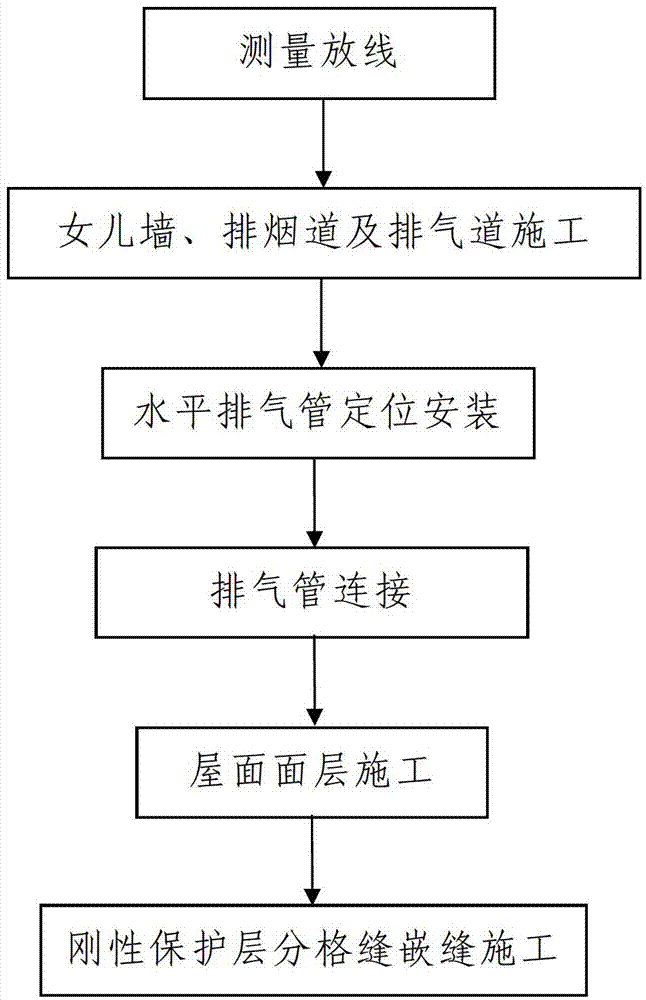

Building roof construction process

A construction technology and construction technology, applied in the direction of building roof, roof covering, roof ventilation, etc., can solve the problems of low work efficiency, influence of construction quality of building roof construction, and difficulty in guaranteeing construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

