Nut machining device with waste recycling function

A waste recycling and processing device technology, applied in grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc. The effect of secondary utilization, improving work efficiency and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

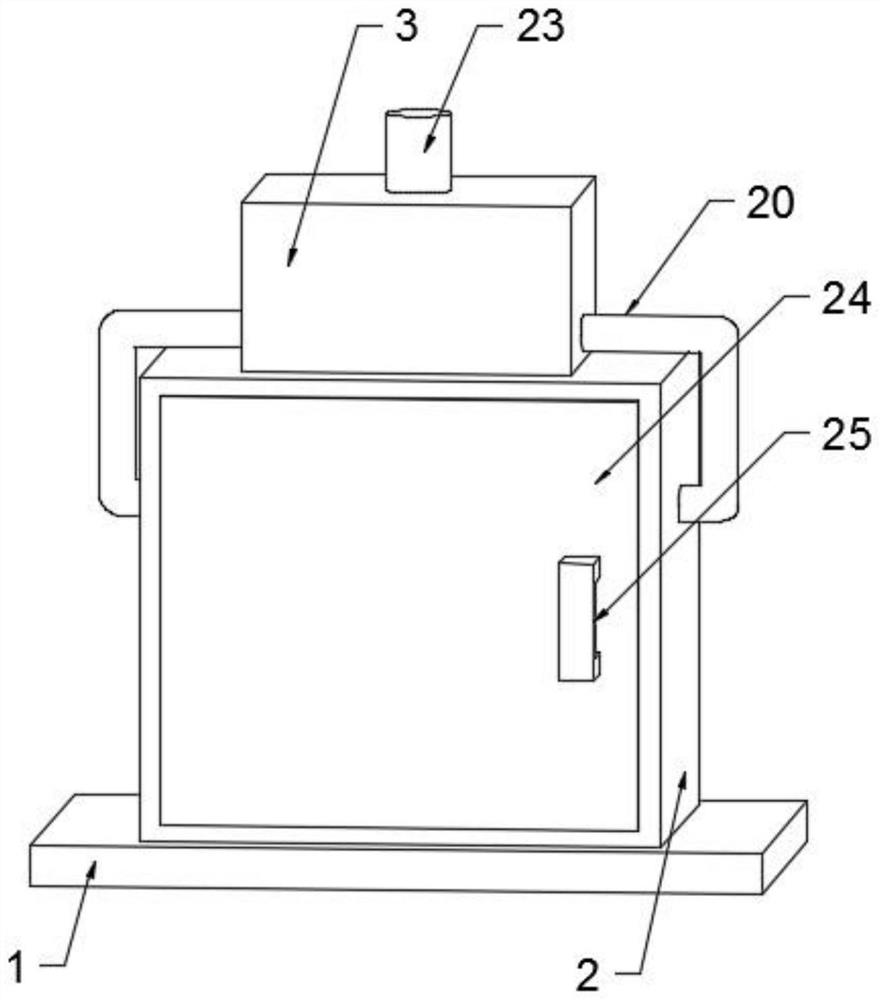

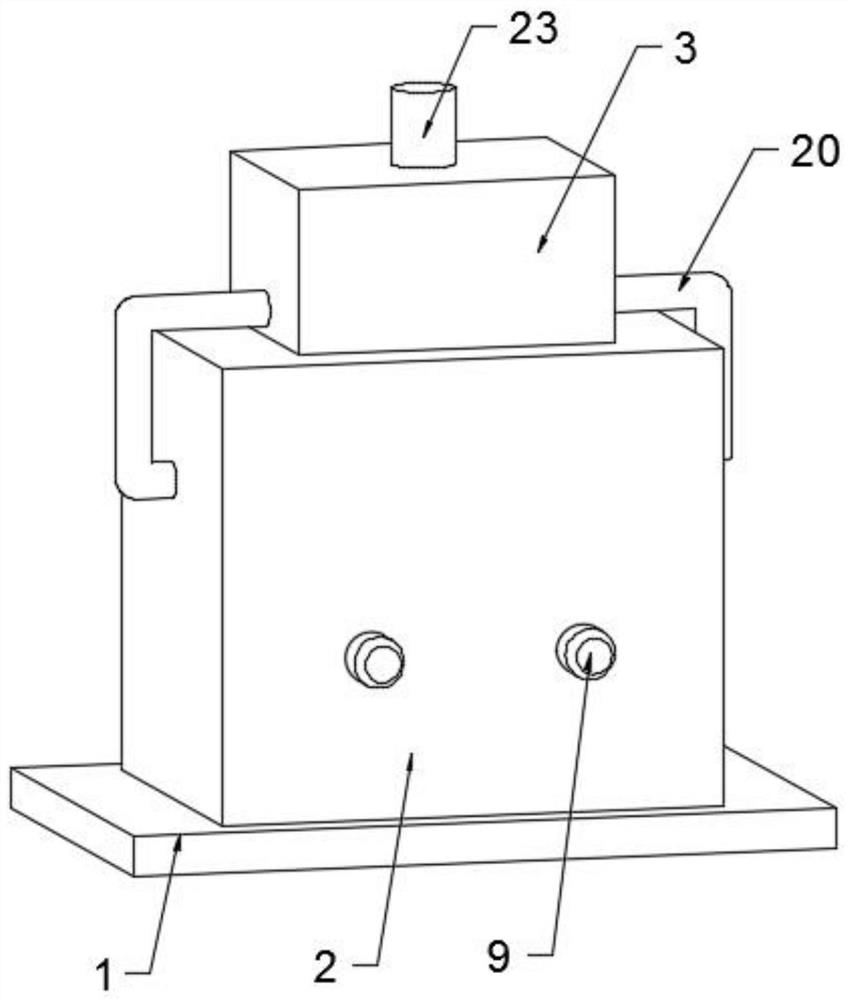

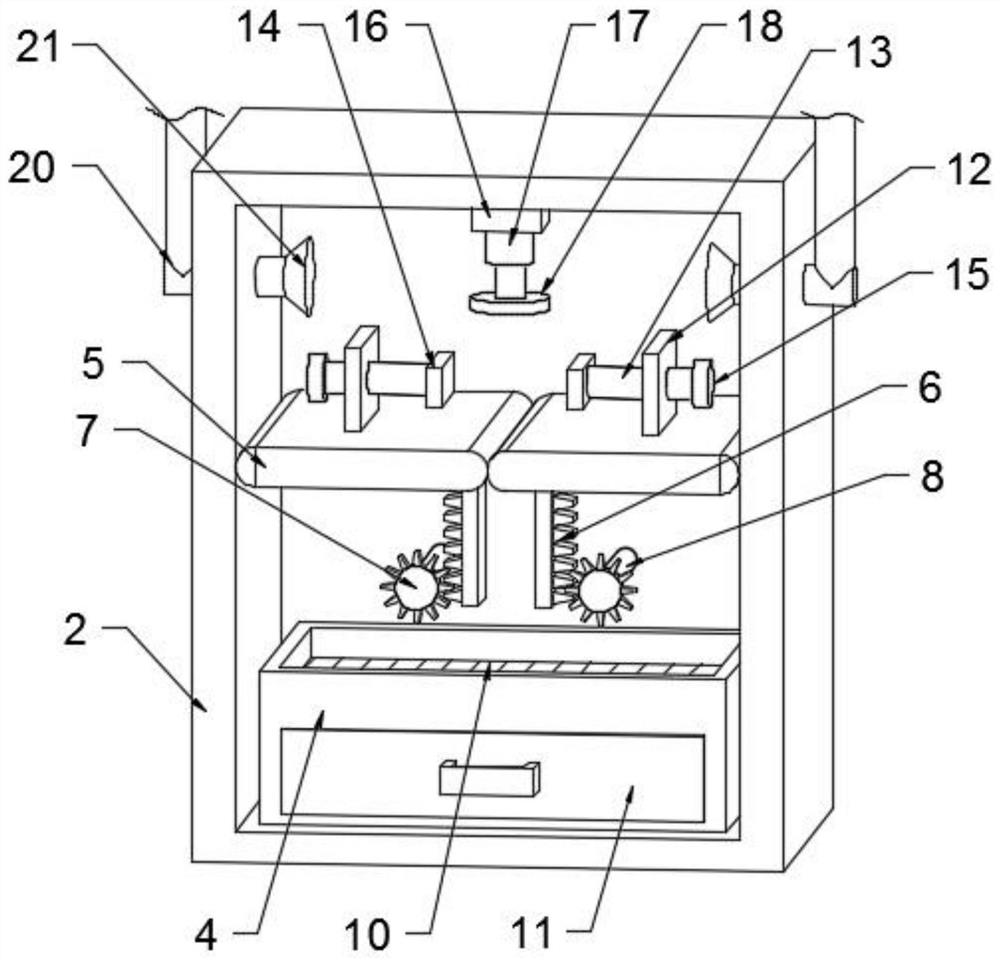

[0030] see Figure 1-Figure 5 , in an embodiment of the present invention, a nut processing device with a waste material recycling function includes a base 1 for supporting and placing a box body 2, the box body 2 fixedly connected to the upper end of the base 1 for supporting and placing a filter box 3, and The filter box 3 fixedly connected to the upper end of the box body 2 is used to support and place the dust suction fan 19, and also includes waste recycling components;

[0031] The waste recycling assembly is used to recycle the waste generated during the grinding process, the waste recycling assembly is fixedly arranged inside the box body 2, the waste recycling assembly includes a recovery box 4, and the recovery box 4 is fixedly connected to the box body 2 On the inner wall of the bottom end of the box body, it is used to support and place the filter plate 10 and the drawer 11. A group of processing plates 5 are hinged on the inner walls of the left and right sides of...

Embodiment 2

[0039] The difference from Embodiment 1 is that: the upper ends of the two groups of processing plates 5 are fixedly connected with a group of fixed plates 12, which are used to support and place threaded rods 13, and the opposite surfaces of the two groups of said fixed plates 12 are rotatably connected with a A group of threaded rods 13 are used to drive the clamping plate 14 to move. The threaded rods 13 of the two groups are all threaded through the fixed plate 12, and are fixedly connected with a rotating block 15, which is convenient for the staff to rotate the threaded rods 13. The threaded rods of the two groups A set of clamping plates 14 are rotatably connected to opposite surfaces of the rod 13 for clamping and fixing the nut.

[0040]The working principle of the present invention is: when in use, utilize the handle 25 to open the box door 24, then rotate two groups of rotating blocks 15, the rotating blocks 15 drive the threaded rods 13 to approach each other, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com