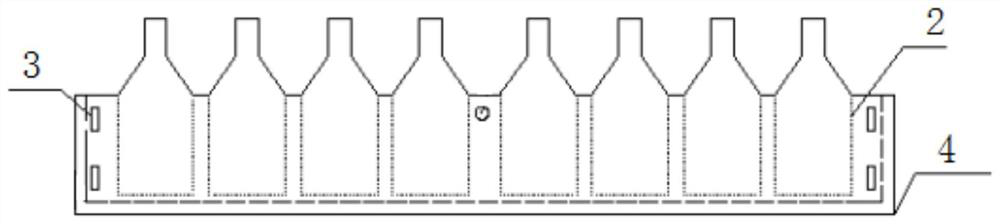

Explosive welding method for copper-aluminum transition wire clamp

PendingCN113084325ASimple processLess manpower and material resourcesNon-electric welding apparatusAluminiumMaterial resources

The invention discloses an explosive welding method for a copper-aluminum transition wire clamp. The explosive welding method comprises the following steps that the surfaces of copper blanks are polished, so that the bonding surfaces of the copper blanks have metallic luster, and the surfaces are smooth and flat; the surfaces of covering materials are polished, so that the bonding surfaces of the covering materials and base materials have metallic luster, and the surfaces are smooth and flat; the multiple copper blanks are evenly placed on a bottom plate with the bonding surfaces facing upwards, and supporting objects are placed at the corners of the bottom plate; required explosives are evenly laid in explosive grooves in the upper surfaces of the covering materials, and the detonation velocity of the explosives is 2000 + / -50 m / s; the positions, close to the end parts of the blanks, in the middles of the long sides of the covering materials are set as detonation points; and the explosives are detonated through detonating devices, explosive welding is completed, and copper-aluminum transition wire clamp semi-finished products produced in a large scale are obtained. Explosive welding can be carried out on the plurality of copper blanks on a welding bench at the same time after the copper blanks are spaced, and the manner is simple, few manpower and material resources are invested, and the production efficiency is high.

Owner:陕西红旗鸿远金属复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com