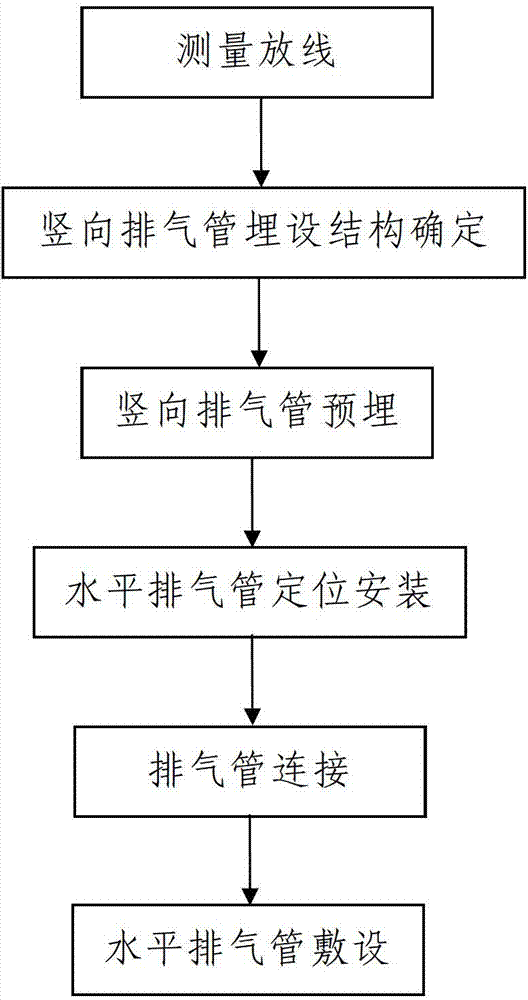

Construction process of concealed roofing exhaust hole

A construction technique and vent hole technology, applied in the field of roof vent construction technology, can solve problems such as poor exhaust effect, poor exhaust, easy to block, etc. The effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

