Correction method and structure of honeycomb grid column steel frame building foundation steel column

A grid column and steel frame technology, applied in building construction, construction, building maintenance, etc., can solve the problems of large manpower and material resources, affecting the progress of the project, and relatively high size requirements, achieving small input of manpower and material resources, ensuring the progress of the project, Effectiveness of addressing bias issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

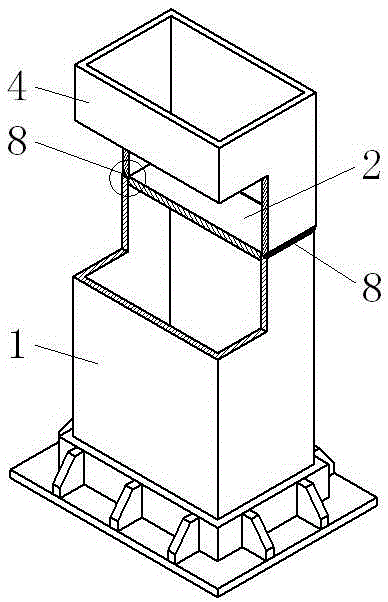

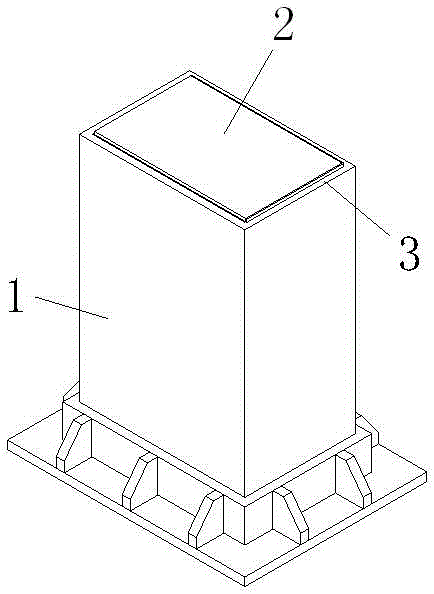

Embodiment 1

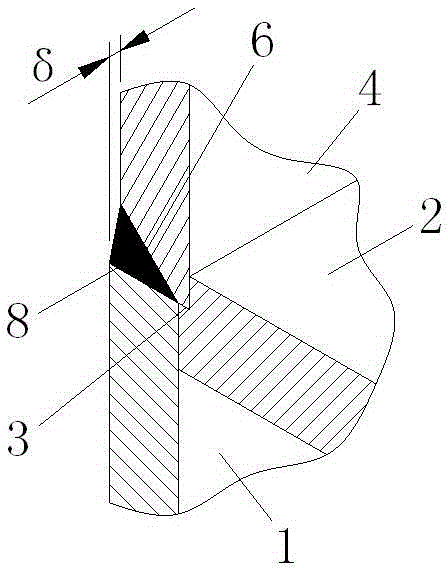

[0031] Example 1. The cross-section of a foundation steel column 1 is a rectangular tube of 600×400mm, and the thickness of the pipe wall is 24mm. The foundation steel column 1 is offset by the design value of 4mm in the X direction (600mm direction), and the design value of the Y direction (400mm direction) is 3mm. . The deviation correction process is as follows: First, an annular groove 3 is milled on the top surface of the basic steel column 1 welded with the sealing plate 2. The groove width of the annular groove 3 is 24mm, which is equal to the wall thickness of the honeycomb grid column 4. The annular groove 3 The center of the center of the base steel column 1 is offset by -4mm in the X direction of the top plane of the base steel column 1, and the Y direction of the base steel column 1 is offset by -3mm, that is to say, the center position of the annular groove 3 is aligned with the design center of the base steel column 1 . Use a semi-automatic cutting machine to m...

Embodiment 2

[0032] Example 2. A basic steel column 1 deviates from the design value of 16mm in the X direction (600mm direction), and there is no deviation in the Y direction (400mm direction). Since the basic steel column 1 has a single-directional deviation, a single-sided steel plate can be used to reinforce the deviation correction structure. The deviation correction process is as follows: Weld a rectangular reinforced steel plate 5 with a thickness of 22 mm, a width of 300 mm, and a length of 700 mm on the side of the negative deviation of the basic steel column 1, and use a cutting machine to process the welding groove 6 on both sides of the reinforced steel plate 5. Welding holes 7 are processed on the reinforcing steel plate 5 . The reinforced steel plate 5 is flattened by a flat machine, and then the reinforced steel plate 5 is sandblasted to Sa2.5 level. When the reinforcing steel plate 5 is welded to the basic steel column 1, the reinforcing steel plate 5 is pressed against th...

Embodiment 3

[0033]Example 3. A foundation steel column 1 deviates from the design value of 30mm in the X direction (600mm direction), and 20mm in the Y direction (400mm direction). Since the foundation steel column 1 has deviations in two directions, double-sided steel plates can be used to reinforce and correct the deviation structure. The deviation correction process is as follows: weld reinforcing steel plates 5 on the two faces of the foundation steel column 1 with negative deviations. One side of the basic steel column 1 with a width of 400 is welded with a rectangular reinforcing steel plate 5 with a thickness of 32 mm, a width of 300 mm, and a length of 950 mm; 950mm rectangular reinforced steel plate 5. The welding groove 6 is processed by a cutting machine on both sides of the reinforcing steel plate 5, and the welding hole 7 is processed on the reinforcing steel plate 5. The reinforced steel plate 5 is flattened by a flat machine, and then the reinforced steel plate 5 is sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com