Method for manufacturing and mounting nuclear power desalting water tank

An installation method and a water tank technology are applied in the field of production and installation of large demineralized water tanks for condensate water polishing systems in nuclear power plants, and can solve the problems of large processing errors of water tanks, long installation construction period, large manpower demand, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a manufacturing and installing method of a nuclear power desalination tank, and the manufacturing and installing method comprises the following steps:

[0042] 1) Prefabrication of the water tank;

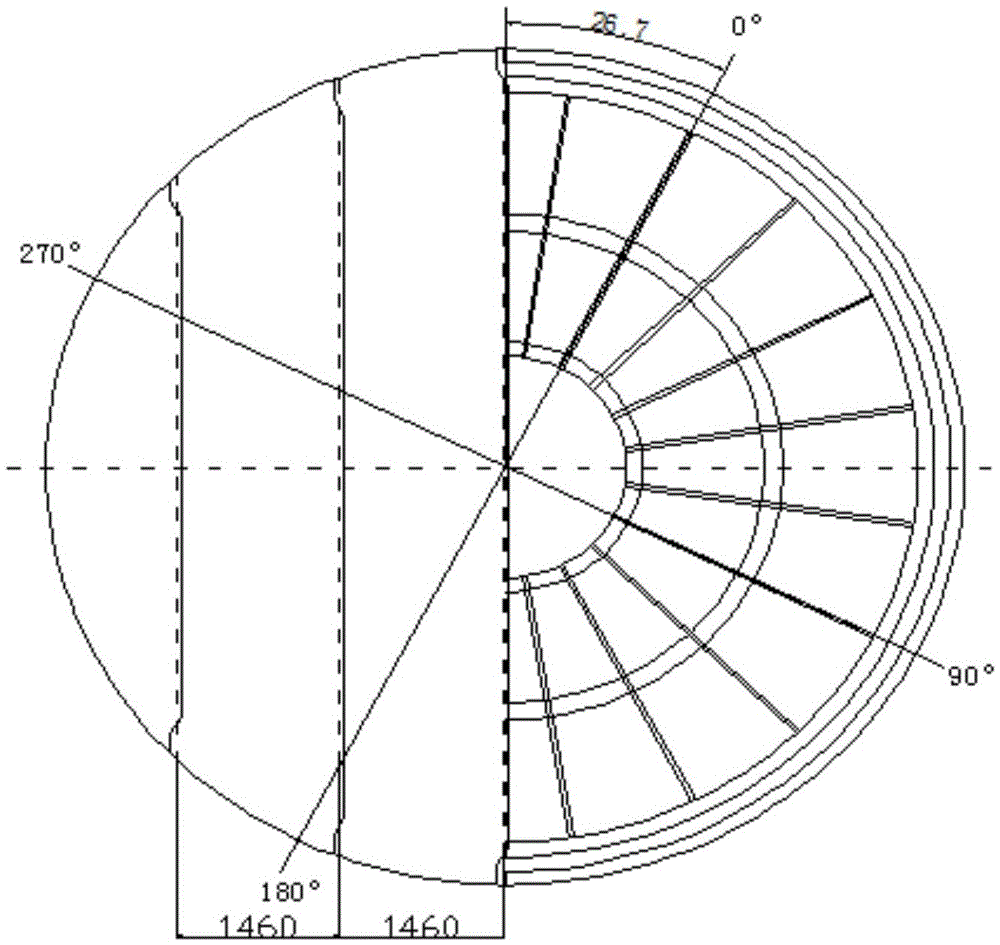

[0043] 2) Assembling of the water tank, the water tank includes a base plate, a top plate and N layers of wall plates between the base plate and the top plate;

[0044] 21) Basic inspection;

[0045] 22) Bottom plate installation:

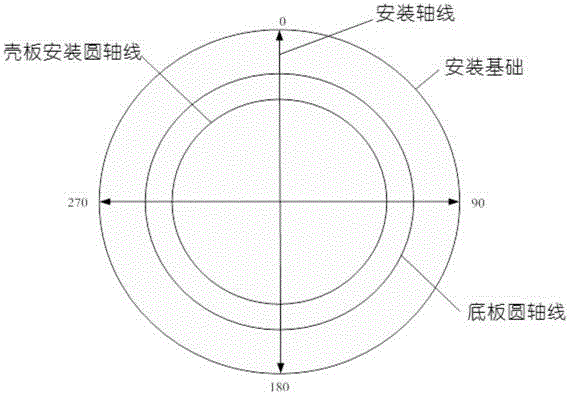

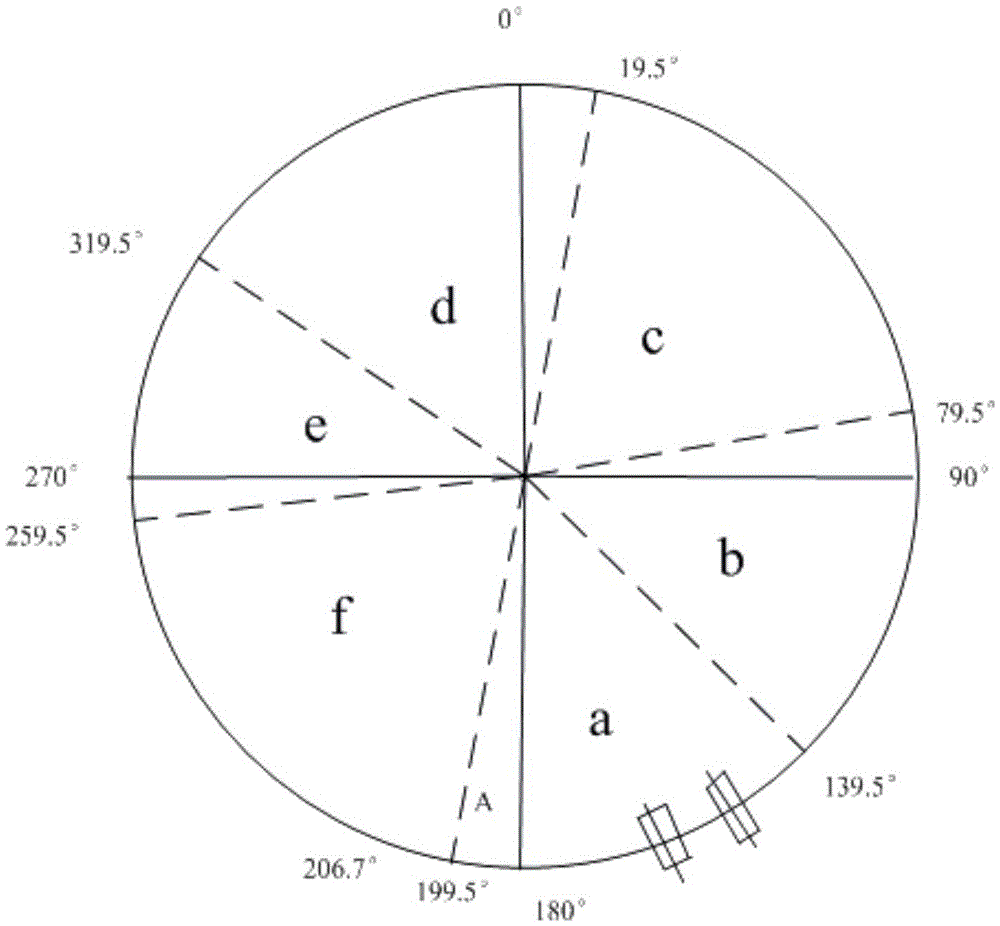

[0046] Take the origin of the coordinates of the installation axis as the center of the circle, draw the circumference line of the base plate on the basis according to the radius of the base plate, and draw the base plate installation reference line according to the layout drawing;

[0047] Take the base plate out from the storage site according to the prefabrication time mark, check whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com