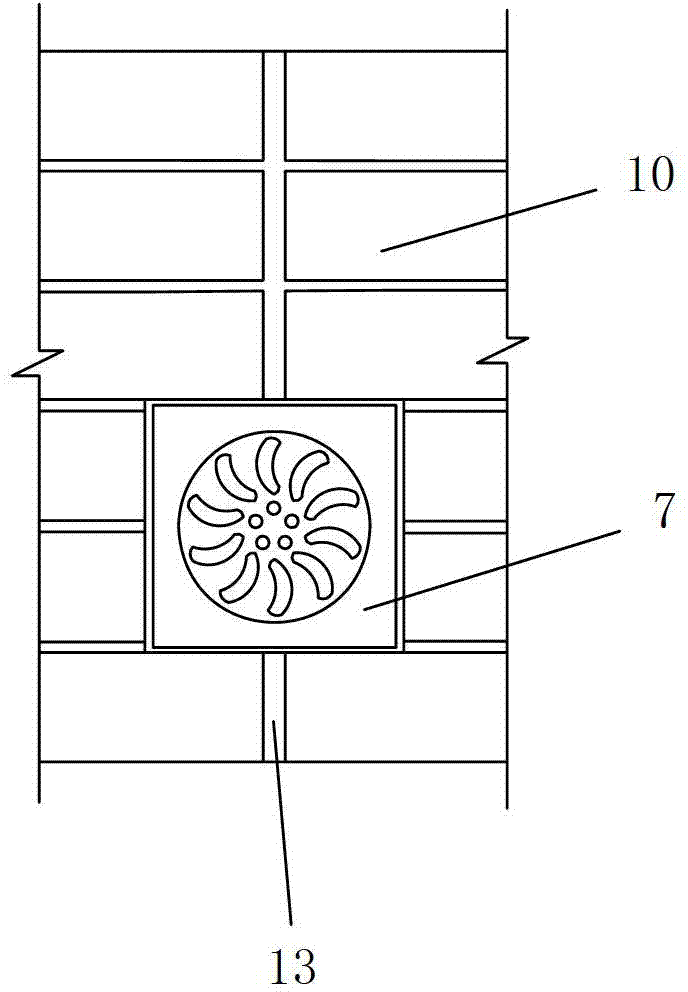

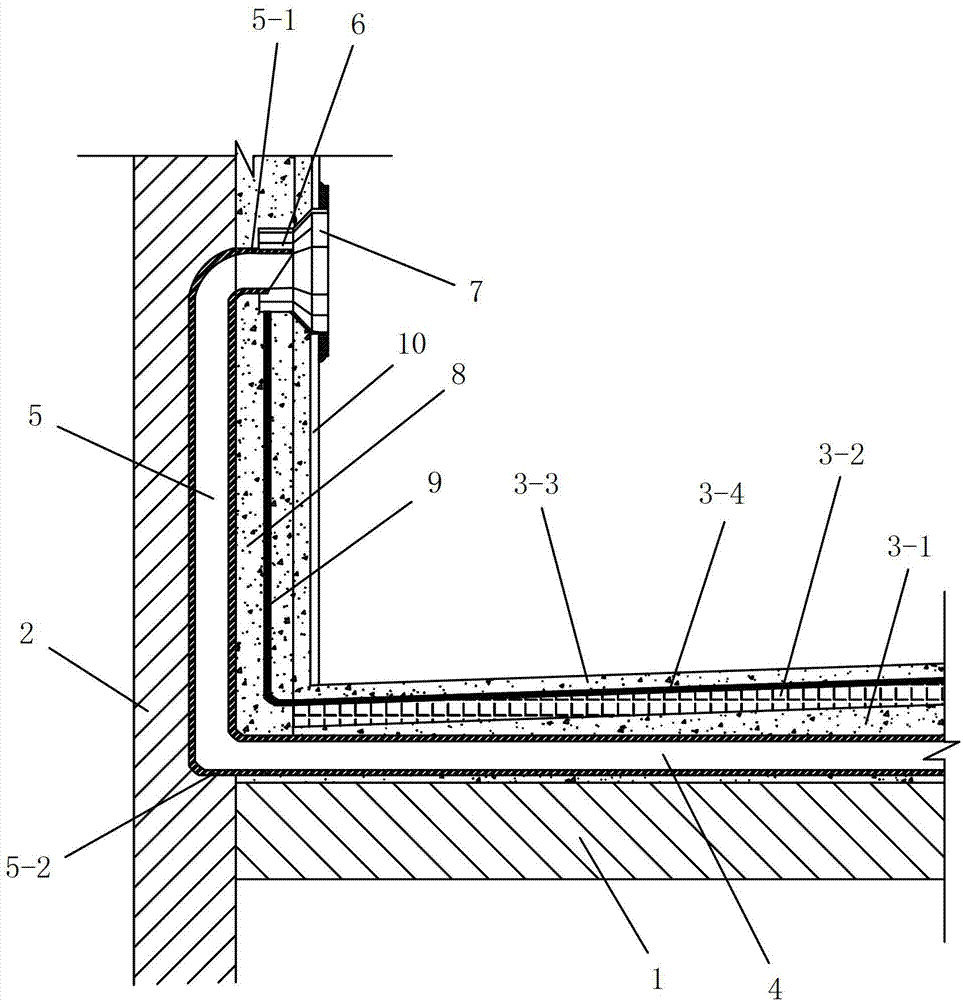

[0047] Such as figure 2 , image 3 As shown, in this embodiment, the constructed roof includes a roof structural panel 1 , a parapet 2 arranged on the sides of the roof structural panel 1 , and a roof surface layer laid on the roof structural panel 1 . A roof exhaust system is provided on the roof to be constructed, and the roof exhaust system includes a plurality of first horizontal exhaust pipes laid in the slope-finding layer 3-1 or the insulation layer 3-2 in the roof surface layer 4. Both ends of each first horizontal exhaust pipe 4 are connected to a vertical exhaust pipe 5, and both the first horizontal exhaust pipe 4 and the vertical exhaust pipe 5 are PVC plastic pipes. The vertical exhaust pipe 5 is buried in the parapet 2, the side wall of the exhaust duct or the side wall of the exhaust duct, and the exhaust duct and the exhaust duct are all arranged on the roof of the construction. The parapet 2, the exhaust duct and the exhaust duct are all reinforced concret...

Embodiment 2

[0094] In this embodiment, the difference from Embodiment 1 is that the plurality of second exhaust pipes are arranged obliquely, and the inclination angle of each second exhaust pipe is the same as the roof of the construction roof at the location where it is arranged. The slope is consistent. The plurality of first horizontal exhaust pipes 4 are arranged parallel to the ridge line of the roof being constructed, and the plurality of first horizontal exhaust pipes 4 include a middle first horizontal exhaust pipe arranged on the ridge line of the constructed roof. The exhaust pipe, the first horizontal exhaust pipe on the left side of the first horizontal exhaust pipe in the middle part, and the first horizontal exhaust pipe on the left side of the first horizontal exhaust pipe in the middle part, and the first horizontal exhaust pipe on the right side of the first horizontal exhaust pipe in the middle part, respectively. A horizontal exhaust pipe, among the multiple first hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com