Chinese yam slicing machine and Chinese yam slicing mode

A slicer and yam technology, applied in metal processing, etc., can solve problems such as low efficiency, operator hand injury, and inability to provide yam slices according to different needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

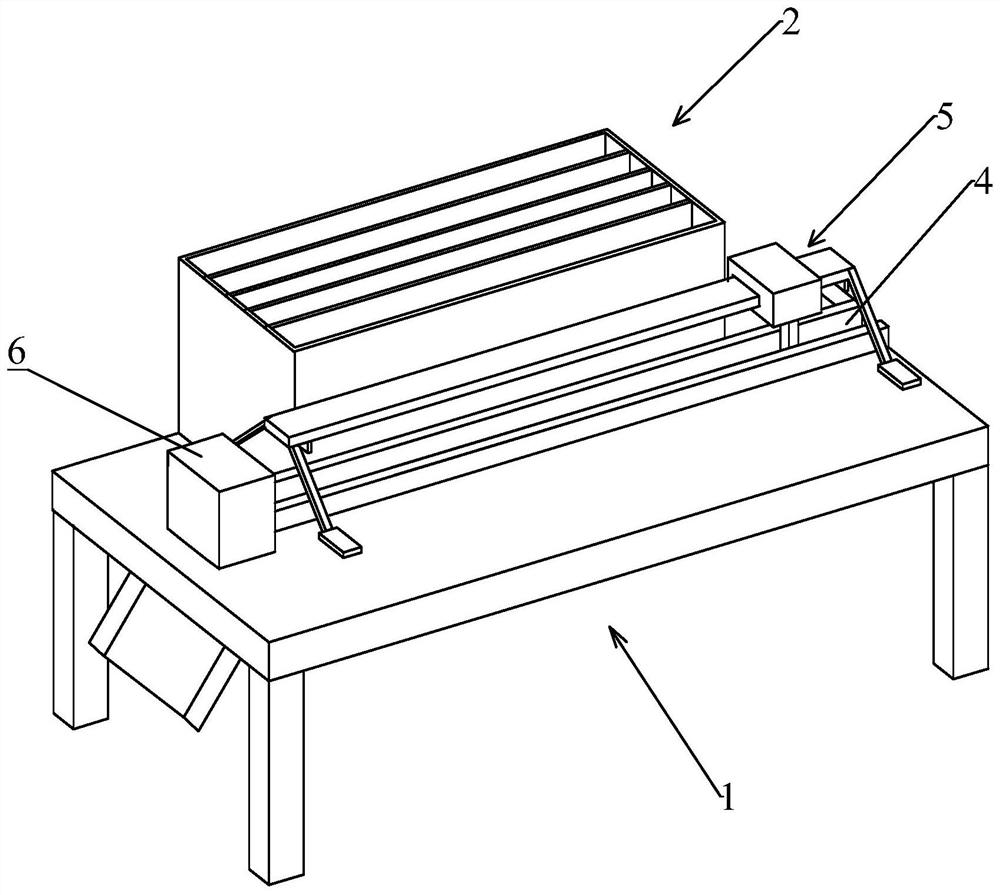

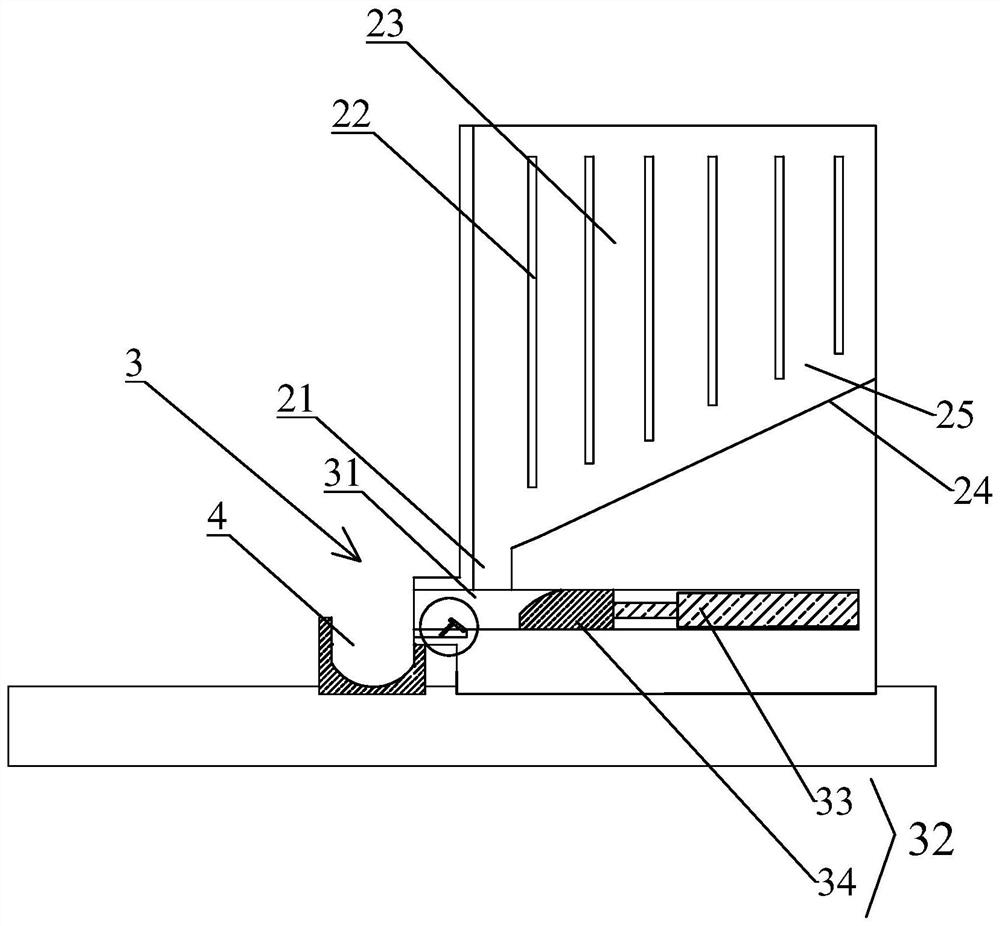

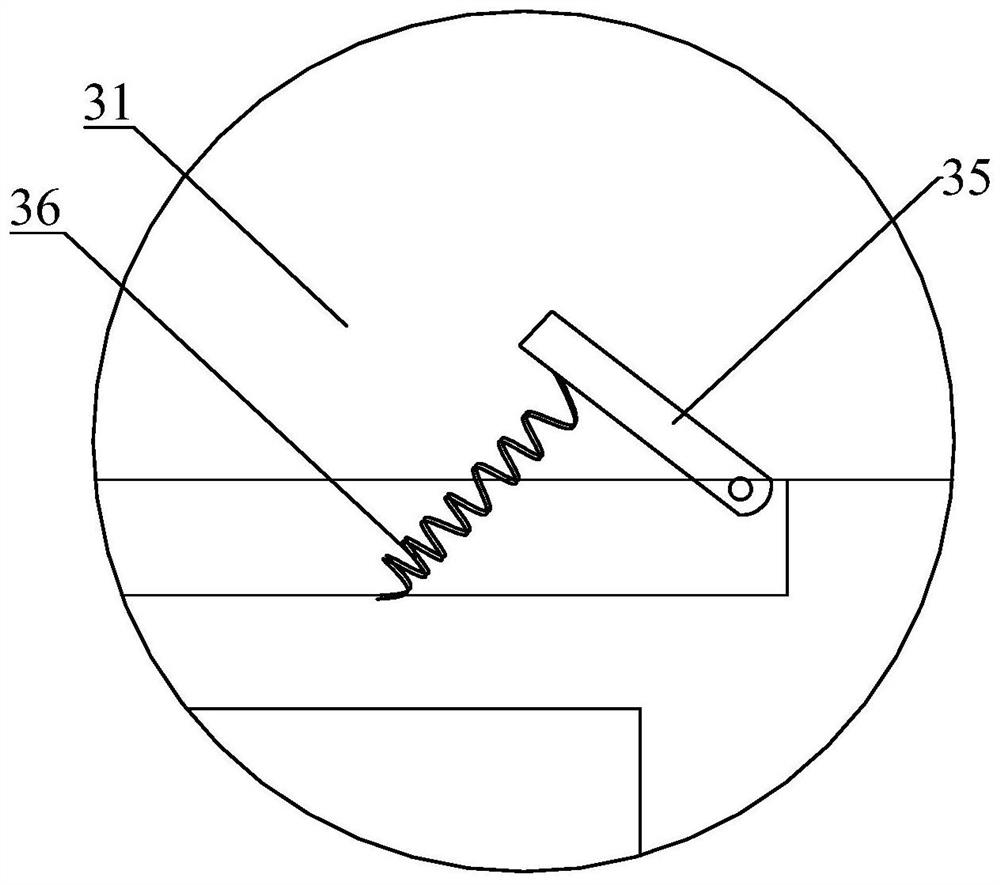

[0025] What the present invention discloses is a kind of yam slicer, such as Figure 1-6 As shown, it is a preferred embodiment of the present invention, such as figure 1 As shown, it includes a frame 1 and a storage box 2 installed on the frame 1, a feeding mechanism 3, a material guide 4, a propulsion mechanism 5 and a slicing mechanism 6, and the storage box 2 can store a large amount of yams that have completed the peeling process. The entrance of the storage box 2 can be docked with the peeling equipment. The peeling equipment is not the focus of this case, so I will not repeat it here. The outlet 21 of the storage box 2 is provided with a feeding mechanism 3. The feeding mechanism 3 is connected to the guide groove 4. The discharging mechanism is responsible for Push the yams slipping out from the outlet one by one in the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com