Crest welder guide rail width closed-loop control system

A closed-loop control and wave soldering machine technology, which is applied in the direction of assembling printed circuits with electric components, can solve the problems of high manpower and material resources, inconvenient use and operation, and reduced welding efficiency, so as to achieve less manpower and material resources, convenient implementation, and improved The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

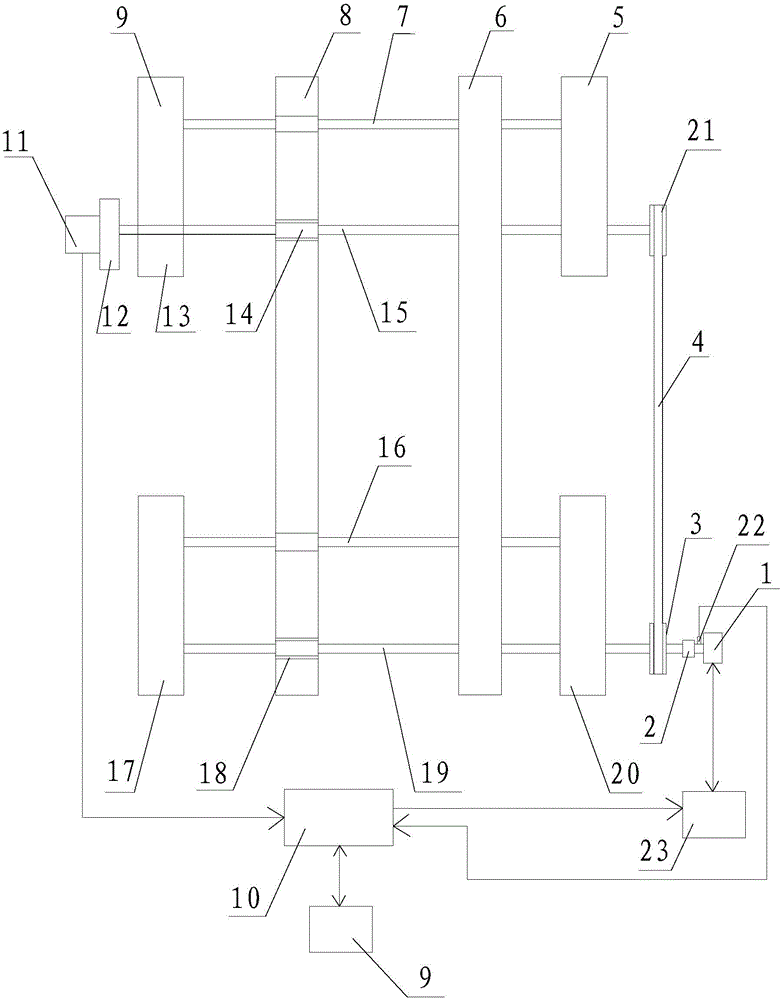

[0028] Such as figure 1 As shown, the present invention includes a guide rail width adjustment mechanism, an electric adjustment assembly and a guide rail width measurement assembly, and a programmable logic controller 10 for closed-loop control of the guide rail width of a wave soldering machine and the programmable logic controller 10. The touch-type liquid crystal display screen 9 is connected, and the rail width adjustment mechanism includes a first fixed block 5 and a second fixed block 13 arranged on the first horizontal straight line at intervals, and a third fixed block arranged on the second horizontal straight line at intervals. The fixed block 20 and the fourth fixed block 17, as well as the fixed guide rail 6 and the moving guide rail 8, the first polished rod 7 is fixedly connected between the first fixed block 5 and the second fixed block 13, the first fixed block 5 and the A first adjusting screw 15 parallel to the first polished rod 7 is rotatably connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com