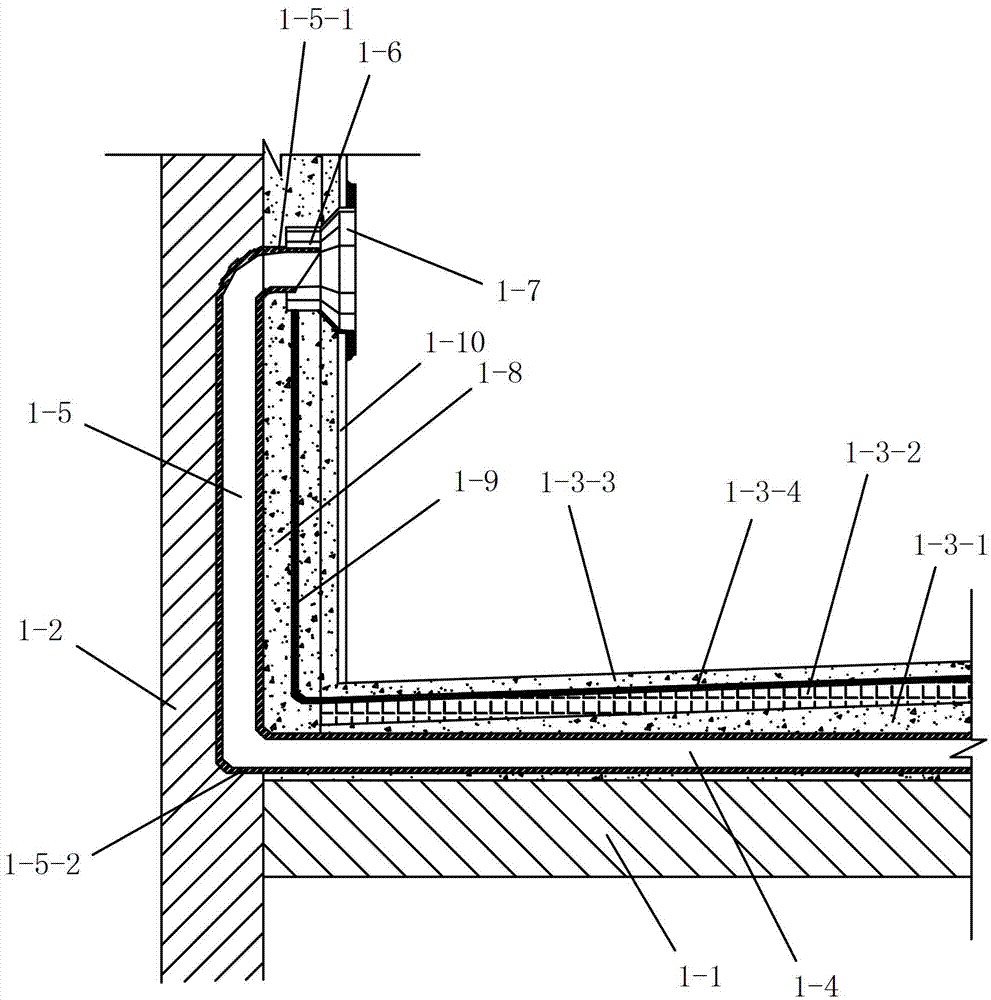

[0066] Such as Figure 1-2 , Figure 1-3 As shown, in this embodiment, the constructed roof includes a roof structural panel 1-1, a parapet 1-2 arranged on the sides of the roof structural panel 1-1, and a roof surface layer laid on the roof structural panel 1-1. . The roof surface layer includes a slope-finding layer 1-3-1 laid on the roof structural board 1-1, a heat-insulating layer 1-3-2 laid on the slope-making layer 1-3-1, and a heat-preserving layer laid on the The roof waterproof layer 1-3-4 on the 1-3-2 and the rigid protective layer 1-3-3 paved on the roof waterproof layer 1-3-4. A roof exhaust system is provided on the constructed roof, and the roof exhaust system includes multiple first horizontal exhaust pipes 1-4 laid in the slope-making layer 1-3-1 or the insulation layer 1-3-2 . Both ends of each first horizontal exhaust pipe 1-4 are connected to a vertical exhaust pipe 1-5, and the first horizontal exhaust pipe 1-4 and the vertical exhaust pipe 1- 5 are P...

Embodiment 2

[0147] In this embodiment, the difference from Embodiment 1 is that the plurality of second exhaust pipes are arranged obliquely, and the inclination angle of each second exhaust pipe is the same as the roof of the construction roof at the location where it is arranged. The slope is consistent. The plurality of first horizontal exhaust pipes 1-4 are arranged parallel to the ridge line of the constructed roof, and the plurality of first horizontal exhaust pipes 1-4 include one arranged on the ridge line of the constructed roof. The first horizontal exhaust pipe in the middle part and multiple channels are respectively arranged on the left side of the first horizontal exhaust pipe in the middle part; The first horizontal exhaust pipe on the right side, among the multiple first horizontal exhaust pipes 1-4, the layout position of the middle first horizontal exhaust pipe is the highest. The plurality of second exhaust pipes includes a plurality of left second exhaust pipes respec...

Embodiment 3

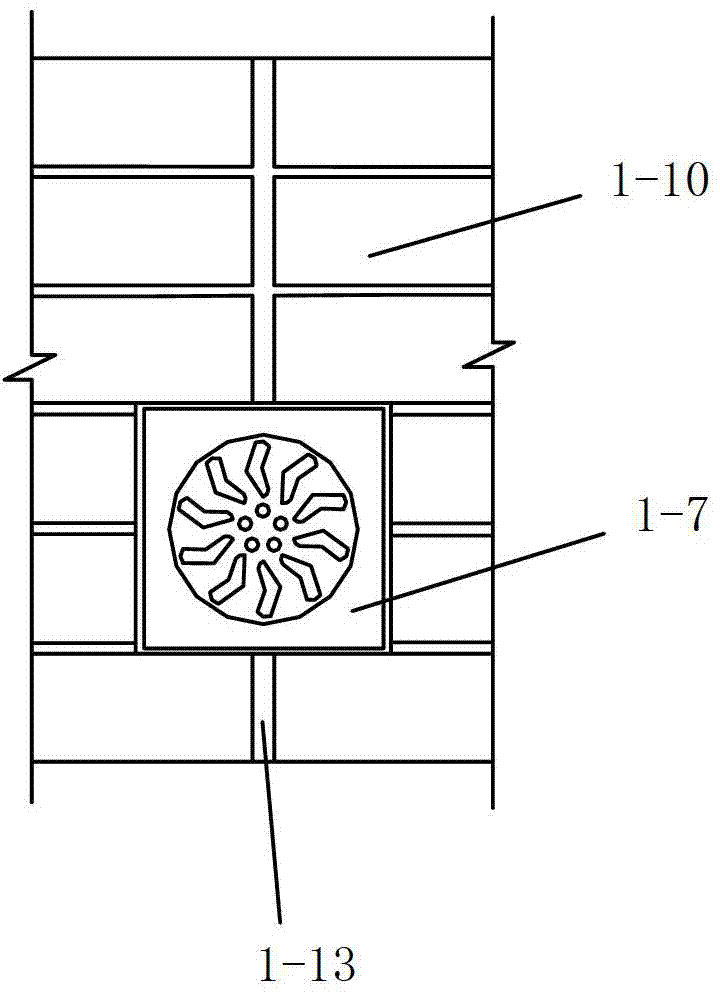

[0154] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that: when constructing the parapet wall 1-2 in step 2, a concrete boss 3 needs to be set on the inner wall surface of the parapet wall 1-2 -2, the concrete boss 3-2 is poured together with the parapet 1-2, and the concrete boss 3-2 is the flooded eaves of the parapet 1-2; the concrete boss 3-2 is Horizontal layout; after the exhaust pipe connection in step 4 is completed, it is necessary to evenly paint a layer of plastering layer 1-8 on the inner wall of the parapet wall 1-2 completed in step 2, and the plastering layer Parapet facing bricks 1-10 are pasted on the first 1-8; the plastering layer 1-8 is divided into upper and lower parts with the concrete boss 3-2 as the boundary, wherein the plastering layer 1-8 is located above the concrete boss 3-2 The plastering layer one 1-8 is cement mortar layer five 3-3-5, and the parapet facing brick 1-10 paved on the cement mortar layer five 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com