A Construction Method for Arch Ribs of an Overhead Box Arch Bridge

A construction method and technology for arch bridges, which are applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of limited construction site, difficult removal, slow traverse speed, etc. The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

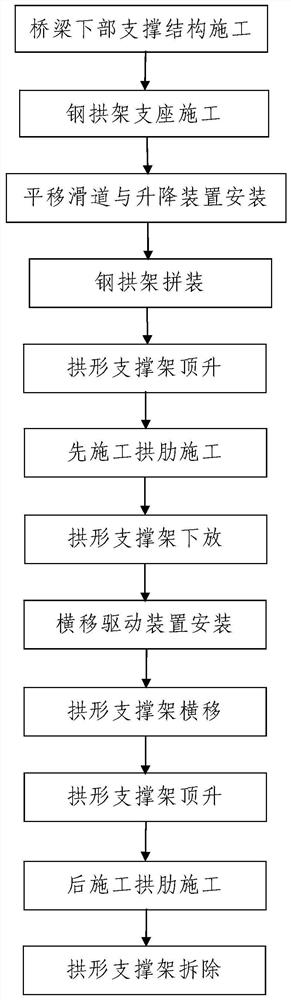

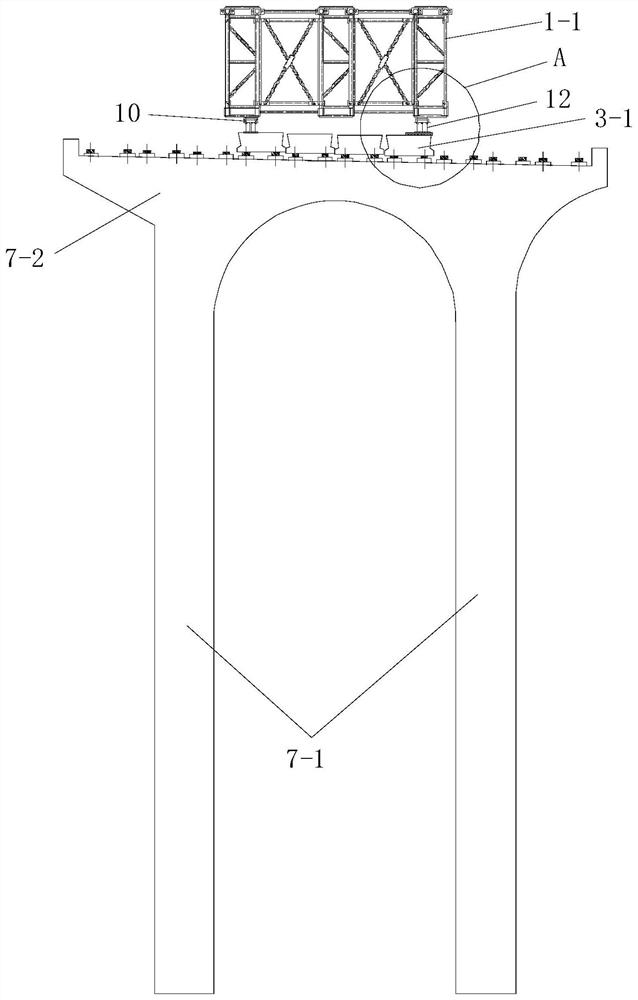

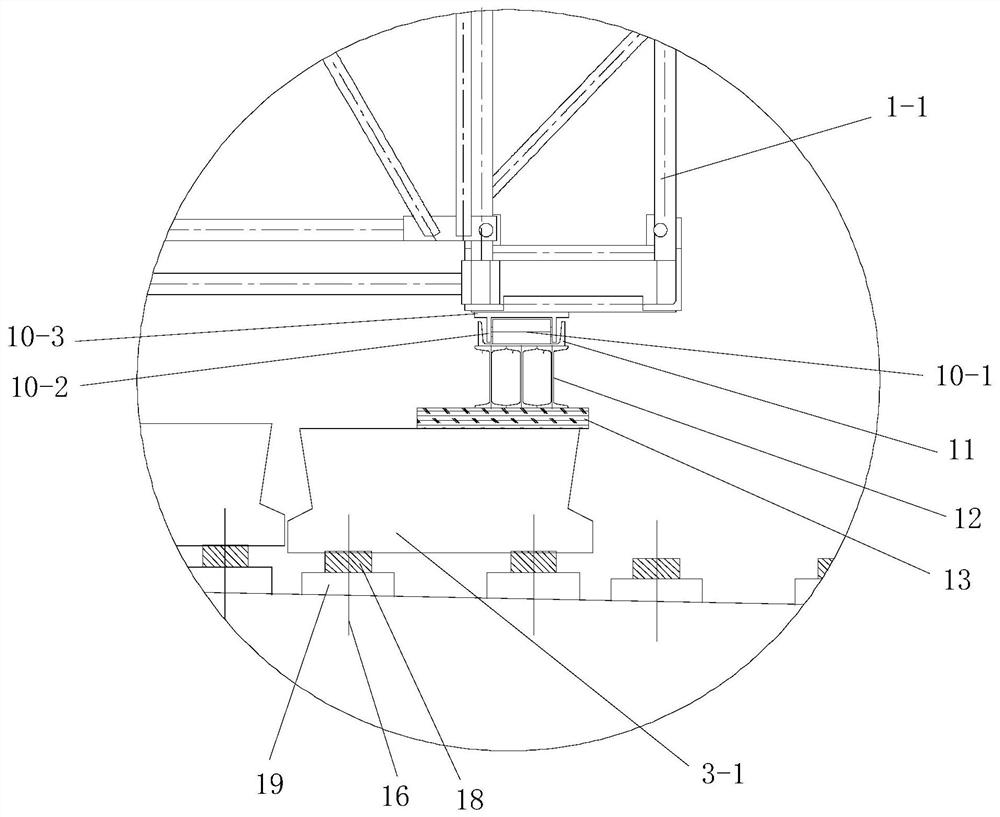

[0199] Such as figure 1 Shown is a construction method for the arch ribs of an upwardly supported box arch bridge. The constructed upwardly supported arch bridge includes two symmetrically arranged arch ribs 2 on the left and right. Described arch rib 2 is the post-construction arch rib that will be constructed after the construction of the first construction arch rib is completed; the front and rear ends of each described arch rib 2 are respectively supported on a permanent support 6, and the permanent support 6 It is a reinforced concrete support, and the arch rib 2 is arranged along the longitudinal direction of the bridge and it is a reinforced concrete arch ring. For details, see Figure 4 ;

[0200] Such as Figure 4 As shown, a main girder is arranged directly above each of the arch ribs 2; the front and rear ends of each main girder are respectively supported on an abutment 8, and the main girder is arranged horizontally and includes supports on The middle beam sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com