Intelligent control environment-friendly waste plastic energy-saving regeneration preparation system

A waste plastic, intelligent control technology, used in plastic recycling, mechanical material recycling, dispersed particle filtration, etc., can solve the problems of high labor intensity and high risk, and achieve the effect of reducing production labor, low transmission power, and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

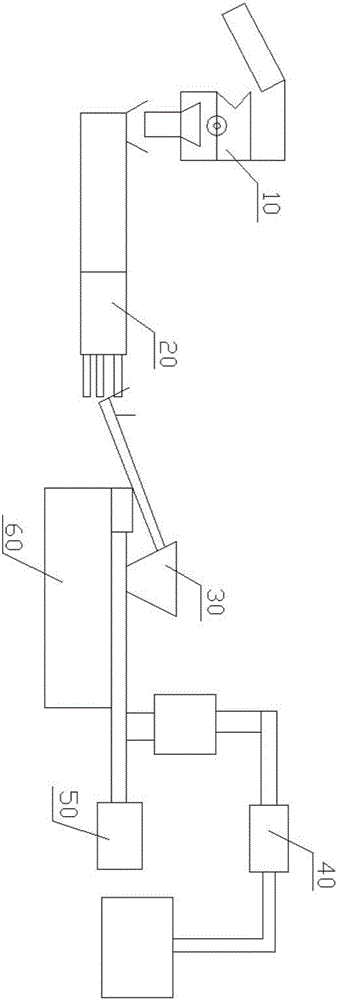

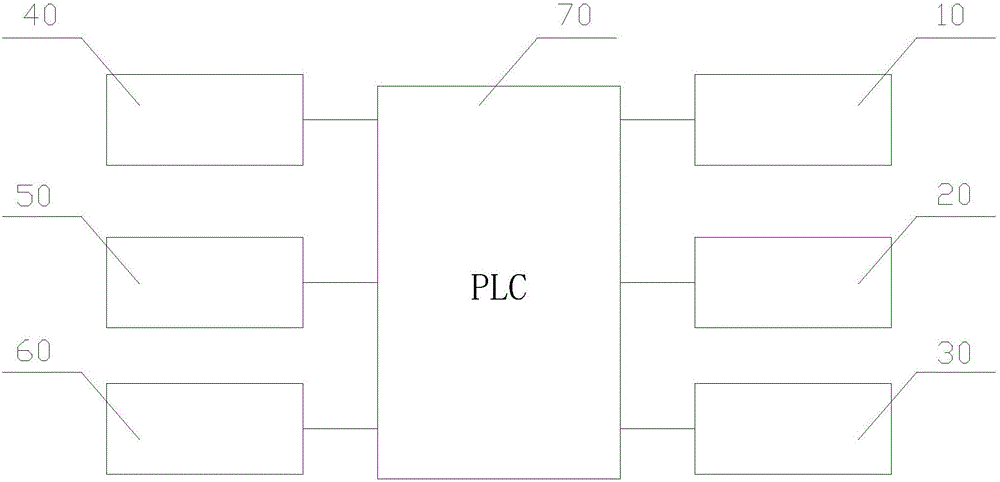

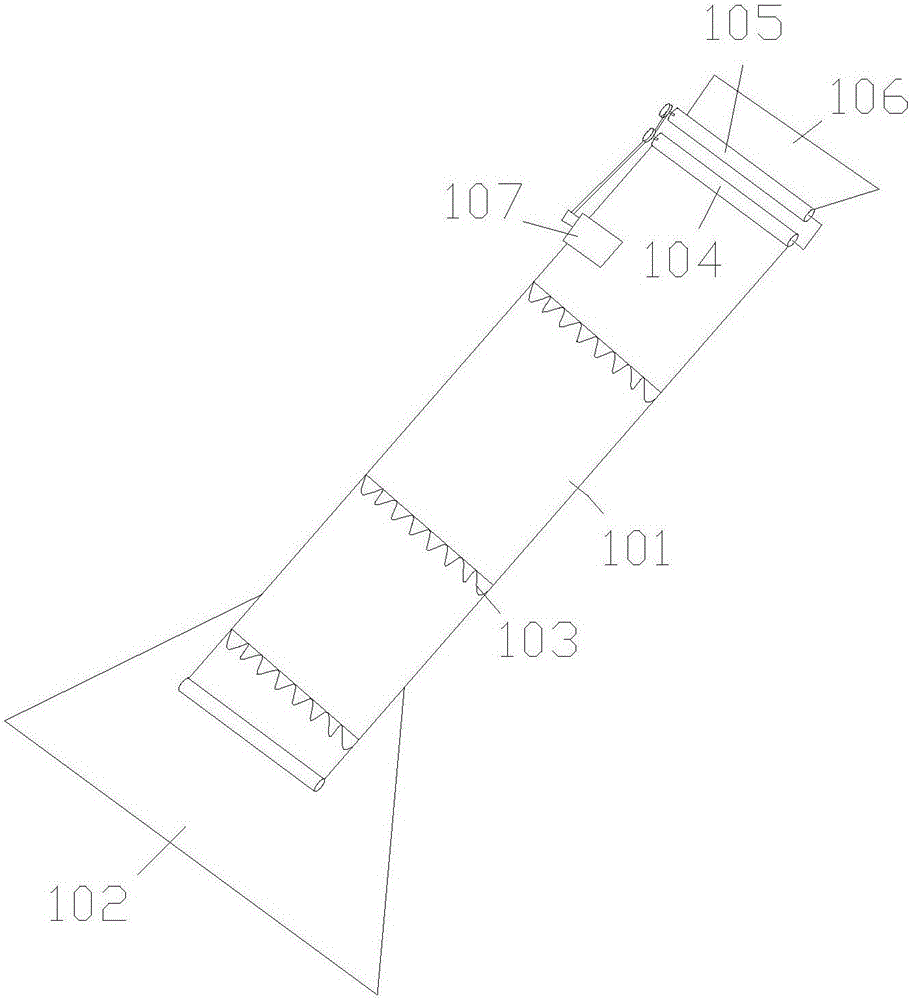

[0040] Such as figure 1 , figure 2 As shown, an intelligent control environment-friendly waste plastic energy-saving regeneration preparation system includes a magnetic roller plastic iron remover 10 connected in sequence, a plastic color sieve machine 20, a fully automatic feeding machine 30, a double four-layer filter Smoke machine 40, air-cooled non-network eager cutting die head 50 and plastic extruder 60. Waste plastics are crushed by a shredder and directly enter the magnetic roller plastic iron remover 10 for iron removal and metal impurities, and then sent to into the plastic color sieve machine 20, and the single-color plastic granules after the color sieving are sent to the fully automatic feeding and feeding integrated machine 30 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com